Method for limiting and protecting wheel sets of 10m<3> underground mine cars

A technology of limit protection and mine wheel, which is applied to the edge of workpieces, arc welding equipment, manufacturing tools, etc., can solve the problems of wasting work time and physical energy consumption, it is difficult for drivers to control the speed of vehicles, and ride on the rails. Achieve the effect of improving the start-up rate of equipment, eliminating production lag, and using less materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

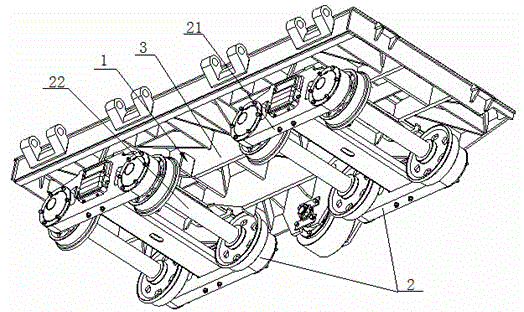

[0021] Such as figure 1 As shown, a 10m3 underground mine wheel pair limit protection method is realized by welding the steel plate 1 on the main beam 3 at the bottom of the mine car, including the following steps:

[0022] (1) Determine the width of the steel plate 1 by measuring the width from the rim of the mine wheel pair 2 to the main beam 3 at the bottom of the mine car; taking the main beam 3 at the bottom of the mine car 2m as the benchmark, after measurement, the wheel set 2 rim to the main beam 3 The width is 150mm. In order to ensure the controllable spacing of the wheelset 3, the width of the steel plate 1 used in the present invention is controlled at 120mm;

[0023] (2) Make a V-shaped groove on the steel plate 1;

[0024] (3) Use a grinder to remove harmful substances at the weld of the main beam 3 of the mine car and the V-shaped groove of the steel plate 1;

[0025] (4) Firstly bake the welding rod before welding, the temperature is 300~350°C, and stand the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com