Prawn grading equipment fault simulation and detection experiment table

A technology of equipment failure and test bench, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., capable of solving misalignment faults of movable shaft and roller bearings, unbalanced rotor mass, unfavorable fault mechanisms and diagnostic methods Experimental research and other issues to achieve the effect of ensuring work reliability and classification accuracy, improving the starting rate and utilization rate, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is attached Figure 1-6 , the structure and implementation process of the present invention are further described by examples.

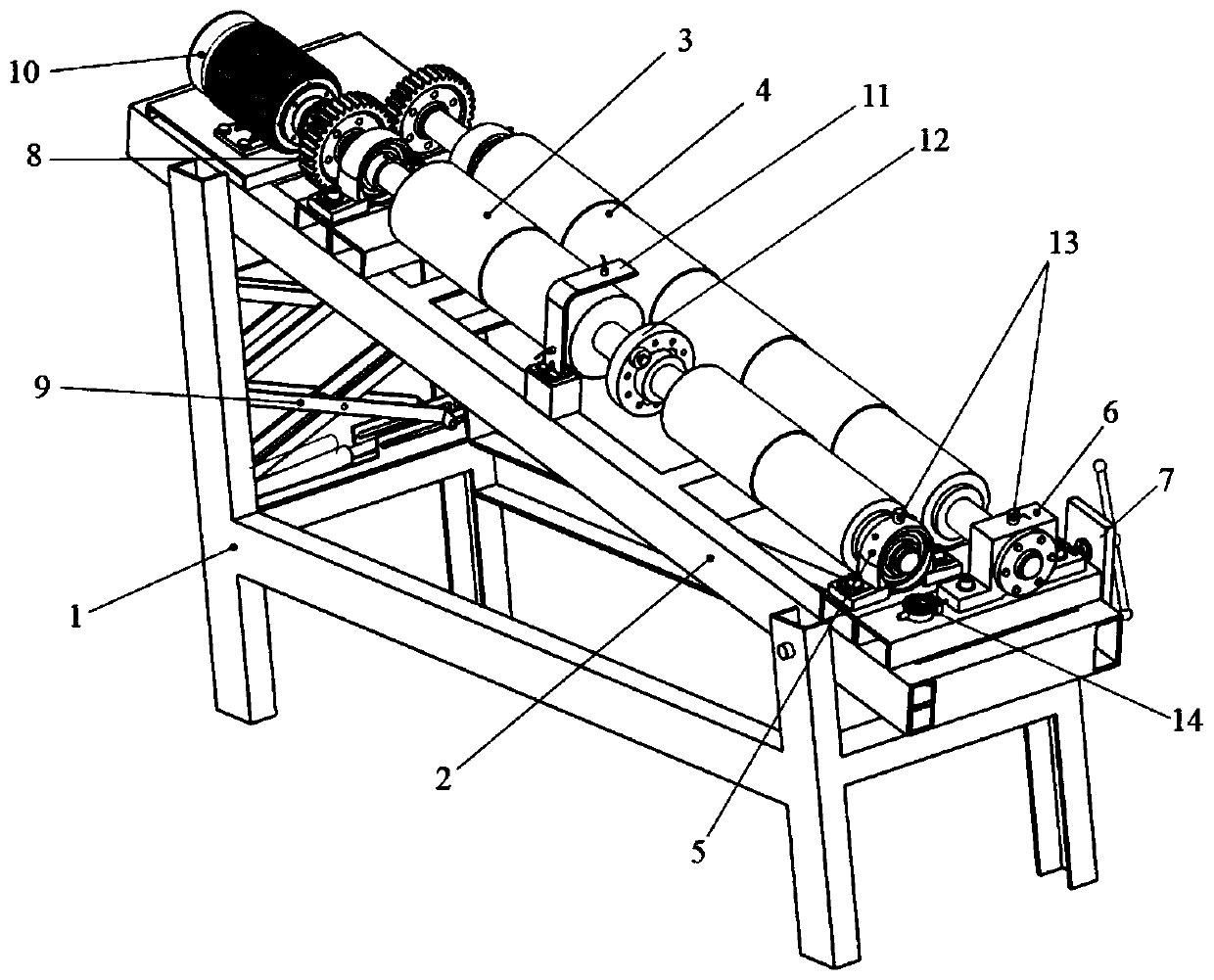

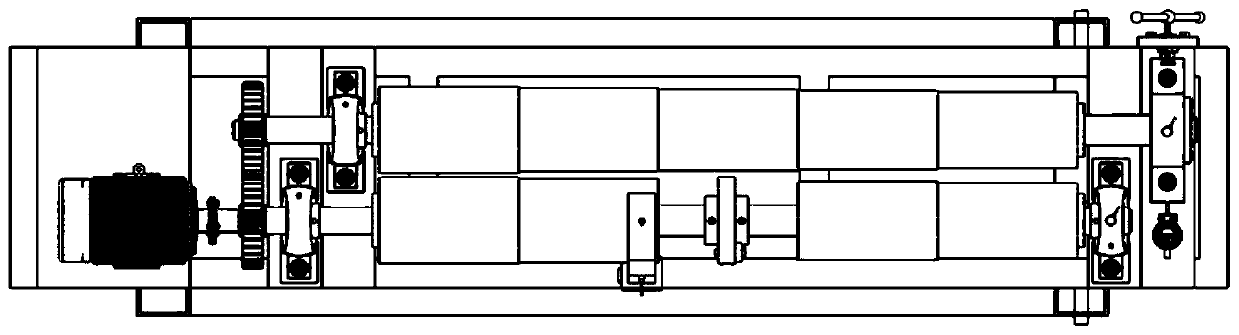

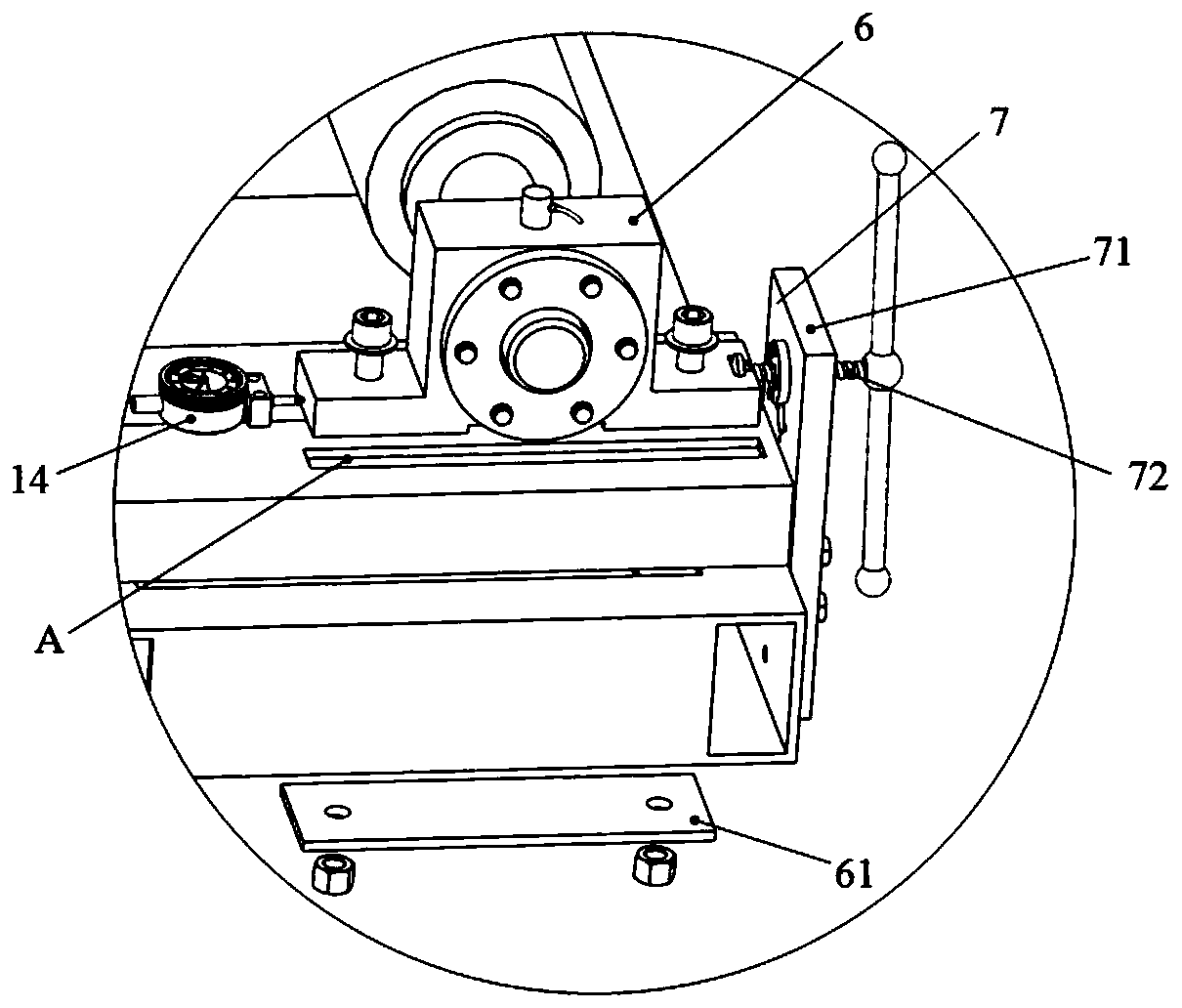

[0023] The purpose of the present invention is to design a prawn grading equipment failure simulation and detection test bench, including a basic frame 1, a shaft roller bracket 2, a fixed shaft roller 3, a movable shaft roller 4, a bearing seat 5, and an easy-change bearing shell seat 6 , Shell seat position adjustment device 7, transmission device 8, lifting device 9, motor 10, vibration displacement measurement device 11, mass eccentricity adjustment device 12. One end of the shaft roller bracket 2 is hinged to the basic frame 1 through a rotating shaft, and the other end is connected to the lifting device 9 in floating contact; the fixed shaft roller 3 is fixedly connected to the shaft roller bracket 2 through the bearing seats at both ends and passed through a shaft coupling. It is connected with the motor 10; the roller of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com