Bottom ring for combined type holder submerged-arc furnace

A technology of bottom ring and holder, which is applied in the field of bottom ring of submerged arc furnace with combined holder, which can solve the problems of secondary fire protection screen, water leakage of bottom ring threaded joint, poor insulation, etc., so as to improve the starting rate and avoid Personal accidents and the effect of reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

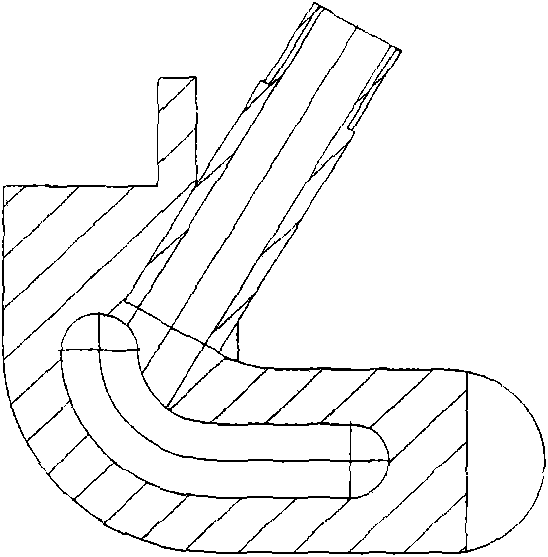

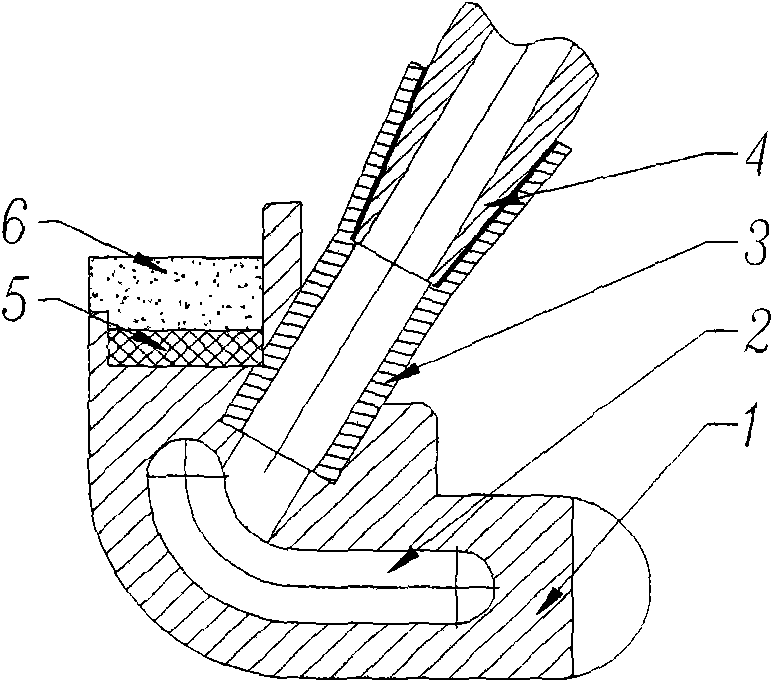

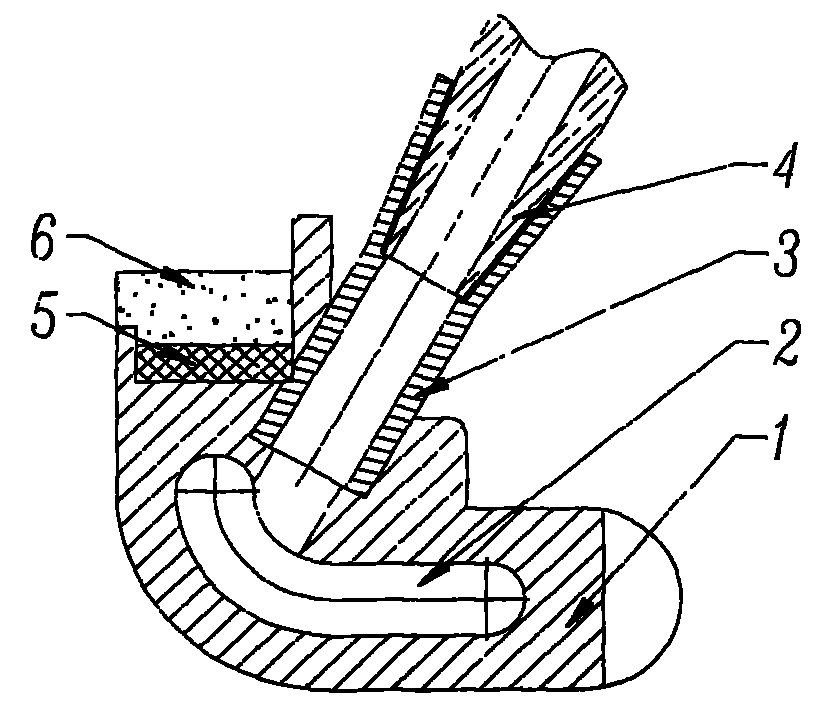

[0009] Example 1, the bottom ring for the submerged arc furnace of the combined holder, including the main body 1, the water channel 2 in the main body, the bottom ring water outlet pipe 3 and the water outlet pipe 4 that are welded and connected to the water channel 2, and the outer side of the bottom ring is in the shape of "concave" , the lower part of the "concave" groove is placed with a mica insulating plate 5, and a white corundum block 6 with a boss is placed on the bottom ring surface, and the boss of the white corundum block 6 is placed in the groove on the upper part of the mica insulating plate 5. The ring water outlet pipe 3 and the outlet water pipe 4 are welded structures.

Embodiment 2

[0010] Example 2, referring to Example 1, the bottom ring water outlet pipe 3 connected to the outlet water pipe 4 is tapered, that is, the bottom ring water outlet pipe 3 and the outlet water pipe 4 are plug-in welded structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com