Underground ore transport train overhaul method

A technology for trains and ore, used in inspection work, train maintenance and maintenance in open-pit mines, can solve problems such as the inability to carry out overhaul and maintenance of electric locomotives and mine cars, and achieve the goal of improving transportation efficiency, increasing operating rate, and efficient working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

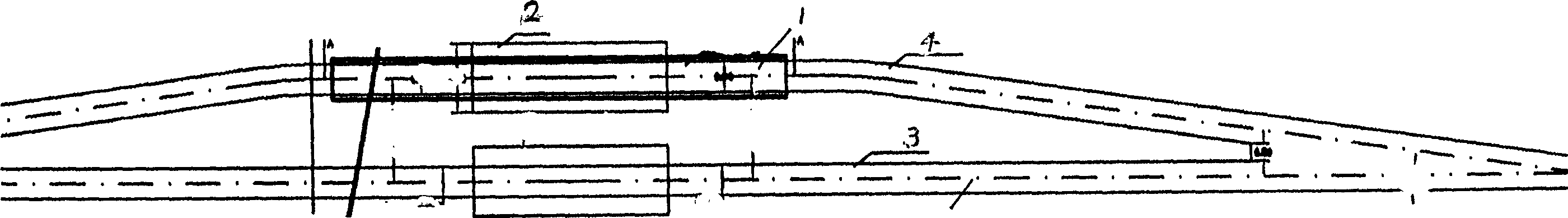

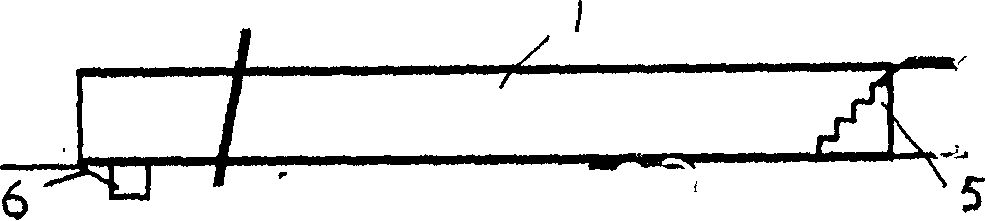

[0017] Concrete technical scheme is as follows: underground ore transportation train maintenance method, on the ore transportation line, select a section of straight roadway (the length of straight line section is about 150m), widen this section roadway, lay into double-track line, wherein a track is used for ore transportation ( Driving line 3), another track is used for train inspection (train inspection line 4), excavates trench below the track for train maintenance, called "train inspection trench", in the train inspection trench, operators can easily Check the condition of the train. According to this principle, it is also possible to add another section of roadway specially for train inspection and maintenance. The main features are: (1) The length of the train inspection trench and the double-track line is determined according to the total length of the ore transport train; (2) The structural parameters of the train inspection trench are: length = total length of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com