Downhole water-coal separation system and water-coal separation method

A separation system and coal machine technology, applied in the field of coal mine machinery, can solve problems such as blockage of sewage pumps and slurry pumps, and achieve the effects of reducing blockage, expanding space, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

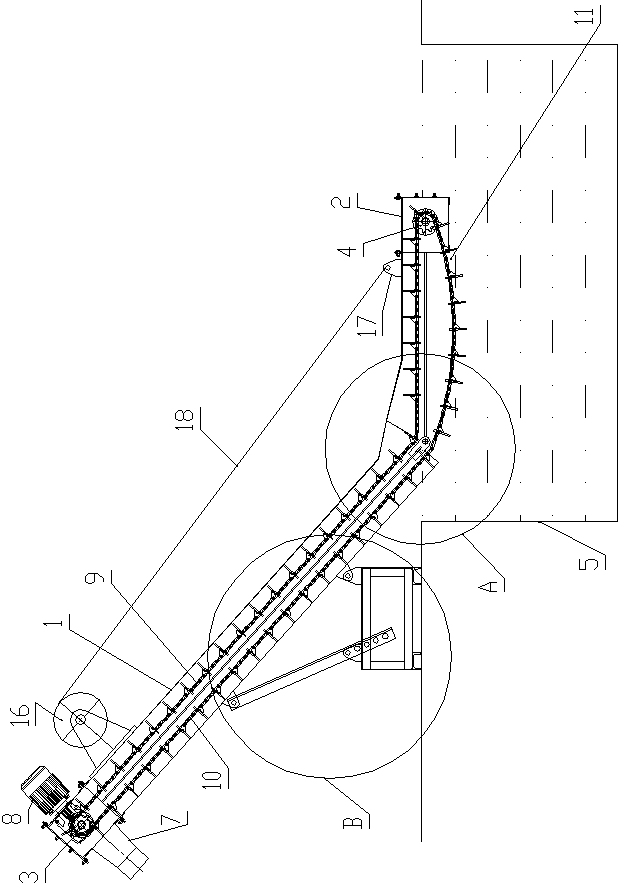

[0061] Such as Figure 1 to Figure 7 As shown, the underground water-coal separation system of the present invention includes an underground coal raking machine 31, a receiving hopper 32, a shredder 33, a stacked screw sludge dewatering machine 34 and a belt conveyor 35;

[0062] The underground coal raking machine 31 includes an upper box body 1 and a lower box body 2, and the upper box body 1 and the lower box body 2 communicate;

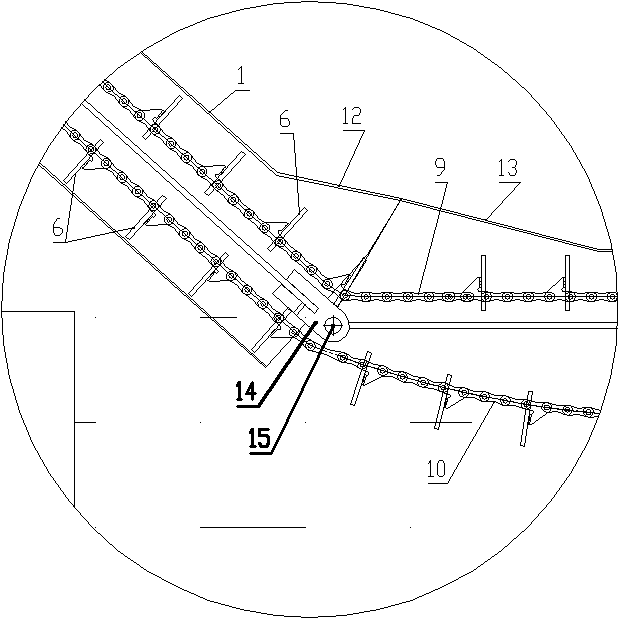

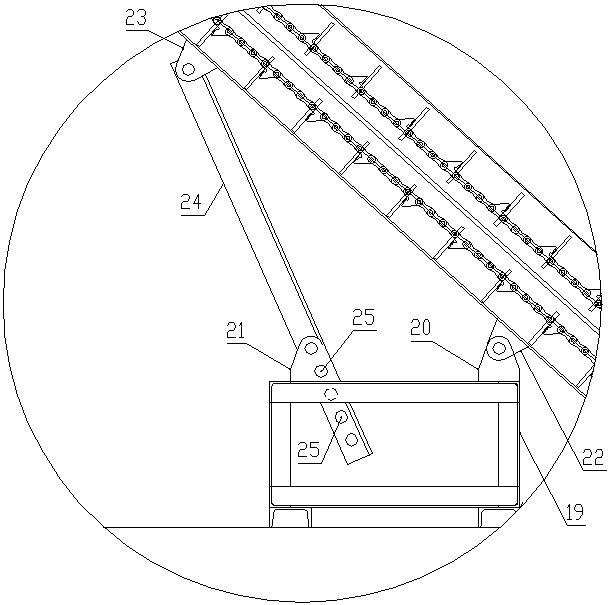

[0063] The angle between the lower box 2 and the horizontal plane is 0±15 degrees, and the angle between the upper box 1 and the horizontal plane is 45±15 degrees; A driven sprocket 4 is provided at the free end, and a conveying chain is wound between the driving sprocket 3 and the driven sprocket 4. The conveying chain is evenly connected with a plurality of scrapers 6 along its length direction, and the width of the scrapers 6 is It is more than 8 times the width of the chain, and the width of the scraper 6 matches the width of the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com