Finished sheet strip roll feeding and unloading device and work method thereof

A technology for finished coils and strips, which is applied in the direction of manufacturing tools, metal processing equipment, metal rolling, etc., and can solve problems such as the shutdown of the main shaft unit of the equipment coiler, the cracking of the shaft of the coiler, difficult observation and waste of manpower, etc. , to achieve the effect of convenient and fast maintenance, saving operator wages and reducing hardware consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

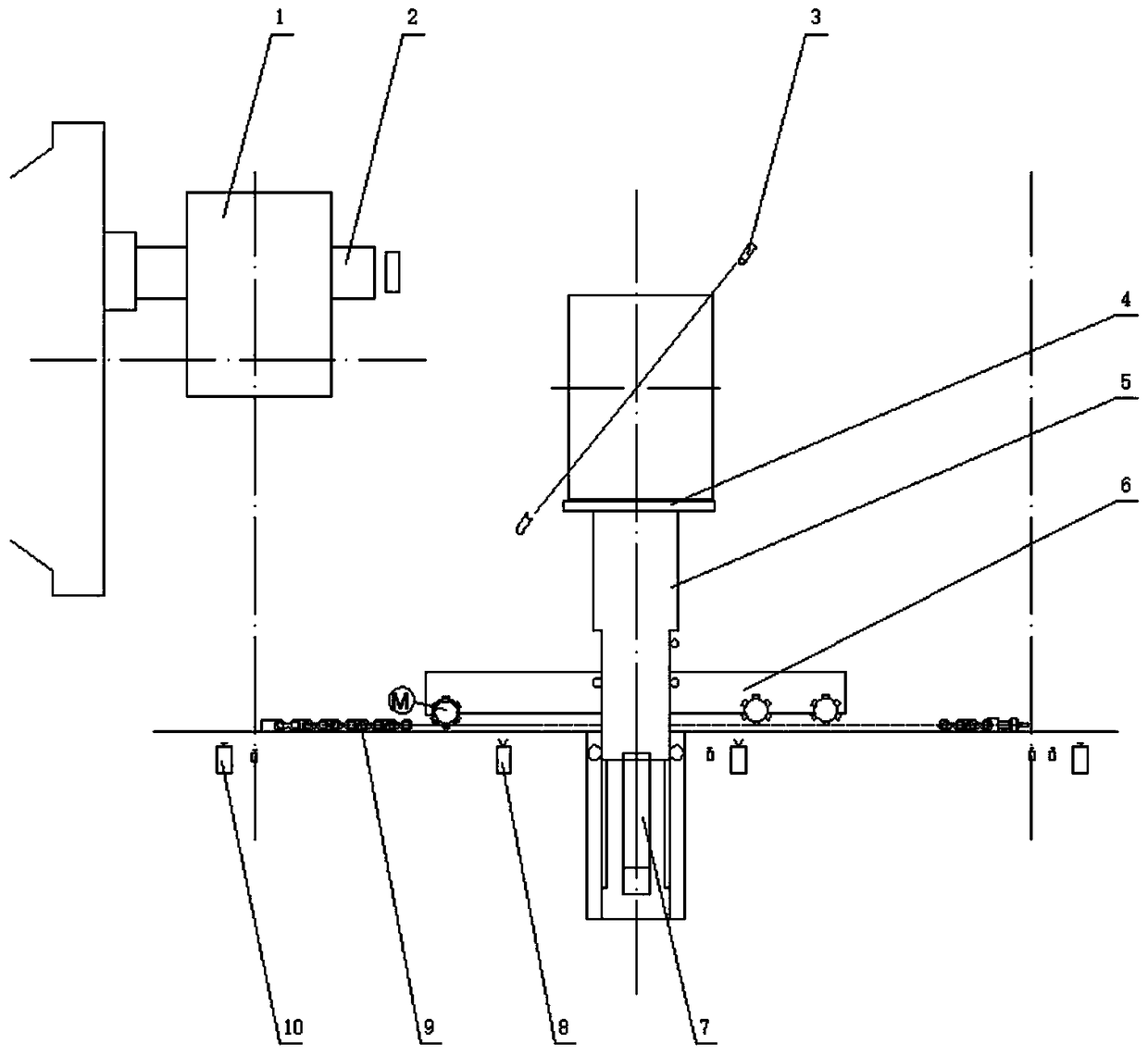

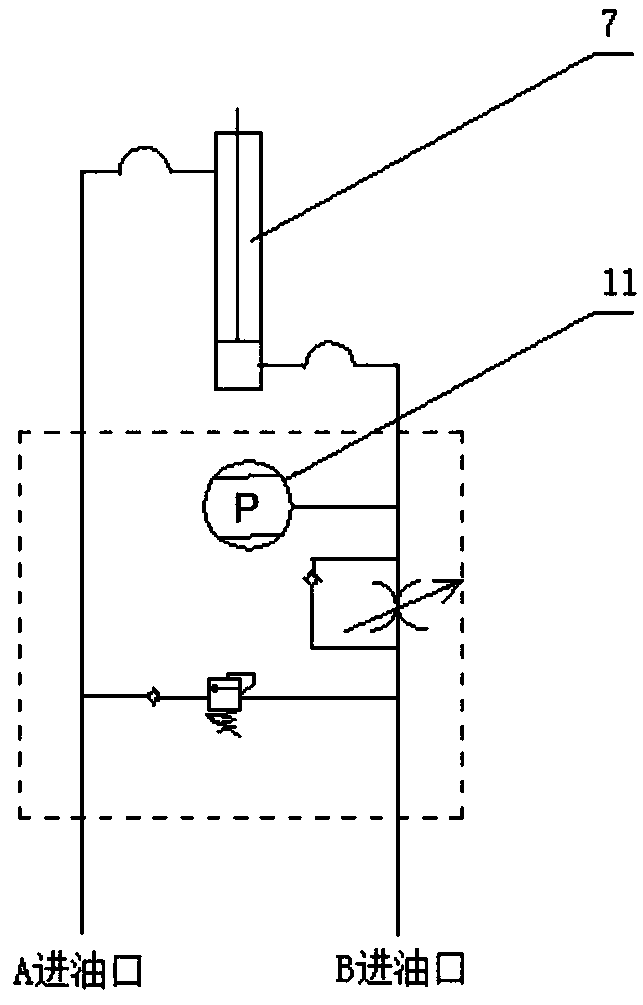

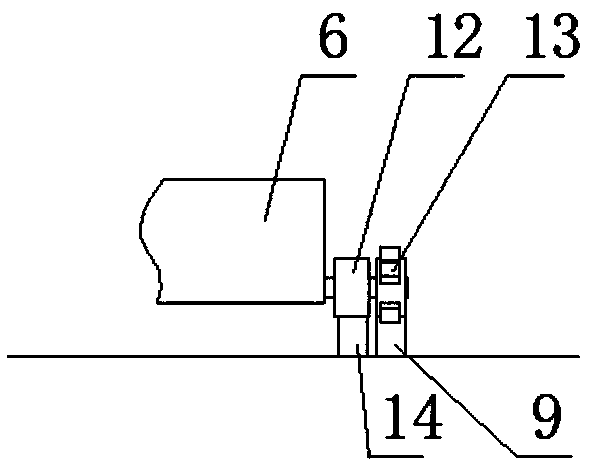

[0026] A device for loading and unloading finished strip coils. The reel of the coiler 2 is arranged horizontally and horizontally, and the finished coil 1 is set on the reel. A parallel rail 14 arranged horizontally and laterally is installed below the coiler, and the parallel rail extends to the stepping The position of the beam (other process equipment, not shown in this embodiment), the guiding drive on the parallel track has a walking trolley 6, and the middle part of the walking trolley is equipped with a vertically arranged lifting slide 5, and the upper end of the lifting slide is fixed with a saddle 4 A lifting hydraulic cylinder 7 is installed at the lower end of the lifting slide plate; a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com