Tool suitable for machining V-shaped diesel engine rack and using method thereof

A diesel engine and frame technology, which is applied to metal processing machinery parts, metal processing equipment, positioning devices, etc., can solve the problems of reducing machine tool utilization, occupying machine tool running time, and large size, so as to reduce product clamping time and improve The effect of operating rate and product processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

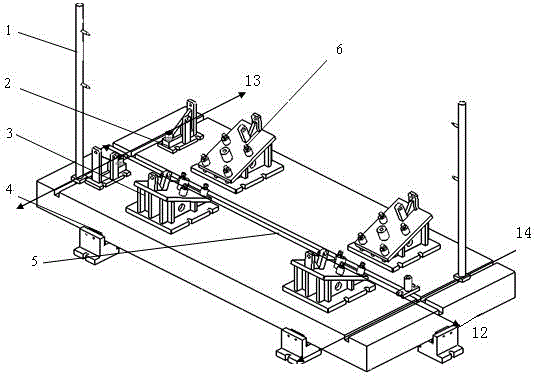

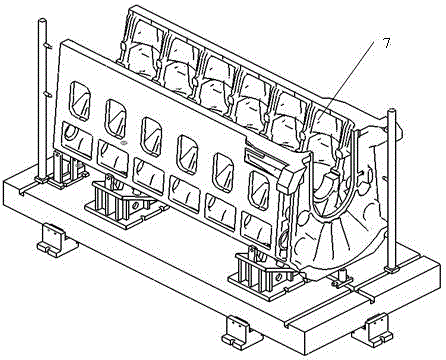

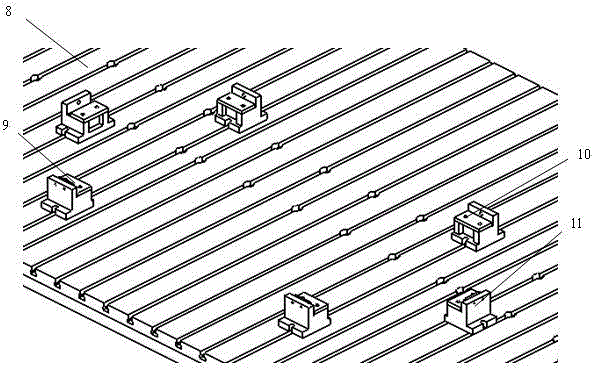

[0024] Attached below figure 1 , attached figure 2 , attached image 3 , attached Figure 4 The present invention is further analyzed: a tool suitable for processing a V-type diesel engine frame includes a base plate 4, and the base plate 4 is provided with a reference keyway 5; The fixture is installed and fixed, and the frame 7 is placed on the fixture;

[0025] The fixture includes four angle tooling 3 supporting the V-shaped cylinder surface of the frame, a horizontal adjustment tool 2, an adjustable top screw 6, and two constant-height contour needles 1; wherein, each of the angle tooling A set of adjustable jacking screws 6 is set on the upper surface of 3, and the contour needle 1 is set in the reference keyway 5 of the bottom plate 4;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com