Fully rotary type underwater propellers

A full-turn, thruster technology, applied in the direction of ship propulsion, propulsion components, outboard propulsion devices, etc., can solve the problems of long transmission chain, small rotation angle, low efficiency of propeller rotation, etc., and achieve short transmission chain and mechanical efficiency High, enhanced controllability and adaptability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

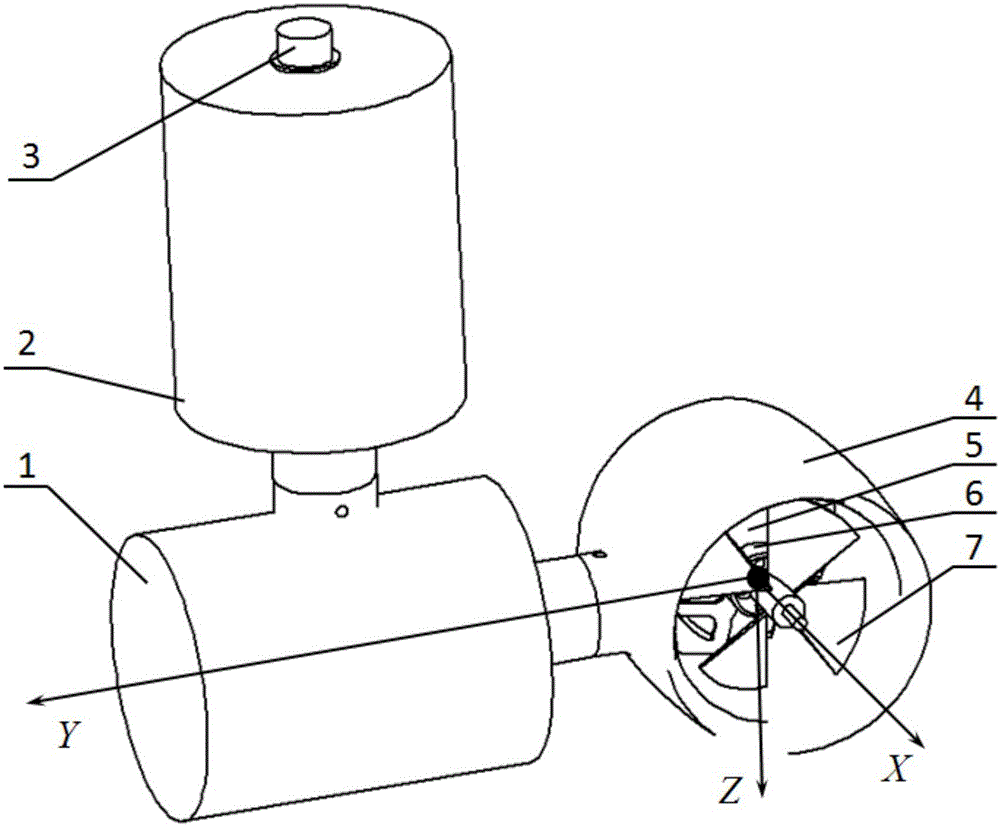

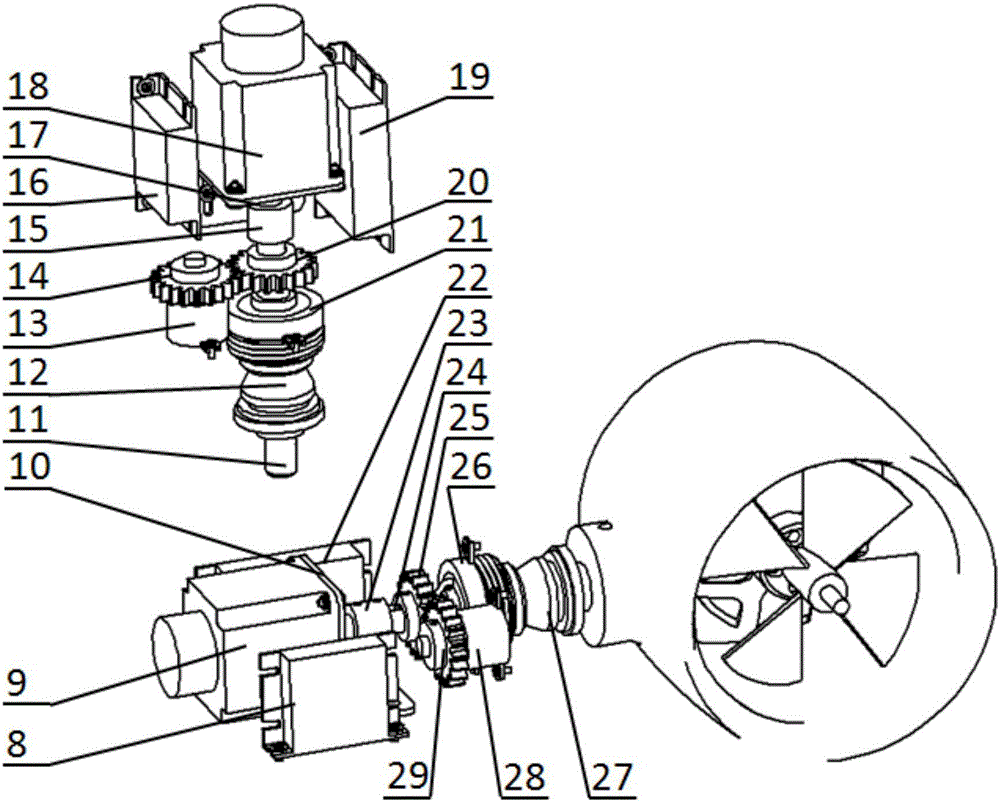

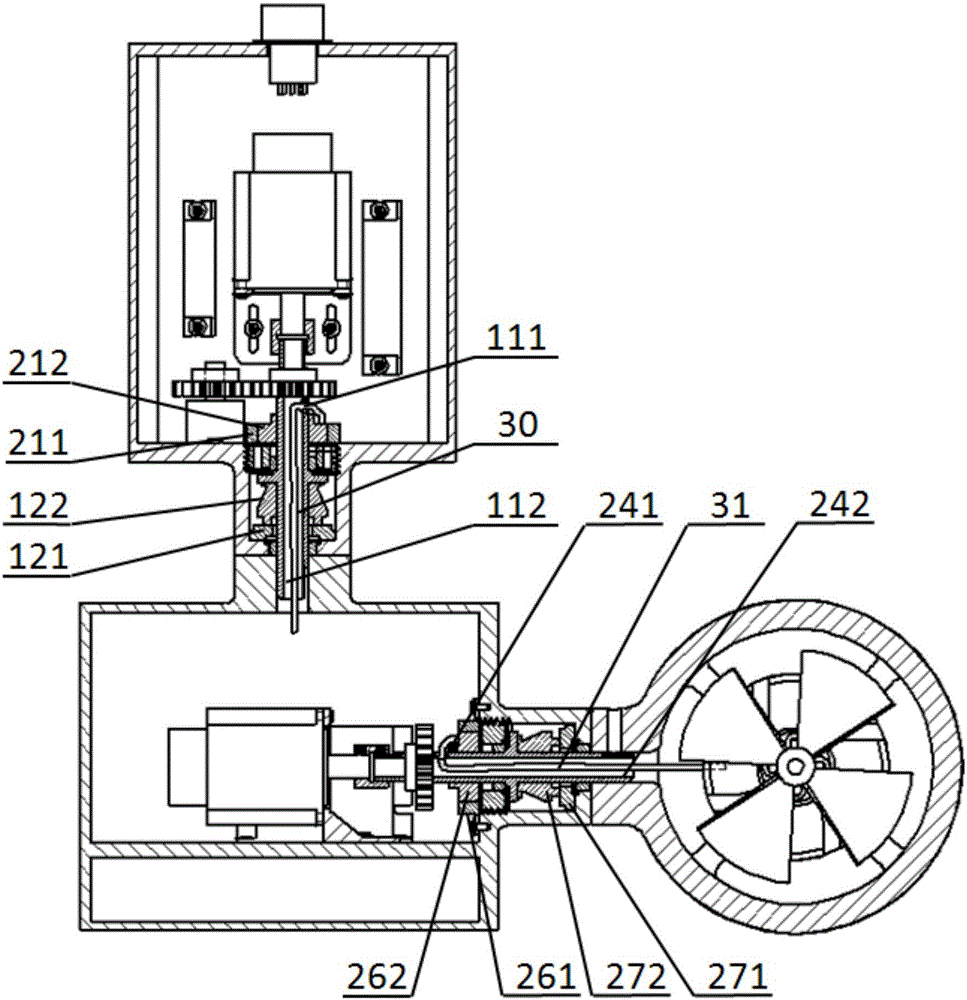

[0023] refer to figure 1 , 2 , 3, the present invention is made of propulsion mechanism, horizontal steering mechanism, vertical steering mechanism and electronic component group.

[0024] The electronic component group has a propulsion motor driver 22, a horizontal steering motor driver 8, a vertical steering motor driver 16, a horizontal steering shaft position detection device 28, a vertical steering shaft position detection device 13, and a controller 19, and each device is connected by a wire. . The first cable 31 is transmitted from the first sealed cabin 1 to the propulsion mechanism through the conductive slip ring 26 of the horizontal steering shaft, and the second cable 30 is transmitted from the second sealed cabin 2 to the first sealed cabin 1 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com