Precise proportioning powder feeding system and powder outlet amount and proportioning amount dynamic control method

A technology of ratio control and powder output, which is used in additive manufacturing, manufacturing tools, manufacturing auxiliary devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and with reference to the accompanying drawings.

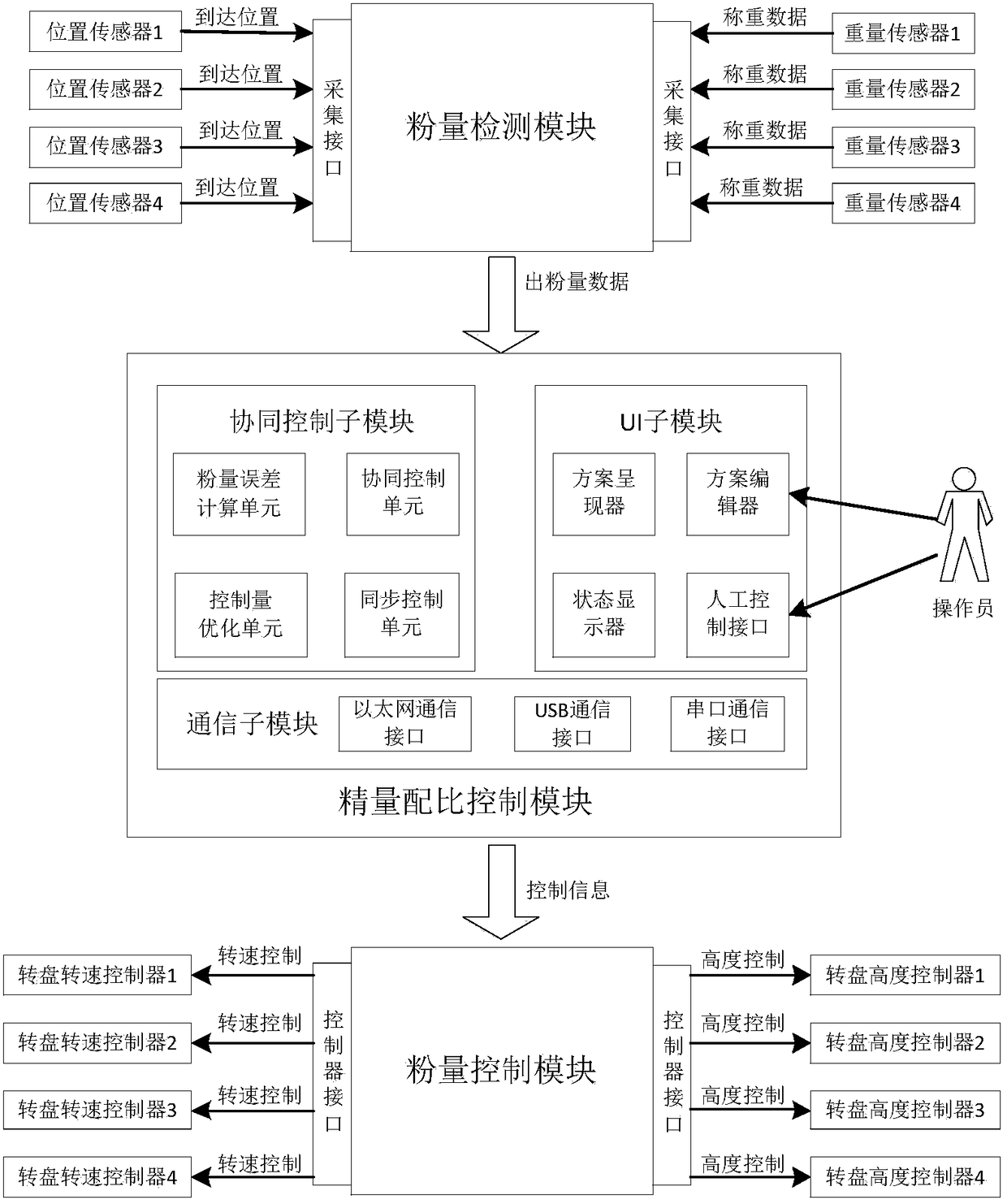

[0050] The basic idea of the present invention is to realize the precise powder feeding of the powder feeder and the mixed powder feeding with adjustable and controllable ratio by using the precise collection and feedback control in the cooperative mode.

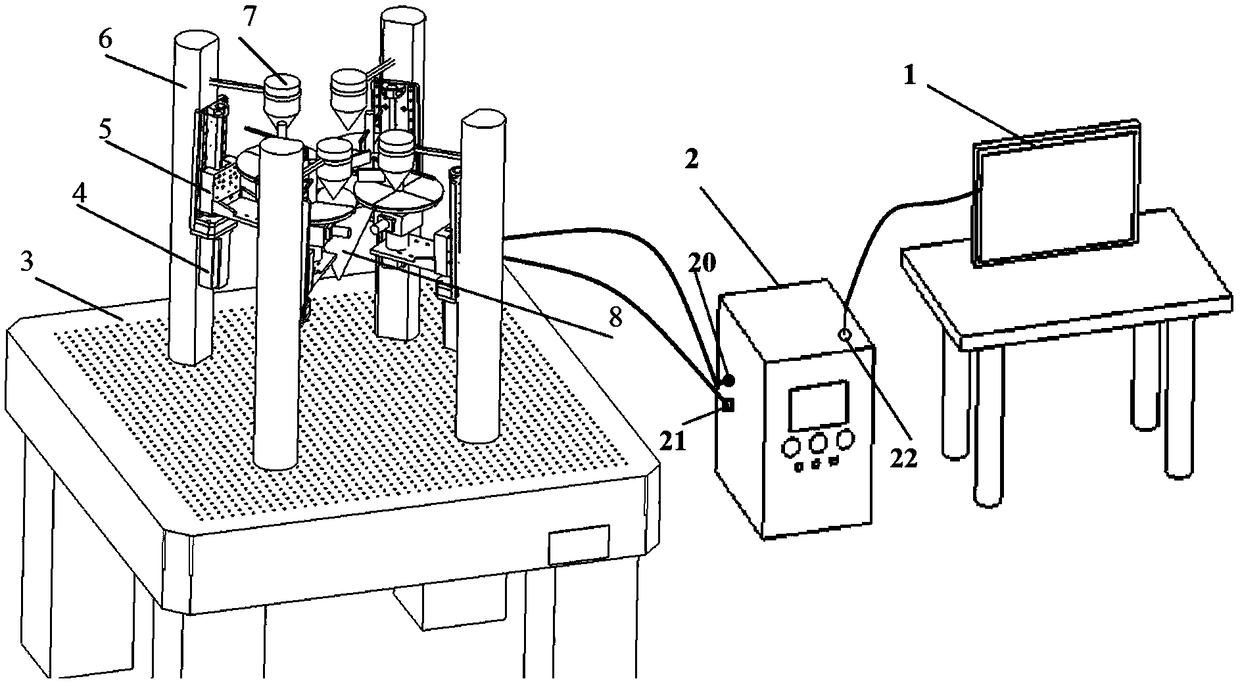

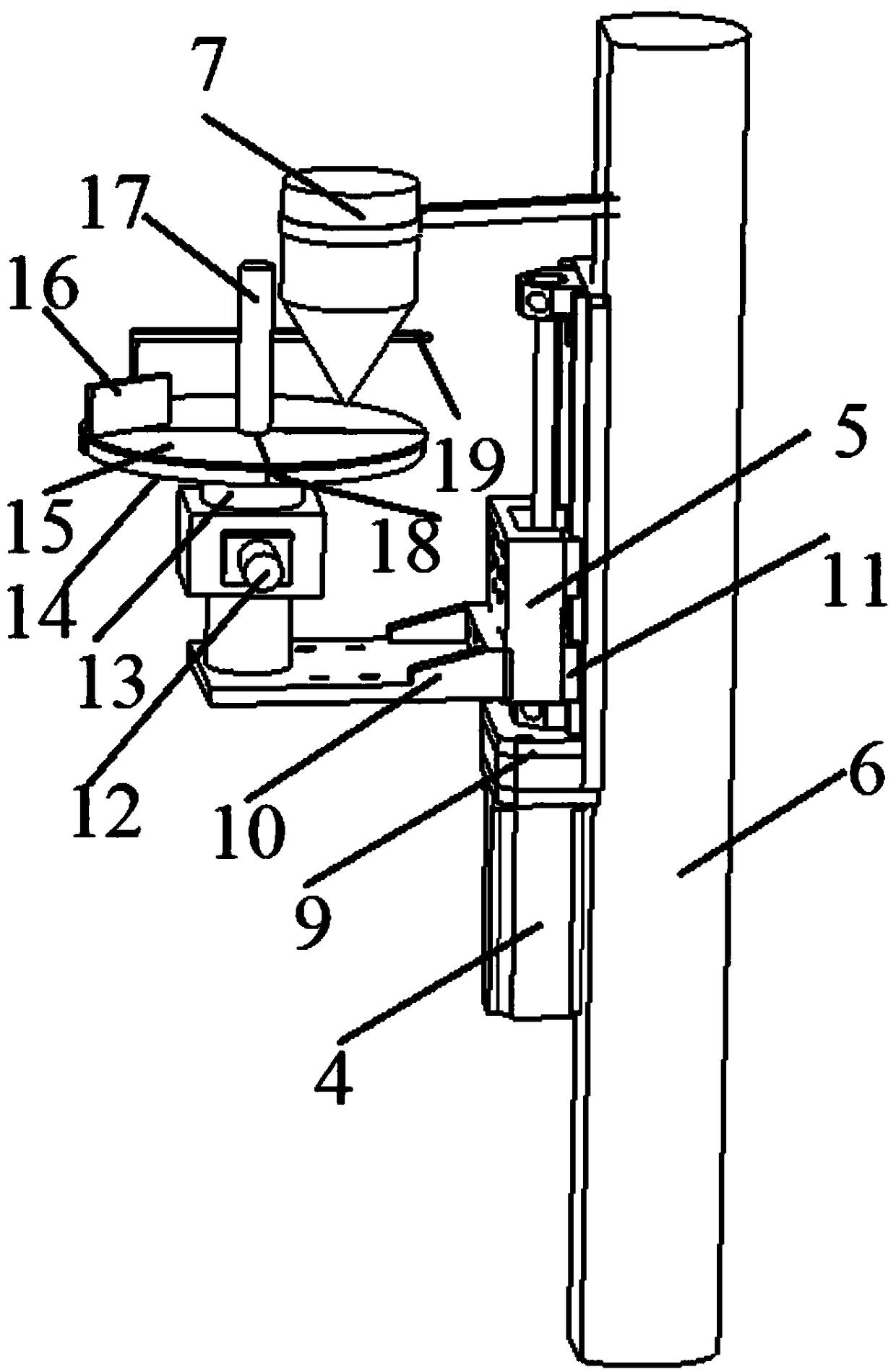

[0051] figure 1 It is a schematic diagram of the overall structure of a four-way precision proportioning control powder feeding system. It can be seen from the figure that the system consists of a support shaft 6, a powder feeder, a powder quantity detection module, a powder quantity control module, and a precision proportioning system. The control module and the powder mixing device 8 are composed of five parts.

[0052] Among them, there are four powder feeders, which are respectively fixed on four support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com