Multiple automobile mode discrimination and control method of automobile body locus line

A control method and body machine technology, which are applied in conveyor control devices, transportation and packaging, comprehensive factory control, etc., can solve problems such as low production efficiency, body damage, and error-prone, reduce labor intensity, improve start-up rate, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

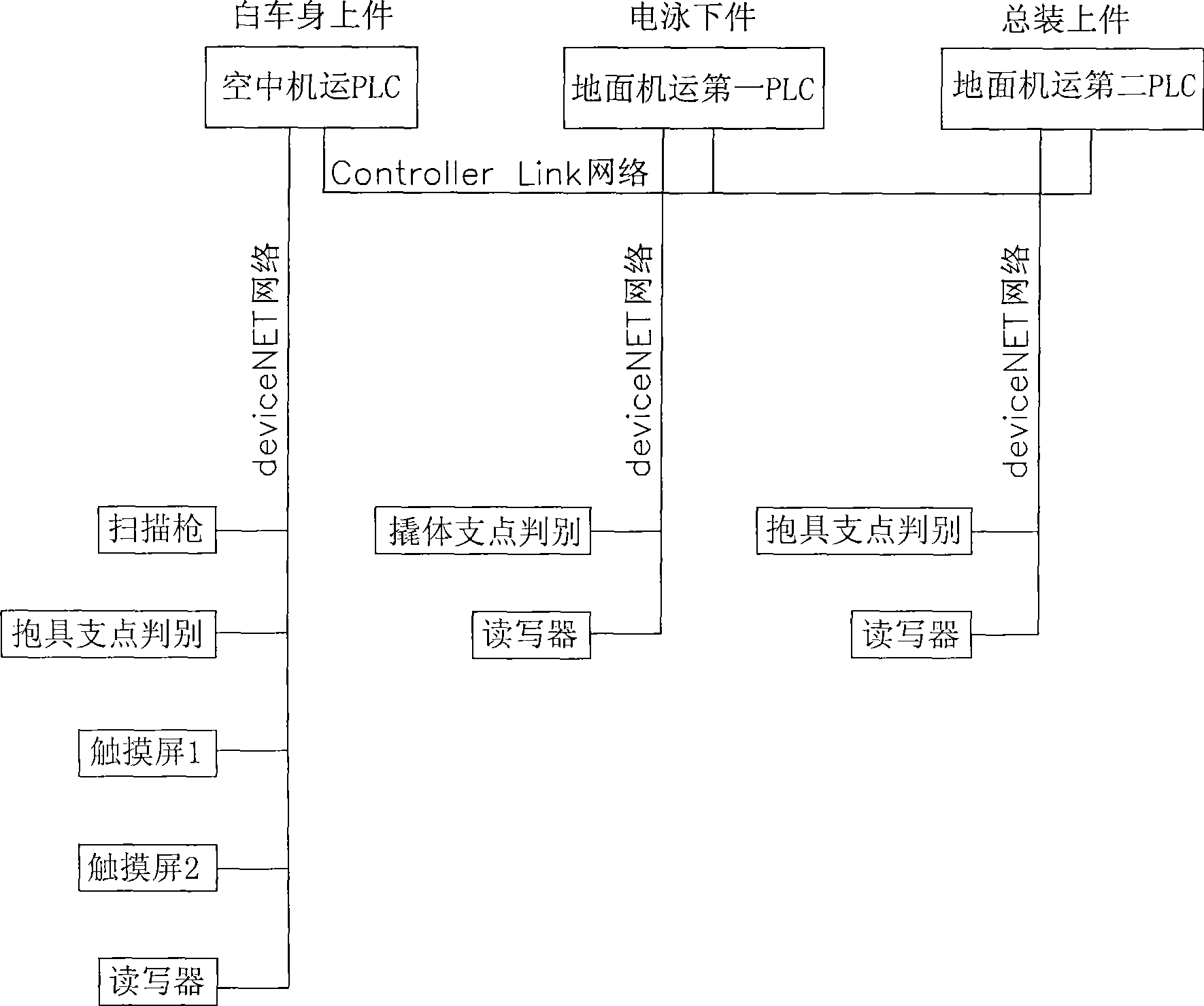

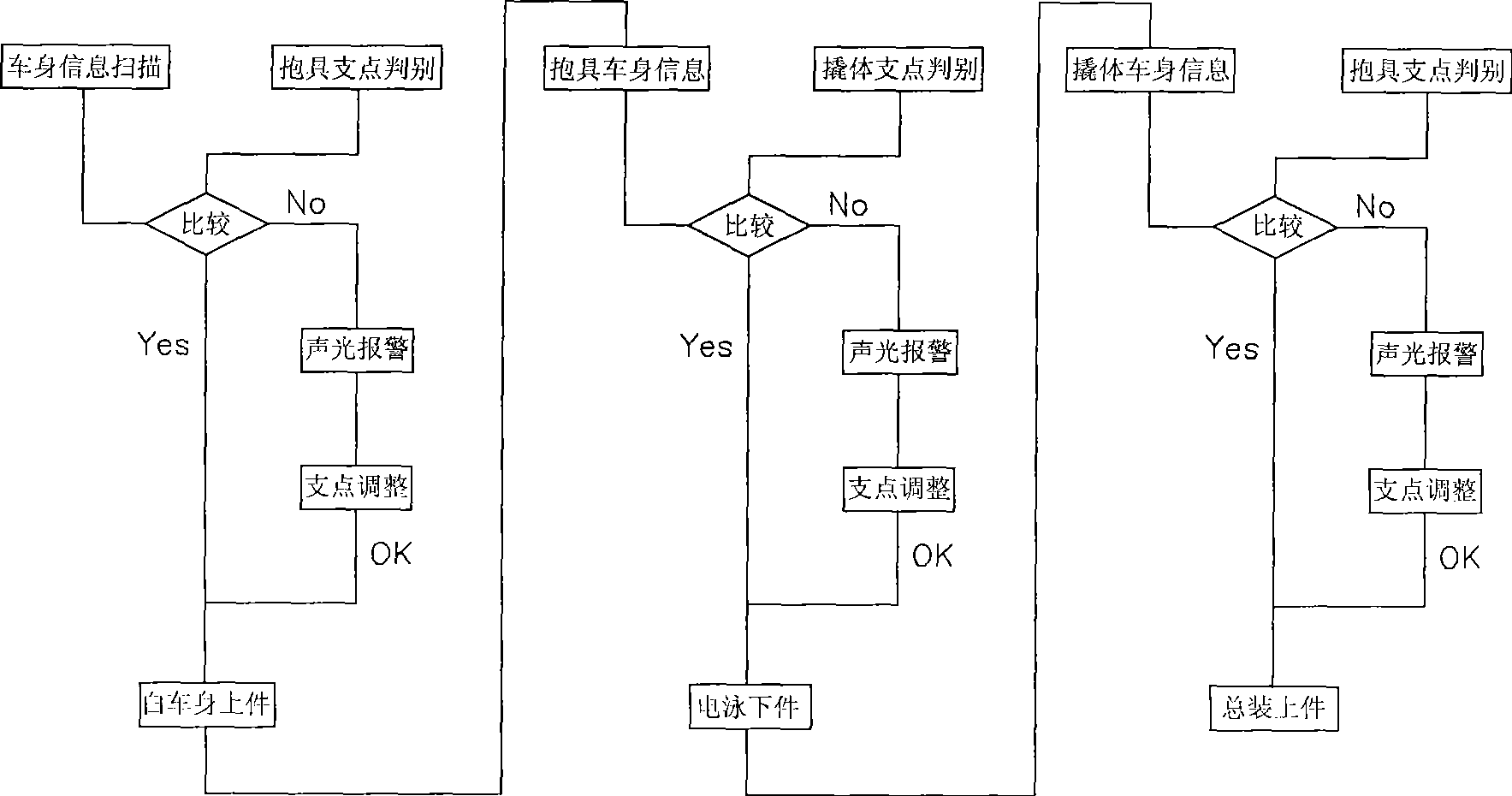

[0013] see figure 1 , figure 2 , a method for discriminating and controlling multiple car models on the vehicle body machine line. When the vehicle body-in-white (body-in-white upper part) is on the air line (body-in-white upper part), the information of the car body is loaded into the air machine transport PLC through the scanning gun. The hold fulcrum information obtained by the fulcrum discrimination system is also input to the airborne PLC, and the airborne PLC compares the body-in-white information with the hold fulcrum information. If the hold fulcrum meets the body-in-white model, the hold will enter In the body-in-white upper part lifter, the body-in-white is automatically hung into the holder, and the information of the body-in-white is loaded into the code carrier of the holder; Alarm, manually adjust the fulcrum of the holding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com