Anti-deformation machining method of medium-pressure air inlet sealing ring of medium-pressure outer cylinder of steam turbine

A processing method and air inlet technology are applied in the field of anti-deformation processing of sealing rings, which can solve the problems of poor product quality and high deformation, and achieve the effect of ensuring product processing quality, drawing size and roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

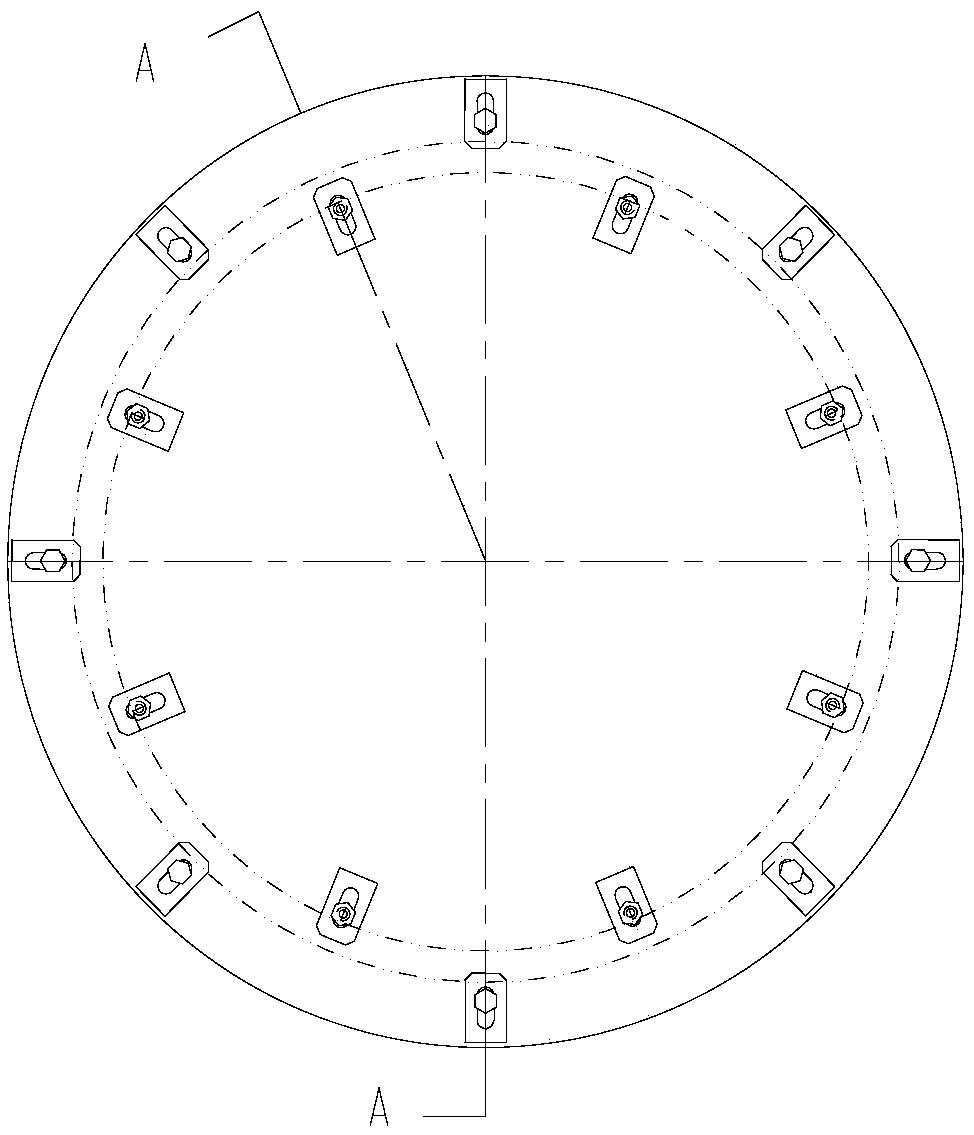

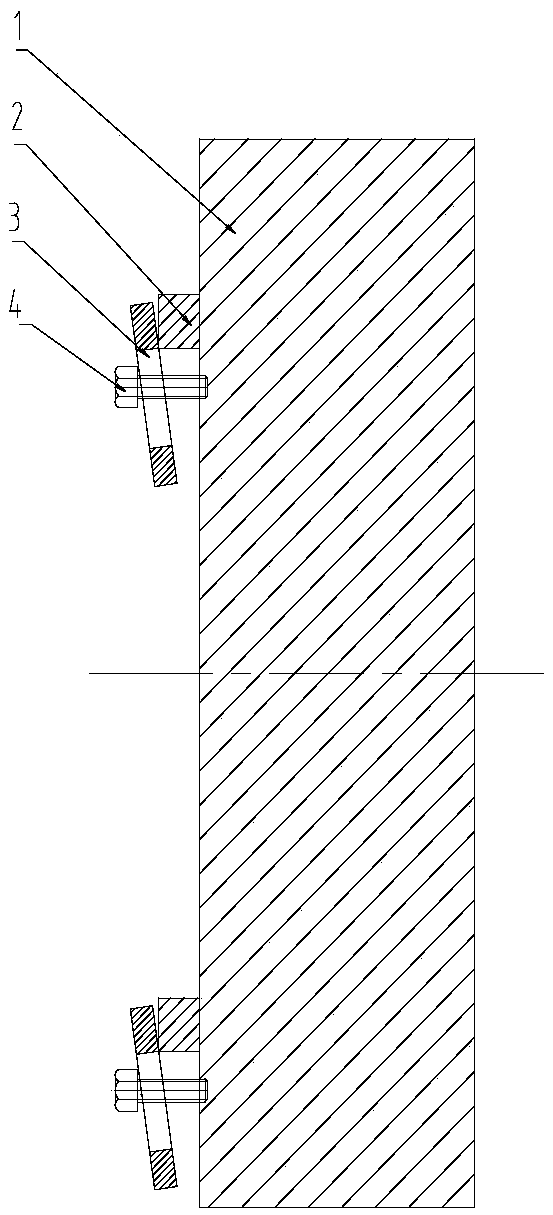

[0025] Specific implementation mode one: combine figure 1 and figure 2 Description In this embodiment, the anti-deformation processing method for the sealing ring of the medium-pressure outer cylinder of the steam turbine medium-pressure inlet is carried out according to the following steps:

[0026] 1. Take the steel plate blank, fix the steel plate blank on the lathe, and carry out rough turning of the outer circle, inner circle and upper and lower end faces. During the rough turning, a 2mm machining allowance is reserved on each side to obtain the rough turning blank;

[0027] 2. Natural aging treatment for rough car blanks for 46 to 50 hours;

[0028] 3. Measure the actual size of the rough turning blank, and process the matching cast iron mold according to the measured size. The interference between the cast iron mold and the rough turning blank is 0-0.01mm; for the outer circle, inner circle and upper and lower end faces of the rough turning blank Carry out semi-finis...

specific Embodiment approach 2

[0036] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the cutting parameters for rough turning of outer circle, inner circle and upper and lower end faces as described in step 1 are: cutting depth 0.4-0.6 mm, feed rate 0.2 ~0.5mm / r, cutting speed is 14~16m / min. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the outer diameter of the rough turning blank in step 1 is 522.5±0.13; the inner diameter of the rough turning blank is 492.8±0.025. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com