Industrial robot remote control method

A remote control and robot technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as long shutdown processing time, fault diagnosis, difficulty in program management program proofreading, and hidden equipment operation problems. The effect of improving the speed of troubleshooting, saving the time of troubleshooting, and improving the level of network management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 This method is applied in Q5 vehicle type

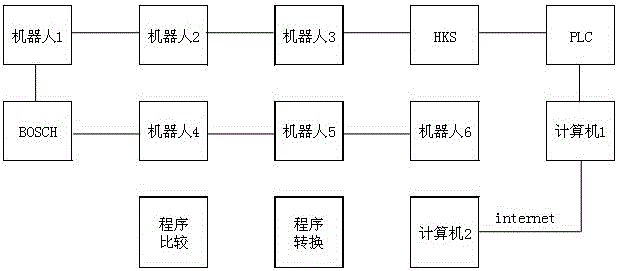

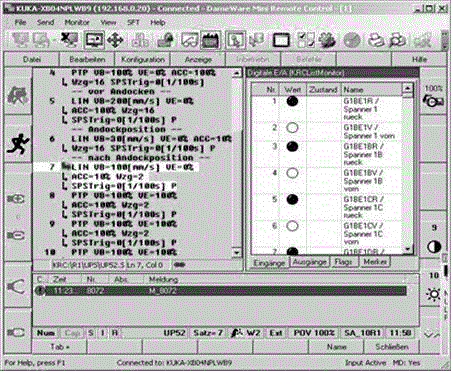

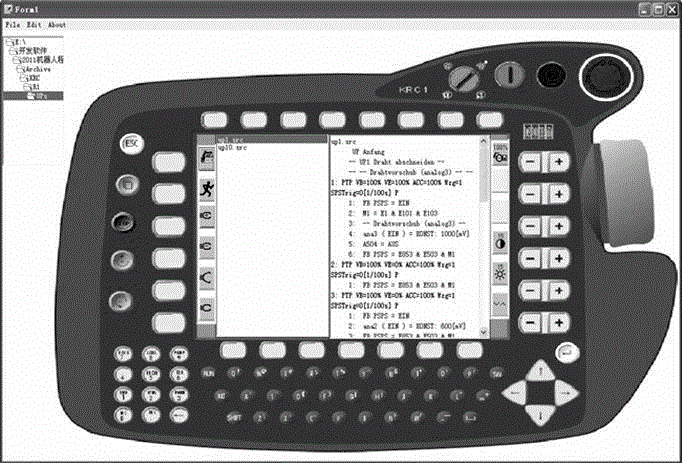

[0025] Connect all KUKA robots on the production line, arc welding quality monitoring system HKS, programmable logic controller PLC, Bosch welding controller BOSCH and equipment with the standard of TCP / IP protocol, modify the original registry of KUKA robots, change KUKA robot configuration. Because the robot is different from a stand-alone machine after networking, network security issues must be considered if there is a network. Operating system default: use the ipc$ channel to establish an empty connection, and anonymously enumerate how many accounts the machine has. Obviously there are certain security risks. This method sets it to disallow empty connections. In this way, the security of the stand-alone dial-up Internet access can be improved. The negative effect is that the LAN cannot communicate with each other. To change the console login can be resolved. Set up the robot to allow console login netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com