Automatic control system for vehicle frame overturning

An automatic control system, a technology of frame flipping, applied in lifting frames, motor vehicles, braking devices of hoisting equipment, etc. The effect of improving the actuation rate and tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

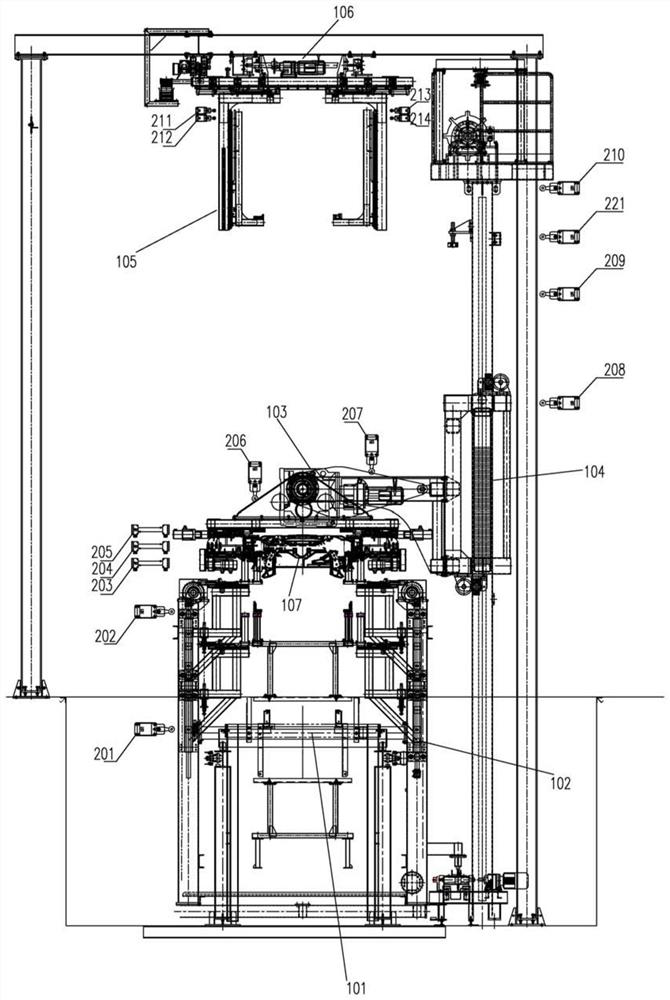

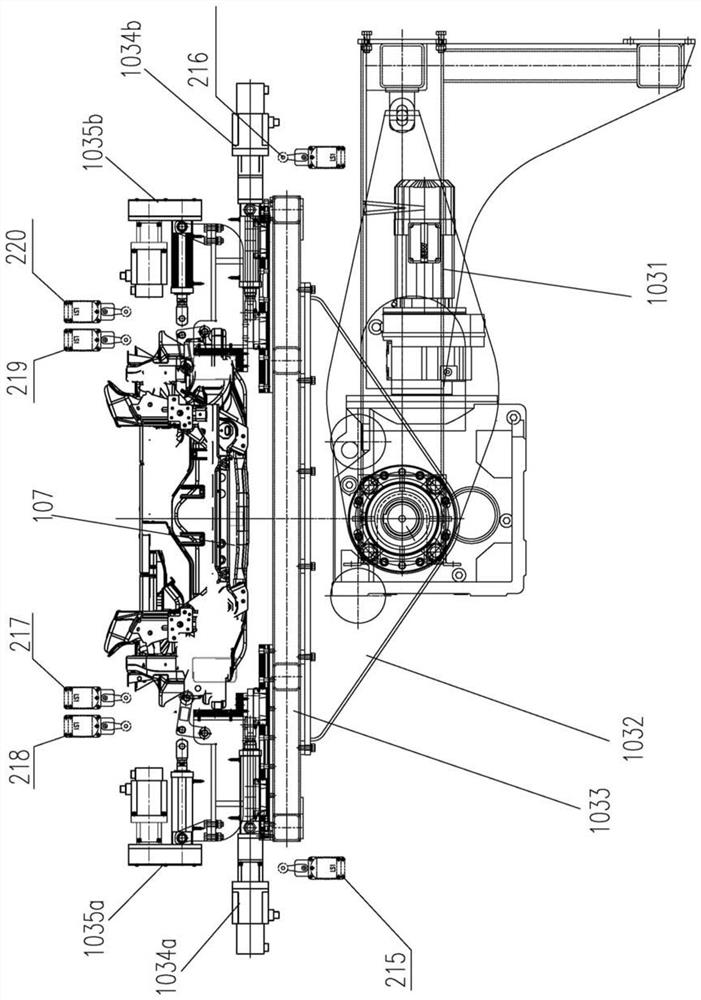

[0023] figure 1 A vehicle frame turning machine shown includes a vehicle frame conveying device 101, a jacking mechanism 102, a turning mechanism 103, a lifting mechanism 104, a transfer spreader 105, and a spreader opening and closing mechanism 106;

[0024] The vehicle frame conveying device 101 is used to transport the vehicle frame 107; the vehicle frame conveying device 101 passes through the jacking mechanism 102; the jacking mechanism 102 is used to lift the vehicle frame 107 upward from the vehicle frame conveying device 101; The mechanism 103 is arranged above the jacking mechanism 102, and is used for clamping the lifted vehicle frame 107 and turning it over 180 degrees, so that the vehicle frame 107 goes upwards and faces the transfer spreader 105;

[0025] The turning mechanism 103 is connected to the lifting mechanism 104. After the turning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com