Engine assembling rotation force driving mechanism

A rotary force and engine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex drive mechanism, lack of lateral force support of drive buckle, drive mechanism stuck, etc., and achieve simple mechanism structure and improved Equipment start-up rate, improve the effect of FTQ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention are described with reference to the above drawings.

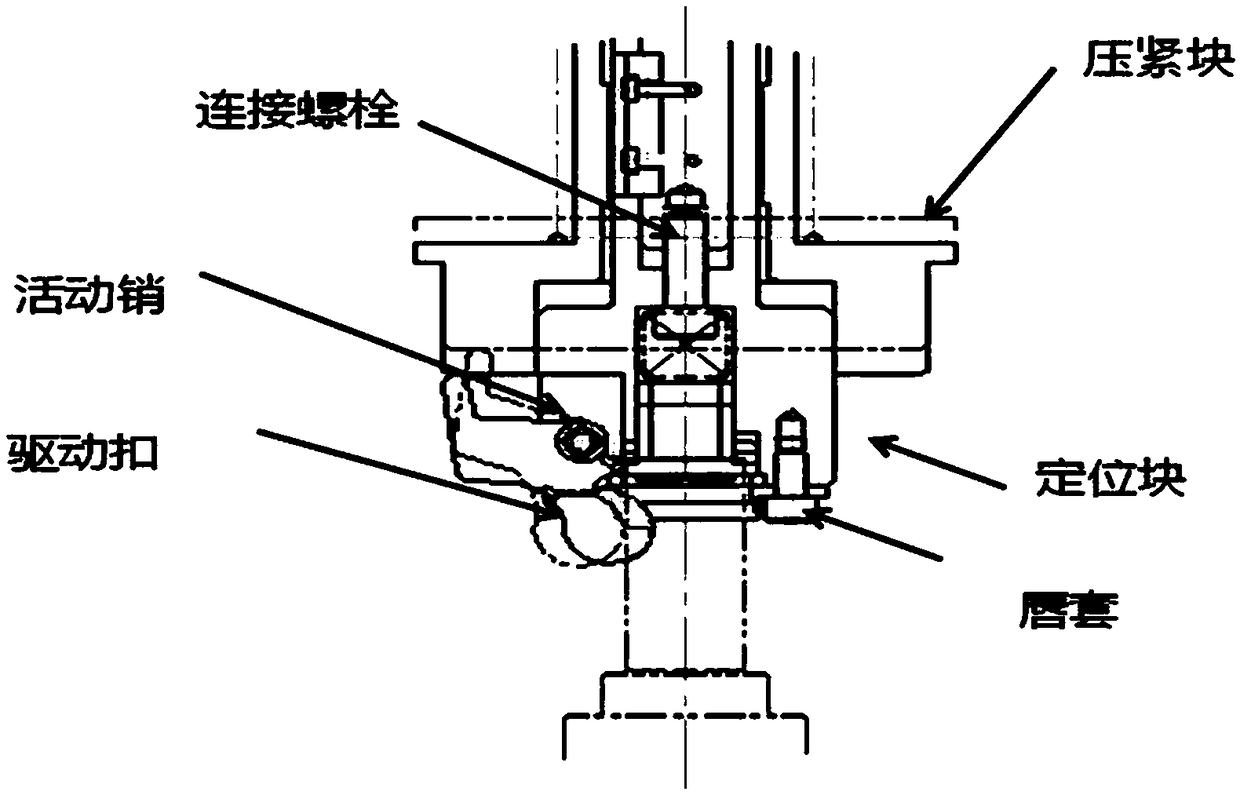

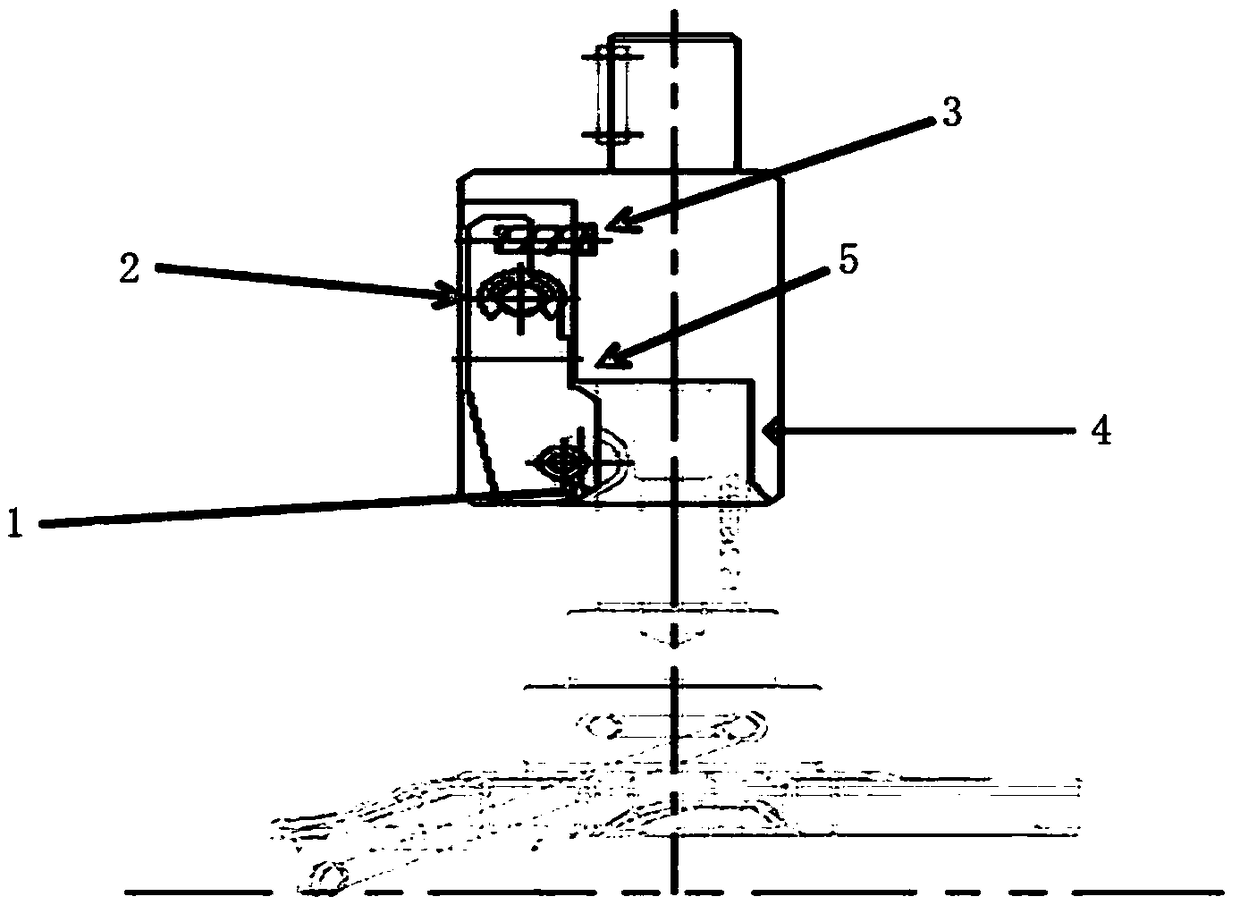

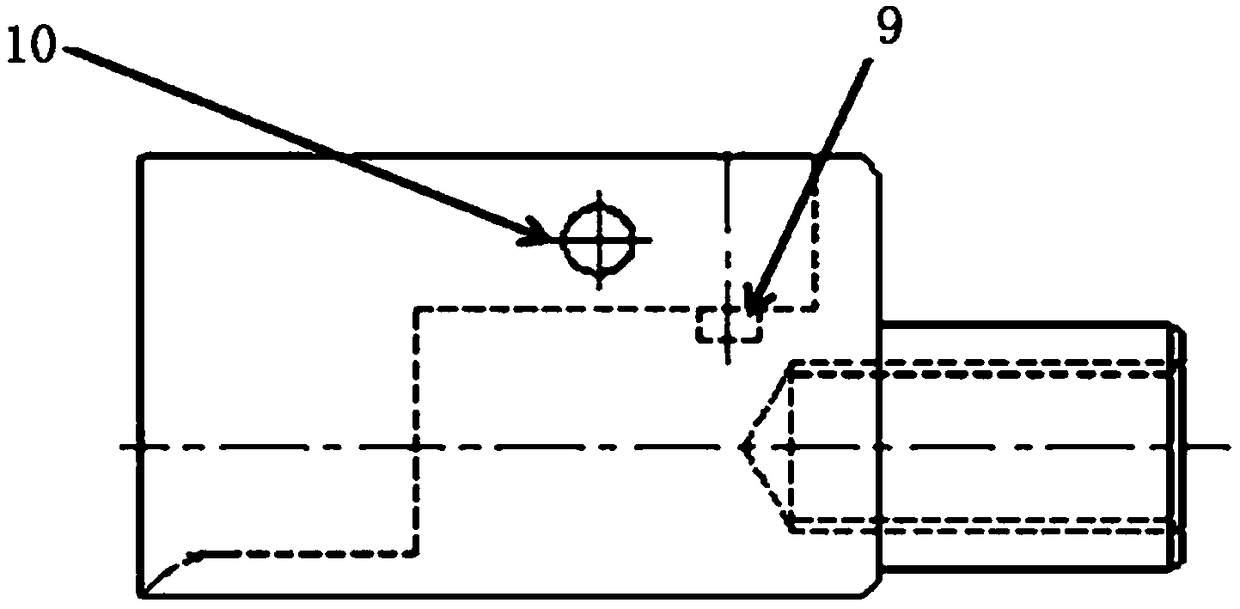

[0022] Depend on figure 2 and Figure 5 It can be seen that the present invention provides an engine assembly rotary force driving device, which includes a driving buckle 1, a movable pin 2, an elastic device 3, a housing 4, and a driving arm 5. The driving buckle 1, the movable pin 2, the elastic force The device 3 is arranged on the driving arm 5, the driving arm is arranged inside the housing 4, the driving arm 5 is connected with the housing 4 through the movable pin 2 and the elastic device 3, and It includes a height adjustment bolt 6, a drive arm installation slot 7, and a drive side protection device 8, the height adjustment bolt 6 is arranged on the drive arm 5, the drive arm installation slot 7 and the drive side protection device 8 It is arranged on the inner wall of the housing 4 , and the driving arm 5 is installed on the driving arm installation groove 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com