Connecting rod type self-centering universal fixture

A self-centering, link-type technology, used in clamping, positioning devices, manufacturing tools, etc., can solve problems such as workpiece processing efficiency affecting the start-up rate of machine tools, waiting for machine tools to stop, cumbersome and time-consuming alignment process, etc. The effect of machine starting rate and machining efficiency, improving the starting rate and shortening the alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

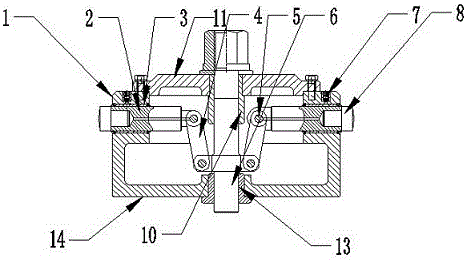

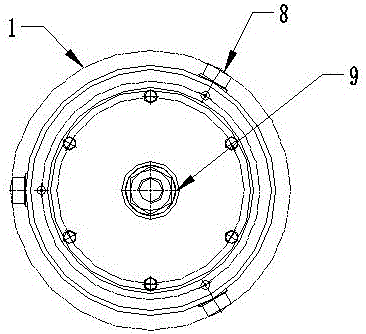

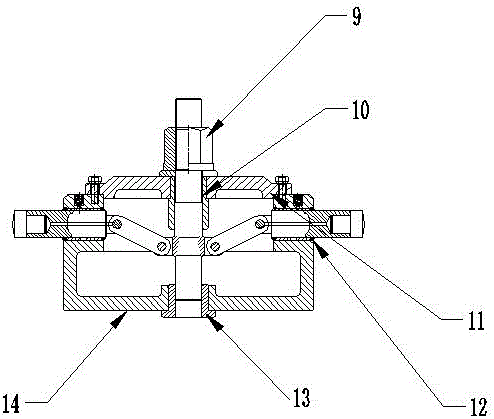

[0040] Examples such as Figure 1-4 As shown, the link-type self-centering universal clamp includes a cylindrical clamp body 1 , one end of the clamp body 1 is fixedly connected with an upper end cover 11 , and the other end of the clamp body 1 is connected with a bottom plate 14 .

[0041] A central shaft 6 is slidably connected to the center of the clamp body 1 , and the axis of the central shaft 6 coincides with the axis of the clamp body 1 .

[0042] The central shaft 6 runs through the upper end cover 11 and the bottom plate 14, and the outer side of the central shaft 6 is covered with a guide sleeve 10, which is fixedly connected with the upper end cover 11. Fixed connection.

[0043] Three clamping slide shafts 2 are evenly arranged on the side wall of the clamp body 1 along its circumferential direction.

[0044] The clamping slide shafts 2 are arranged perpendicular to the axis of the central shaft 6, and the angle between two adjacent clamping slide shafts 2 is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com