Cylinder hole honing tool

A technology for honing and cutting tools, applied in the field of honing equipment, can solve the problems of inability to achieve geometric accuracy, precise control, diameter and roundness fluctuations of cylinder holes, ensure product processing quality, reduce tool costs and labor waste, and improve equipment start-up. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

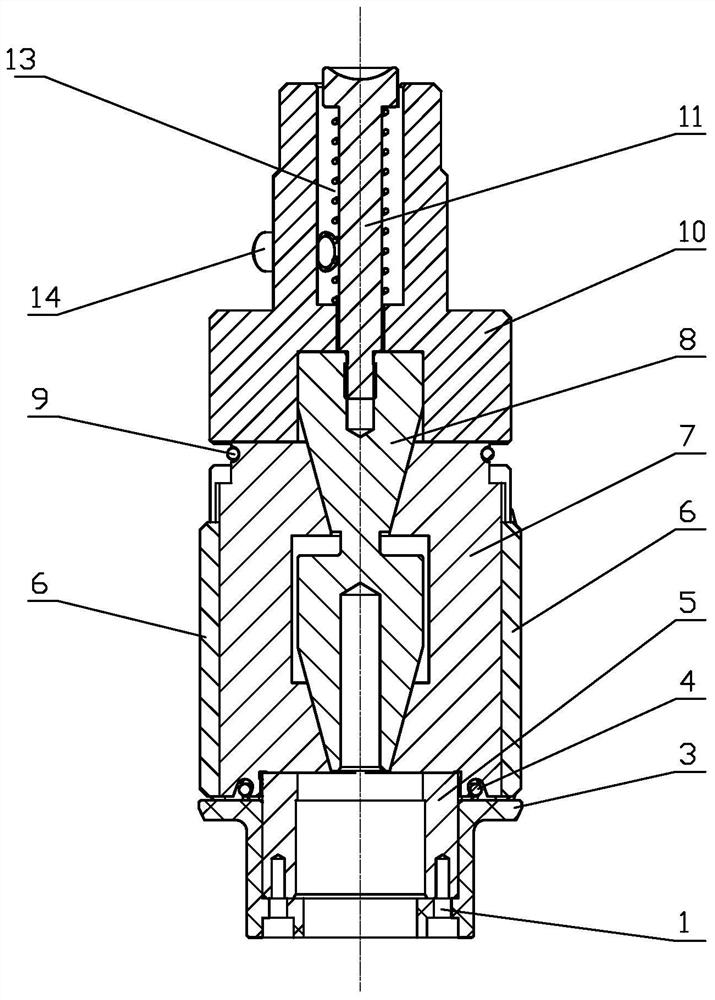

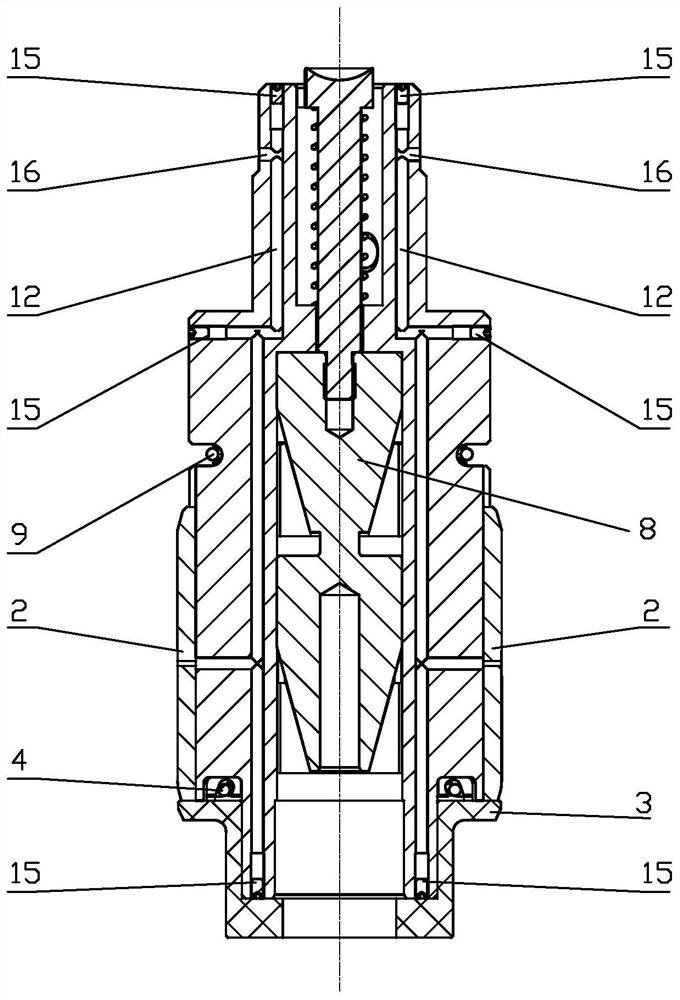

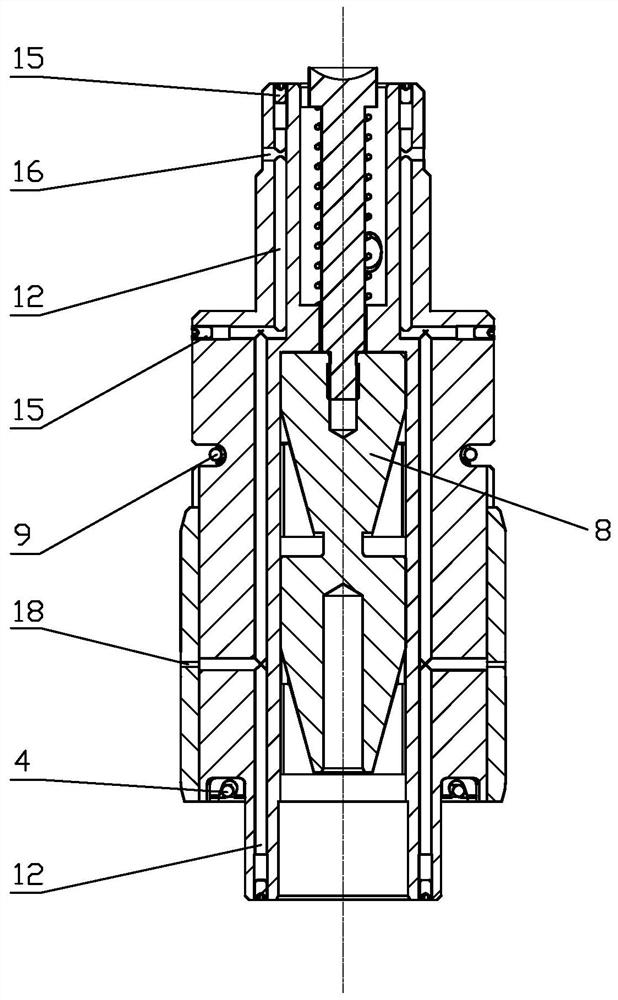

[0035] The present invention will be further described below in conjunction with specific drawings.

[0036] Such as Figure 5 As shown, the cylinder bore honing tool of the present invention is used for honing the cylinder bore 22 of the engine block 24, and the anti-rotation pin 14 and the locking groove 17 of the honing tool are respectively connected with the anti-rotation pin mounting hole 21 and the locking groove 17 of the connecting rod 19. The locking key cooperates to fix. The present invention specifically includes the head body 10, the sand bar seat 7 and the support body 5 connected in sequence, such as figure 1 As shown, the head body 10 and the sand bar seat 7 are provided with an expanding cone 8, and the sand bar seat 7 is provided with a sand bar 6; Cone 8; expanding knife bar 11 and expanding cone 8 cooperate to drive sand bar seat 7 and sand bar 6 radial knife; expanding knife bar compression spring 13 is combined with expanding knife bar 11, and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com