Flow drill screwing process parameter conversion key point self-adaption switching method

A technology of adaptive switching and process parameters, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as nailing failure, and achieve the effect of ensuring normal and stable progress, improving quality qualification rate and equipment start-up rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

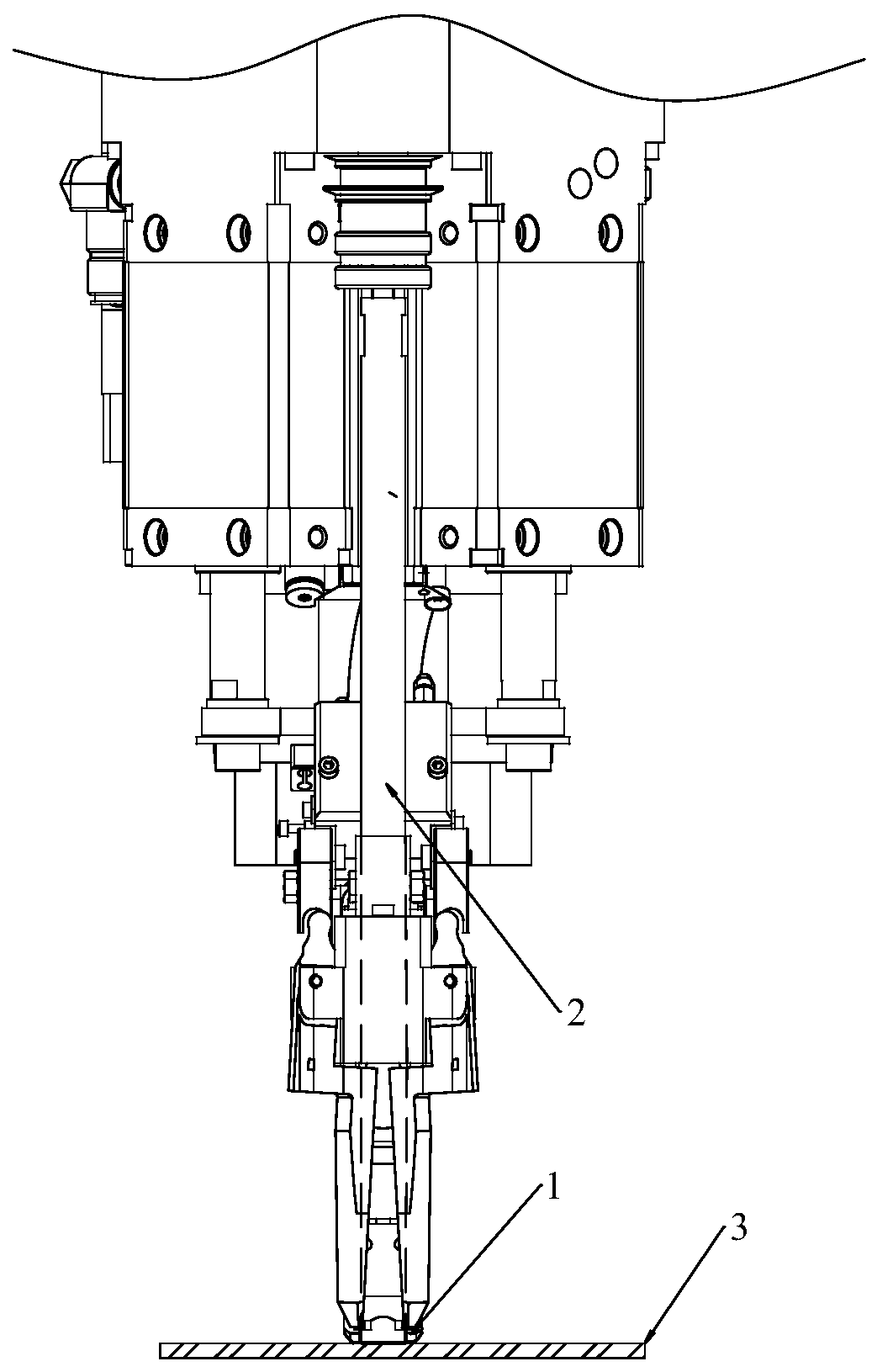

[0027] The invention is applied in the flow drilling and tightening process, through the acquisition of riveting force and displacement signals, combined with the control logic to realize accurate identification of each stage, the conversion point can automatically adapt to plate thickness fluctuations.

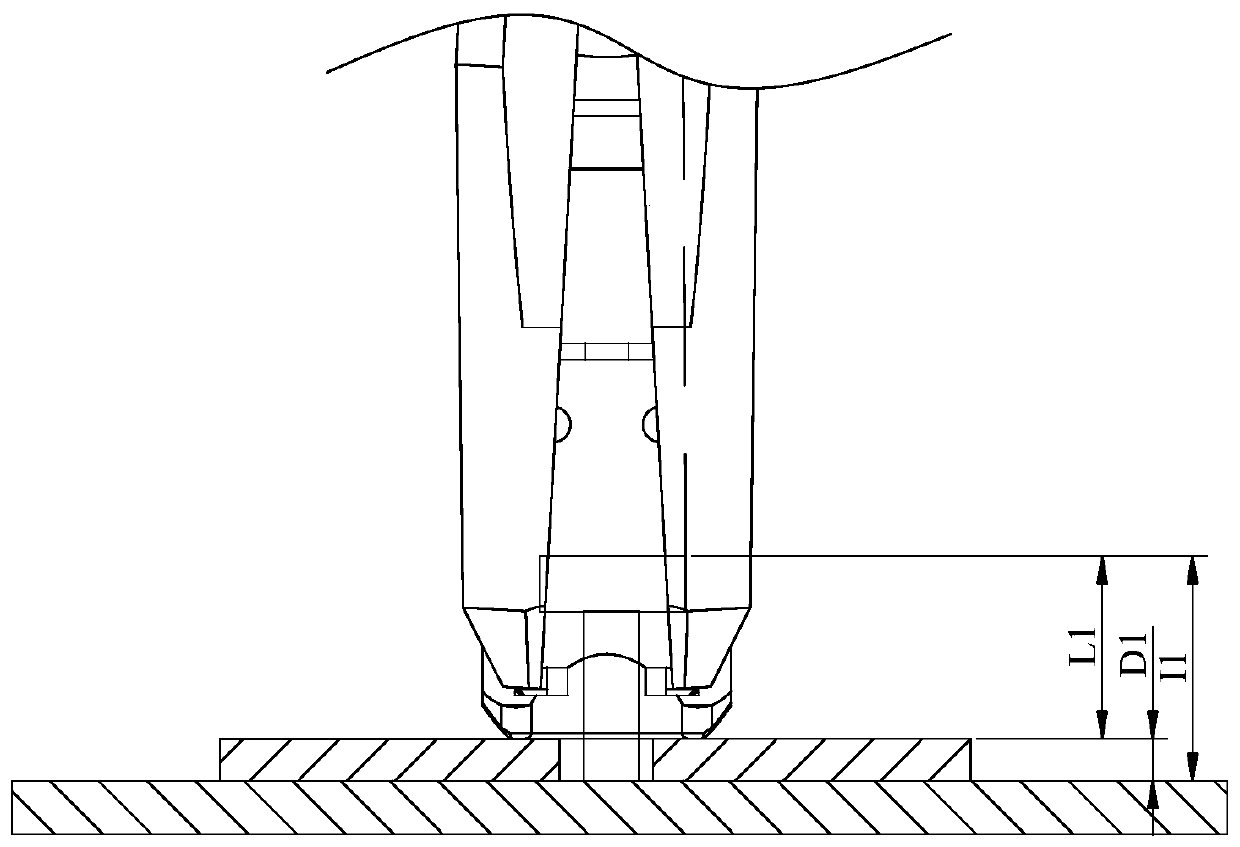

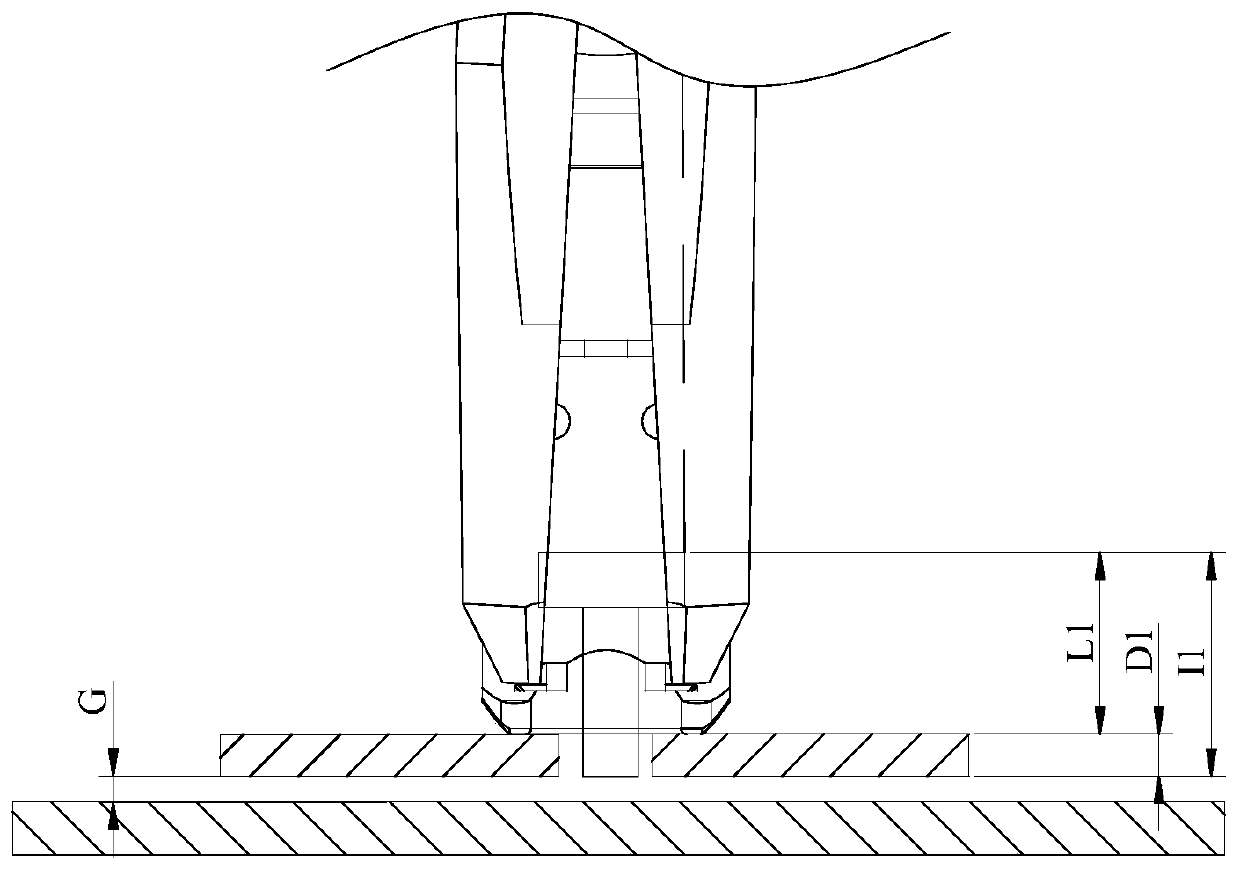

[0028] Such as Figure 4 As shown, a pressure sensor 4 is installed on the top of the guide rod of the equipment to obtain the actual pressure value F of the guide rod in real time. At the same time, the guide rod 2 and the briquetting block 1 are also equipped with code rulers to obtain and calculate the relative position L of the guide rod and the briquetting block in real time.

[0029] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com