Energy dissipation node of prefabricated assembly concrete structure

A concrete structure and prefabricated assembly technology, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems that it is difficult to ensure the construction quality of the core area of prefabricated beam-column joints, and there are many wet operations. Good seismic effect, increased safety and reliability, and small building space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

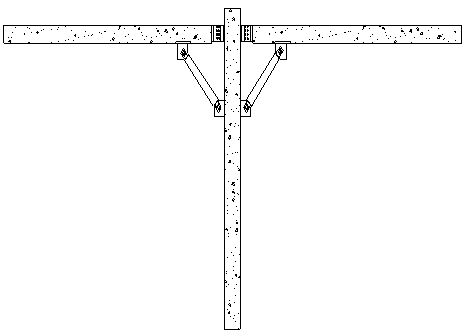

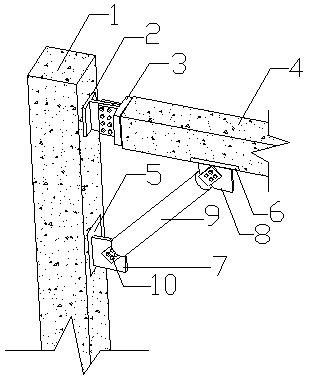

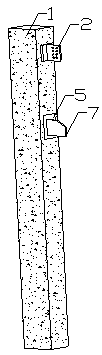

[0026] see Figure 1-Figure 8 , the prefabricated concrete structure energy dissipation joints, including prefabricated reinforced concrete columns (1) and prefabricated reinforced concrete beams (4) are connected at right angles, energy dissipation angle Beams (4) are connected at oblique angles, and the specific features are: the prefabricated reinforced concrete columns (1) are connected at right angles to the prefabricated reinforced concrete beams (4) and the energy-dissipating angle braces (9) are obliquely connected between them. The corner connections are all connected through prefabricated reinforced concrete columns (1) and embedded parts on prefabricated reinforced concrete beams (4).

Embodiment 2

[0027] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0028] The structure in which the prefabricated reinforced concrete column (1) is connected at right angles to the prefabricated reinforced concrete beam (4) is: there is a column embedded part A (3) on the top side wall of the prefabricated reinforced concrete column (1), and the prefabricated reinforced concrete beam (4) Beam embedded parts A (3) on the end face are matched and fixedly connected by high-strength bolts (10).

[0029] The column embedded part A (2) is a "T"-shaped member, and its anchor plate (2-2) has multiple anchor bars (2-3), which are embedded in the prefabricated reinforced concrete column (1) , there are multiple evenly distributed bolt holes on the connecting plate (2-1) perpendicular to the anchor plate (2-2); (3-2) has multiple anchor bars (3-3) pre-buried in the prefabricated reinforced concrete beam (4), and two parallel connectin...

Embodiment 3

[0034] like Figure 1-Figure 8 As shown, the prefabricated assembled beam-column energy-dissipating steel joint includes prefabricated reinforced concrete column (1), column embedded part A (2), beam embedded part A (3), prefabricated reinforced concrete beam (4), column prefabricated Embedded part B (5), beam embedded part B (6), column connecting plate (7), beam connecting plate (8), energy-dissipating support (9), high-strength bolts (10).

[0035] Steps of factory processing prefabricated components:

[0036] The column embedded part A (2) is composed of an anchor bar, an anchor plate and a steel plate, the anchor bar and the anchor plate are connected by a perforated weld, and the anchor plate is welded to a steel plate, such as Figure 5 shown.

[0037] The beam embedded part A (3) is composed of an anchor bar, an anchor plate and two steel plates, the anchor nail and the anchor plate are connected by a perforated weld, and the anchor plate is welded to the two steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com