Automatic welding machine for slurry pipe hoops

An automatic welding machine and mud technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low precision, poor welding quality, and long assembly time of positioning fixtures, and achieve high precision, ensure welding quality, and ensure the quality of welding. The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

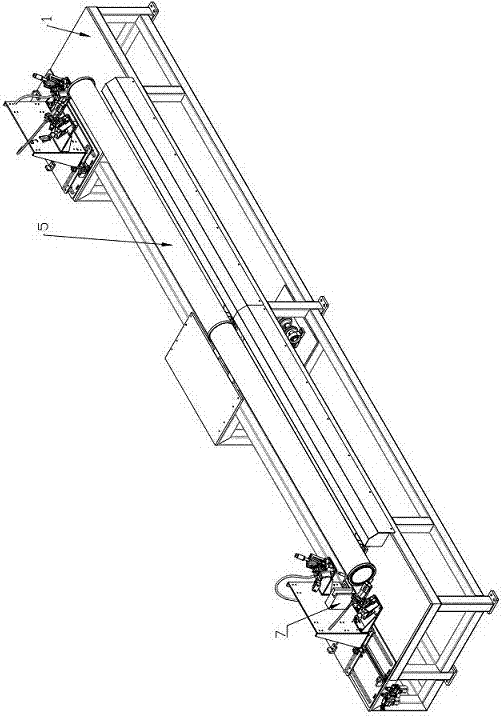

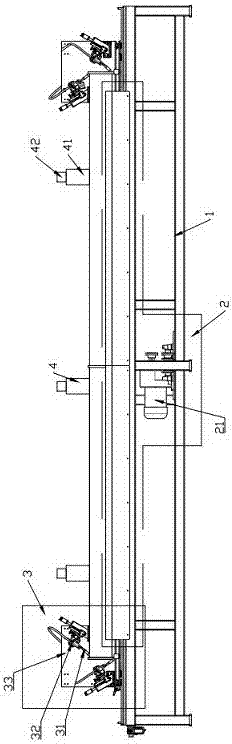

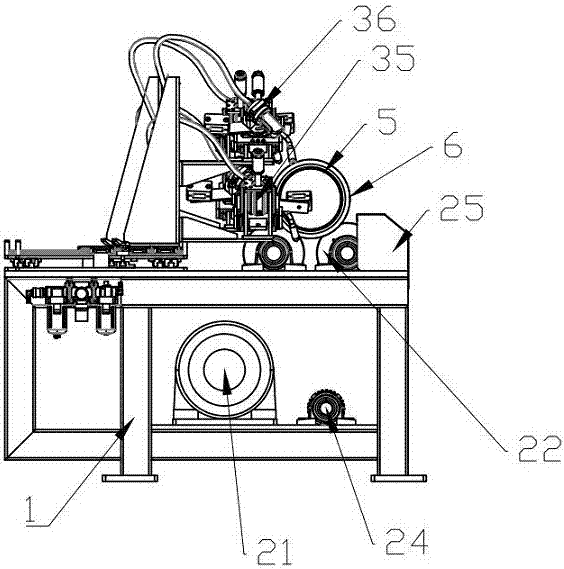

[0031] Embodiment 1: A kind of mud pipe hoop automatic welding machine, see Figure 1 to Figure 4 , the controller is electrically connected with the transmission mechanism 2, the gun feeding mechanism 3, and the pressing mechanism 4 installed on the frame 1; For the same two rotating rollers 33, the distance between the rotating rollers is not greater than the outer diameter of the pipe to be welded; the torch feeding mechanism 3 includes a welding torch 31 installed on the welding torch fixing platform, the welding torch 31 is connected with a welding torch adjusting member 32, and the welding torch fixing platform 33 Installed on rack 1;

[0032] The compression mechanism 4 includes two compression wheels 41 installed on the compression frame 42, the bottom of the compression frame 42 is fixed on the frame 1, and the compression wheels 41 are correspondingly installed above the welding pipe of the welding machine.

[0033] The outer surface of the pinch wheel 41 is covered...

Embodiment 2

[0041] Embodiment 2: The principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the sliding connection between the welding torch fixing table and the frame is realized by a slide rail, and a positioning element for fixing is provided on the slide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com