Patents

Literature

101results about How to "Realize collaborative work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

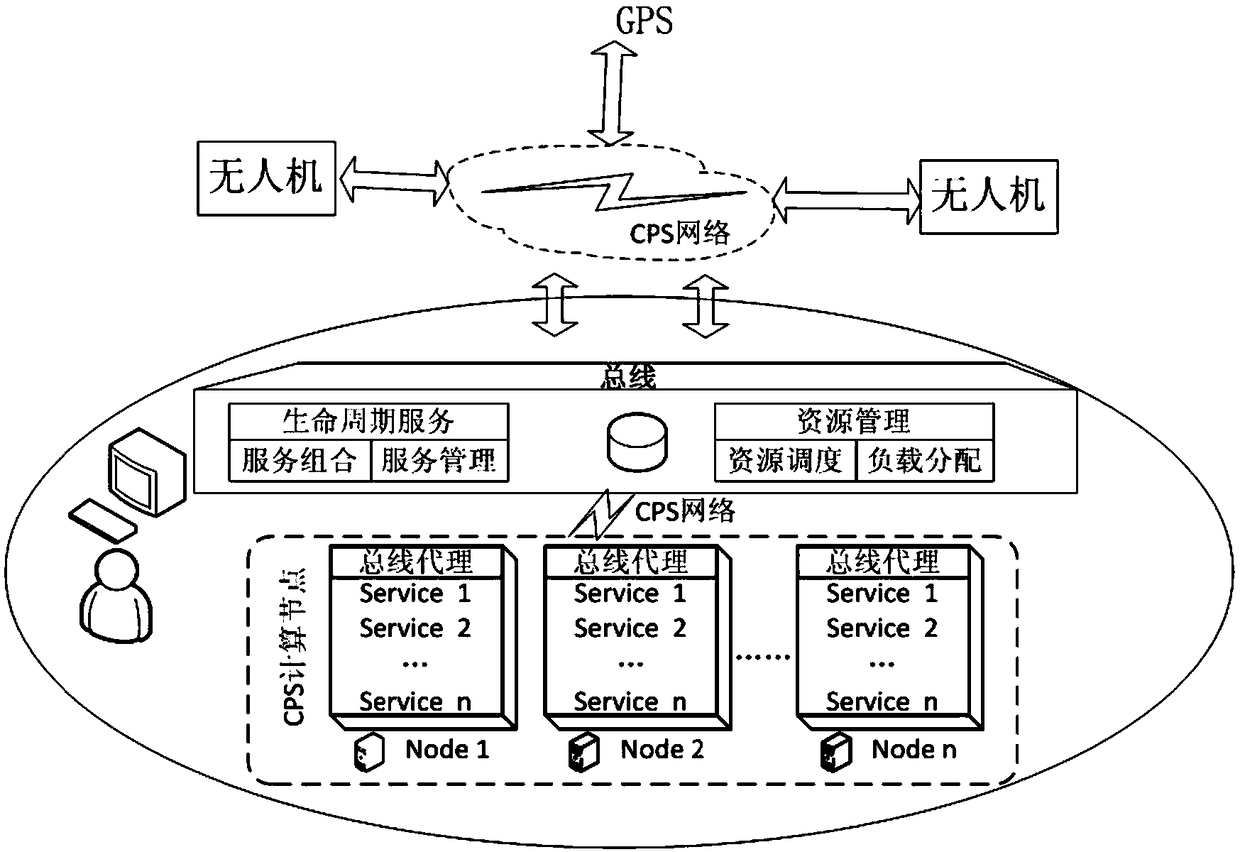

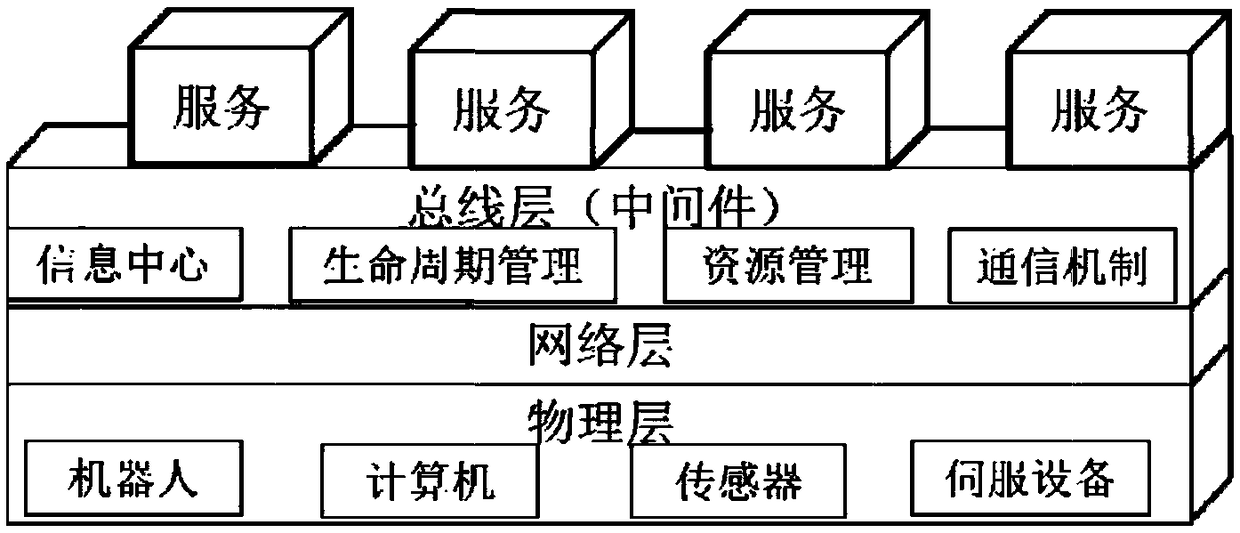

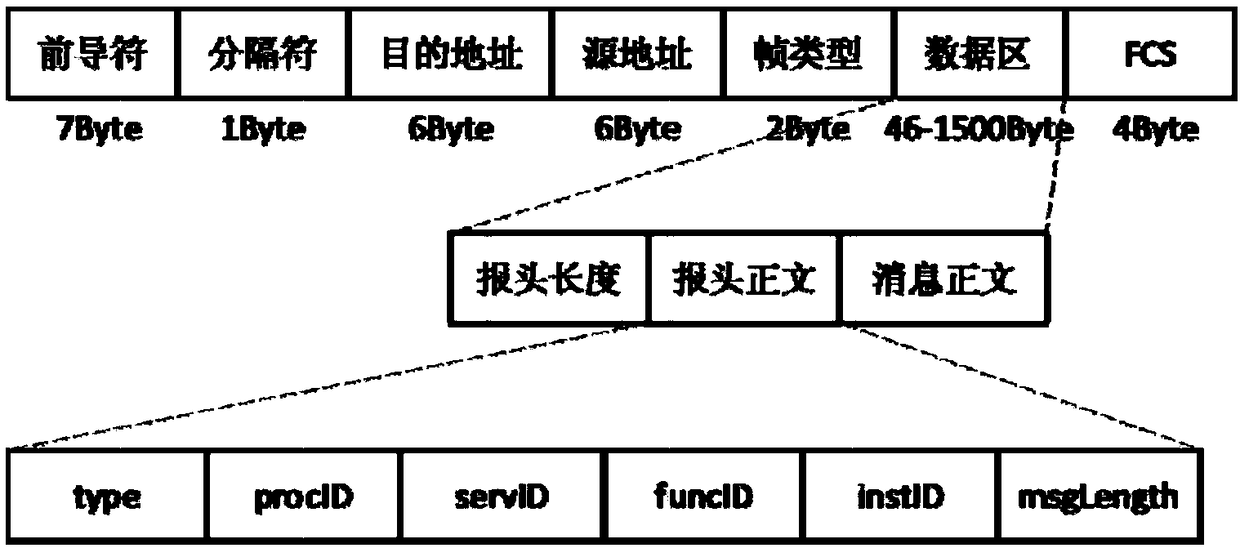

Integrated unmanned aerial vehicle control system based on software bus

ActiveCN108762295AImplement lookupRealize collaborative workPosition/course control in three dimensionsSoftware busResource utilization

The invention provides an integrated unmanned aerial vehicle control system based on a software bus. The system comprises a software bus-based integrated unmanned aerial vehicle control system architecture (1), a lightweight software bus communication framework (2) and a centralized software bus-based global resource management mode. Through the service-oriented system architecture, the reliability and the openness of an assembly are improved, the heterogeneity of resources are shielded, functions of the resources are packaged, and a one-stop multi-control bus control system with multiple functions integrated is designed; and a transparent data transmission mechanism is provided for a heterogeneous node, and decoupling between a user and a message protocol is realized. A multi-perspectiveglobal resource management mode for a multi-unmanned aerial vehicle system with computing resource heterogeneity and task interdependence is designed, and the real-time performance and the certainty of the control system are ensured. While the openness and the reliability of the architecture are ensured, the real-time performance of the control system and the resource utilization ratio are improved.

Owner:SOUTH CHINA UNIV OF TECH

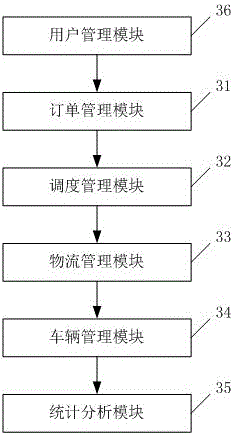

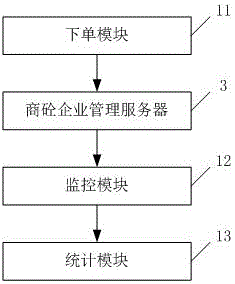

Commercial concrete online ordering system based on intelligent mobile phone application

InactiveCN106570673AQuick upgradeRealize collaborative workBuying/selling/leasing transactionsLogisticsLogistics managementTerminal equipment

The embodiment of the invention discloses a commercial concrete online ordering system based on an intelligent mobile phone application; the commercial concrete online ordering system comprises a construction end, a commercial concrete end, and a commercial concrete enterprise management server; a construction unit uses the construction end to select a commercial concrete supplier, and sends an order request to the commercial concrete enterprise management server; the commercial concrete enterprise management server sends the request sent by the construction end to the commercial concrete end; the commercial concrete end inspects the construction unit order, schedules production and dispatches vehicles, and sends the order to the commercial concrete enterprise management server; the commercial concrete enterprise management server monitors the order process, and sends the monitoring information to the construction end and commercial concrete end; the construction end and the commercial concrete end use terminal equipment to monitor the order process in real time. The commercial concrete online ordering system can improve management scientificity, management efficiency and production efficiency, can improve order automatic management level, thus realizing seamless cooperation works between the commercial concrete supplier, a commercial concrete user, and logistics, satisfying higher service quality, reducing operation cost, and promoting enterprise fast upgrading.

Owner:广州市图吉信息科技有限公司

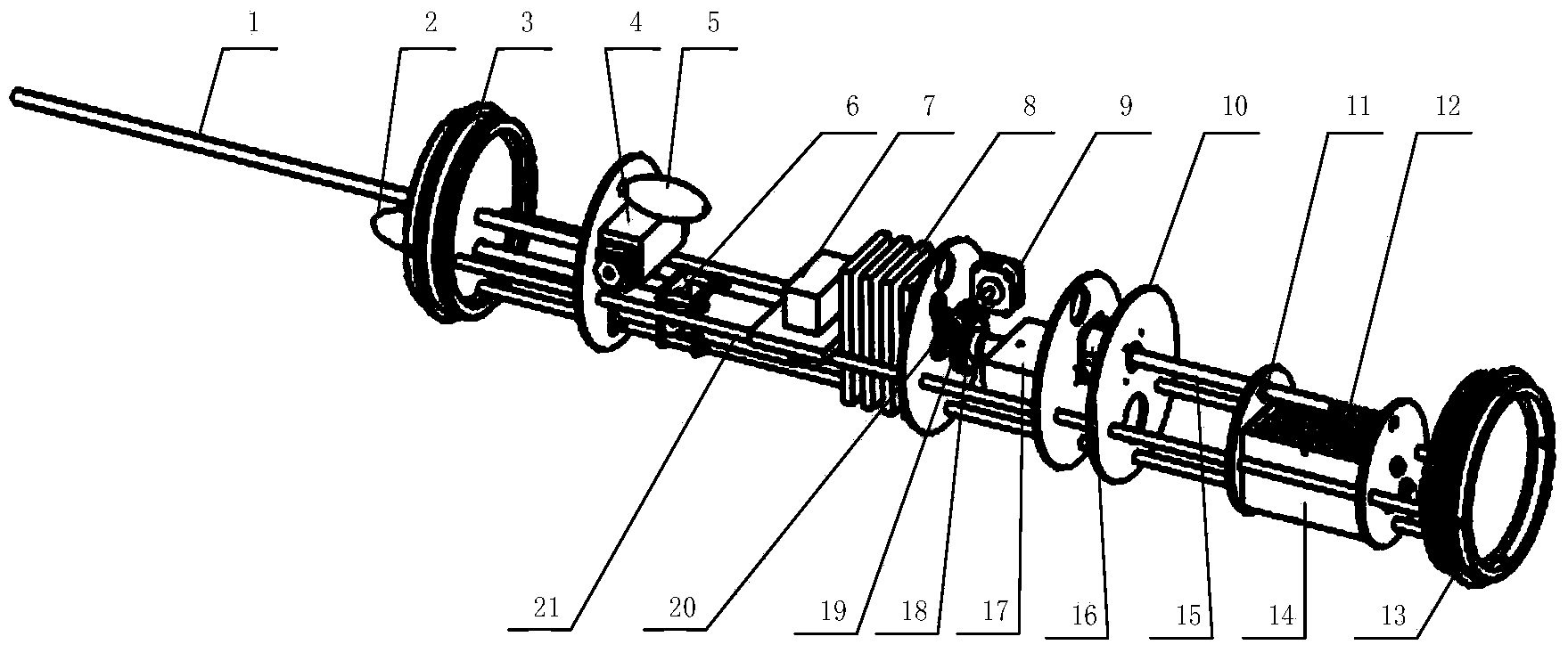

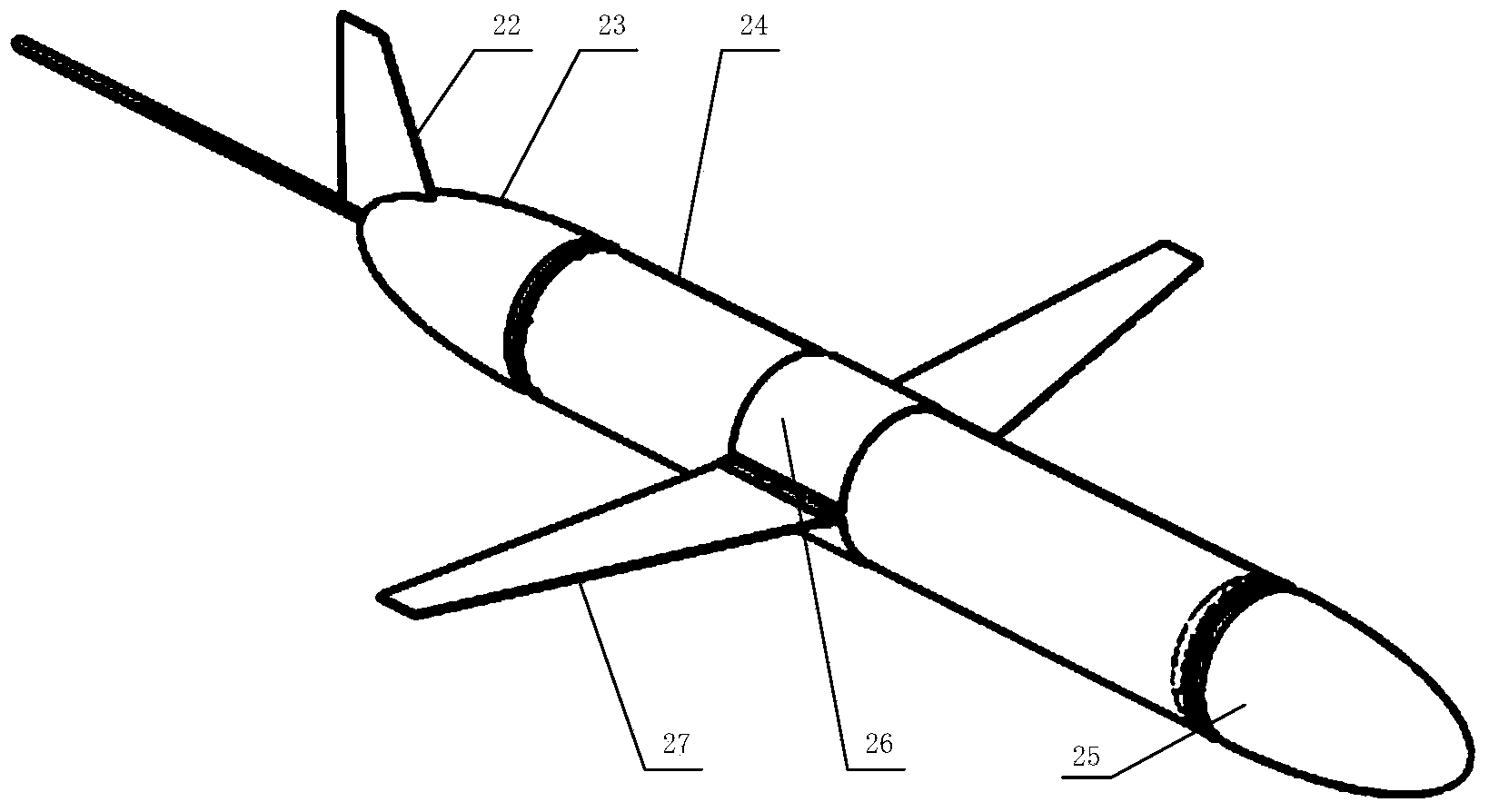

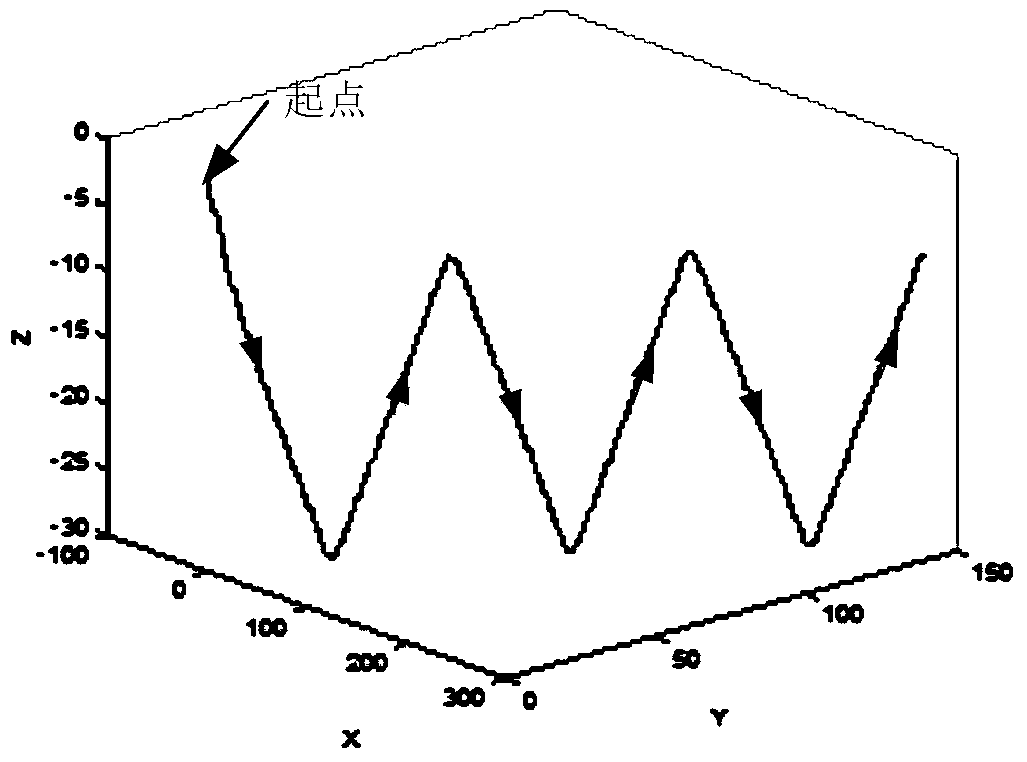

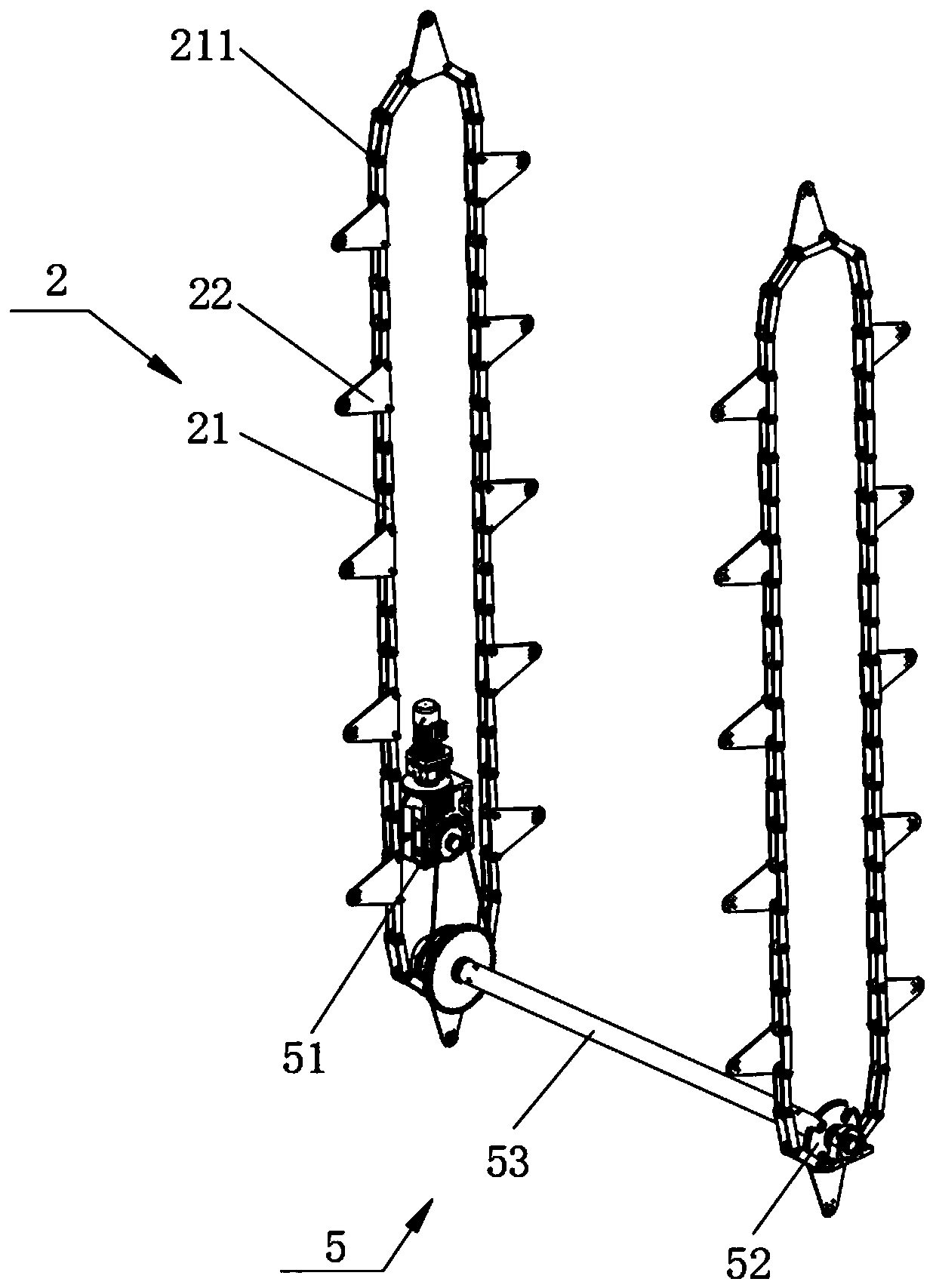

Underwater three-dimensional detection gliding robot

InactiveCN103612728AReduce dependenceRealize collaborative workUnderwater vesselsUnderwater equipmentMarine engineeringControl system

The invention provides an underwater three-dimensional detection gliding robot. The robot comprises an appearance system, an internal adjusting system, and a control system; the internal adjusting system and the control system are arranged in the inner side of the appearance structure; and the control system is used to communicate and control the internal adjusting system. The appearance system is in a streamline shape and is provided with a communication part, so that the system has the advantages of low energy consumption, strong autonomy and enduring performance, low maintenance cost, little dependence on mother ship, and capability of achieving cooperative work, and fully satisfy the requirements of large scale, long period, and large size on sea environment supervision. The internal adjusting system comprises a pitching adjusting part, a rolling adjusting part, and a floating force adjusting part so as to make the robot have two work states: a linear gliding and a spiral gliding, so that fixed point spiral covering type sea supervision and vertical cross-section zigzag cruising supervision can both be realized, and a tri-dimensional supervision from the horizontal level to the deep sea is actually achieved.

Owner:SHANGHAI JIAO TONG UNIV

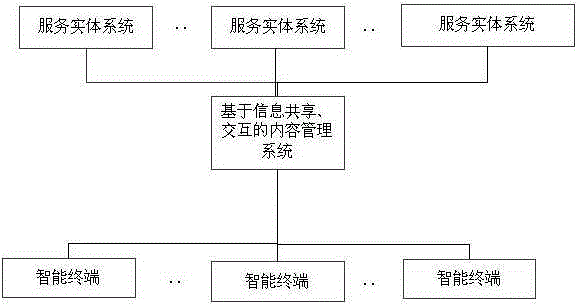

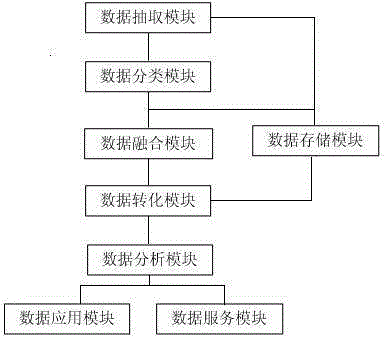

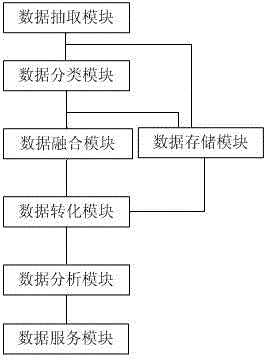

Content management system based on information sharing and interaction

InactiveCN106470216ARealize high-precision position positioningRealize information sharingTransmissionMulti fieldData sorting

The invention discloses a content management system based on information sharing and interaction, and relates to the technical field of electronic information. The system is characterized in that the system comprises a data extraction module, a data classification module, a data fusion module, a data conversion module, a data storage module, a data analysis module, a data application module and a data service module. The system is advantageous in that a general information pushing method in a position service mode based on place names and address data is supported, the management with a unified interface is performed on access terminals and user equipment with different interfaces and different categories, the geographical information technology, the integrated circuit technology, and the electronic application technology are integrated during related operation, the goals of multi-field cross-functionality-department, cross-industry, and cross-discipline information sharing and cooperative operation are achieved, government-enterprise cooperation and business-enterprise cooperation are realized, and intelligent service and intelligent management between enterprises and institutions and ordinary audiences can be achieved.

Owner:江贻芳

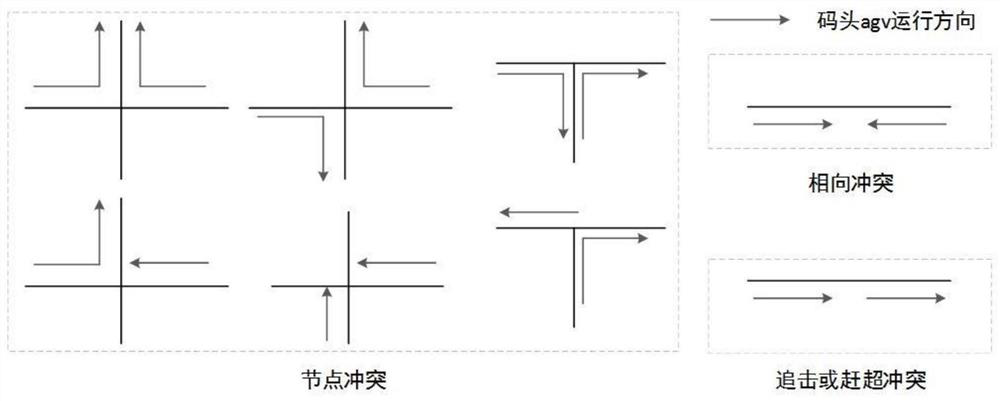

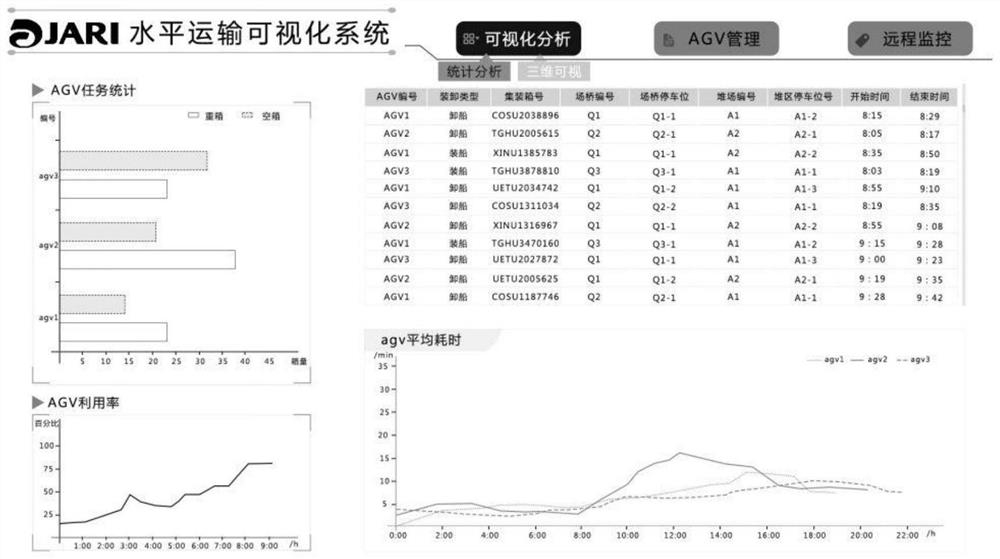

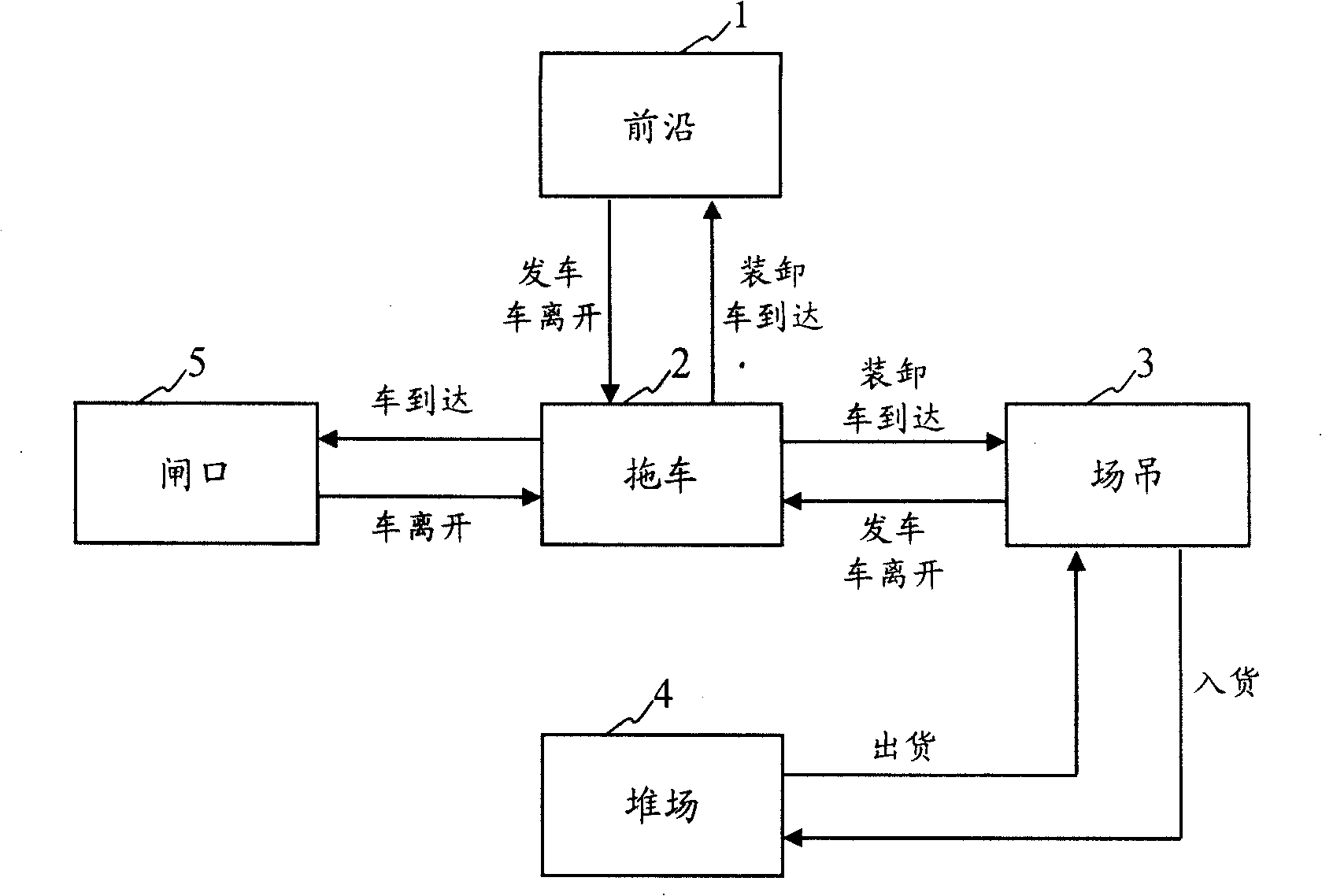

Container wharf horizontal transportation visualization system

ActiveCN111612234ARealize intelligent distributionAchieve optimizationForecastingResourcesStatistical analysisModular design

The invention discloses a container wharf horizontal transportation visualization system. The system is used for collecting and distributing operation links in a container wharf field. The system comprises a task allocation module, a statistical analysis module and a visualization module, and the task allocation module is used for storing basic data based on an intelligent scheduling algorithm andstrategy, interacting with an external system, carrying out AGV intelligent allocation and optimization of container carrying tasks and carrying out comprehensive management on vehicle passing; the statistical analysis module is used for performing statistical analysis and display on the container carrying task sequence, the AGV average time consumption, the vehicle effective rate utilization rate and the average operation period; and the visualization module is used for realizing cooperative linkage of a virtual scene and a real wharf container transfer scene and carrying out remote monitoring on a field operation progress and a general situation. The system adopts a modular design, can operate independently or operate in an embedded manner, can realize intelligent task allocation and optimization, improves the operation efficiency, combines virtuality and reality, realizes real-time linkage, and is convenient for remote supervision.

Owner:中船重工信息科技有限公司

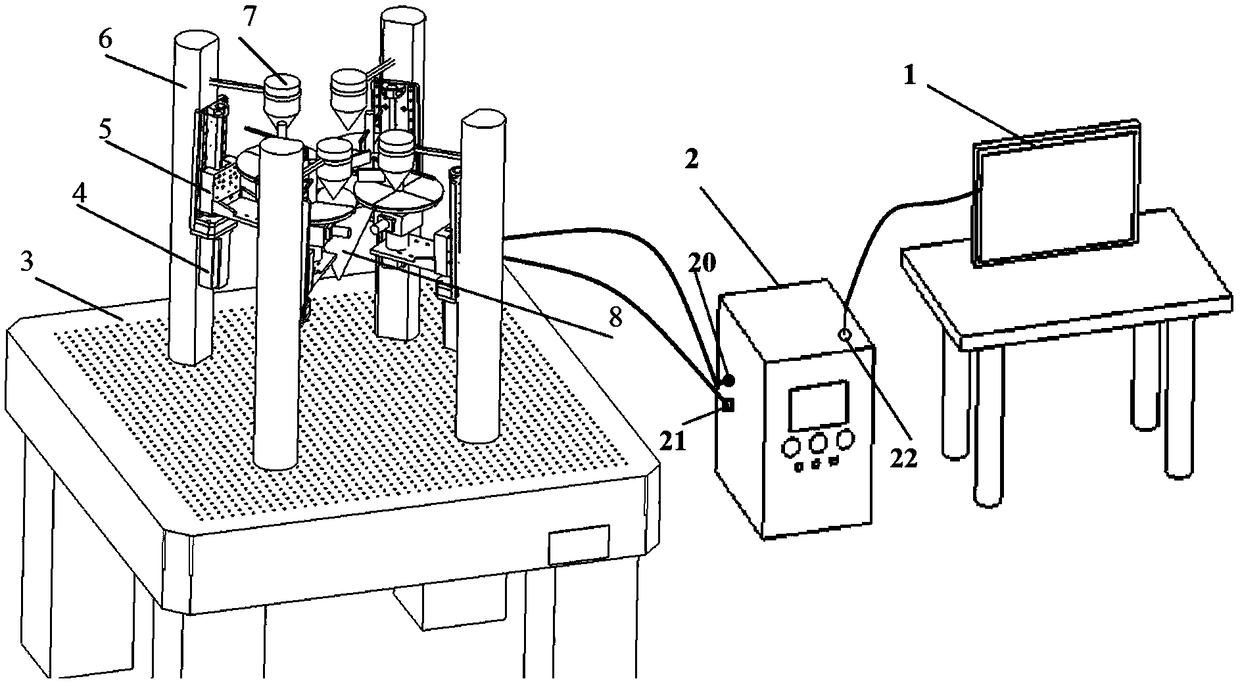

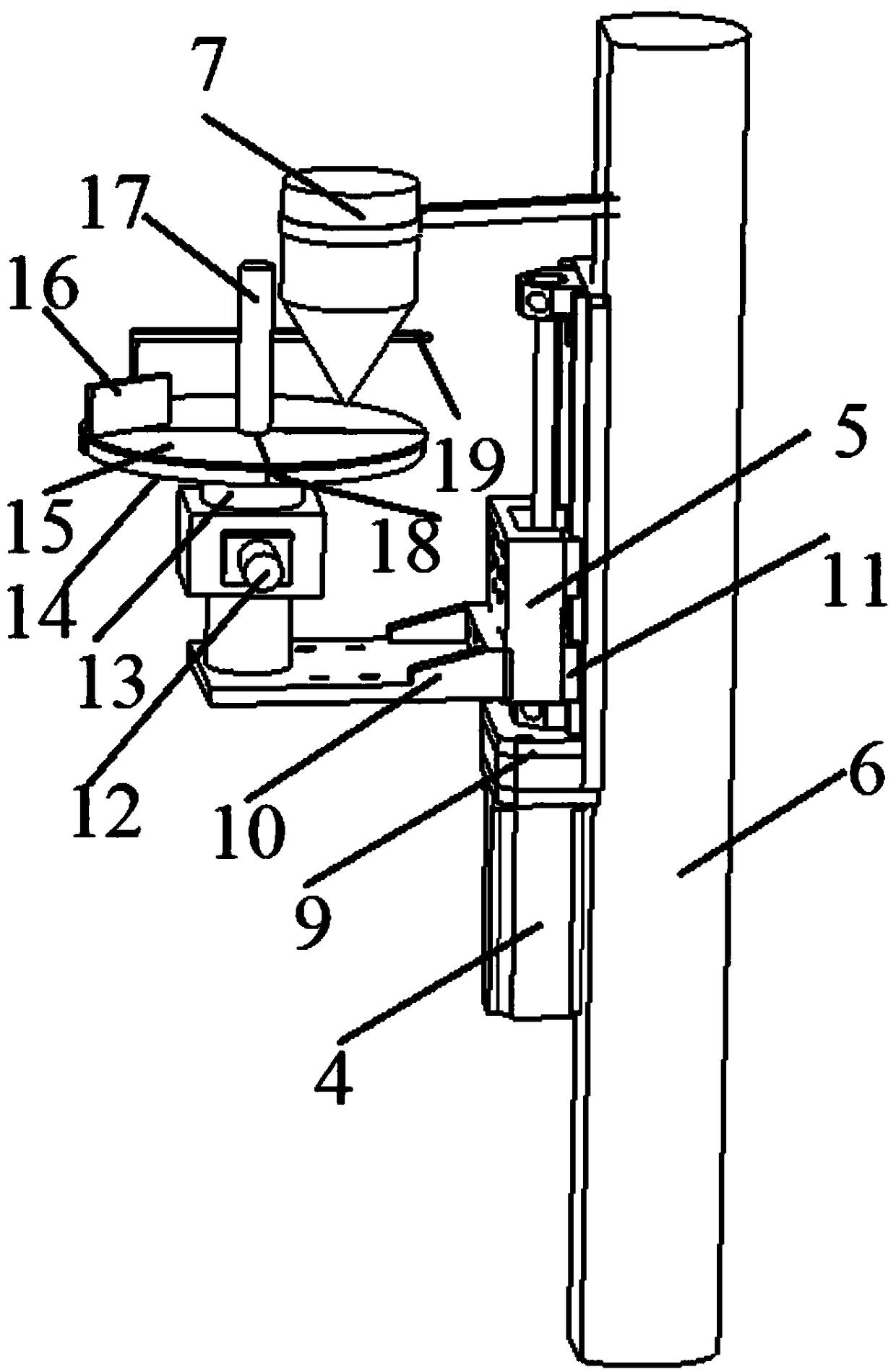

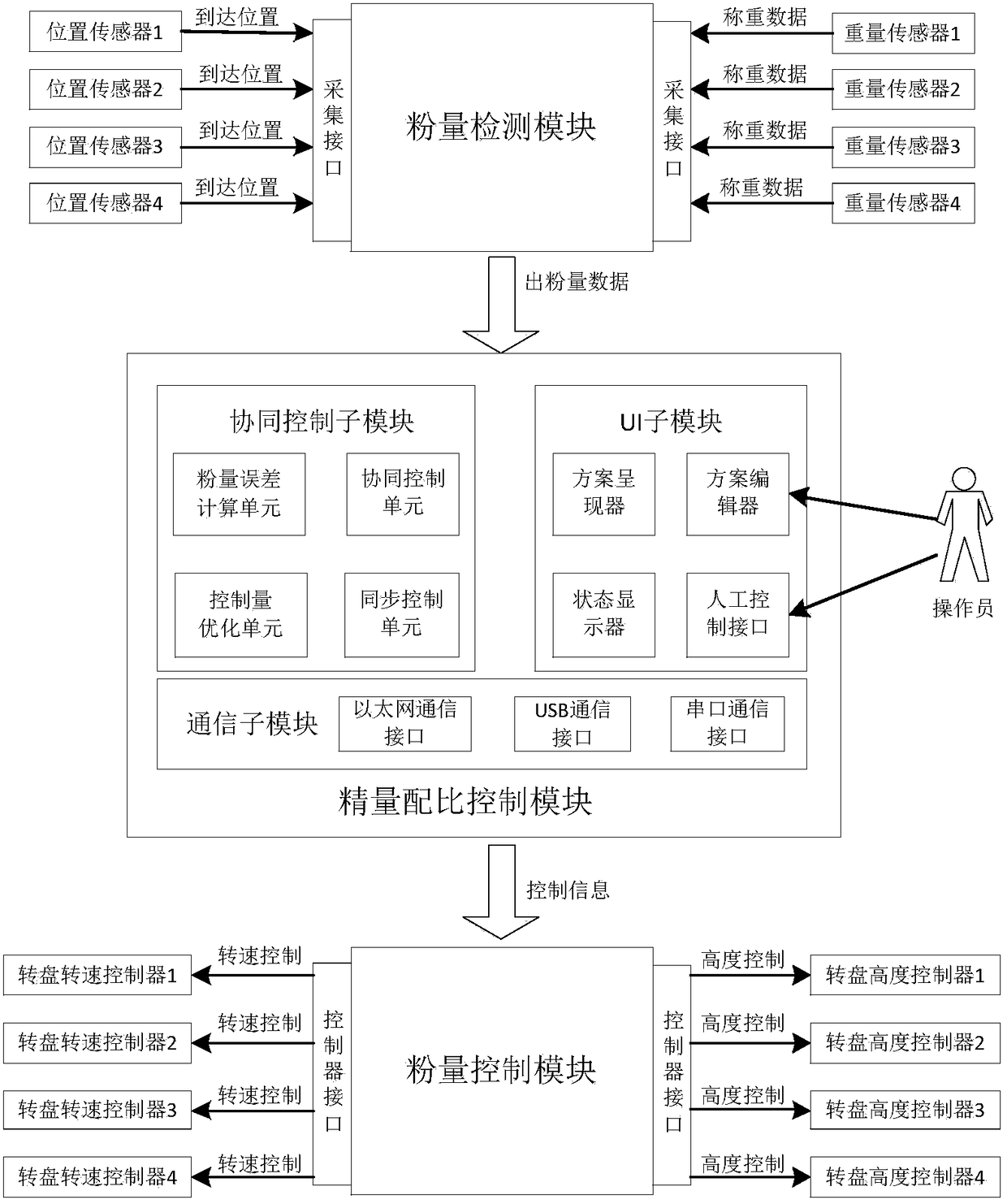

Precise proportioning powder feeding system and powder outlet amount and proportioning amount dynamic control method

ActiveCN108189406ARealize collaborative workThe ratio is easy to controlAdditive manufacturing apparatusManufacturing material handlingMulti materialLaser processing

The invention relates to a precise proportioning powder feeding system and a powder outlet amount and proportioning amount dynamic control and detection method, and belongs to the field of synchronouspowder feeders in additive manufacturing and laser manufacturing. The system consists of a control computer, a control cabinet, powder feeders, powder amount detecting modules, powder amount controlmodules and a precise proportioning control module, wherein the powder feeders store and hold powder and convey the powder to a laser machining area; the powder amount detecting modules acquire precise powder amount output by the powder feeders in real time, and transmit powder amount data to the precise proportioning control module; and the powder amount control modules control the powder amountoutput by the powder feeders in real time, receive control information of the precise proportioning control module, and regulate the power outlet amount in real time. The precise proportioning controlmodule controls the powder feeding amount and the powder feeding proportioning amount dynamically in real time to achieve precise proportioning control. The precise proportioning powder feeding system and the powder outlet amount and proportioning amount dynamic control and detection method support mixed powder feeding of a plurality of materials, ensure precise proportioning control of various materials, and effectively improve the powder feeding precision, the continuity, the stability and the controllability.

Owner:JILIN UNIV

Unitization simulation platform of container pier

InactiveCN101315646ALow costLower performance requirementsTransmissionSpecial data processing applicationsNetwork connectionSimulation

The invention relates to a unitization simulation platform of a container terminal, the simulation model comprises a plurality of unit models which are respectively installed in different computers, all the computers are connected by a network; each unit model works independently, or the interaction of information among the unit models is carried out by the network to realize the collaborative work among all the unit models. The simulation platform divides a complex container terminal system into a plurality of the unit models which are operated on different computers at the same time, and task is transmitted among the interfaces of the unit models by the computer network so as to form a distributed simulation environment, thus greatly improving operating speed, simultaneously, reducing requirement on the performance of the computer and reducing the cost of the simulation platform. All the unit models can operate independently, and can finish simulation work collaboratively, with flexible running modes. The simulation platform divides the model with large scale and complex relationship into a plurality of the unit models, thus simplifying the model and causing the simulation platform to be easy to be modified and extended.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

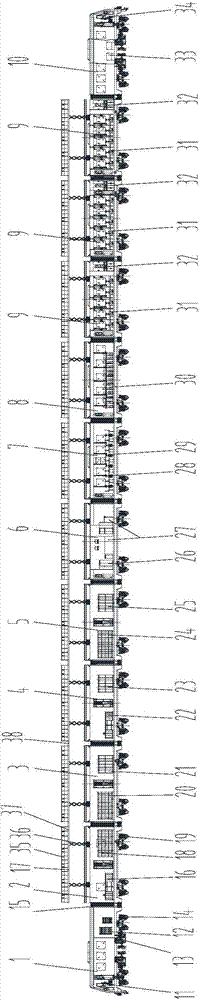

Electrified railway contact network overhaul train

ActiveCN103879418AImprove working environmentImprove working accuracyCarriagesContact networkMulti machine

The invention provides an electrified railway contact network overhaul train. The electrified railway contact network overhaul train is composed of a first tractor, a plurality of work vehicles and a second tractor. The work vehicles are arranged between the first tractor and the second tractor, the first tractor, the work vehicles and the second tractor are all connected through folding wind shields, the tops of the work vehicles are respectively provided with a lifting work platform, and the lifting work platforms are communicated with one another after being lifted. The electrified railway contact network overhaul train is provided with the communicated work platforms, construction work can be performed on a contact network with the line range of 160 m at the same time, the functions of erecting lines of the contact network, maintenance, repair, high-altitude work and the like are integrated, multi-machine multi-work type cooperative work is achieved, a large amount of skylight time is saved, the electrified railway contact network overhaul train has the highest self running speed of 120 km / h and has the functions of transportation and storage of construction materials, machine maintenance and transportation and storage of tools and safety spares, and thus the construction site can have the workshop operation functions, the operating environment of workers is improved, and the operating precision is improved.

Owner:BAOJI CSR TIMES ENG MACHINERY

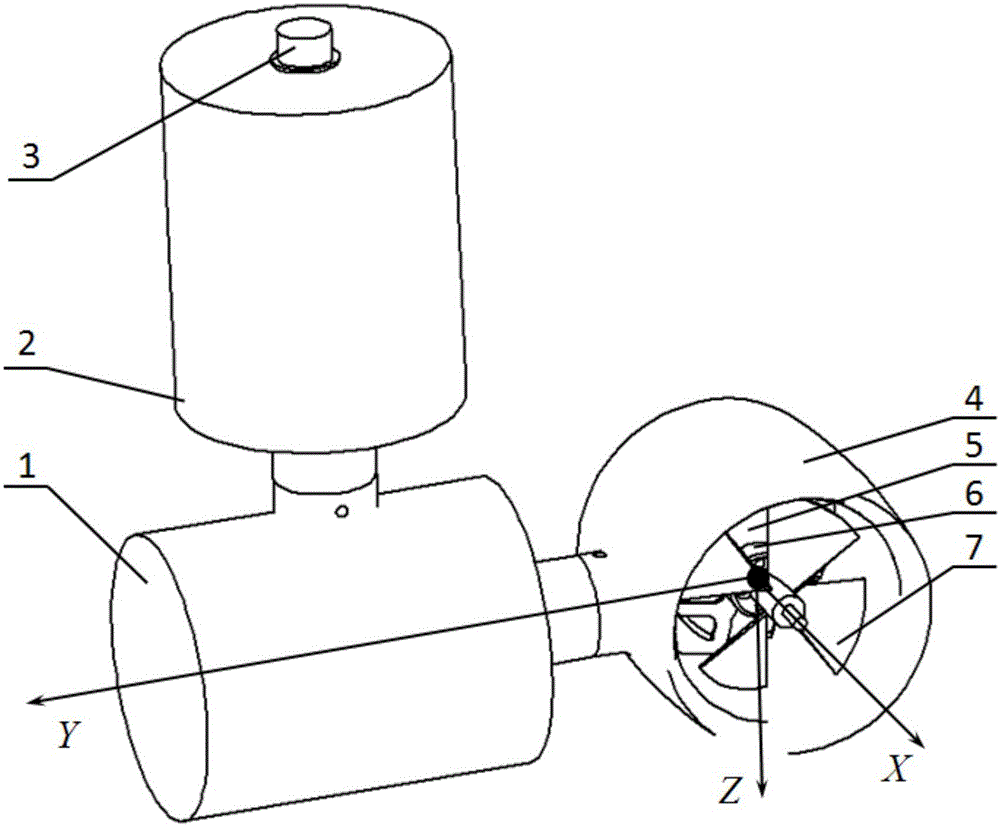

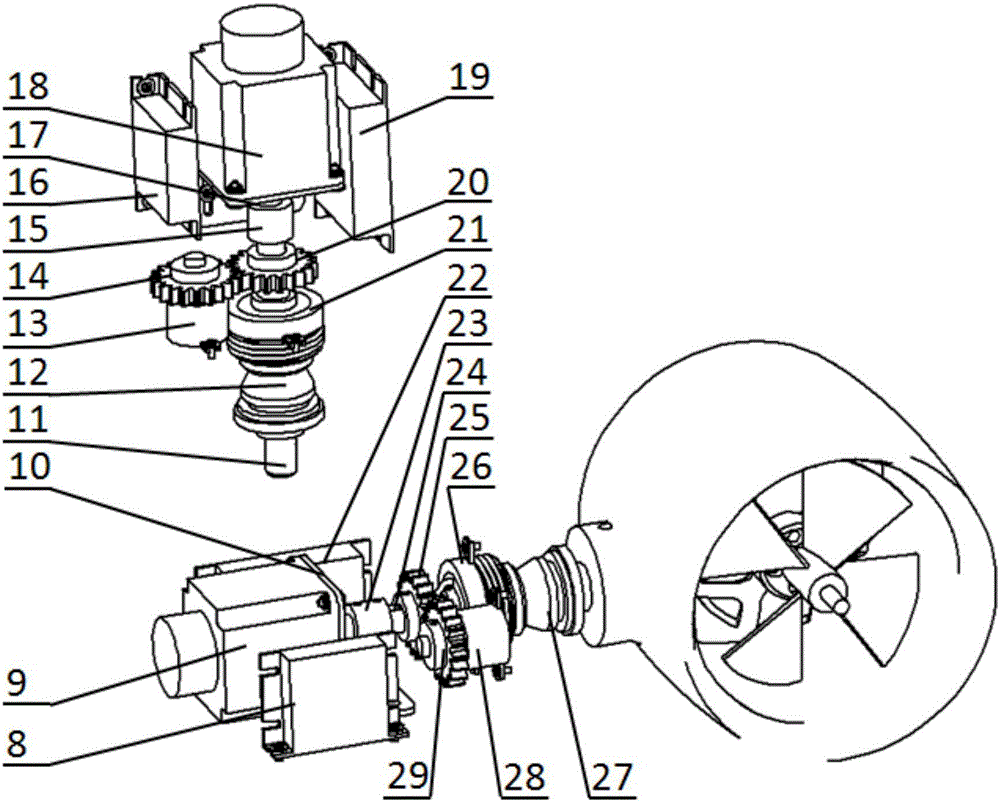

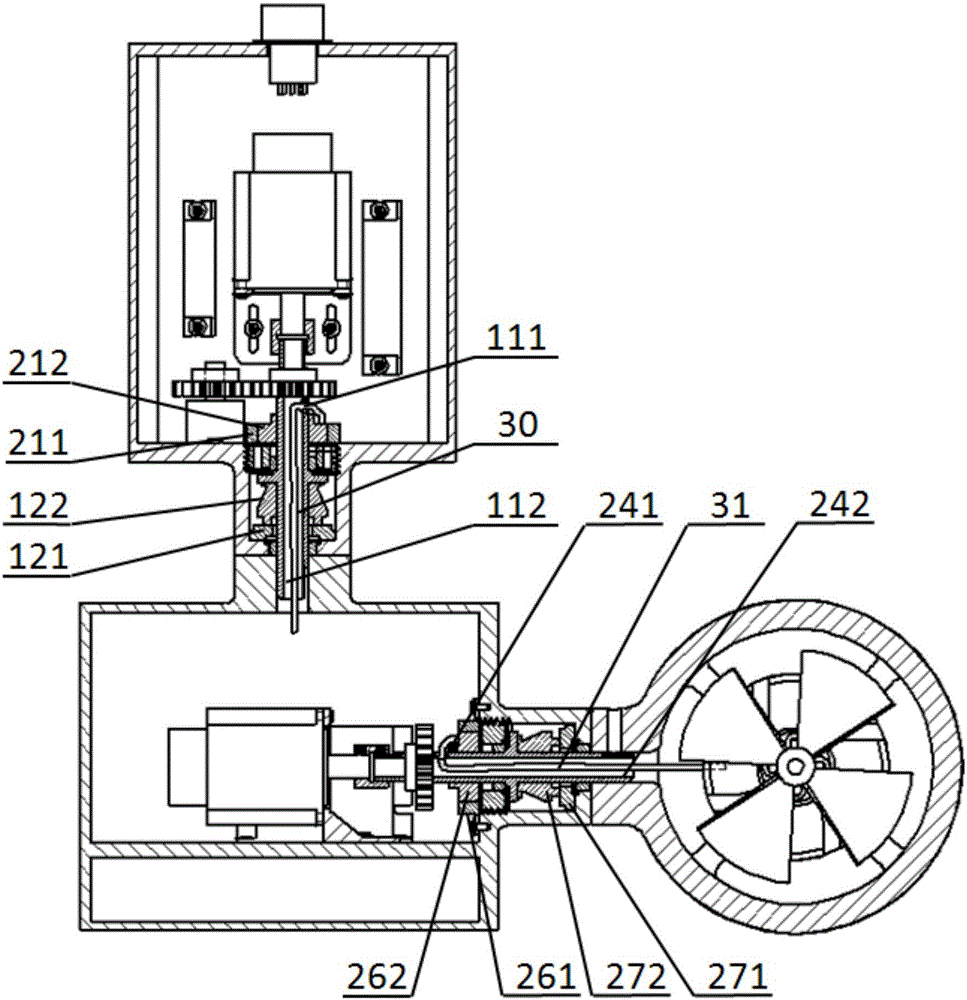

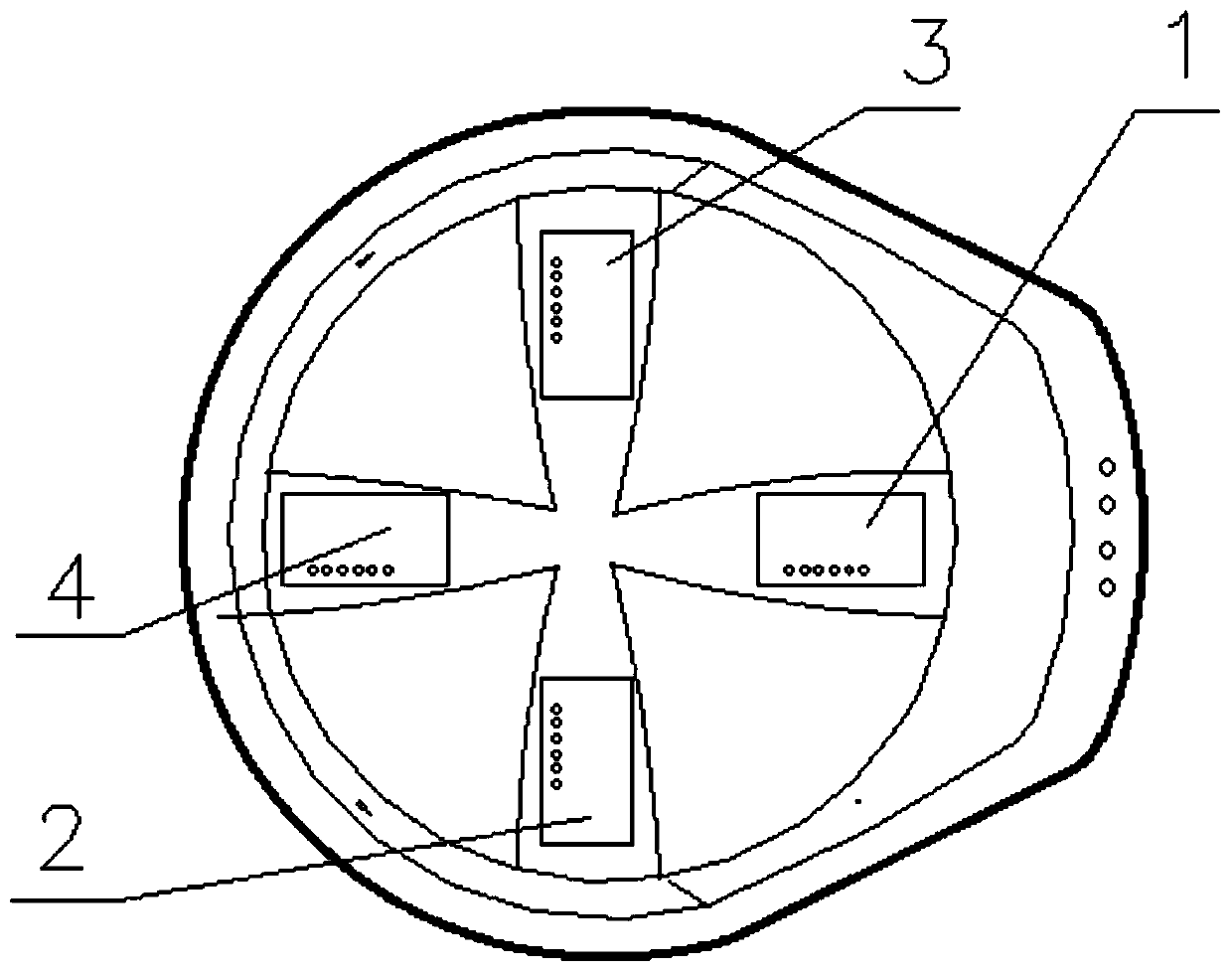

Fully rotary type underwater propellers

InactiveCN106741791AImprove controllabilityImprove adaptabilityPropulsion power plantsOutboard propulsion unitsUnderwaterModularity

The invention relates to fully rotary type underwater propellers. Each fully rotary type underwater propeller is composed of a propulsion mechanism, a horizontal steering mechanism, a vertical steering mechanism and an electronic element set; under the action of the horizontal steering mechanism and the vertical steering mechanism, the propulsion mechanism can rotate around the Y axis and the Z axis; the situation that internal cables are wound due to relative rotation between the components is avoided, and thus the propulsion mechanism can rotate at any angle around the Y axis and the Z axis and can continuously rotate by multiple circles; the rotation angles of the propulsion mechanism around the Y axis and the Z axis can be determined by detecting output signals of a horizontal steering shaft position detecting device and a vertical steering shaft position detecting device; and a second sealed cabin is provided with at least one watertight plug connector, and the watertight plug connectors can conduct electric power and signal transmission with submersibles or the outside and can also achieve collaborative operation among the multiple fully rotary type underwater propellers. The fully rotary type underwater propellers are high in flexibility and compact in structure, and the modular design of the submersibles is beneficially achieved.

Owner:NAVAL UNIV OF ENG PLA

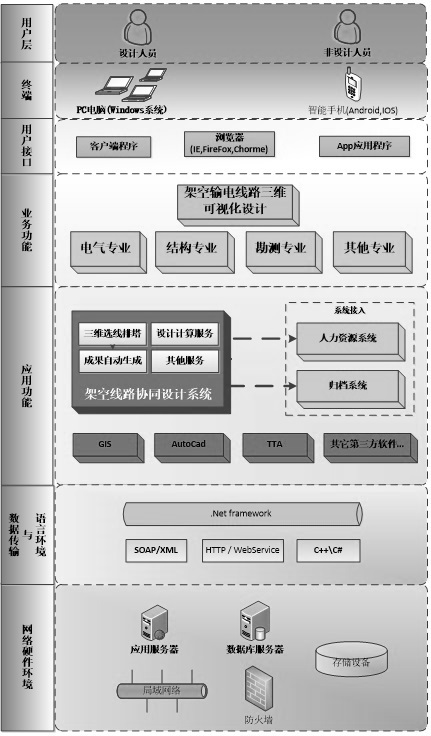

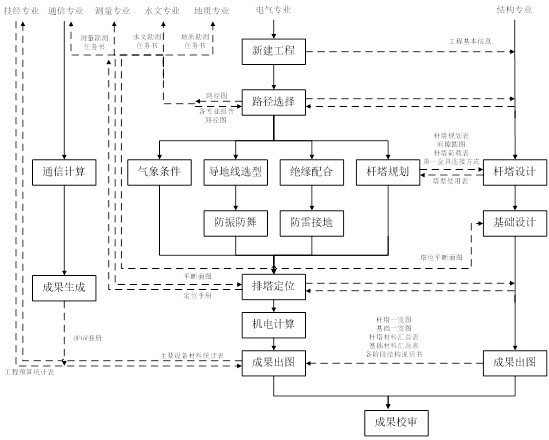

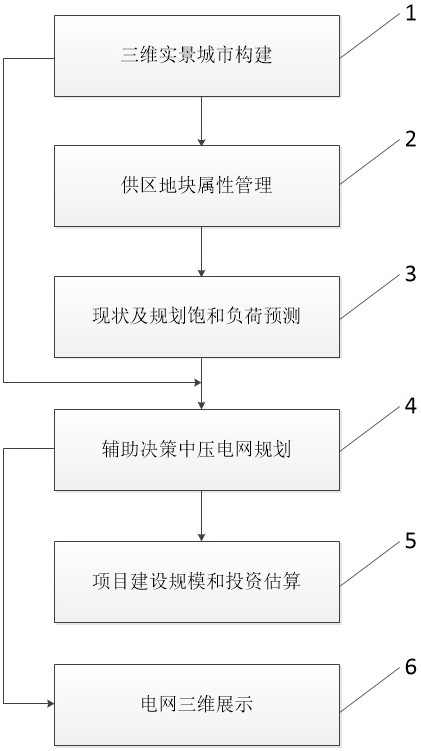

Urban medium-voltage power grid planning and designing platform based on three-dimensional real scene

PendingCN112035983AImprove efficiencyHigh precisionGeometric CADConfiguration CADInformatizationControl engineering

The invention relates to the field of power grid planning, in particular to an urban medium-voltage power grid planning and designing platform based on a three-dimensional real scene. The platform realizes the line design of the whole design period of the power distribution engineering and the three-dimensional visual display of the design process and result, and also has the functions of three-dimensional live-action line design, cable three-dimensional design, three-dimensional distance verification, tower model analysis and space analysis. The platform has the following beneficial effects that various existing resources are integrated, and informatization management and data sharing are promoted; the platform serves power planning and design integrated services, and the working efficiency is improved; all service links are integrated, and cooperation and connection of the whole service process and content are achieved; application and research tools are integrated, the technical content of planning and design is improved, and lean planning and design are achieved.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO +1

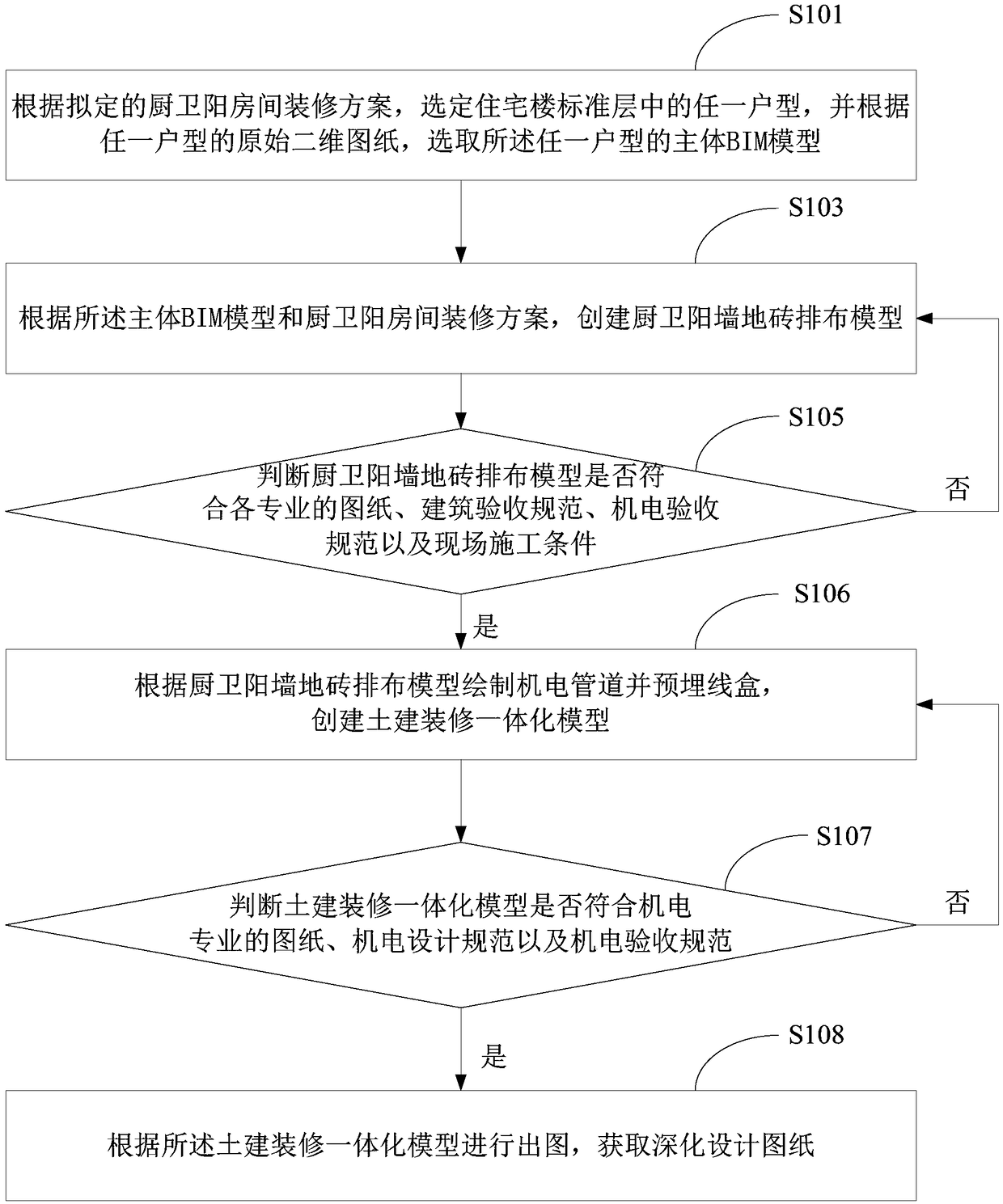

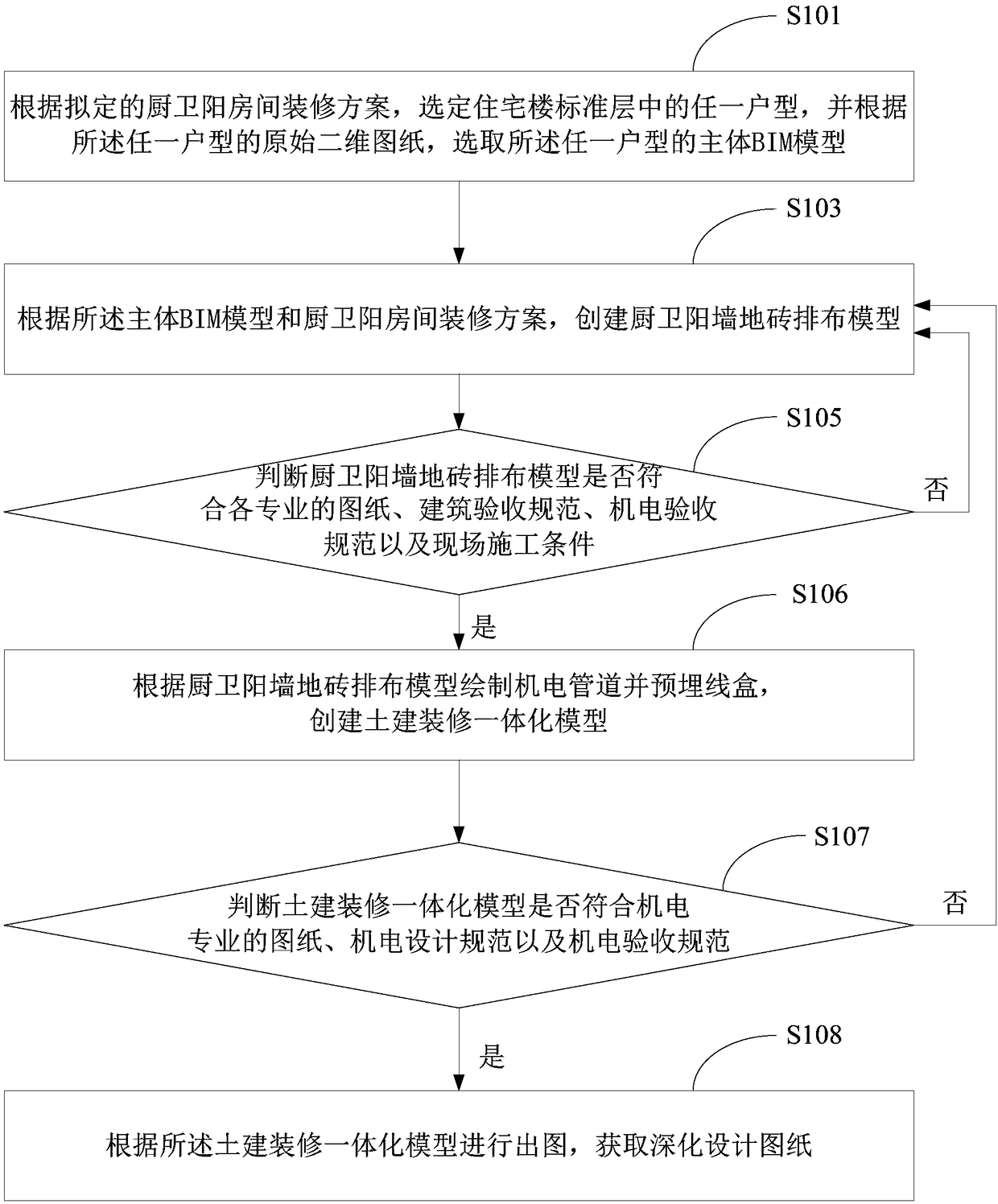

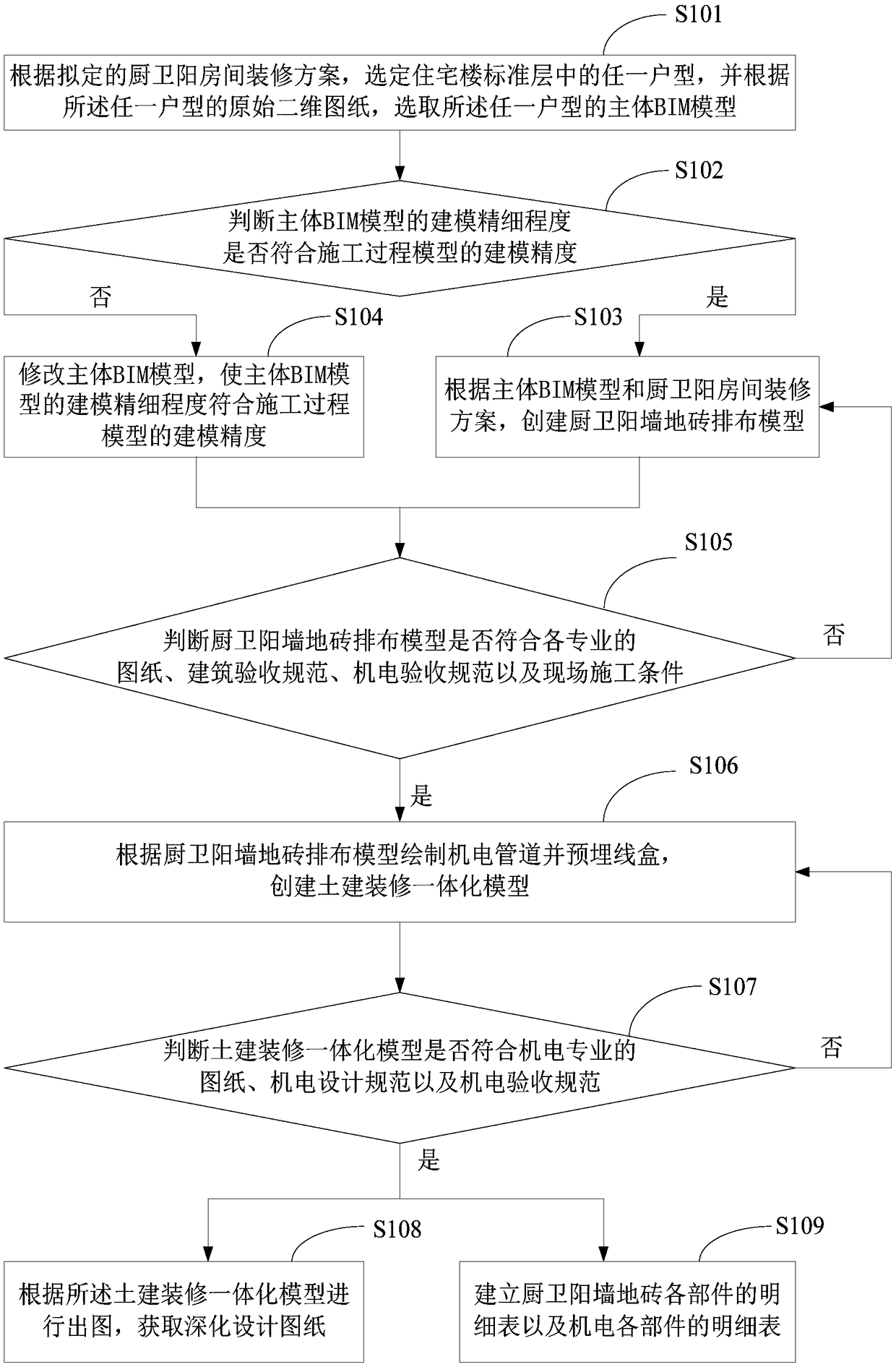

BIM technology-based kitchen, bathroom, balcony and room decoration deepening design method

ActiveCN108765545ARealize collaborative workRealize integrated designGeometric CADDesign optimisation/simulationIntegrated designDesign methods

The invention relates to a BIM technology-based kitchen, bathroom, balcony and room decoration deepening design method. The method comprises the steps of selecting a house main body BIM model according to the original two-dimensional drawing of any house; creating a kitchen, bathroom, balcony wall and floor tile arrangement model according to the BIM main body model and the kitchen, bathroom, balcony and room decoration scheme; determining whether the kitchen, bathroom, balcony wall and floor tile arrangement model conforms to the drawing, the specification and the on-site construction condition; if yes, drawing the electromechanical pipeline according to the kitchen, bathroom, balcony wall and floor tile arrangement model, pre-burying a wire box, and creating a civil engineering decoration integrated model; determining whether the civil engineering decoration integrated model accords with an electromechanical professional drawing and specification, and if yes, drawing according to thecivil engineering decoration integrated model, and obtaining a deepened design drawing. The method provides an integrated design of all fields, the collaborative operation of the design party and theconstruction party can be realized, the phenomenon of reworking caused by collision of the fields in the construction process is effectively avoided, the construction and arrangement are more reasonable, and the construction efficiency is improved.

Owner:SHANDONG LIAOCHENG CONSTR

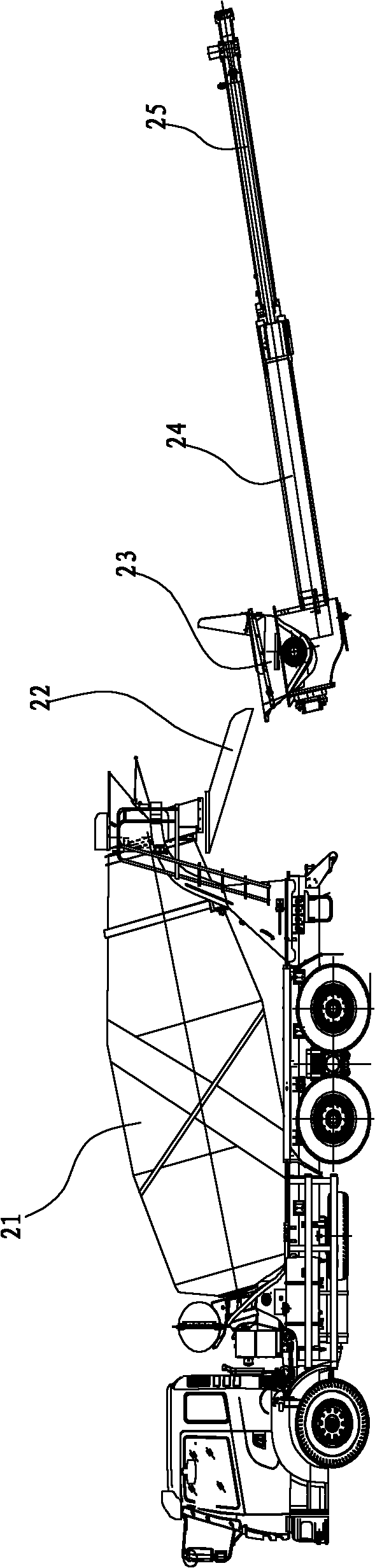

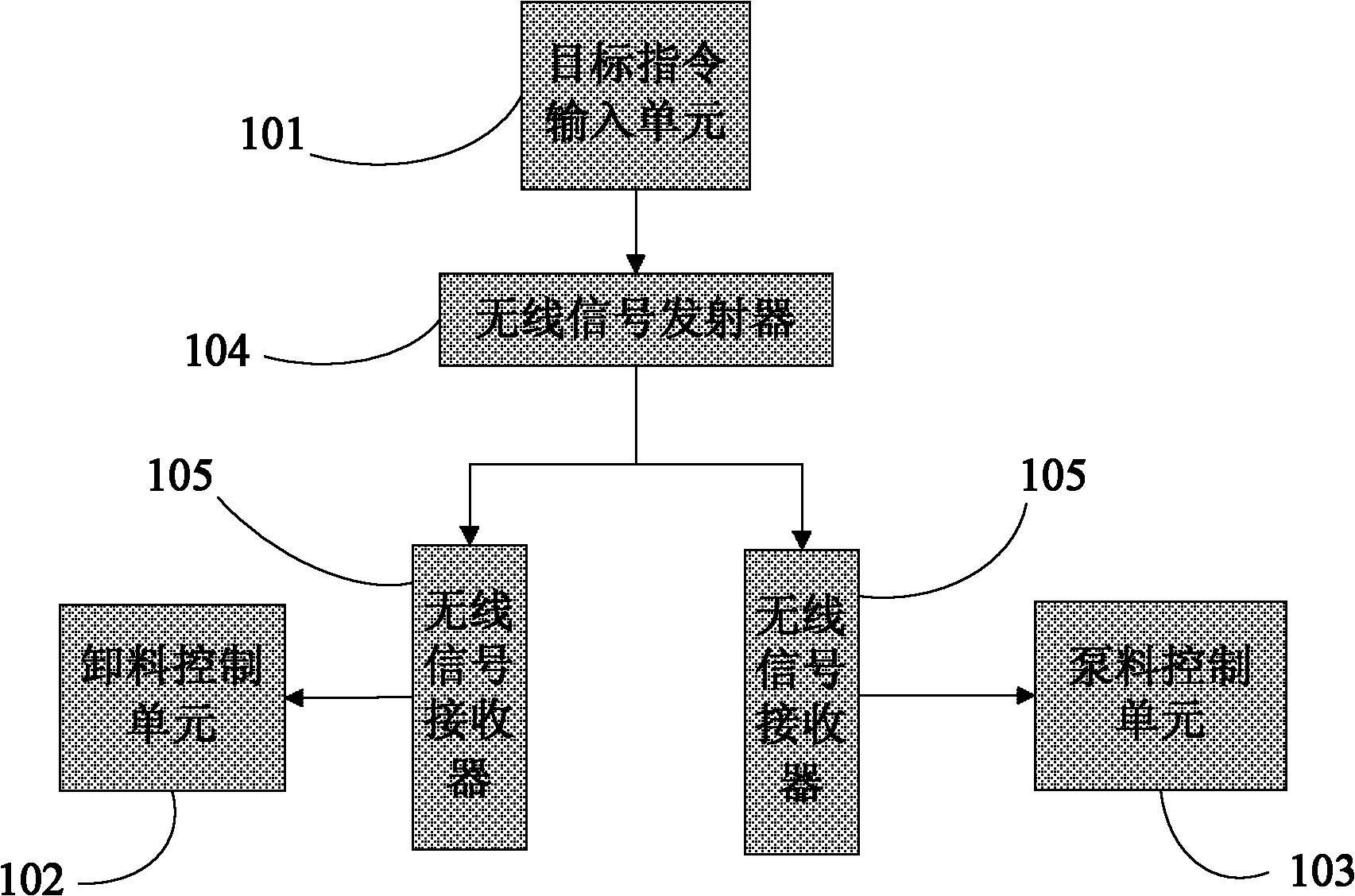

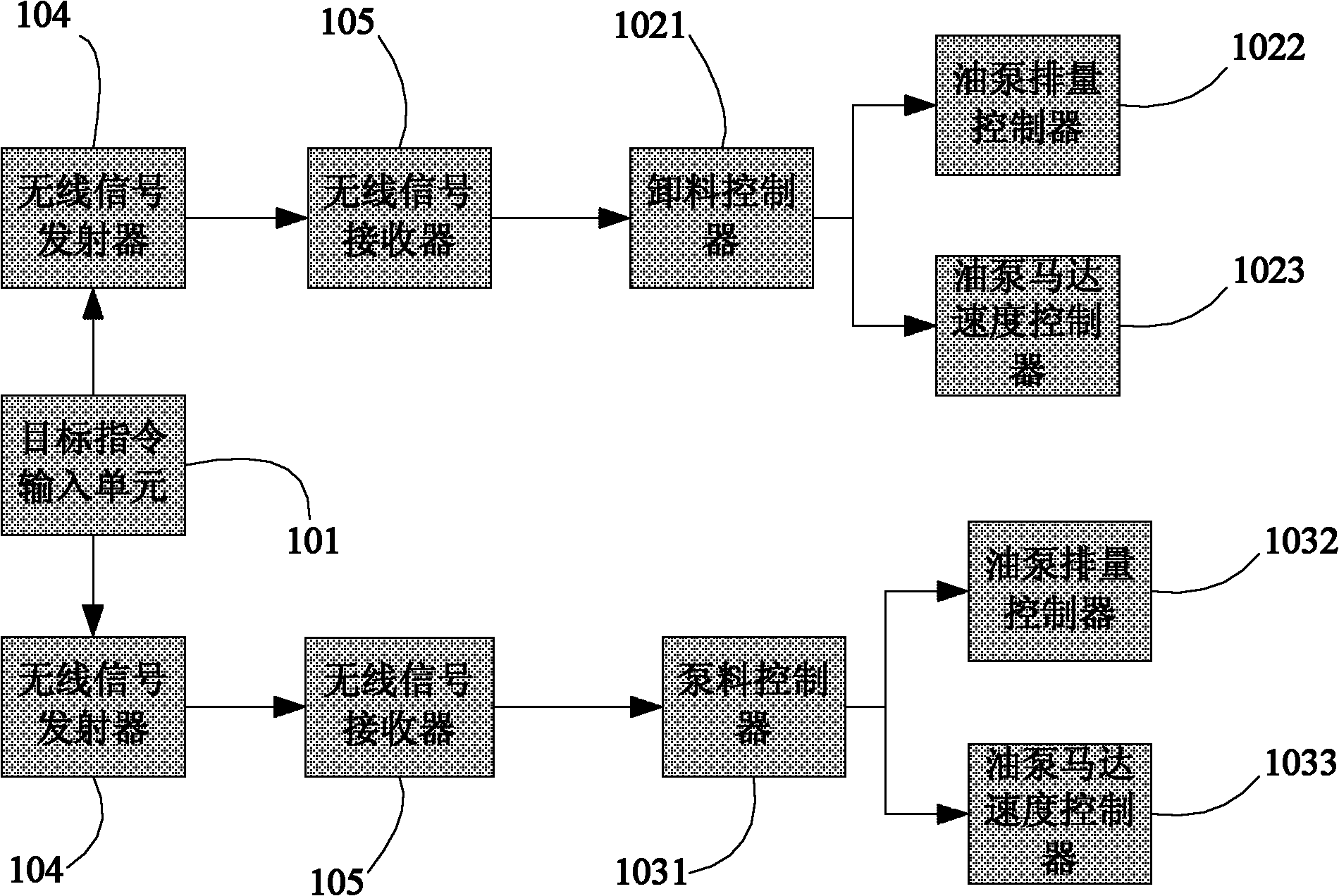

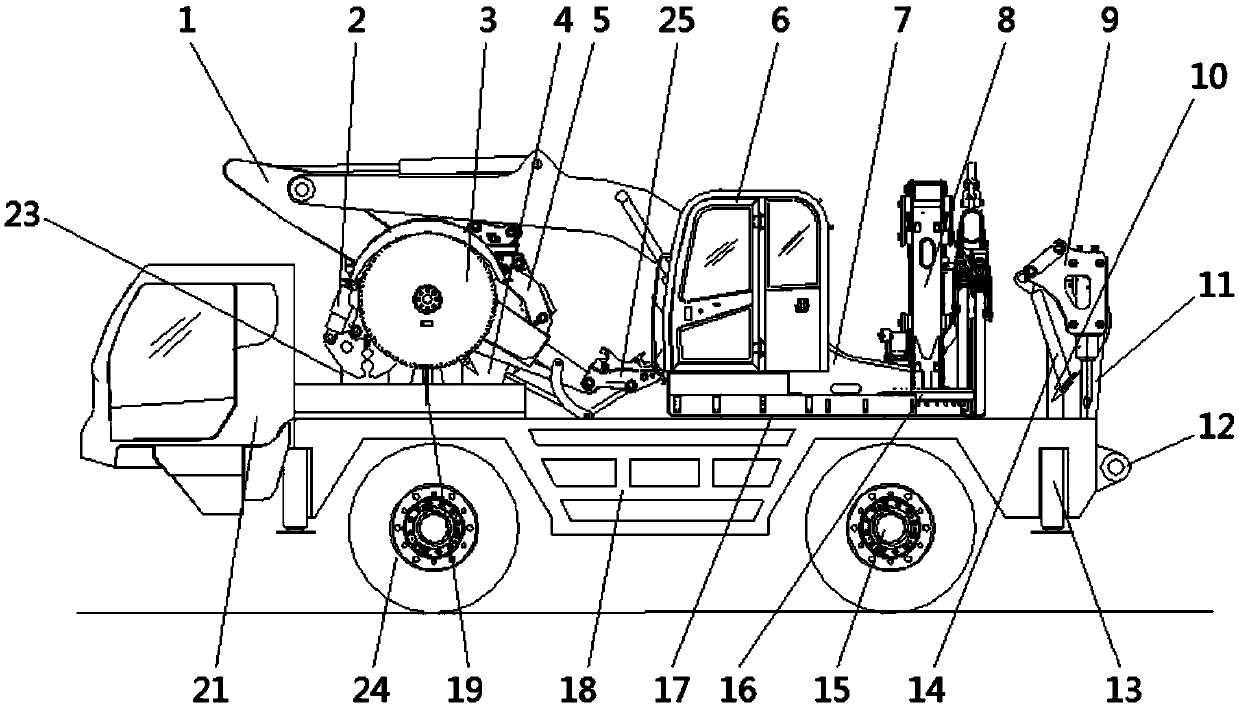

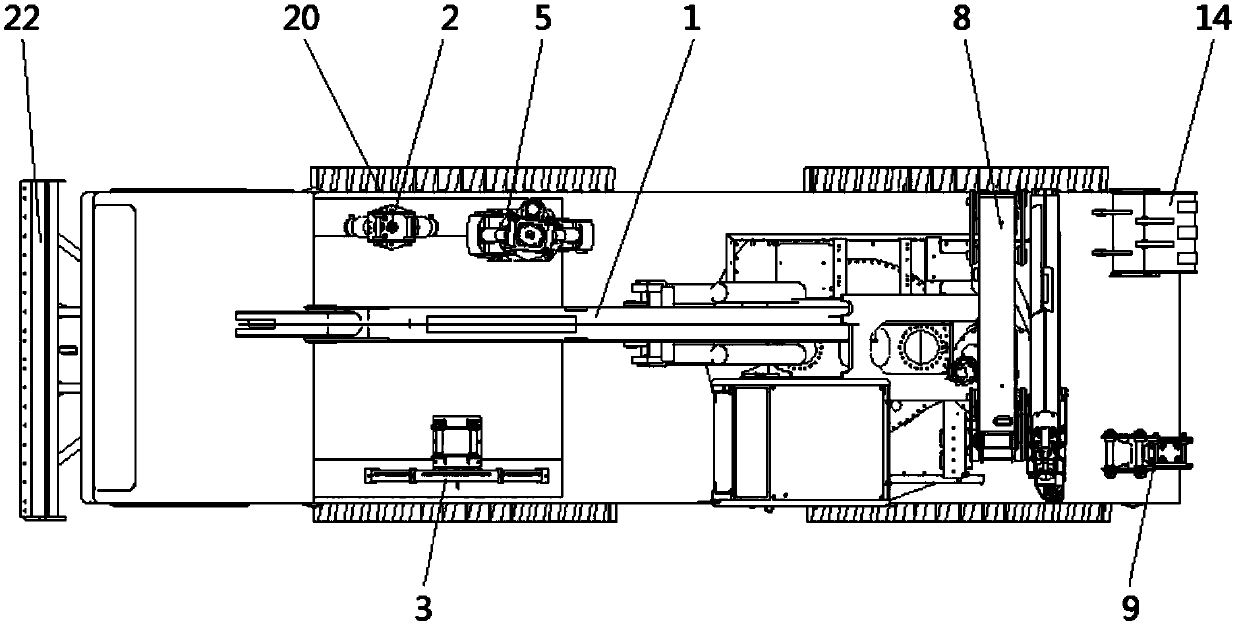

Mixer truck and pump truck coordinative operation system, mixer truck and pump truck coordinative operation method, mixer truck and pump truck

InactiveCN102322147AReduce operating intensityRealize collaborative workBuilding material handlingTruckIncoordinations

The invention relates to a mixer truck and pump truck coordinative operation system, a mixer truck and pump truck coordinative operation method, a mixer truck and a pump truck. The coordinative operation system comprises a target instruction input unit, a discharge control unit and a pumping control unit; the target instruction input unit is used for inputting a target instruction corresponding to discharge needed by on-site operation; the discharge control unit is used for controlling the mixer truck according to the target instruction, so that the discharge or discharge speed of the mixer truck can reach the discharge corresponding to the target instruction; and the pumping control unit is used for controlling the pump truck according to the target instruction, so that the pump output or the pumping speed of the pump truck can reach the discharge corresponding to the target instruction. The invention utilizes the target instruction input unit to input the discharge corresponding to the target instruction, the discharge control unit and the pumping control unit uniforms the respectively controlled discharge or discharge speed and pump output or pumping speed, i.e. uniforming the discharge speed and the pumping speed or uniforming the discharge and the pump output, consequently, the coordinative operation of concrete discharge and pumping is realized, and overflowing or emptying caused by the incoordination of discharge and pumping can be prevented.

Owner:SANY HEAVY IND CO LTD (CN)

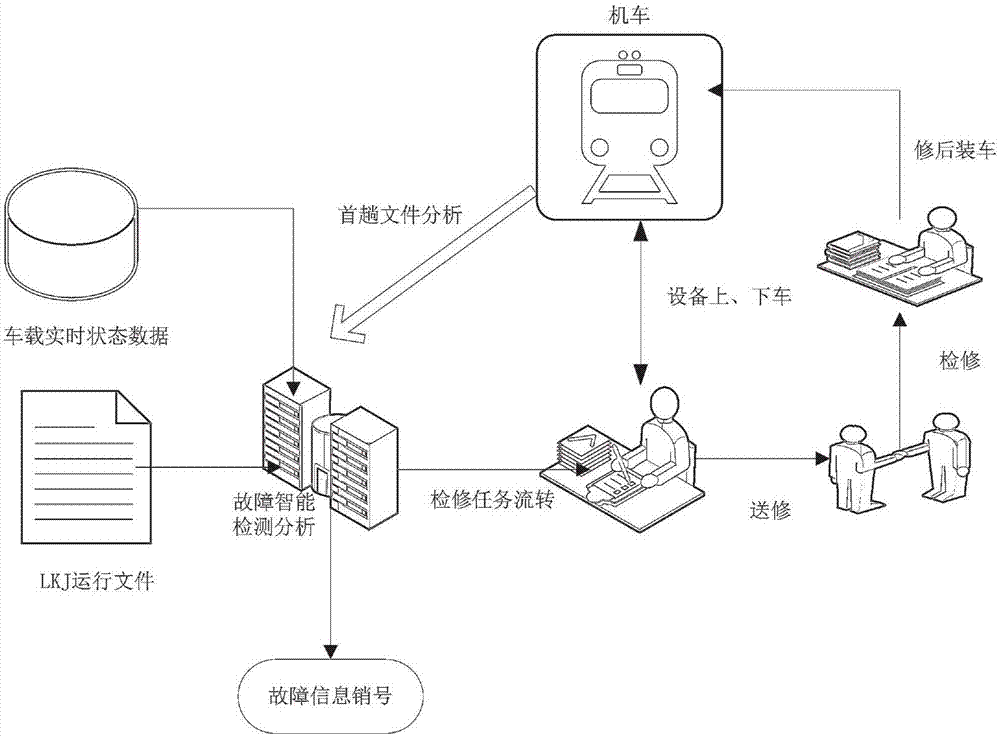

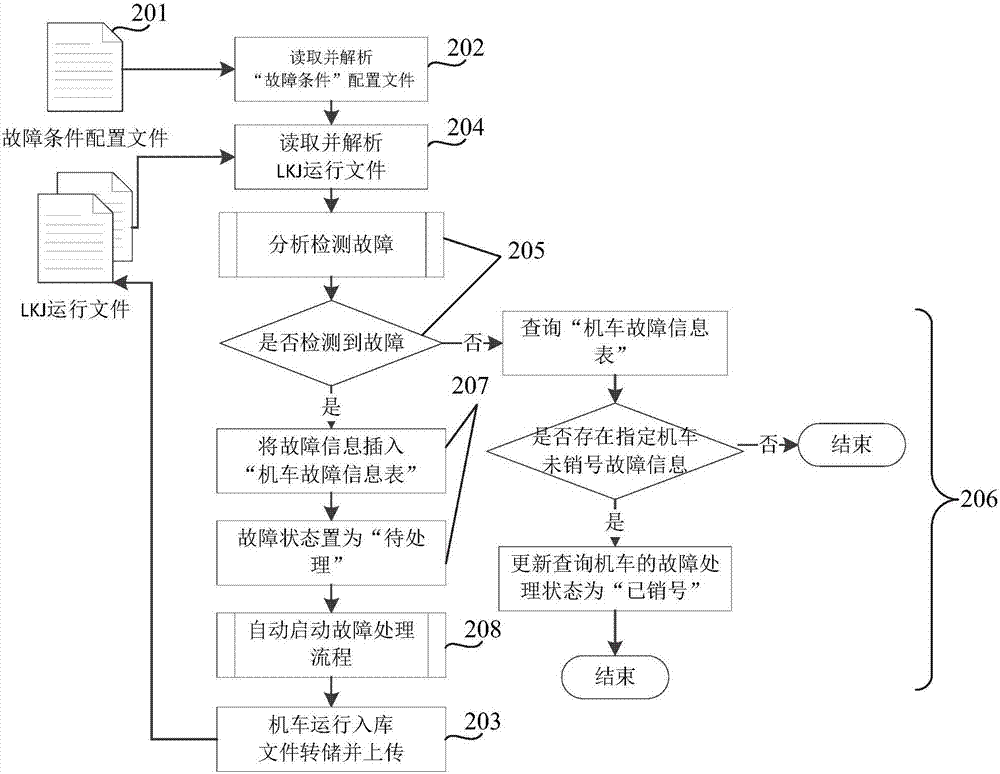

Method for device fault intelligent diagnosis and number-cancelling processing of train running monitoring system (LKJ)

ActiveCN107139972AAvoid frequent modificationReduce maintenance workloadSignalling indicators on vehicleArray data structureStatistical analysis

The invention provides a method for device fault intelligent diagnosis and number-cancelling processing of LKJ. The method includes the steps of reading and parsing a fault condition configuration file, and parsing and writing the judgment criterion of various fault types into a fault condition object array; reading and parsing a dump LKJ running file based on a protocol, and parsing and writing each record information item in the LKJ running file into a memory data table; according to the fault judgment condition in the fault condition object array, traversing and statistically analyzing the record information in the memory data table to determine whether or not the fault condition is satisfied; if yes, carrying out a fault processing procedure; if the analysis does not find a fault, extracting the locomotive information in the LKJ running file, and querying whether or not the non-number-cancelling fault information about the locomotive extracted in the LKJ running file exists in a locomotive fault information table; if the non-number-cancelling record information is found, setting the state of fault processing to be a number-cancelling state, and finishing the procedure; if the record information of satisfying the condition is not found, finishing the procedure.

Owner:HUNAN CRRC TIMES SIGNAL & COMM CO LTD

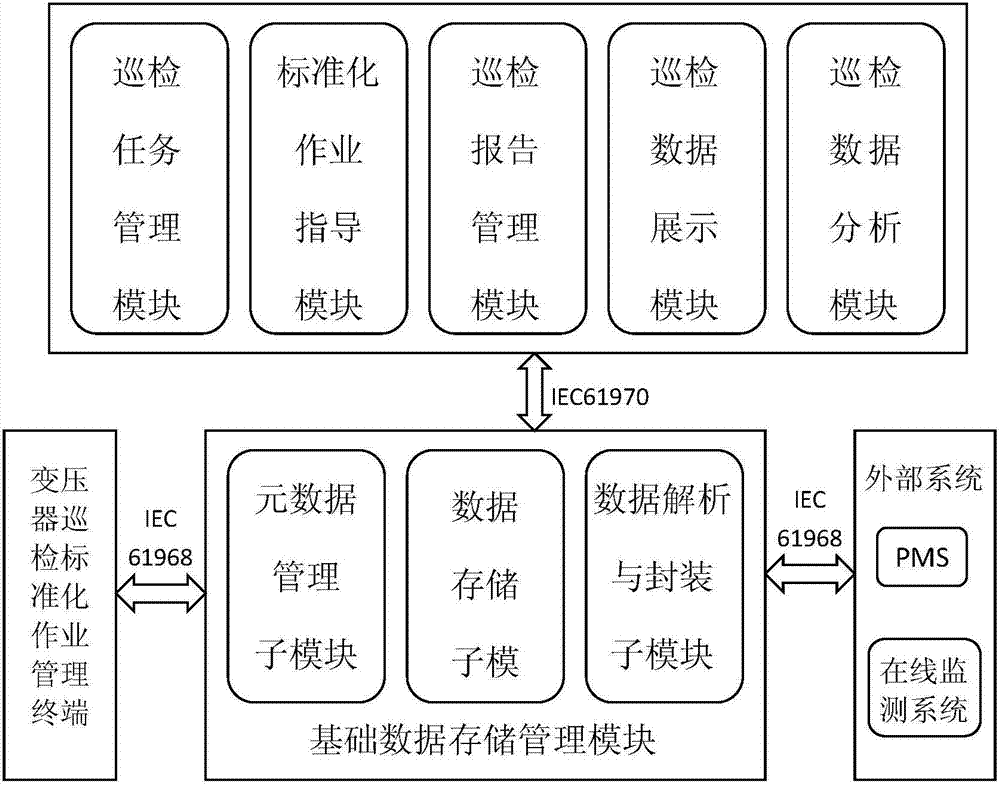

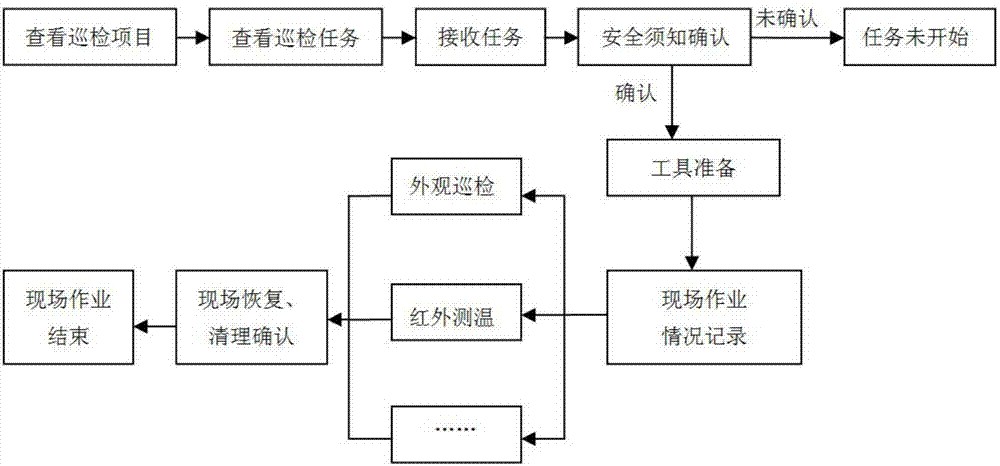

Data analysis system applied to professional transformer inspection

PendingCN107271806ARealize comprehensive display of informationAchieve normalizationTesting dielectric strengthRadiation pyrometryData displayData analysis system

The invention relates to a data analysis system applied to professional transformer inspection. The system comprises an inspection task management module, a standardized operation guidance module, an inspection report management module, an inspection data display module, an inspection data analysis module, as well as a basic data storage management module providing data interaction for the above modules. Data interaction between the basic data storage management module and a transformer professional inspection standardization operation management terminal and an external management system is achieved. The system displays various events, information and data related to a transformer in a time sequence orderly on a life time axis of the transformer, displays the operation status of the transformer from putting into operation till now, and achieves comprehensive information exhibition from management, device and other perspectives. The system achieves inspection data standardization and structured storage, with big data analysis capability.

Owner:SHANDONG POWER EQUIP +1

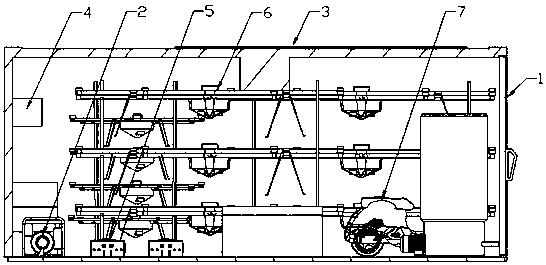

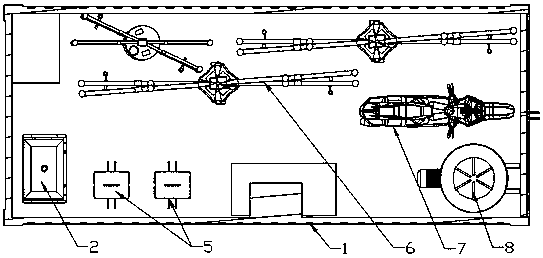

Mobile-type shared agricultural unmanned aerial vehicle service station

PendingCN107792383ALower operating thresholdHighly integratedBatteries circuit arrangementsElectric powerElectricityAgricultural engineering

The invention aims to provide a mobile-type shared agricultural unmanned aerial vehicle service station capable of being simple in structure, self-sufficient, convenient to manage and high in integration level. The mobile-type shared agricultural unmanned aerial vehicle service station comprises at least one box body (1), a plurality of functional areas are arranged in the box bodies (1), and eachfunctional area is internally provided with an electricity supply system, an electricity storage system, an unmanned aerial vehicle operating system, a replenishment system, a transportation tool system and a management system. Each electricity supply system supplies electricity to the corresponding replenishment system and the management system. Each management system is connected with the corresponding electricity supply system, the electricity storage system, the unmanned aerial vehicle operating system and the replenishment system in an electrical signal mode. The management systems of each box body (1) are in communication with one another. The management systems are in communication connection with a peripheral master control console. The mobile-type shared agricultural unmanned aerial vehicle service station is applied in the field of agricultural equipment.

Owner:ZHUHAI YUREN AGRI AVIATION CO LTD

Building construction system and control method

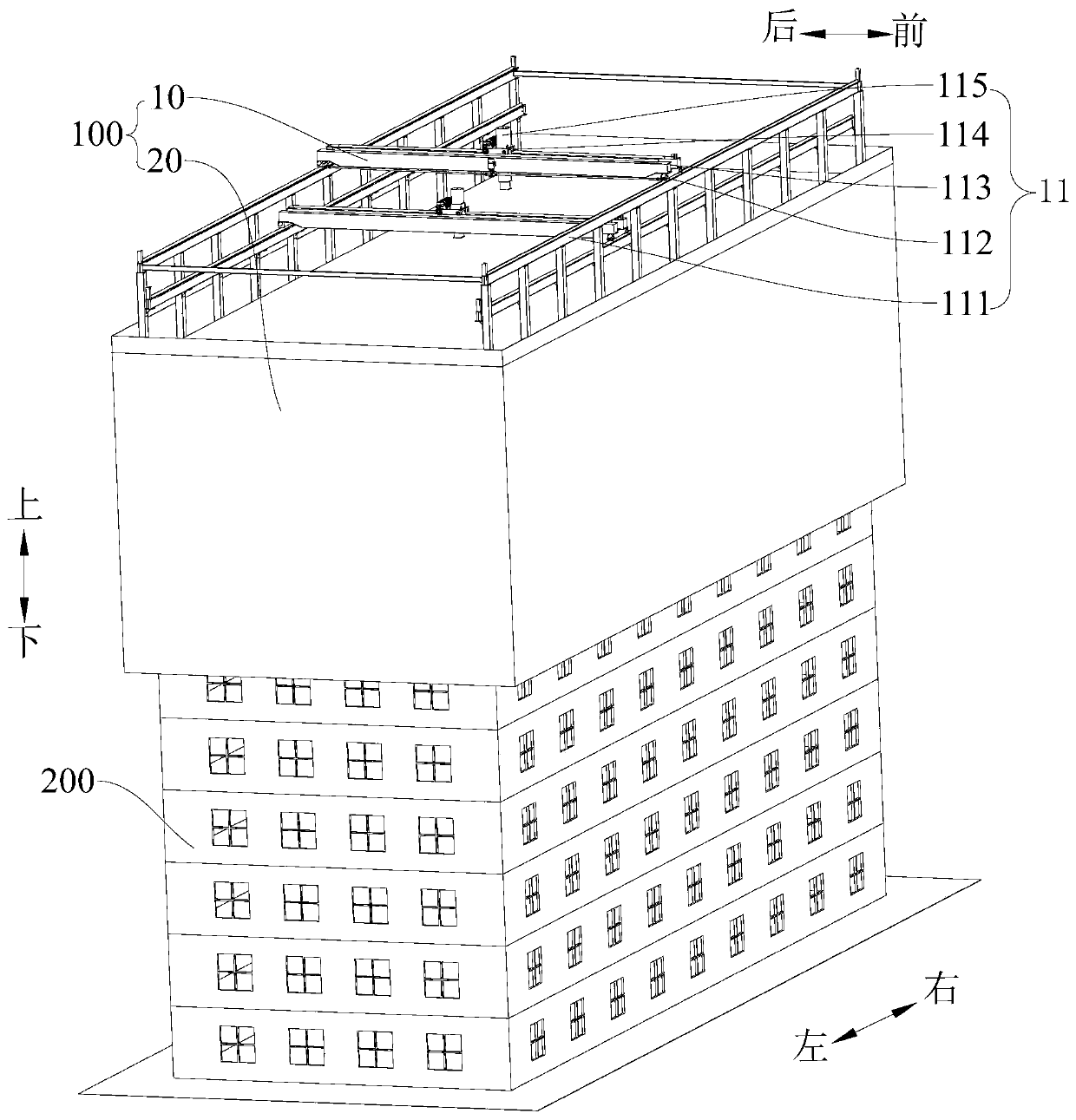

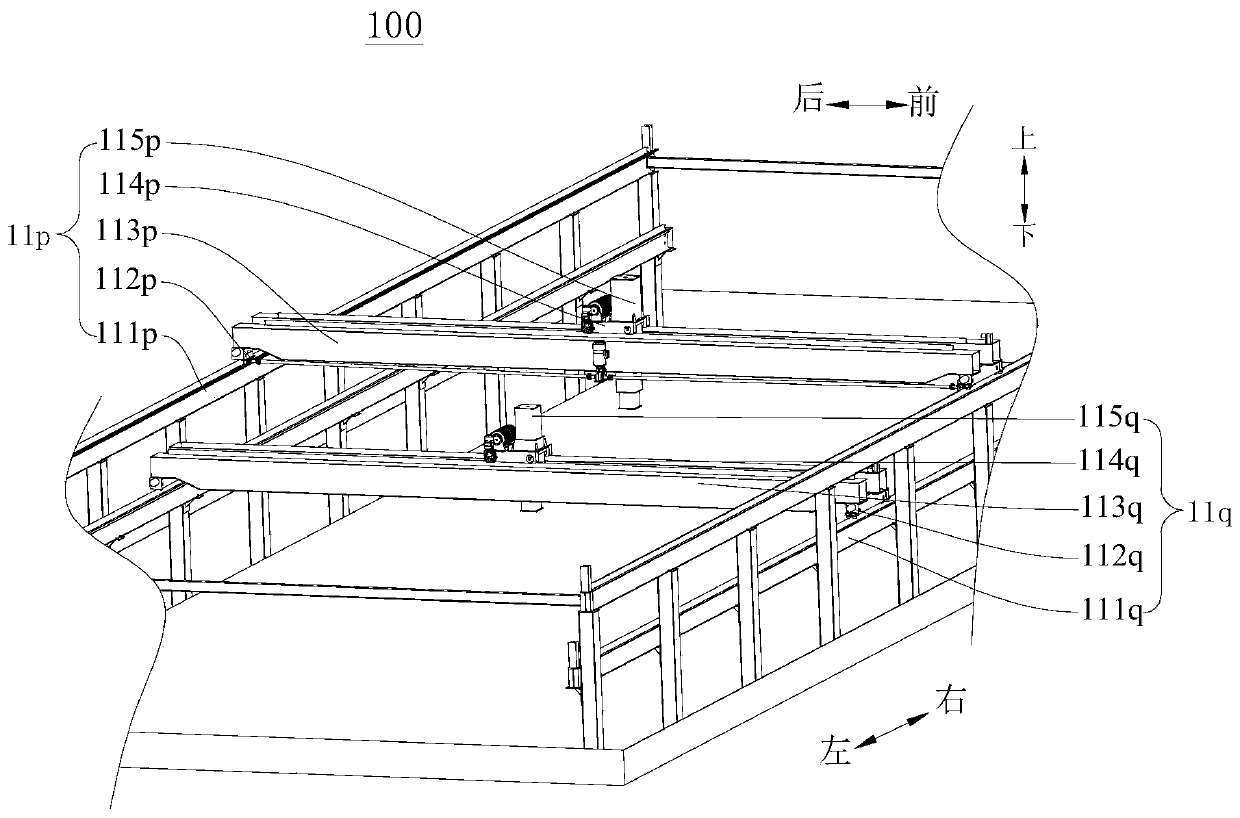

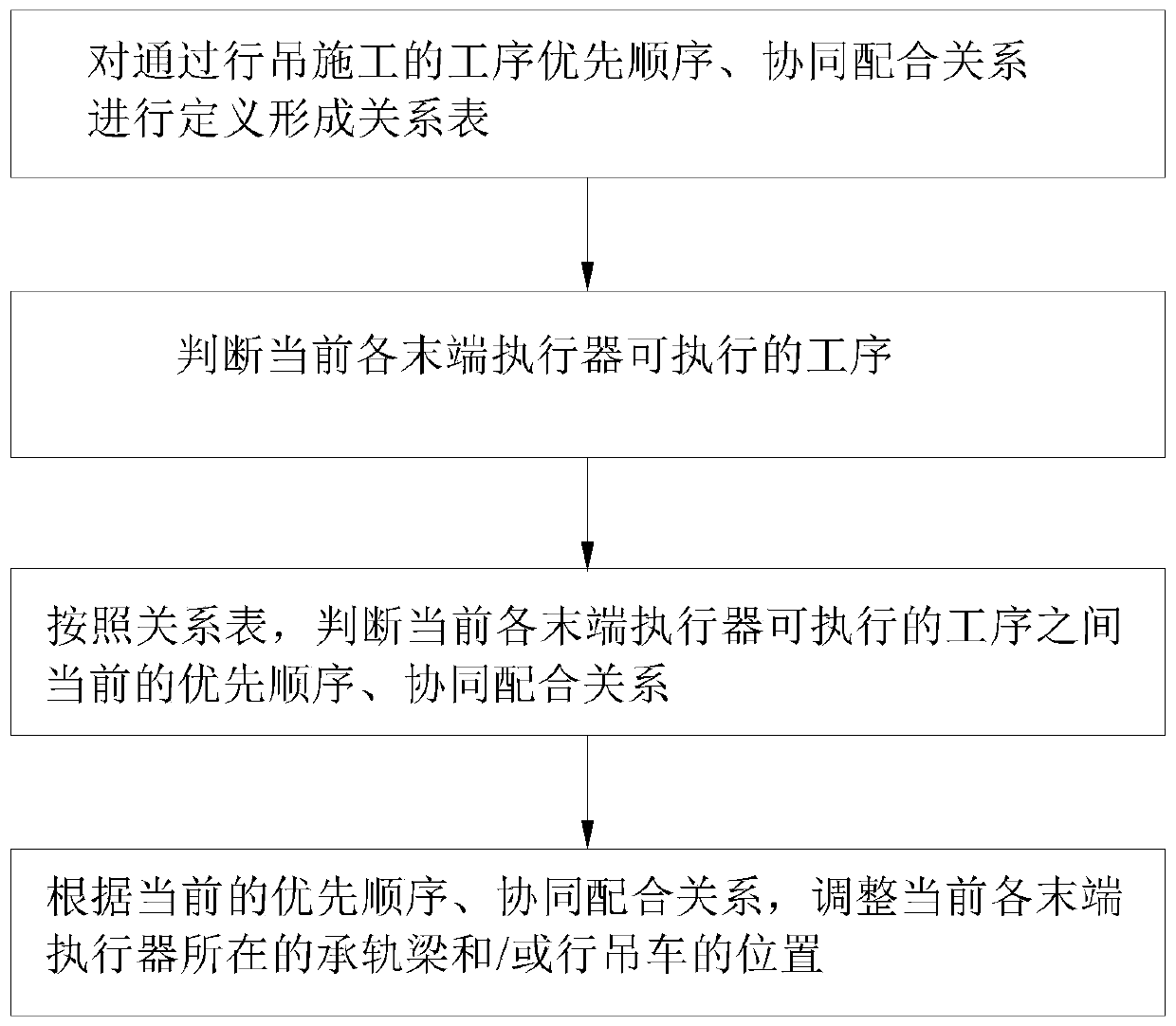

InactiveCN110294421AMeet the requirements of simultaneous construction on multiple working surfacesMeet the requirements of simultaneous constructionTravelling cranesSafety gearArchitectural engineeringActuator

The invention discloses a building construction system and a control method. The building construction system comprises a climbing frame system and a crane system. The crane system comprises a plurality of crane devices, each crane device comprises a crane track, a walking device, a bearing rail beam and a crane, each crane is applicable to craning an end effector, and the heights of the bearing rail beams of the multiple crane devices are different; except for the crane device where the lowest bearing rail beam is located, the other crane devices all need to be avoided, at least the crane devices needing to be avoided are provided with telescopic booms, and the telescopic booms are connected to the cranes and used for installing the end effectors. The requirement for constructing multipleworking faces of a construction layer at the same time can be met, the working efficiency is improved, the end effectors carried on the cranes can replace relatively without mutual restriction, cooperative work of some construction procedures can be achieved, the construction progress can be accelerated, and time and labor are saved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Emergency rescue vehicle

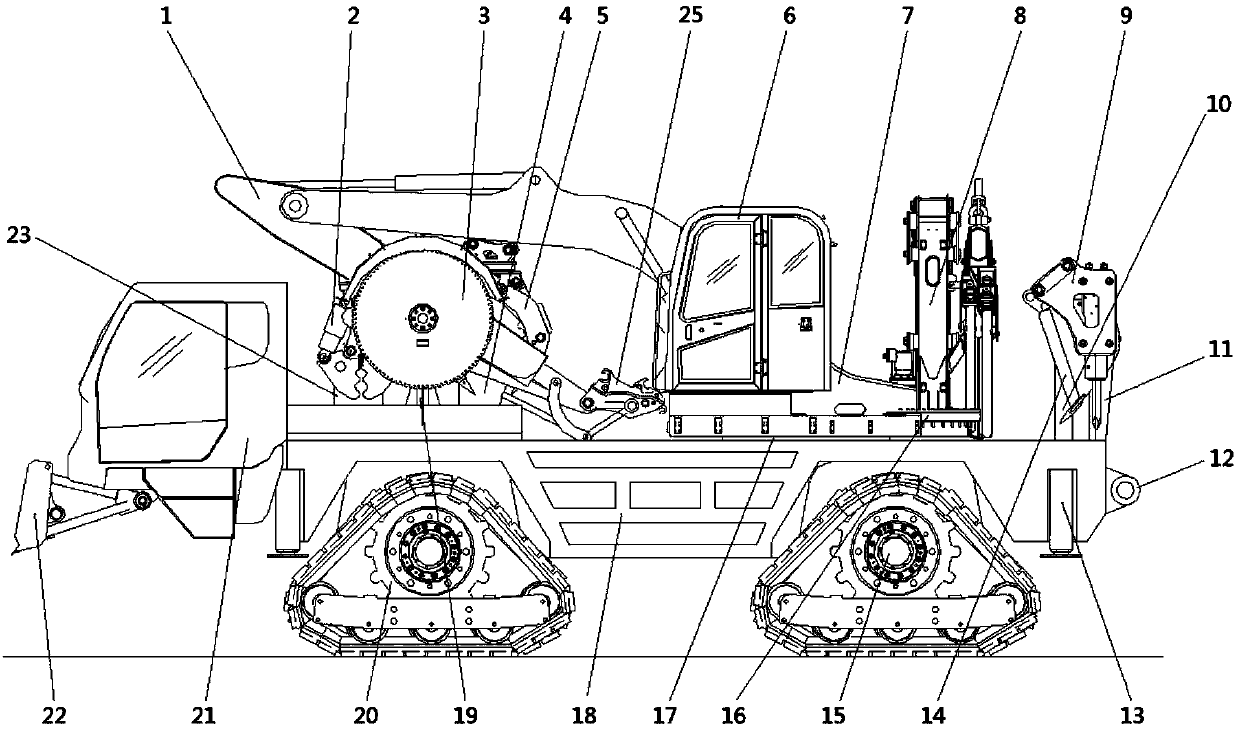

PendingCN107653920ARealize collaborative workSave installation spaceMechanical machines/dredgersEndless track vehiclesEngineeringEmergency rescue

The invention relates to an emergency rescue vehicle. The emergency rescue vehicle comprises a chassis, a first manipulation arm, a second manipulation arm, a first rotating mechanism and a second rotating mechanism, wherein the first manipulation arm is mounted on the first rotating mechanism; the second manipulation arm is mounted on the second rotating mechanism; the second rotating mechanism is mounted on the first rotating mechanism; the first rotating mechanism is mounted on the chassis; and each of the first rotating mechanism and the second rotating mechanism can rotate for 360 degrees. According to the emergency rescue vehicle provided by the invention, on the premise that the relative rotation of the first rotating mechanism and the second rotating mechanism is not affected and when the first rotating mechanism rotates to drive the first manipulation arm and the second manipulation arm to rotate simultaneously, the cooperative work of the two manipulation arms is realized, the power source used for driving the first manipulation arm and the second manipulation arm to rotate independently is not needed, the installation space of the chassis is saved, the arrangement of alldevices on the chassis is more reasonable, the manipulation spaces of the first manipulation arm and the second manipulation arm are expanded, and the manipulation capacity of the two manipulation arms is improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

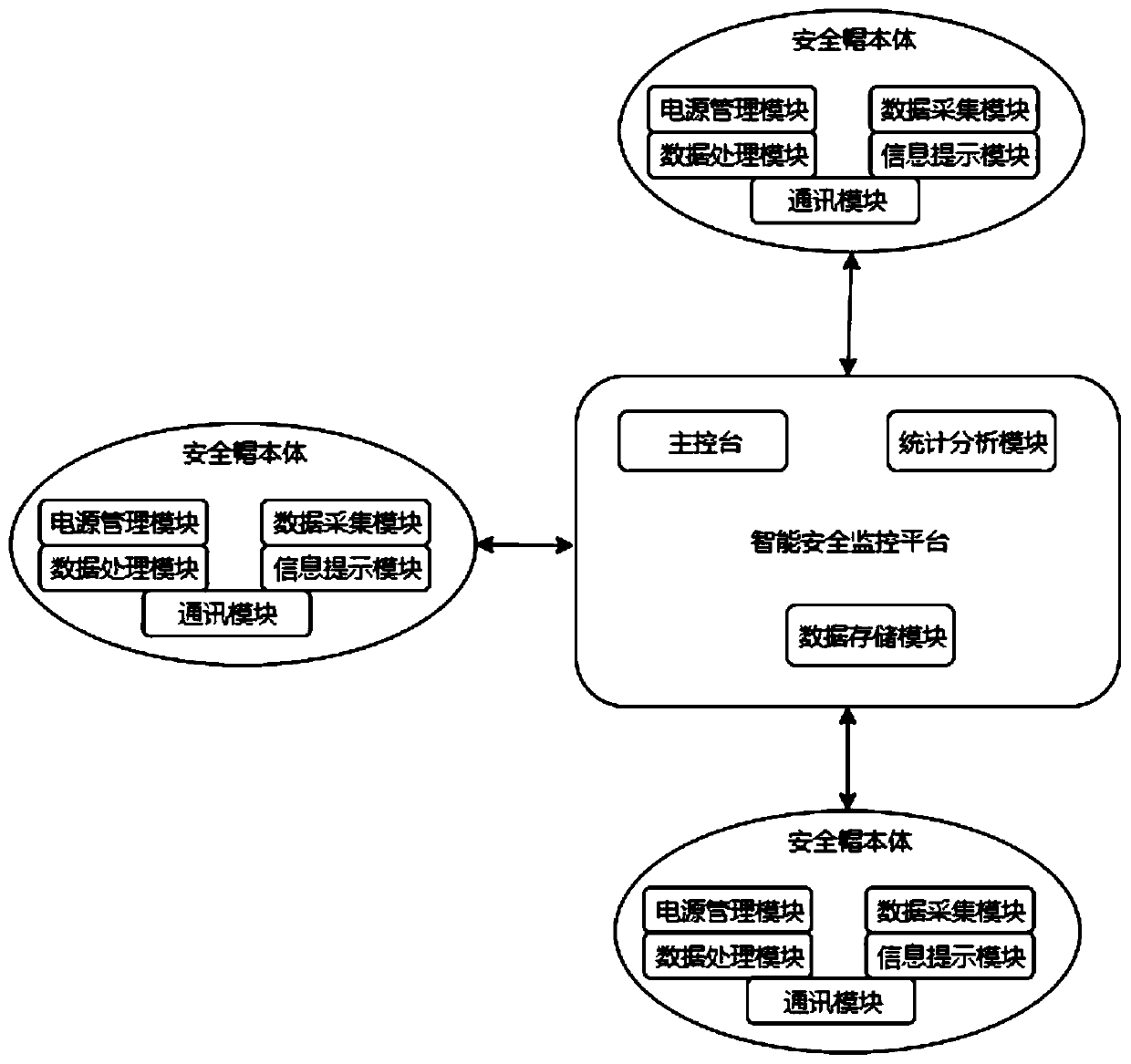

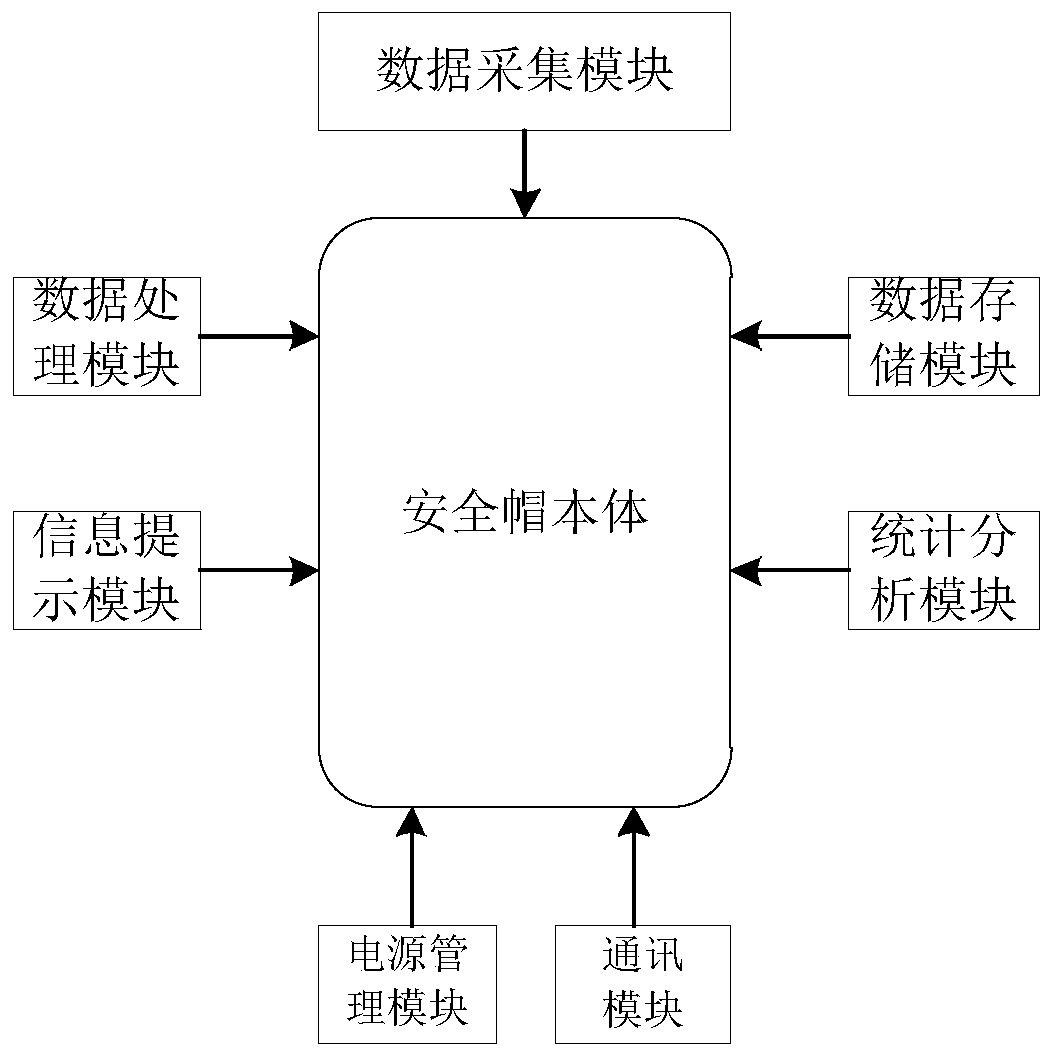

Safety monitoring system based on intelligent safety helmet

InactiveCN111493441AAvoid long stayEnsure personal safetyTelevision system detailsMeasurement devicesData acquisitionSecurity monitoring

The invention provides a safety monitoring system based on an intelligent safety helmet. The safety monitoring system comprises an intelligent safety helmet and a safety monitoring platform in communication connection with the intelligent safety helmet for information interaction, wherein the intelligent safety helmet comprises a safety helmet body, and a data acquisition module, a data processingmodule and an information prompting module which are arranged on the safety helmet body. When an operator wears the intelligent safety helmet, multidirectional multifunctional safety monitoring can be conducted on the operator, the operation safety of the operator is ensured, and pre-stored operation tasks can be corrected.

Owner:贰佰号科技(北京)有限公司 +1

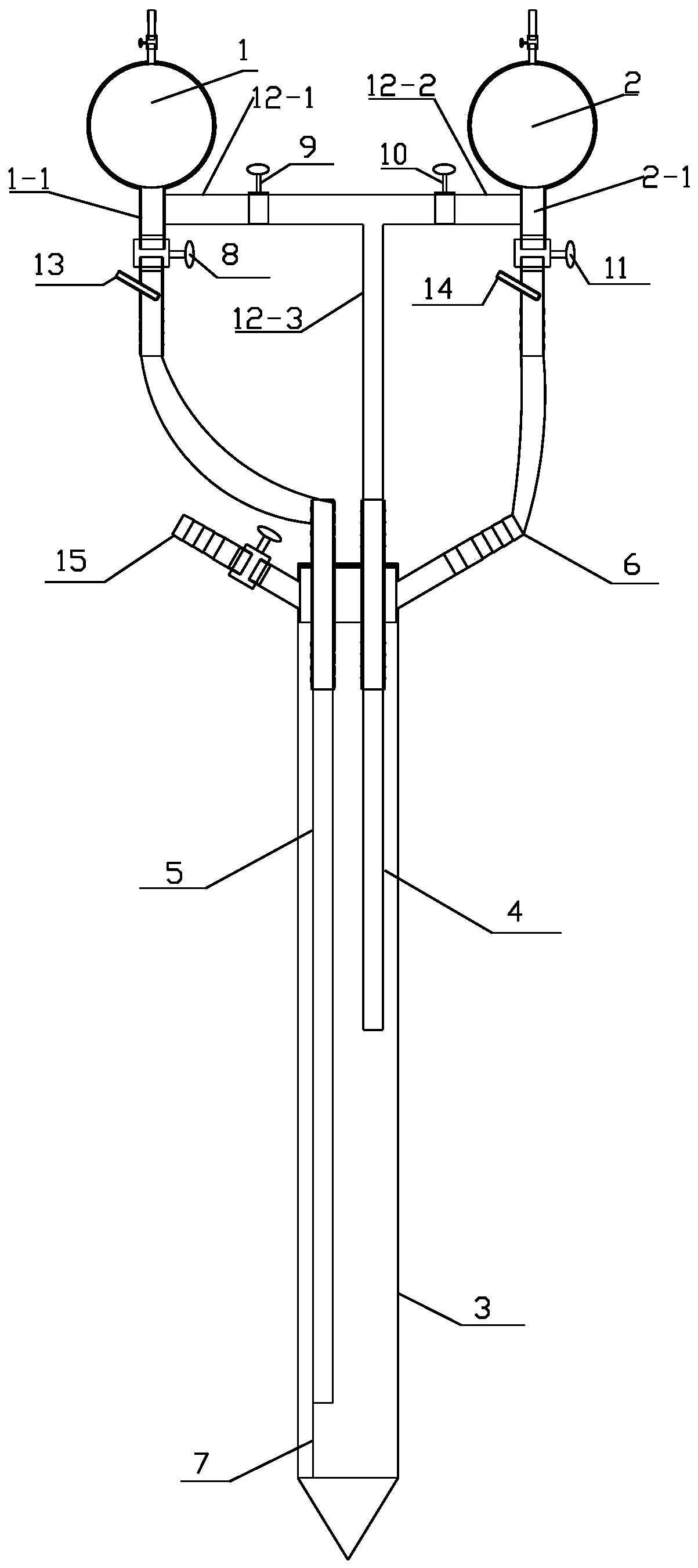

Freezer capable of achieving staged freezing and staged freezing method

ActiveCN111365001ASave civil costSmall footprintShaft sinkingChilling requirementStructural engineering

The invention discloses a freezer capable of achieving staged freezing and a staged freezing method. The freezer comprises a liquid distribution ring, a liquid collection ring, a tee joint, a freezingpipe, an upper-section frozen liquid supply and lower-section frozen liquid return pipe, and a lower-section frozen liquid supply pipe. The bottom ends of the upper-section frozen liquid supply and lower-section frozen liquid return pipe and the lower-section frozen liquid supply pipe extend into the freezing pipe along the axis of the freezing pipe, and the upper ends of the upper-section frozenliquid supply and lower-section frozen liquid return pipe and the lower-section frozen liquid supply pipe extend out of the top end of the freezing pipe. The distance between the bottom end of the lower-section freezing liquid supply pipe and the bottom of the freezing pipe is smaller than the distance between the upper-section frozen liquid supply and lower-section frozen liquid return pipe andthe bottom of the freezing pipe. By staged freezing, the demand for chilling requirement can be reduced, the number of equipment in a freezing station can be reduced, the equipment installation work can be reduced, the floor area of the freezing station can be reduced, the civil construction cost of the freezing station can be reduced, and the total freezing cost can be reduced. By staged freezing, the cooling capacity can be rationally used, the freezing of the upper part of a shaft can be accelerated, and the early excavation of the shaft can be achieved.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

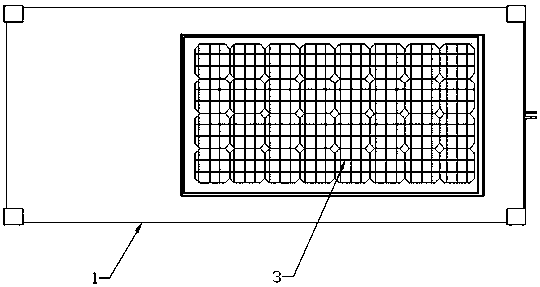

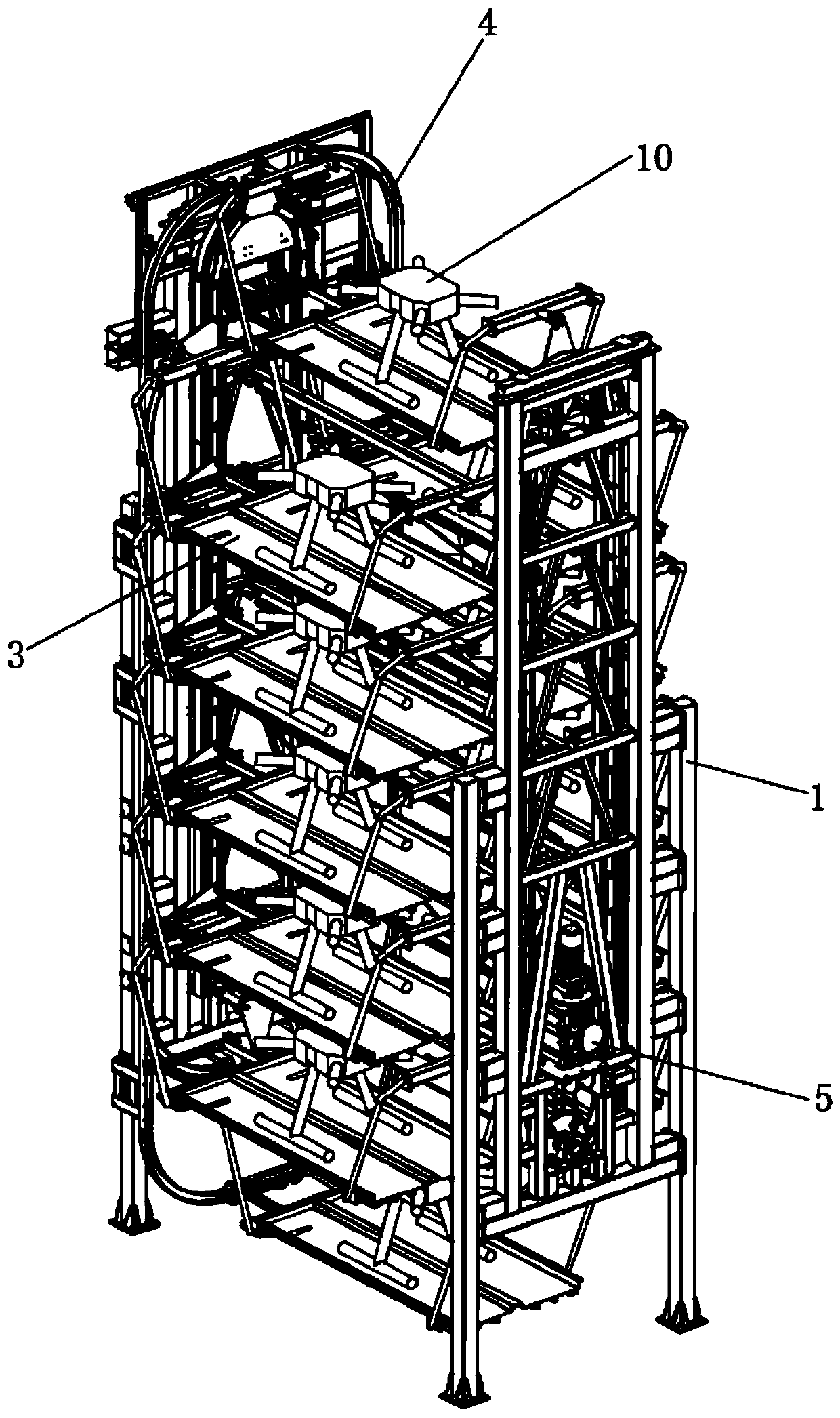

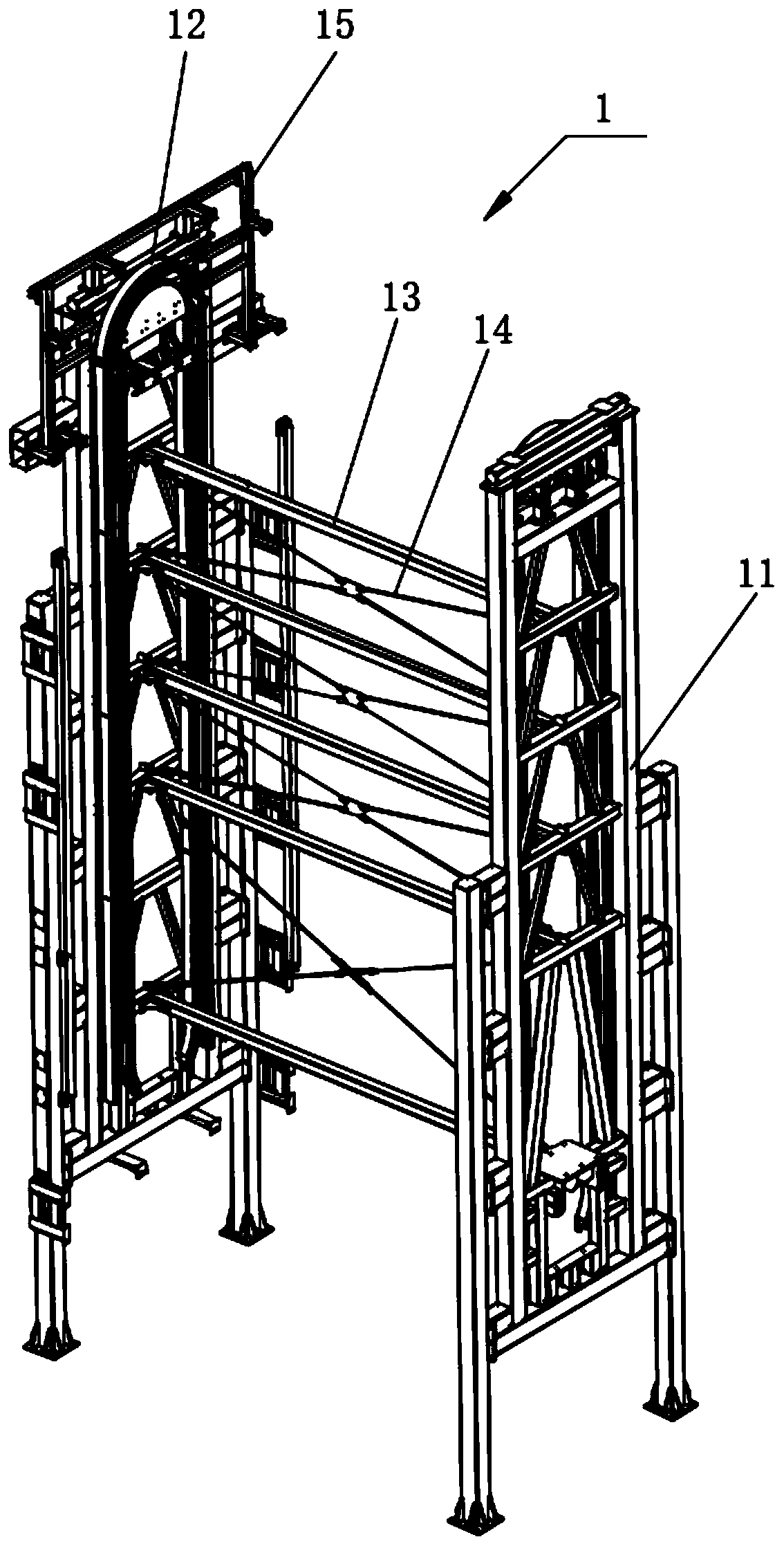

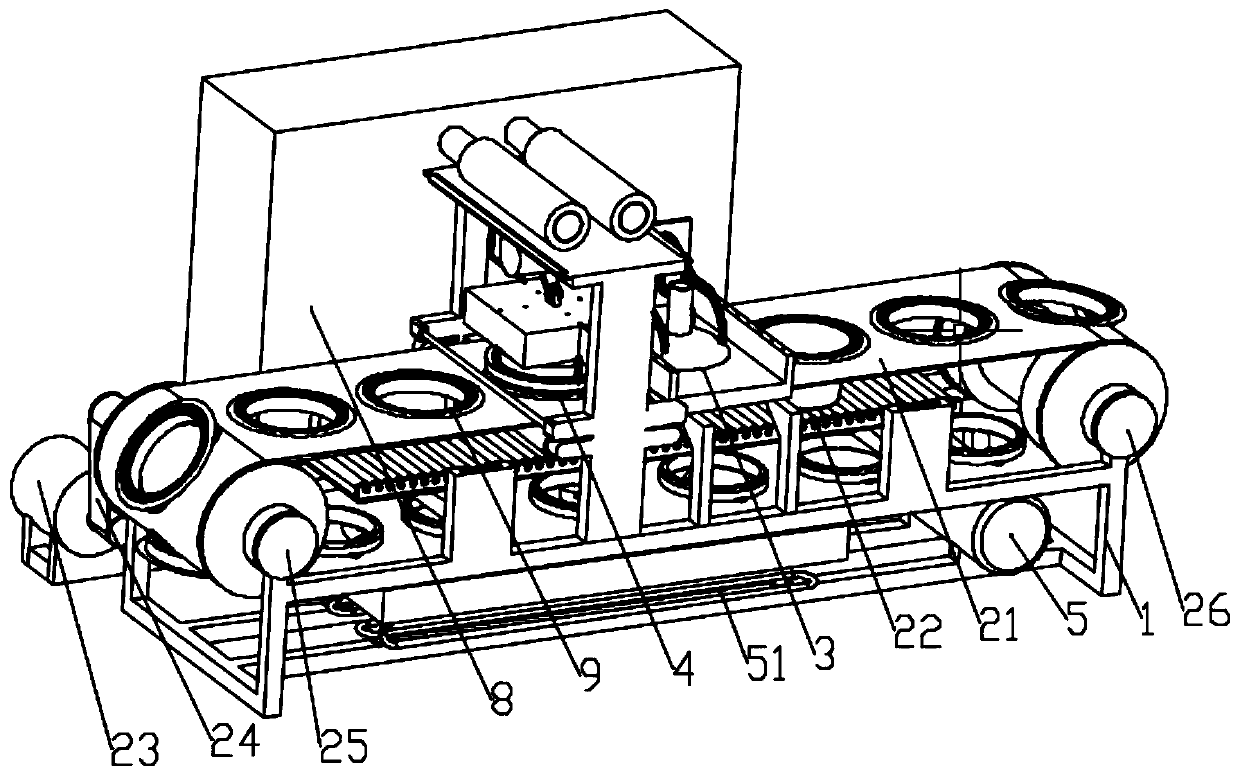

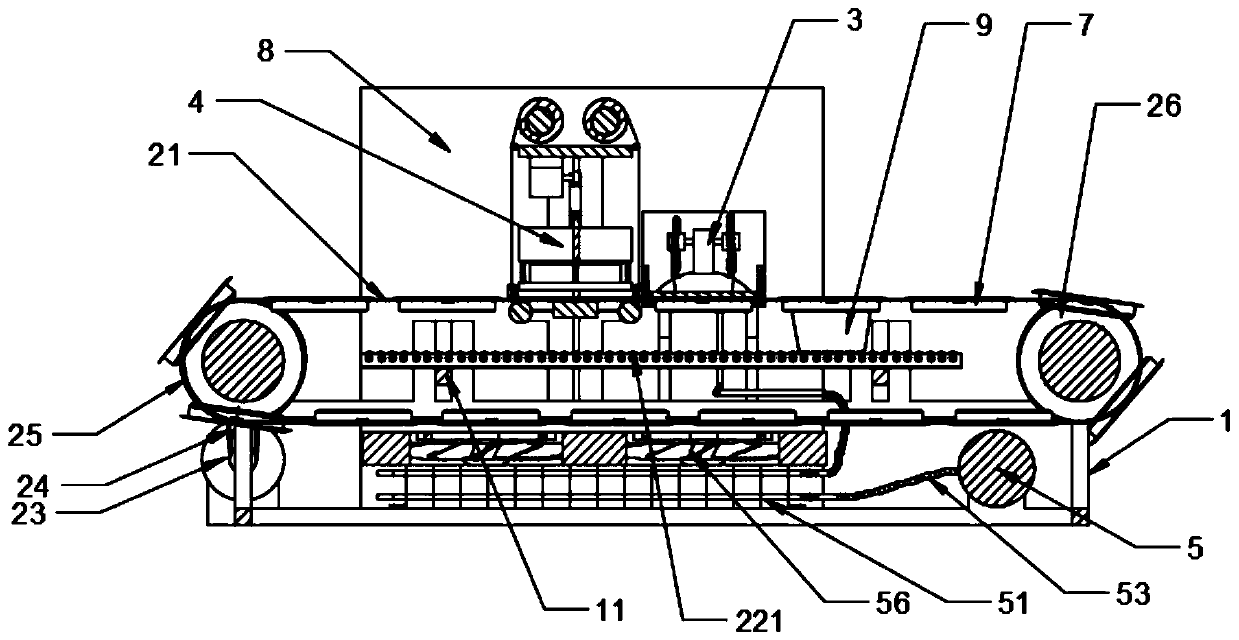

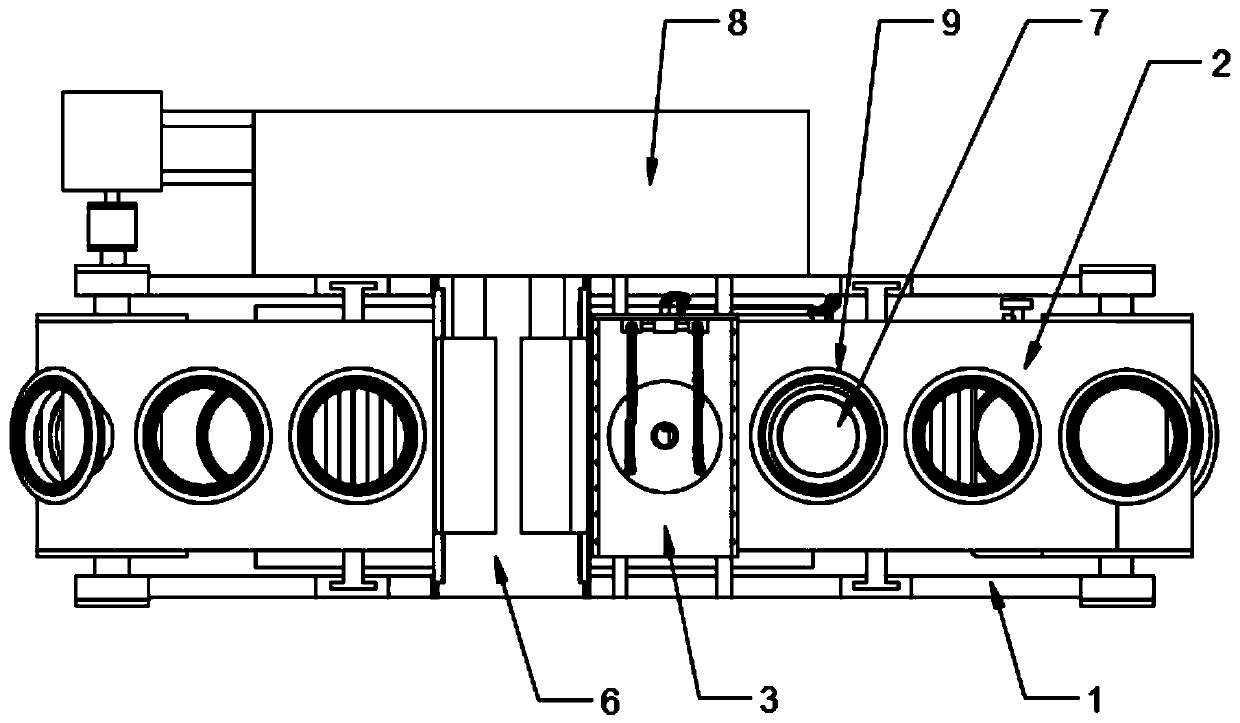

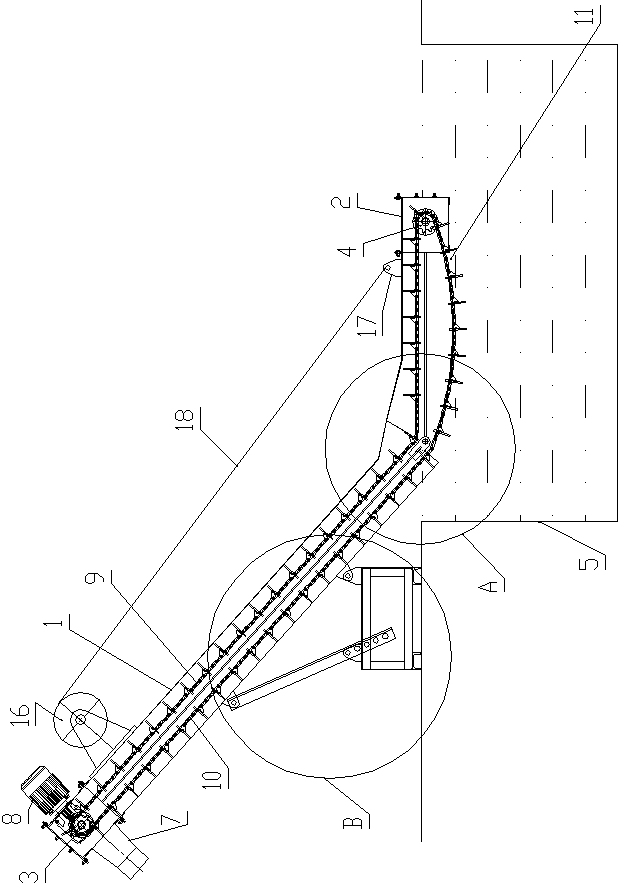

Multi-machine circulation type unmanned aerial vehicle automatic machine warehouse

InactiveCN110409899ARealize parking storageRealize collaborative workParkingsMarine engineeringMulti machine

The invention belongs to the field of unmanned aerial vehicle machine warehouses, and discloses a multi-machine circulation type unmanned aerial vehicle automatic machine warehouse. The multi-machinecirculation type unmanned aerial vehicle automatic machine warehouse comprises a rack, two chain circulation mechanisms synchronously running and tray mechanisms, wherein the two chain circulation mechanisms are symmetrically and vertically arranged on frame bodies on the two sides of the rack, the two ends of each tray mechanism are each connected with one chain circulation mechanism, and at least two tray mechanisms are arranged, can cyclically move between the bottom of the rack and the top of the rack along with the chain circulation mechanisms and are used for containing unmanned aerial vehicles. The chain circulation mechanisms are used for connecting at least two tray mechanisms, the tray mechanisms can be driven to cyclically move between the bottom of the rack and the top of the rack, the unmanned aerial vehicles can land and be stored on the tray mechanism located on the top, and accordingly, parking and storing of the multiple unmanned aerial vehicles can be achieved. Through the chain circulation mechanisms, any one tray mechanism can be arranged on the top of the rack, accordingly, simultaneous operation and collaborative operation of the multiple unmanned aerial vehicles can be achieved, and the problem that due to faults of single unmanned aerial vehicles, operation cannot continue is solved.

Owner:上海复亚智能科技有限公司

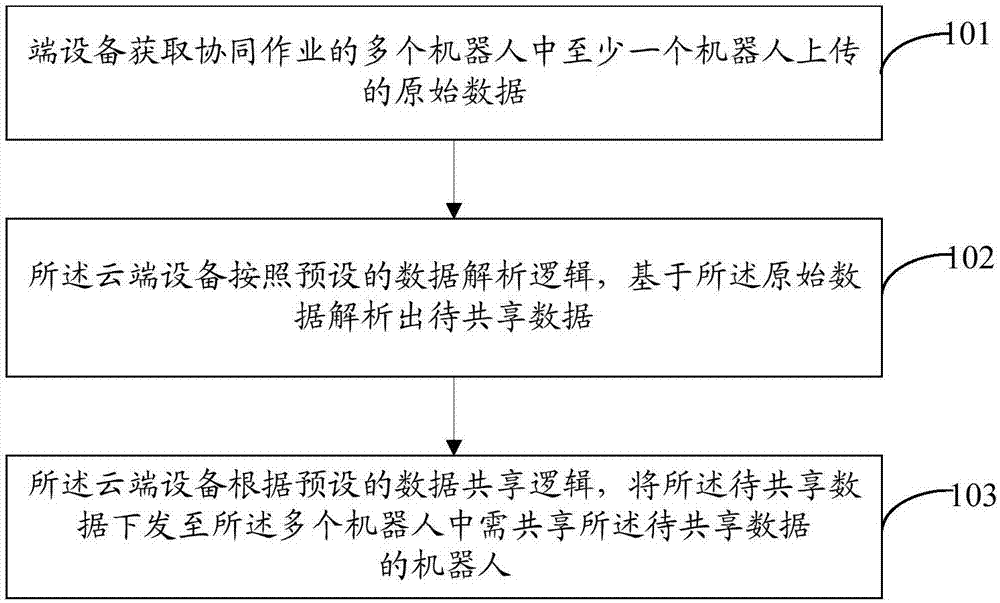

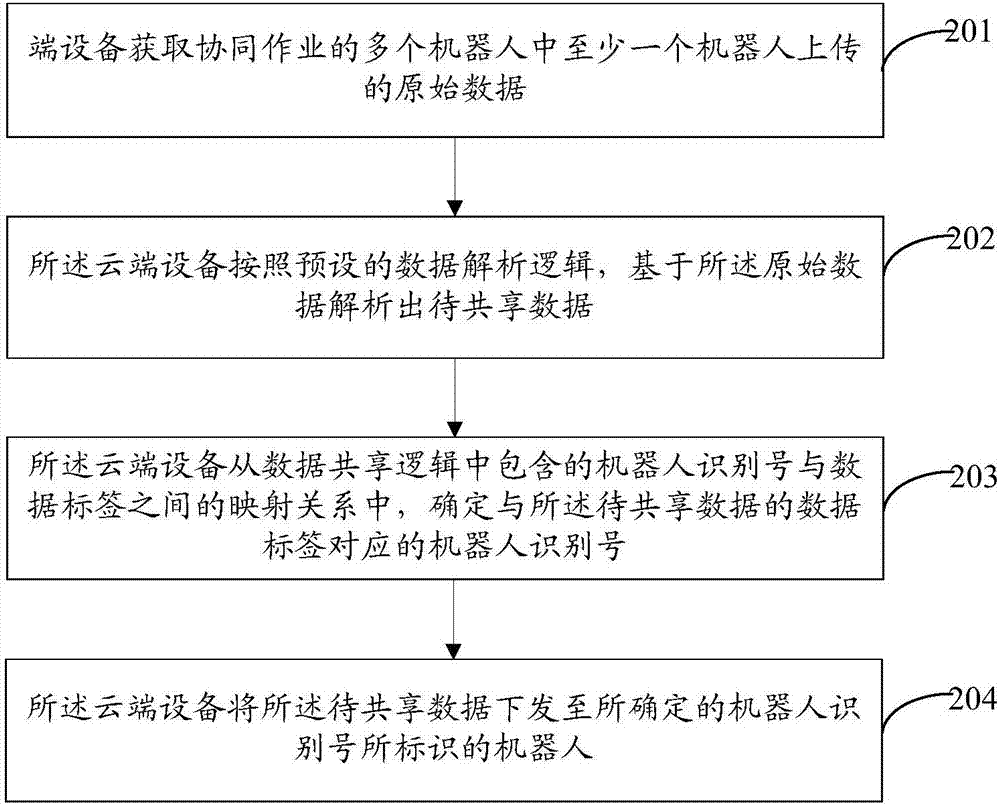

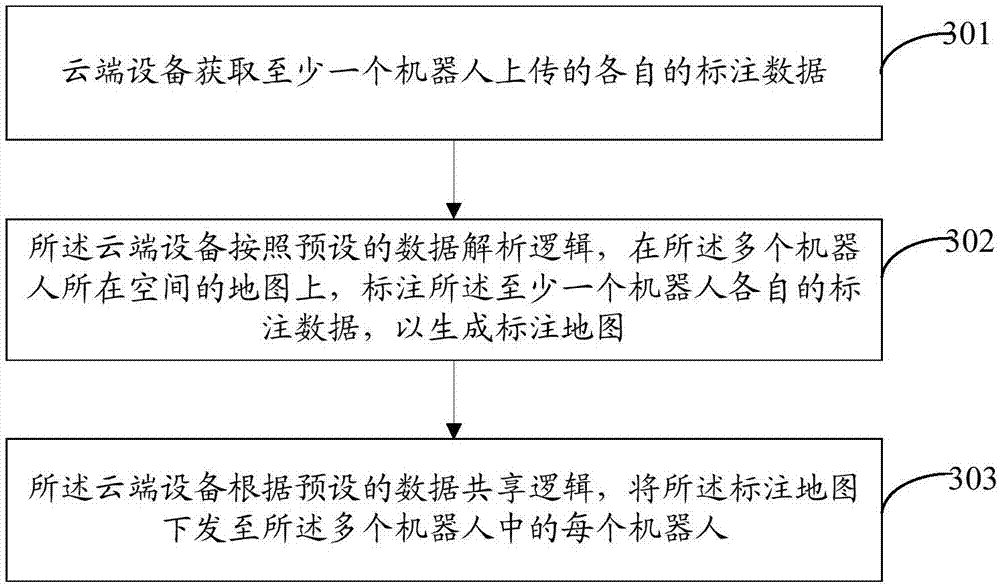

Data sharing method and device

ActiveCN106936916AReduce processing burdenSolve the defects of low collaborative operation efficiencyTransmissionOriginal dataData sharing

The embodiment of the application provides a data sharing method and device. The method comprises the steps that: cloud equipment acquires original data uploaded by at least one of a plurality of robots which collaboratively operate; the cloud equipment parses out data to be shared on the basis of the original data according to a preset data parsing logic; and according to a preset data sharing logic, the cloud equipment issues the data to be shared to robots in the plurality of robots, which need to share the data to be shared. The technical scheme of the embodiment of the application overcomes the defect of low collaborative operation efficiency caused by a large data processing load of one single robot, and implements high-efficiency multi-robot collaborative operation.

Owner:上海木木聚枞机器人科技有限公司

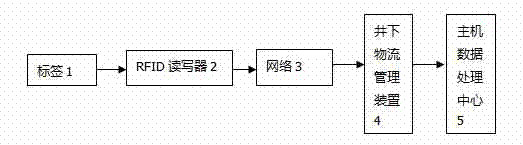

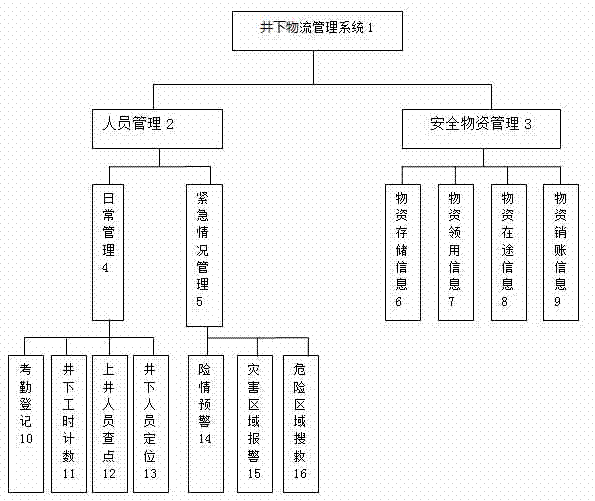

Mining underground logistics management system and method based on RFID technology

InactiveCN104766190ARealize collaborative workRealize monitoringLogisticsReader writerKnowledge management

The invention discloses a mining underground logistics management system and method based on RFID technology. The system is characterized by comprising an RFID electronic label, an RFID reader-writer, a network, an underground logistics management device and a host data processing center, wherein the RFID electronic label is mounted on an underground material or staff, and the RFID electronic label collects information of the underground material or staff via the RFID reader-writer. Communication with the underground logistics management device is carried out via the network, data is stored in the host data processing center, and monitoring for staff, early warning against accidents and the like are realized. Process data of logistics, people stream and dangerous materials is integrated and processed; information is exchanged and tightly integrated between safe production management and real-time process control; multi-level layered real-time monitoring and management of any position are realized; and coordination between person and person, material and material, and person and material as well as intelligent management are realized.

Owner:常州高特电子技术有限公司

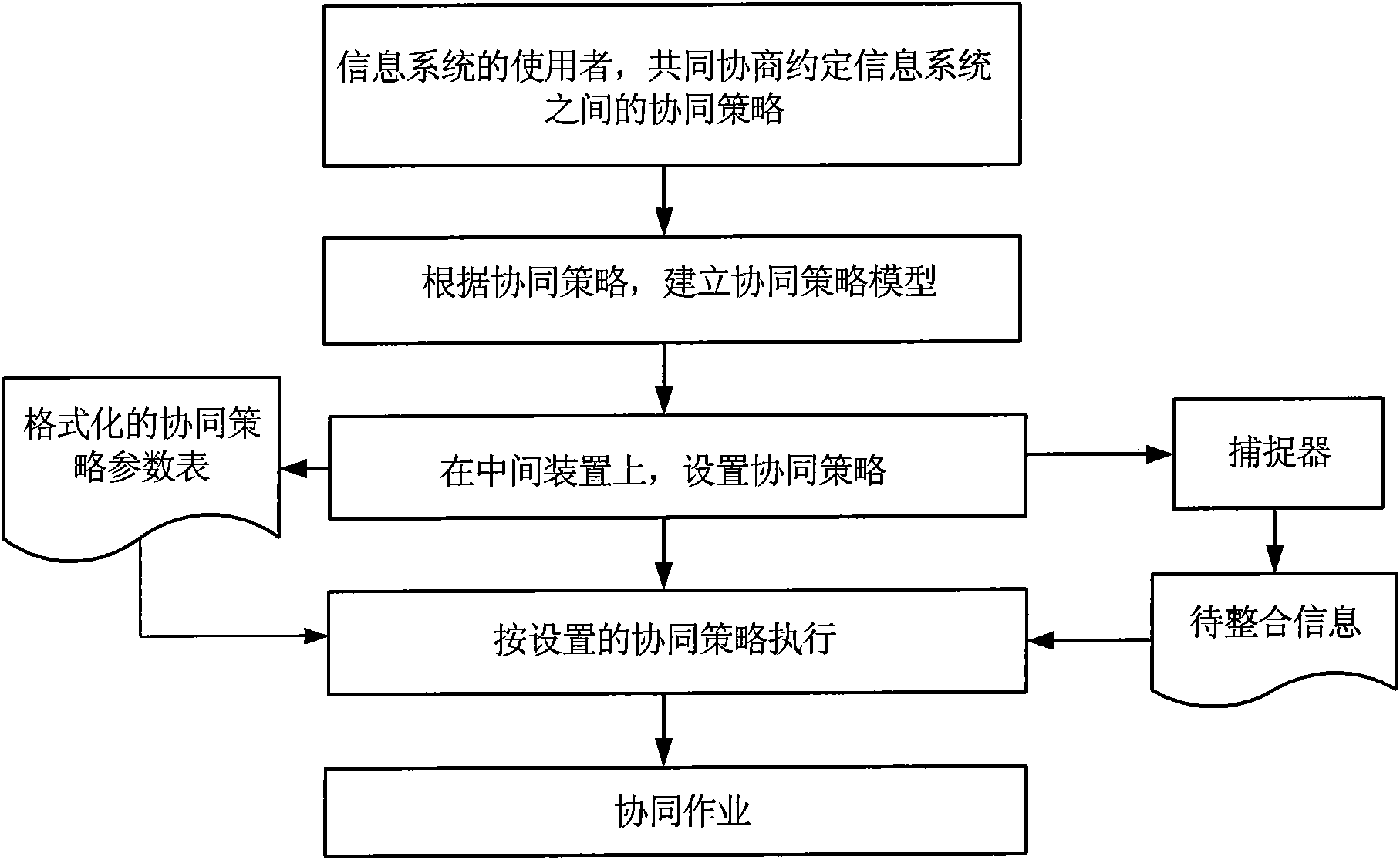

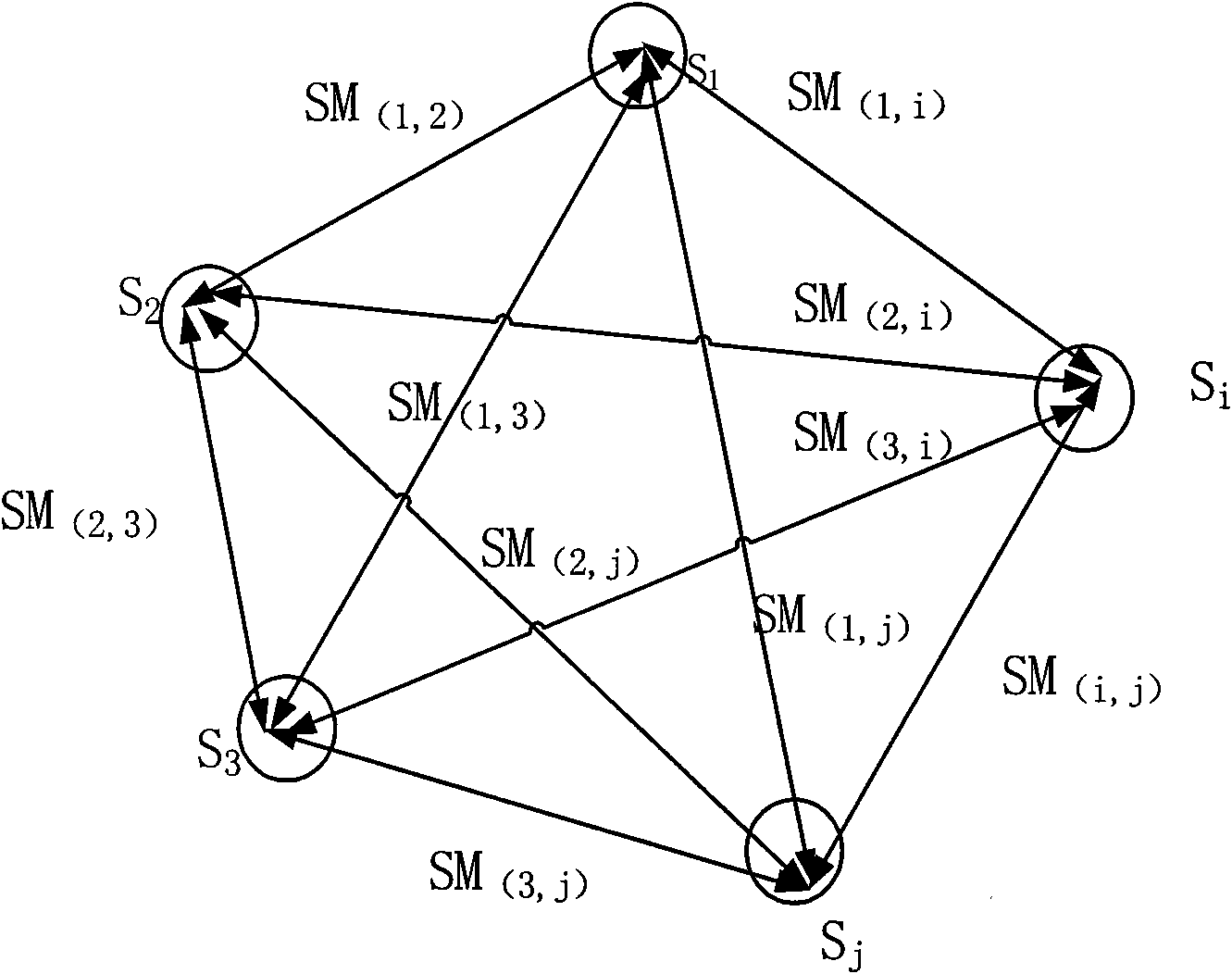

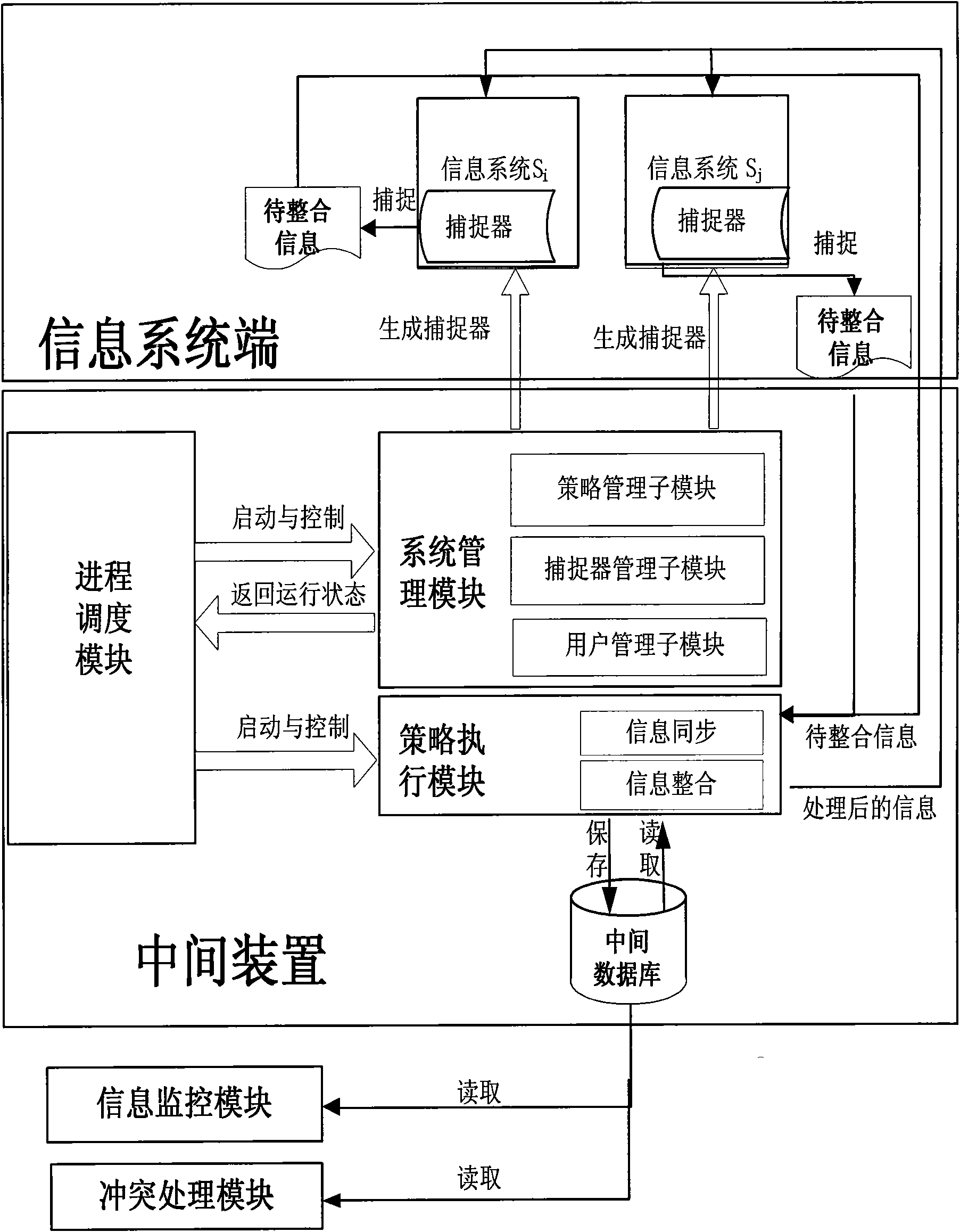

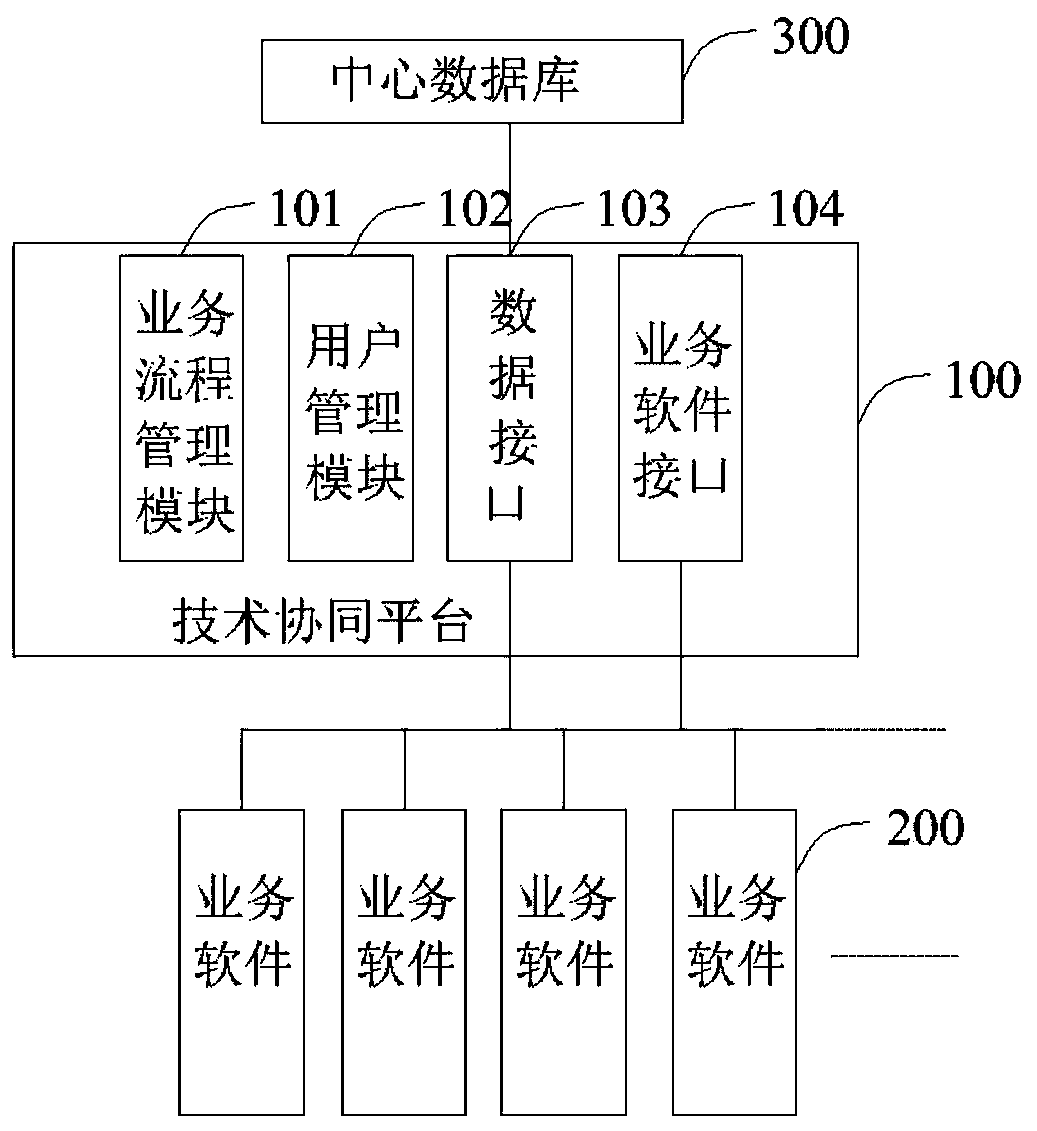

Method and device for collaborative operation of information systems

ActiveCN101599081ARealize collaborative workLess investmentMultiprogramming arrangementsSpecial data processing applicationsStrategy executionPrior information

The invention discloses a method and a device for collaborative operation of information systems. The device comprises intermediate devices arranged on network nodes of each information system and catchers arranged in databases of each information system, wherein the intermediate devices communicate with the databases of each information system respectively and comprise process scheduling modules, system management modules, strategy execution modules and intermediate databases; the catchers are generated and maintained by the system management modules dynamically and generate information to be integrated dynamically according to collaborative strategies; and the process scheduling modules monitor commands of the system management modules and schedule the system management modules and the strategy execution modules to achieve the collaborative operation between the information systems. The method and the device are free from man-made modifications to the prior information systems, and can conveniently achieve the collaborative operation of the information systems only by agreeing on a collaborative operation strategy and allocating collaborative operation devices on the system network nodes without developing the information systems, and have less investment and wide practicability.

Owner:SHENZHEN MICROPROFIT ELECTRONICS

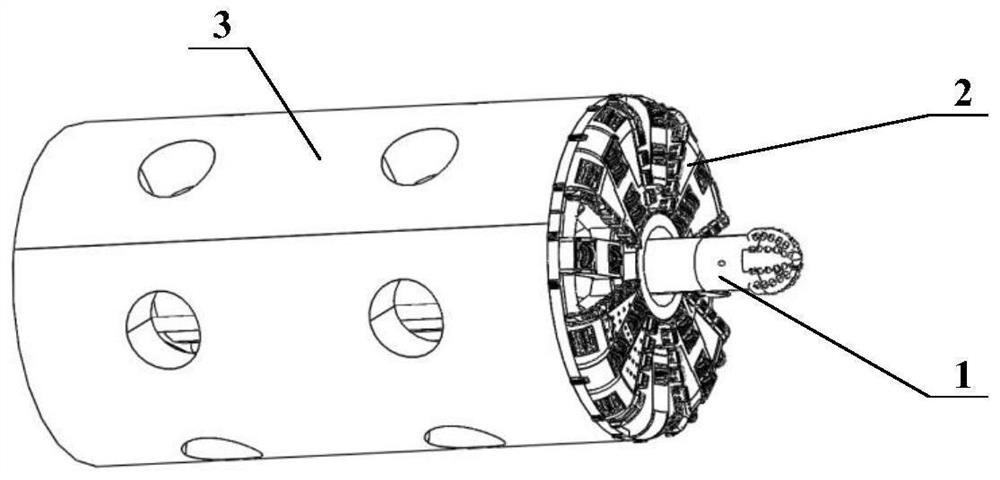

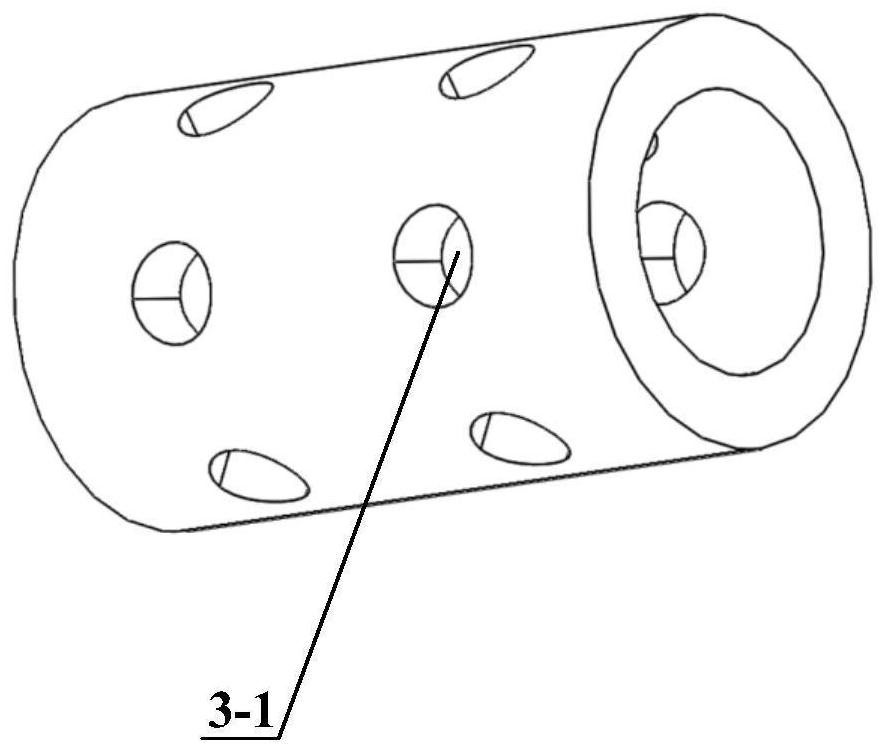

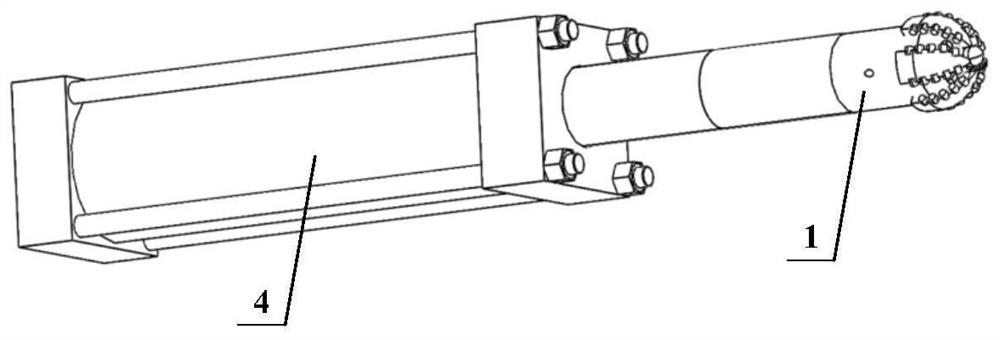

Composite cutterhead device suitable for hard rock crushing and using method of composite cutterhead device

ActiveCN114109380AExpand the scope of workMeet the needs of rock breakingMining devicesTunnelsMechanical engineeringRock breaking

The invention discloses a composite cutterhead device suitable for hard rock crushing and a using method thereof.The device comprises a PDC drill bit body, a hydraulic telescopic device, a TBM cutterhead and a TBM cutter body, the TBM cutterhead is arranged at the end of the TBM cutter body, the hydraulic telescopic device is fixed into the TBM cutter body, the telescopic end of the hydraulic telescopic device can stretch out of the TBM cutterhead, and the telescopic end of the hydraulic telescopic device can stretch out of the TBM cutterhead. The telescopic end of the hydraulic telescopic device is connected with a PDC drill bit body, the structure is compact, the arrangement space of the device is saved, the rock breaking requirement of a complex stratum is met, the TBM cutterhead operation range is enlarged, and the working efficiency can be improved.

Owner:CHINA UNIV OF MINING & TECH +1

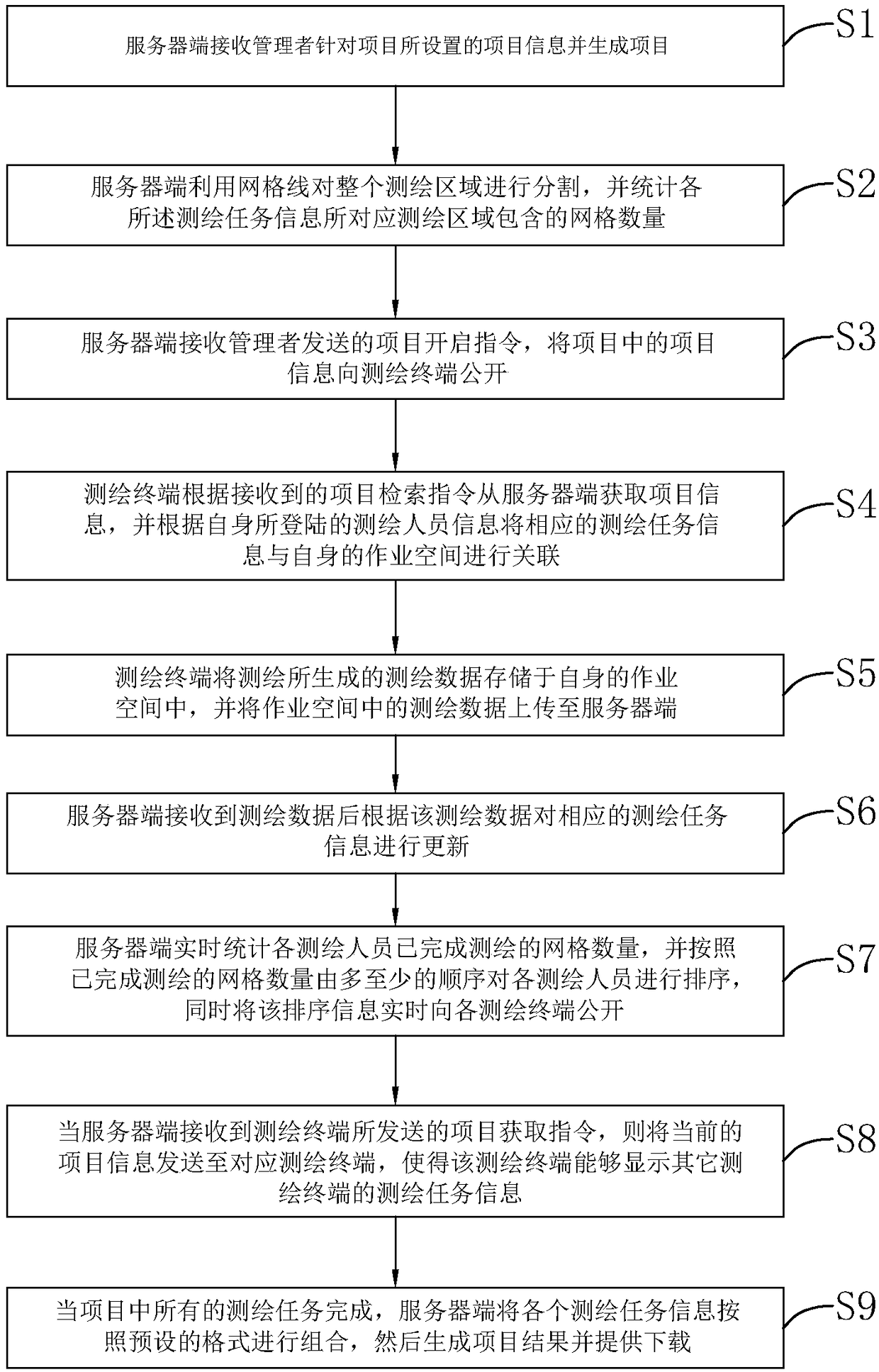

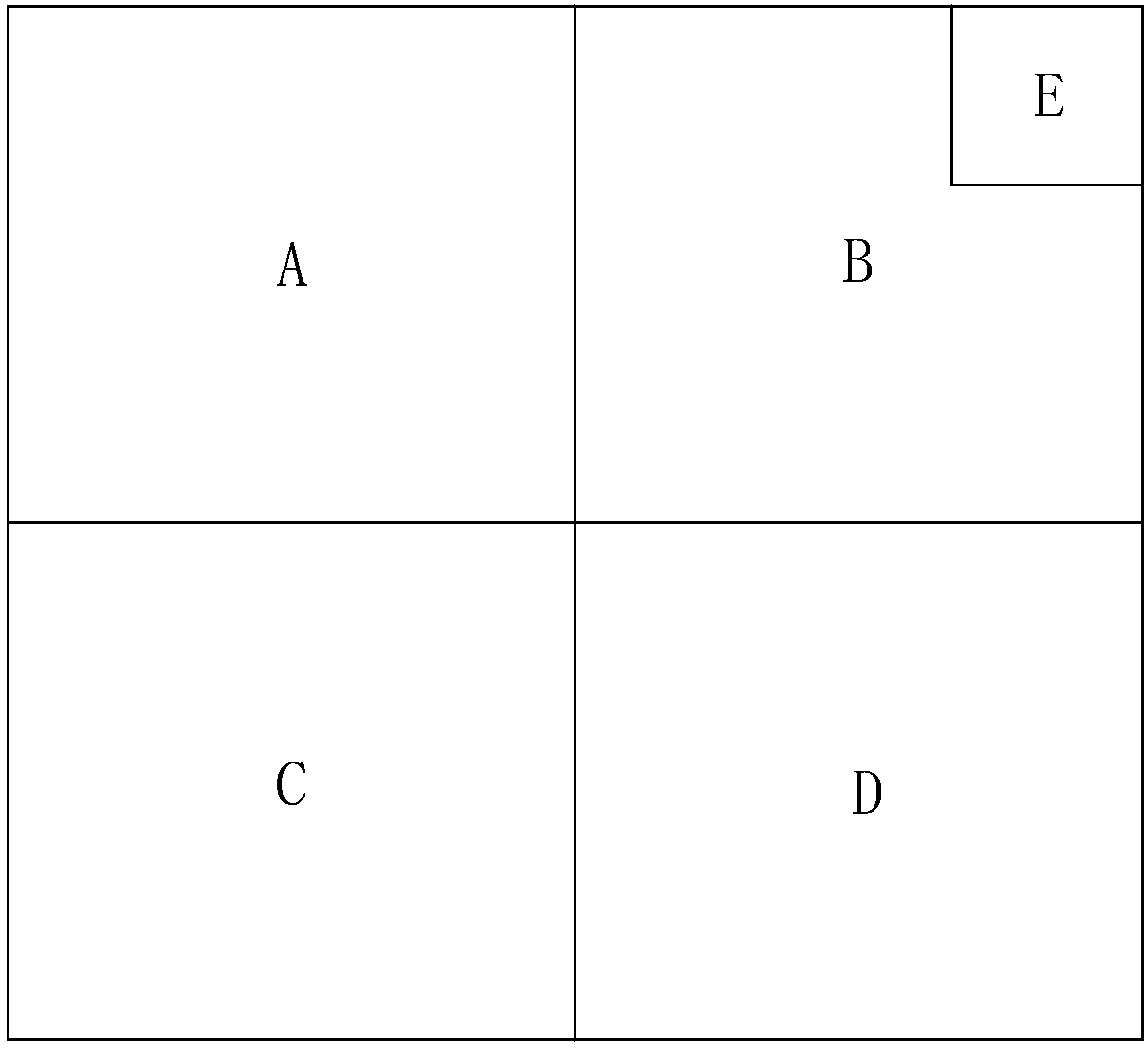

Surveying and mapping collaborative operation method

The invention discloses a surveying and mapping collaborative operation method, which belongs to the technical field of surveying and mapping. The surveying and mapping collaborative operation methodcomprises the following steps that: a server side receives item information and generates an item; the server side utilizes a grid line to segment a whole surveying and mapping region and carries outstatistics the amount of grids contained in each surveying and mapping region; the server side receives an item starting instruction sent from an administrator; a surveying and mapping terminal obtains the item information, and enables surveying and mapping task information to be related to an operation space; the surveying and mapping terminal uploads surveying and mapping data in the operation space to the server side; after the server side receives the surveying and mapping data, the surveying and mapping task information is updated; and the server side carries out statistics on the amountof grids which finish surveying and mapping by each surveying and mapping person in real time, and sorts each surveying and mapping person. By use of the surveying and mapping collaborative operationmethod, the real-time sharing of multi-member collaborative surveying and mapping and each group of surveying and mapping data is realized, the situations of surveying missing, repeated surveying andwrong surveying are effectively avoided, an item progress and a surveying and mapping operation are completely controllable, and surveying and mapping efficiency is greatly improved.

Owner:平湖市城工建设测绘设计有限责任公司

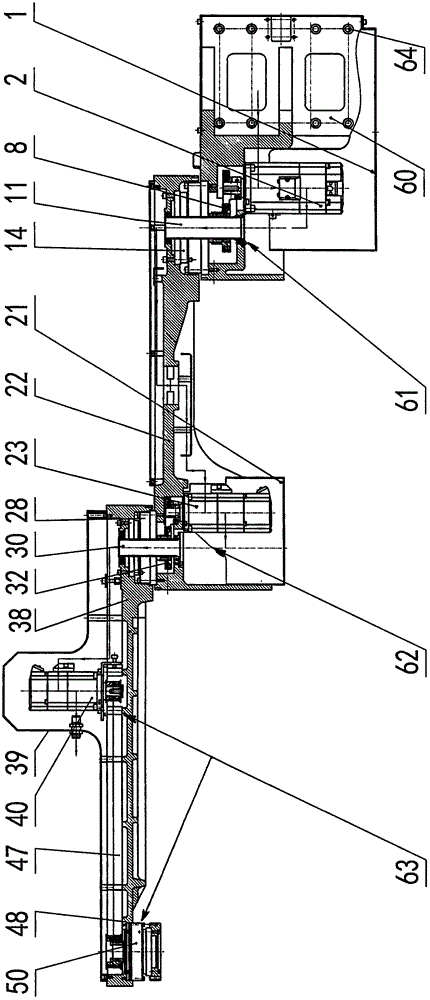

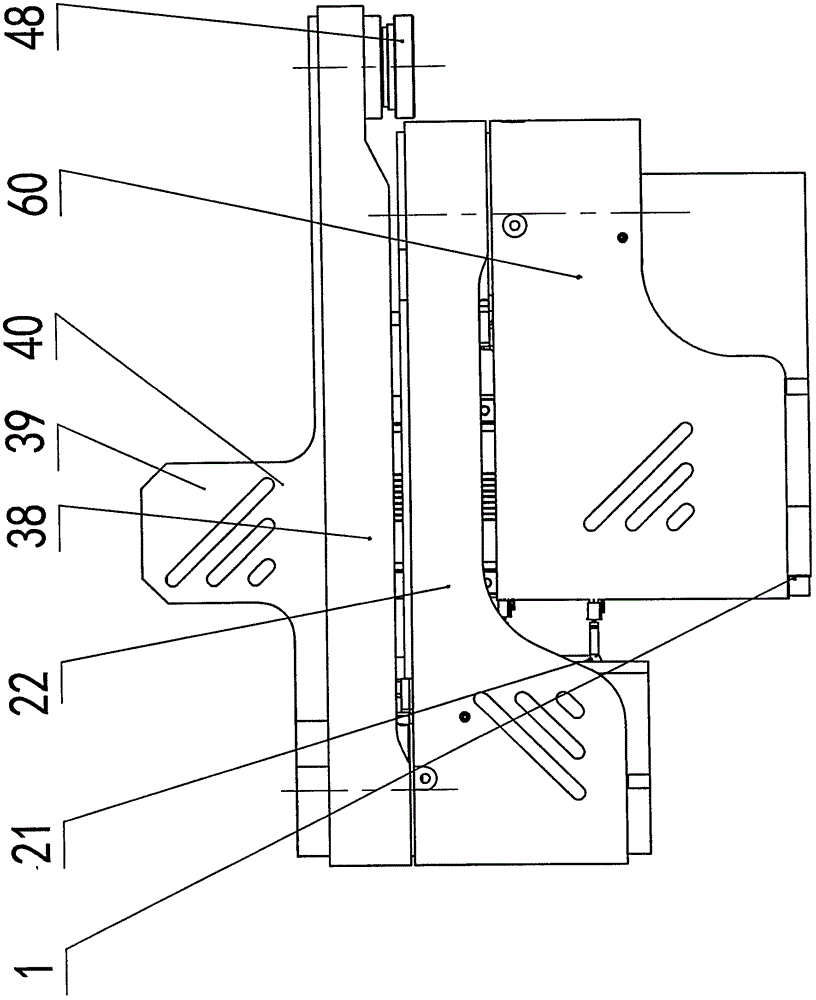

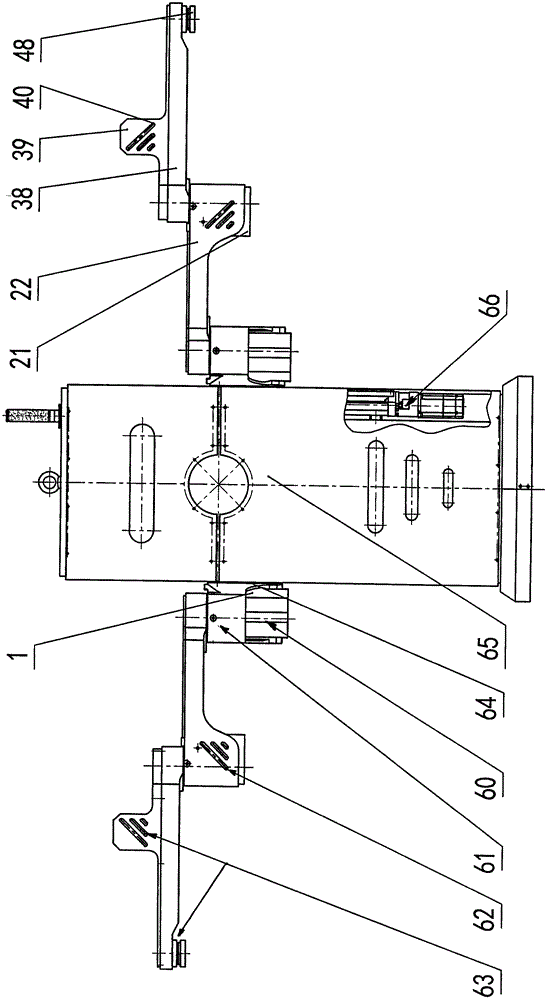

Parallel extension and retraction type double-arm robot

InactiveCN106182081AImprove processing qualityRealize collaborative workProgramme-controlled manipulatorArmsParallel ExtensionsEngineering

The invention discloses a parallel extension and retraction type double-arm robot comprising a cabinet (65) and two lifting arms (60). The two lifting arms are installed on the left side and the right side of the cabinet correspondingly. Linear modules (66) are installed in the cabinet and connected with the lifting arms (60) through respective sliding blocks (64). The other end of each lifting arm is sequentially connected with a first rotating arm (22), a second rotating arm (38) and a tail-end rotating flange (48). The lifting arms, the first rotating arms and the second rotating arms of the parallel extension and retraction type double-arm robot are in a parallel extension state or a parallel overlap state and can ascend, descend, rotate, extend, retract and be overlapped. The parallel extension and retraction type double-arm robot is small in occupied space, high in work efficiency, wide in work covering range and capable of completely replacing manual operation, reducing the production cost and improving the production safety. Through the high integration degree of the parallel extension and retraction type double-arm robot, cooperative operation of the double arms can be achieved, and therefore the production efficiency and the machining quality of workpieces can be improved.

Owner:HSOAR GRP

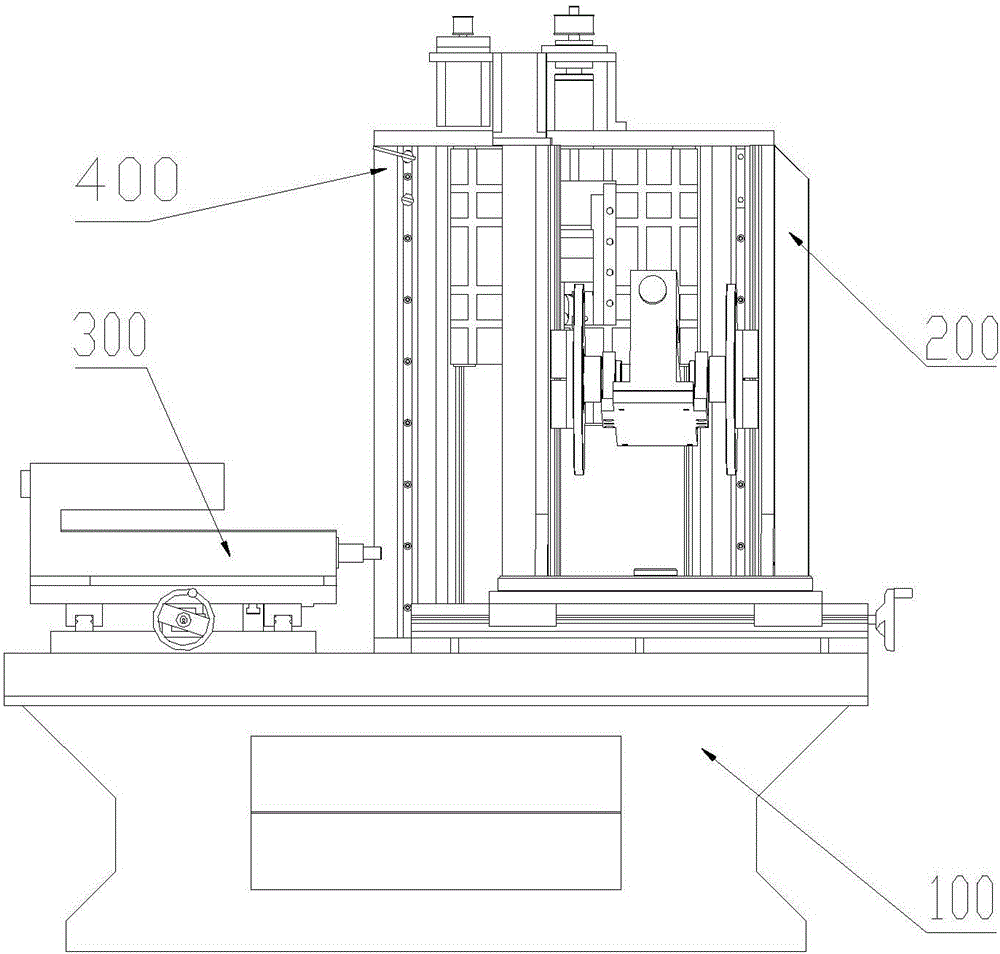

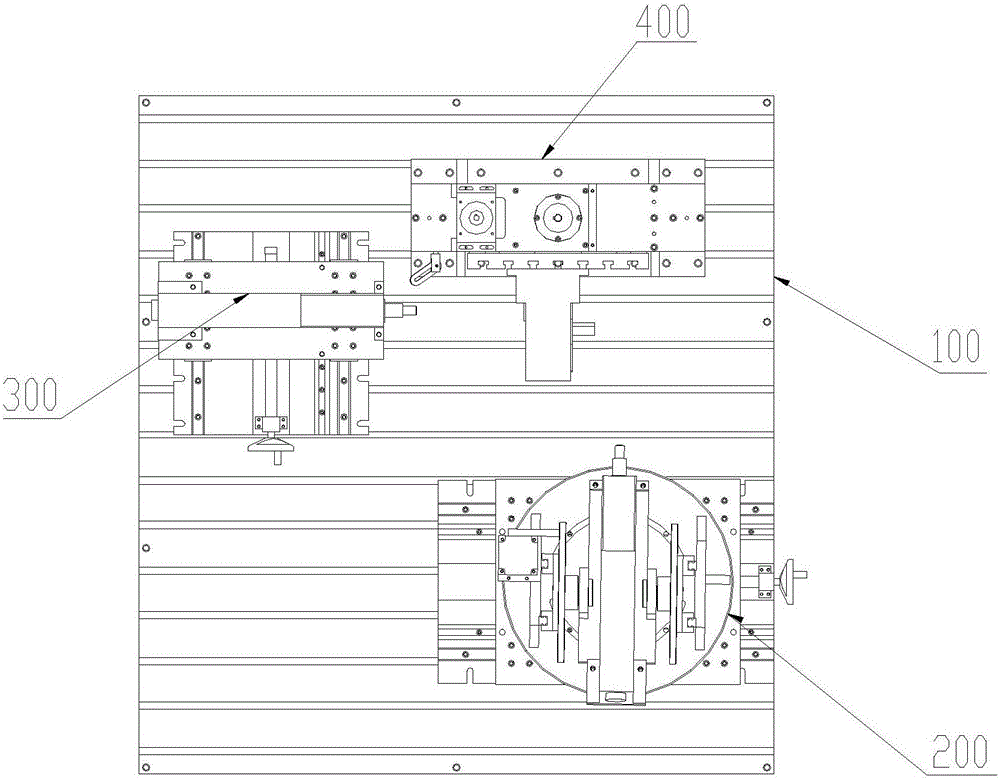

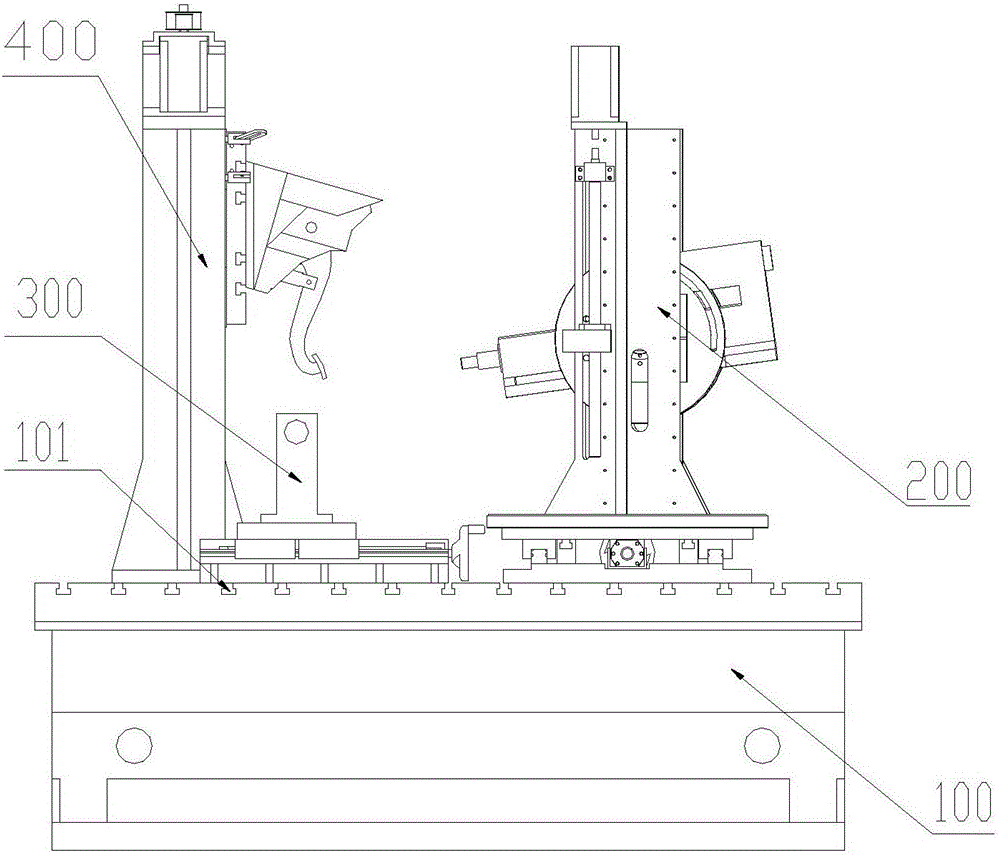

Pedal rigidity comprehensive performance testing equipment

The invention discloses pedal rigidity comprehensive performance testing equipment, and the equipment can carry out the omnibearing testing of the rigidity of a pedal, and also can customize the load applying position and angle according to different standards. A testing method is flexible, and is better in testing effect. The equipment comprises a pedestal, a longitudinal loading mechanism, a lateral loading mechanism, and a test sample installation mechanism, wherein the longitudinal loading mechanism, the lateral loading mechanism and the test sample installation mechanism are disposed on the pedestal. The test sample installation mechanism is used for installing a test sample. The longitudinal loading mechanism is used for applying a longitudinal load to the test sample. The lateral loading mechanism is used for applying a lateral load to the test sample.

Owner:CHONGQING FEIZHOU MACHINERY AUTOMATION EQUIP CO LTD

Continuous modified atmosphere fresh-keeping packaging machine and packaging method thereof

PendingCN110525720AFully automatedImprove work efficiencyPackaging by pressurising/gasifyingModified atmosphereEngineering

The invention discloses a continuous modified atmosphere fresh-keeping packaging machine and a packaging method thereof. The packaging machine comprises a conveying mechanism, an atmosphere modification mechanism and a sealing and cutting mechanism which are arranged on a rack; at least four stations are arranged on a containing opening conveying belt and synchronously conduct feeding, atmospheremodification, sealing and cutting and discharging procedures respectively; packaging containers are placed in the containing opening stations, and a containing opening bearing mechanism is borne at the lower ends of the containing opening packaging containers. The containing opening atmosphere modification mechanism comprises an atmosphere modification chamber main body; the containing opening atmosphere modification chamber main body and the conveying face of the containing opening conveying belt are elastically sealed, a dynamic sealing space is formed above the conveying belt, the atmosphere modification chamber main body is connected with an inflation mechanism, the inflation mechanism sprays nitrogen to the containing opening packaging containers, an exhaust channel is formed in the atmosphere modification chamber main body, and an oxygen sensor for monitoring the oxygen concentration is installed on the inner wall of the containing opening exhaust channel. The dynamic sealing space can effectively prevent space gaps caused by station transfer from influencing air tightness, and the oxygen sensor monitors the oxygen content in exhausted gas to prevent a large amount of oxygenfrom remaining in the packaging container.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Downhole water-coal separation system and water-coal separation method

PendingCN109985436AImprove working environmentExtended cleaning cycleSludge treatmentEarth drilling and miningCoal waterWorking environment

The invention discloses a downhole water-coal separation system. The downhole water-coal separation system comprises a downhole coal raker, a receiving hopper, a shredder, a spiral sludge dewatering equipment and a belt conveyor. The invention further discloses a corresponding water-coal separation method. The method comprises the steps of mounting, primary water-coal separating, secondary water-coal separating, crushing, concentrating and dehydrating, wherein concentrated and dewatered coal cakes are conveyed to a skip bucket by mine cars. According to the system and the method, the mountingis convenient, the operating is simple and convenient, the field adaptability is high, the water-coal separating effect is good, seaborne coal, silt coal and even bulk coal can be raked out conveniently, the influence on mine drainage caused by blockage to a main water pump is prevented, tasks which are difficultly completed by downhole equipment in the past can be completed, and blockage does notoccur. According to the system and the method, the cycle of excavation of a borehole bottom sump of a coal mine can be prolonged, so that the labor intensity of workers is lowered, the blockage to the main water pump is reduced, and the downhole working environment of the coal mine is improved.

Owner:HENAN WANHE MACHINERY

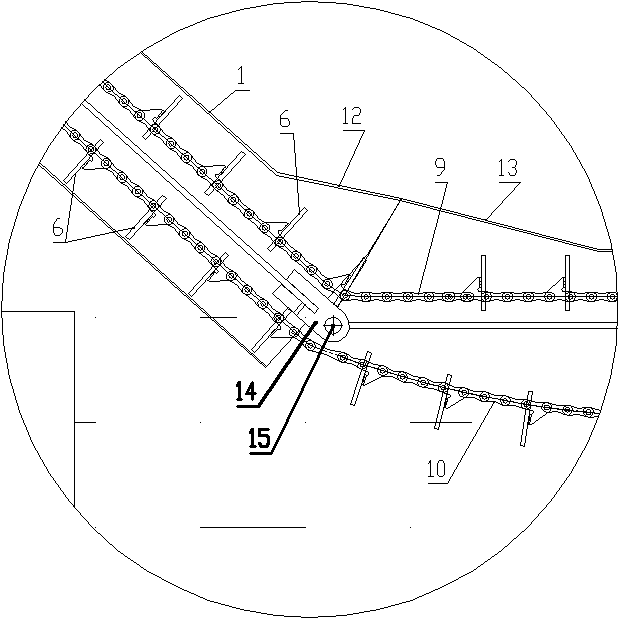

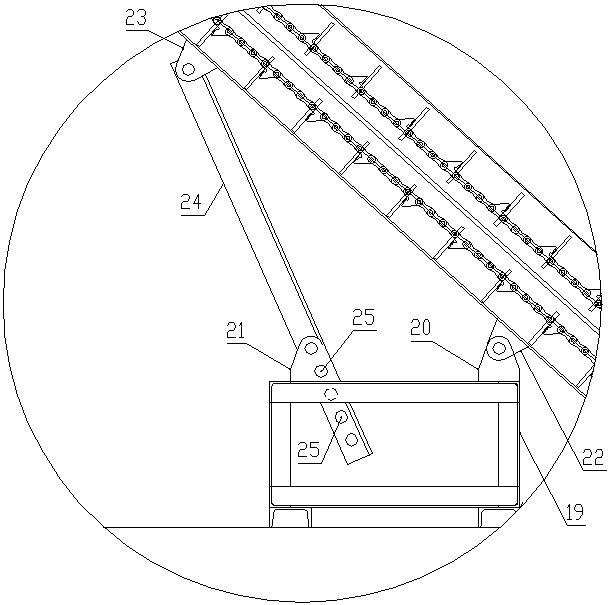

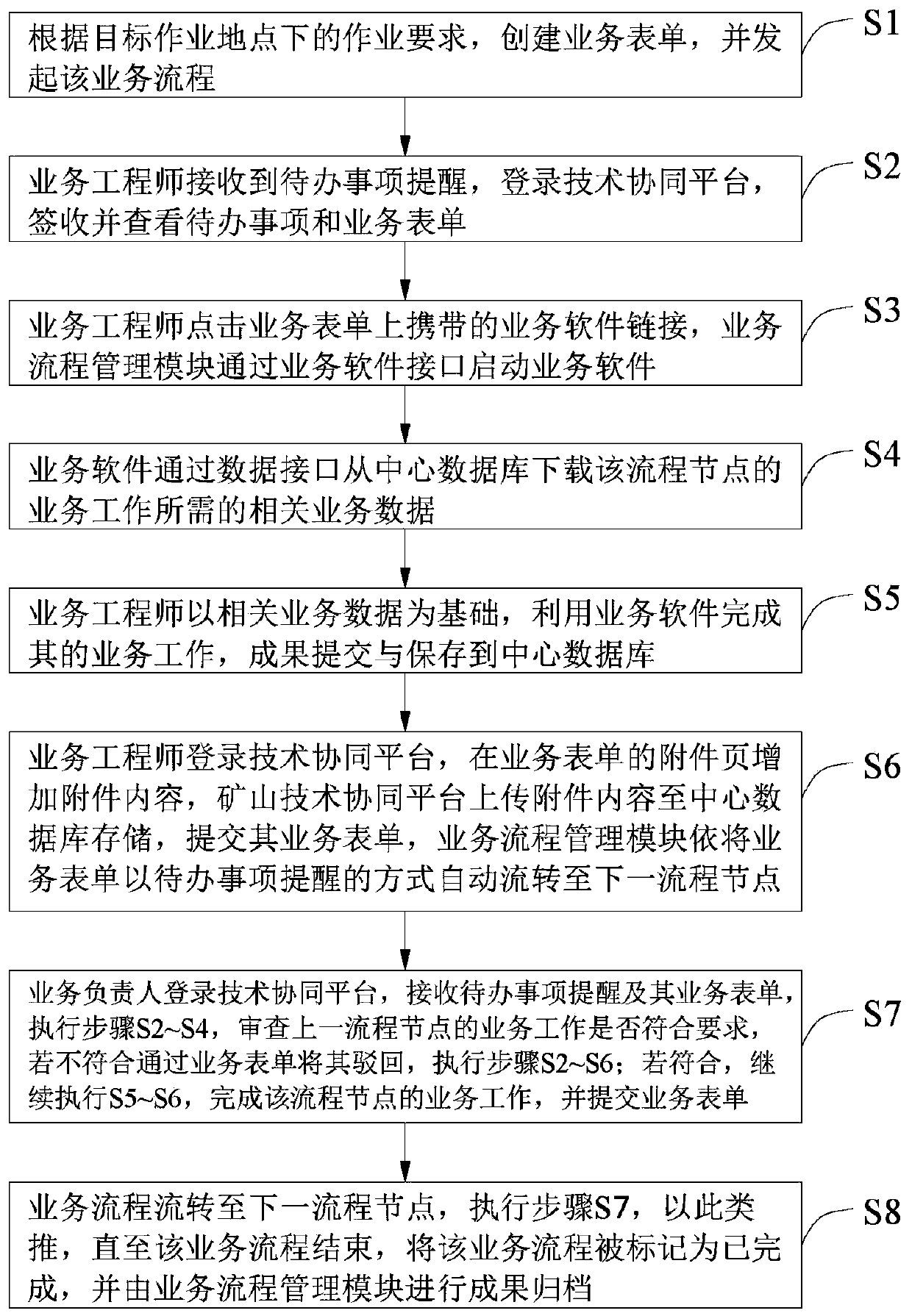

Mine business to-do list processing method

PendingCN110163562ASolve poor communication transmissionResolve delaysOffice automationFull life cycleBusiness class

The invention discloses a mine business to-do list processing method. The method comprises the following steps: creating a business form and initiating a business process; logging in the technical collaboration platform, and signing and checking the to-do list and the business form; clicking a service software link, and starting service software; the service software downloads related service datafrom the central database; completing the business work by a mine business engineer through business software; the attachment page is uploaded to a central database; submitting a service form and automatically forwarding to a next process node according to the service process flow; receiving the mine business to-do reminding by the next process node, checking whether the business work of the previous process node meets the requirements or not, rejecting if the business work of the previous process node does not meet the requirements, and continuing if the business work meets the requirements;and enabling the mine business process flow to the next process node, and so on until the business process is finished. According to the invention, the unification, process management and collaborative operation of the mine full-life-cycle business are realized, the data sharing is realized, the data loss and inconsistency are avoided, and the working efficiency and quality of the mine business are improved.

Owner:CHANGSHA DIGITAL MINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com