Part discharging roller machine

A rolling bed and lower parts technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of hard collision of car body skids, unreasonable delivery and handover forms, and unfavorable long-term operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

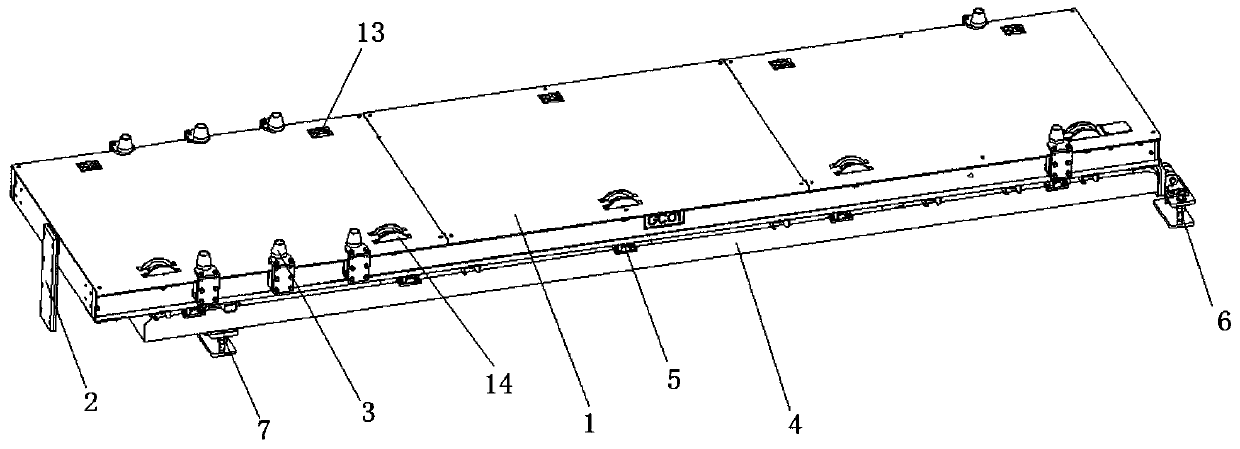

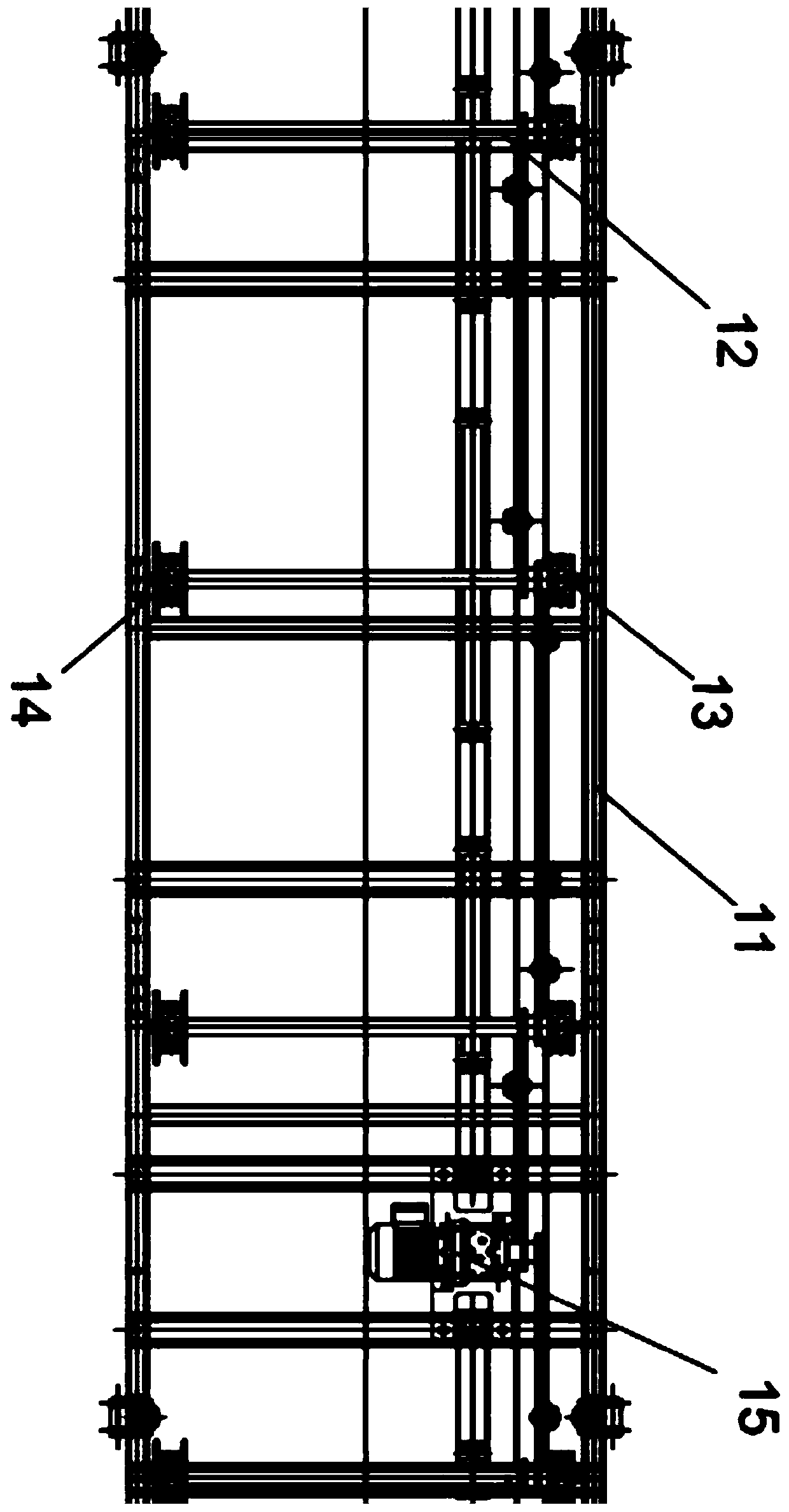

[0038] The embodiment of the present invention provides a kind of roller bed of lower parts, such as figure 1 and figure 2 shown, including:

[0039] The bed body 1 is provided with a connecting guide device 2 at one end, and a plurality of guide wheel devices 3 are arranged on both sides of the upper surface of the bed body 1;

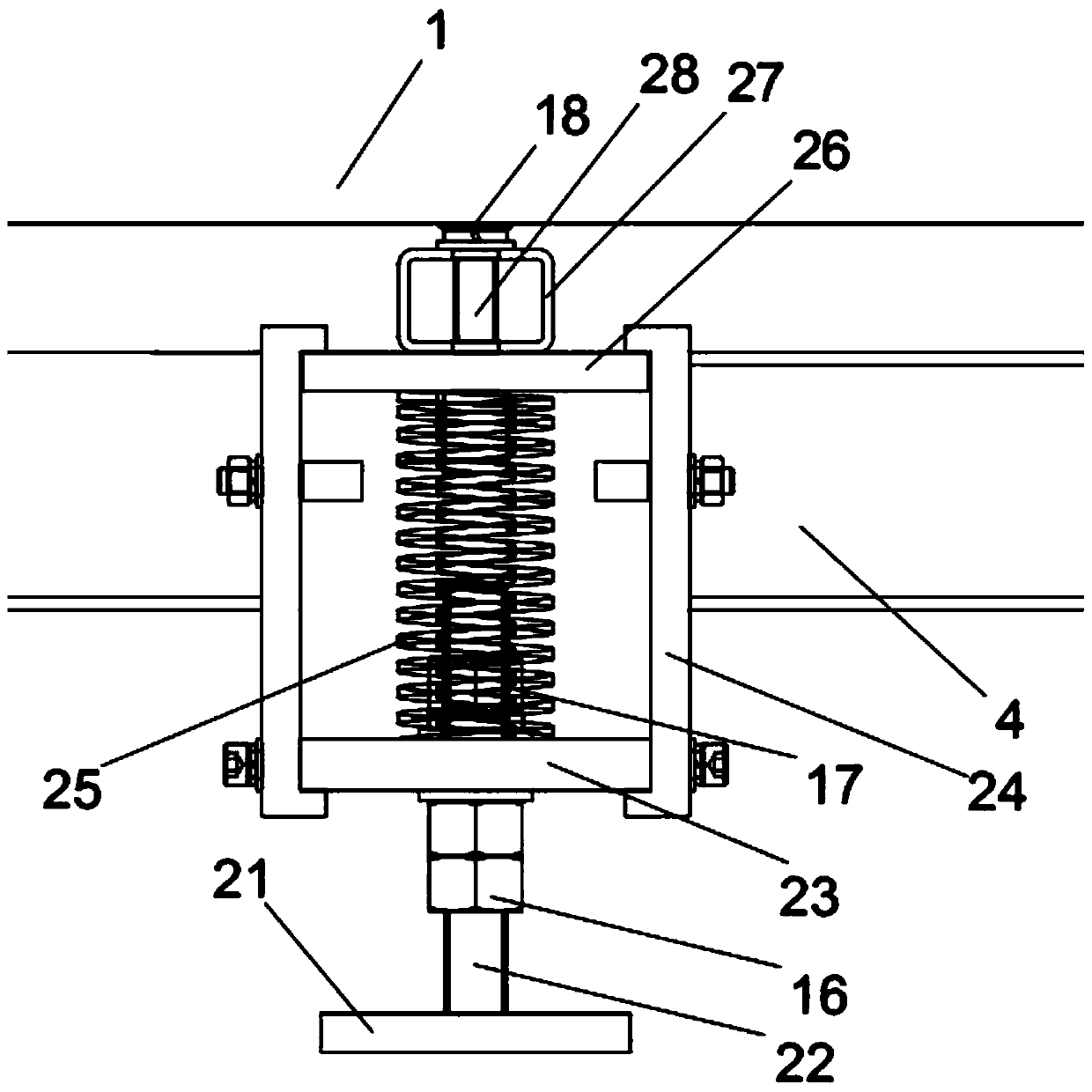

[0040] The frame 4 is located directly below the bed body 1, and the upper surface of the frame 4 is connected to the lower surface of the bed body 1 through a plurality of connecting devices 5, on two corresponding sides of the frame 4 and close to the A pair of supporting feet 6 are provided at the position of the connection guide devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com