A multi-purpose automatic oxidation line with replaceable tank body

A technology for replacing tanks and oxidation lines, which is applied in the field of zipper manufacturing, can solve the problems of inability to flexibly adapt to production needs and the single production process of oxidation lines, and achieve the goals of saving oxidation potions and time, improving oxidation efficiency, and increasing the operating rate and utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

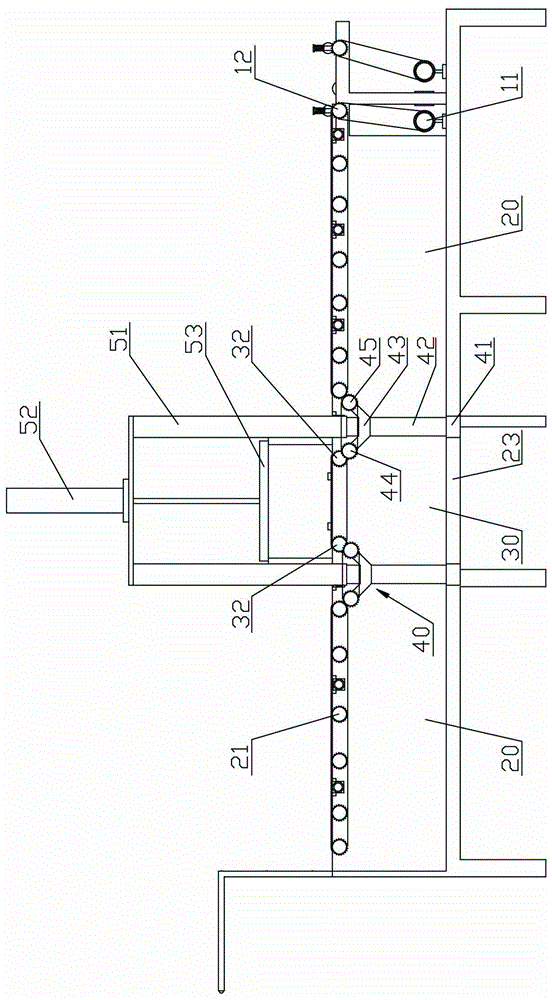

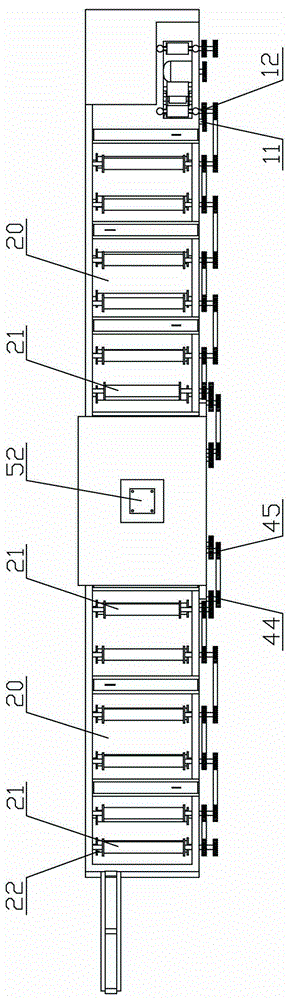

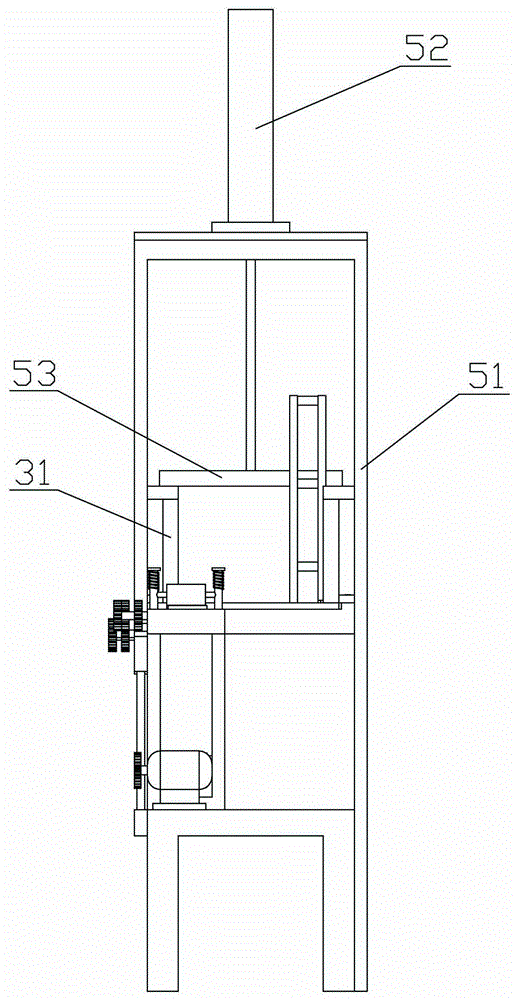

[0020] A multi-purpose automatic oxidation line with replaceable tank body, refer to Figure 1 to Figure 4 , including a machine head and a plurality of fixed oxidation tanks 20, each fixed oxidation tank 20 is provided with a first transmission shaft 21 and a first driven shaft 22, the machine head includes a motor 11 and a traction wheel 12, and the traction wheel 12 is composed of The motor 11 drives the rotation, and the traction pulley 12 is arranged at the outlet end of the end-fixed oxidation tank 20, and is connected with the first drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com