Food processor locking mechanism

A technology of food processor and locking mechanism, which is applied in home appliances, applications, kitchen utensils, etc. It can solve problems such as inconvenient access, accidental injury, food overflow and waste, etc., so that it is very easy to promote and use, avoid misuse, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

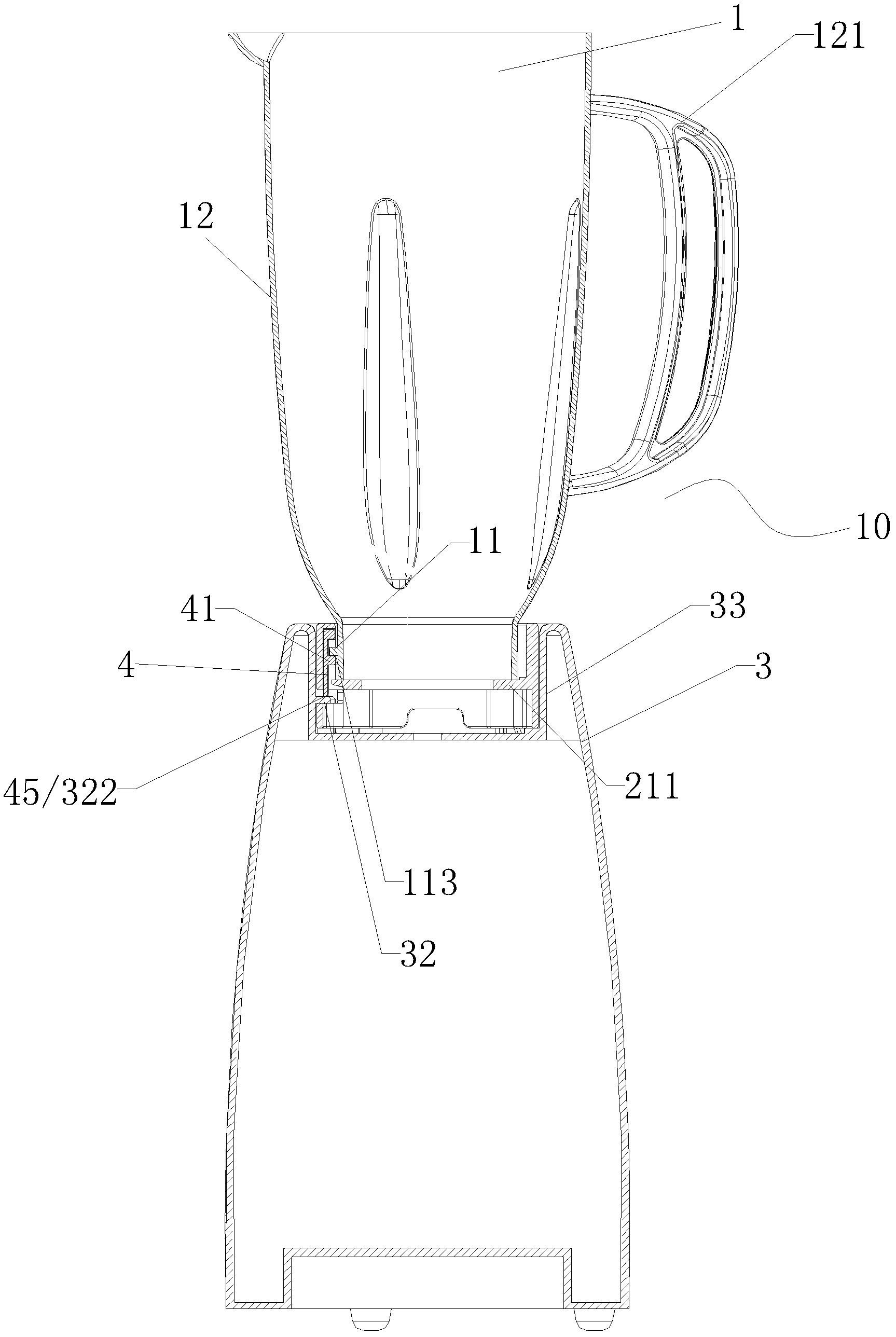

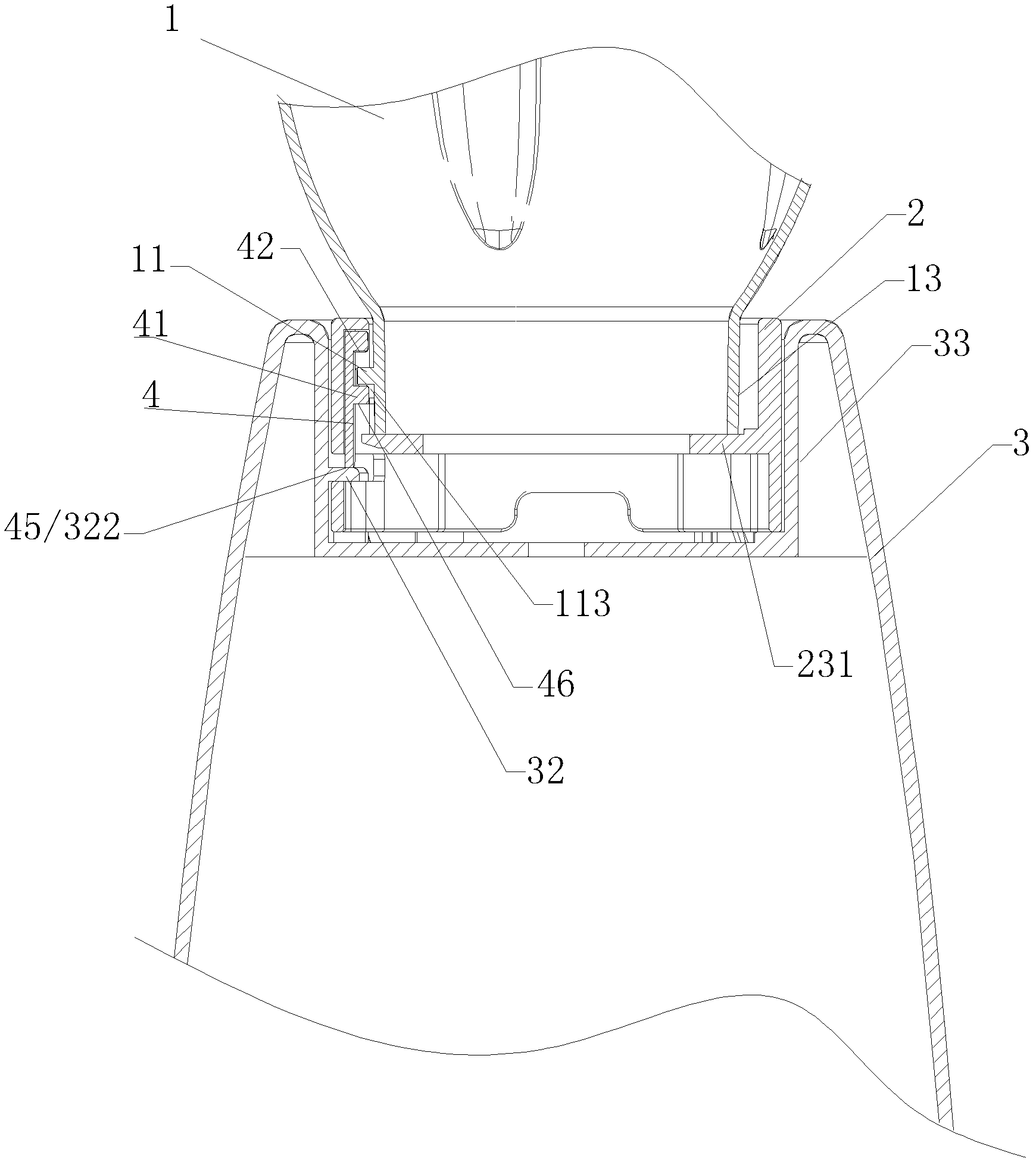

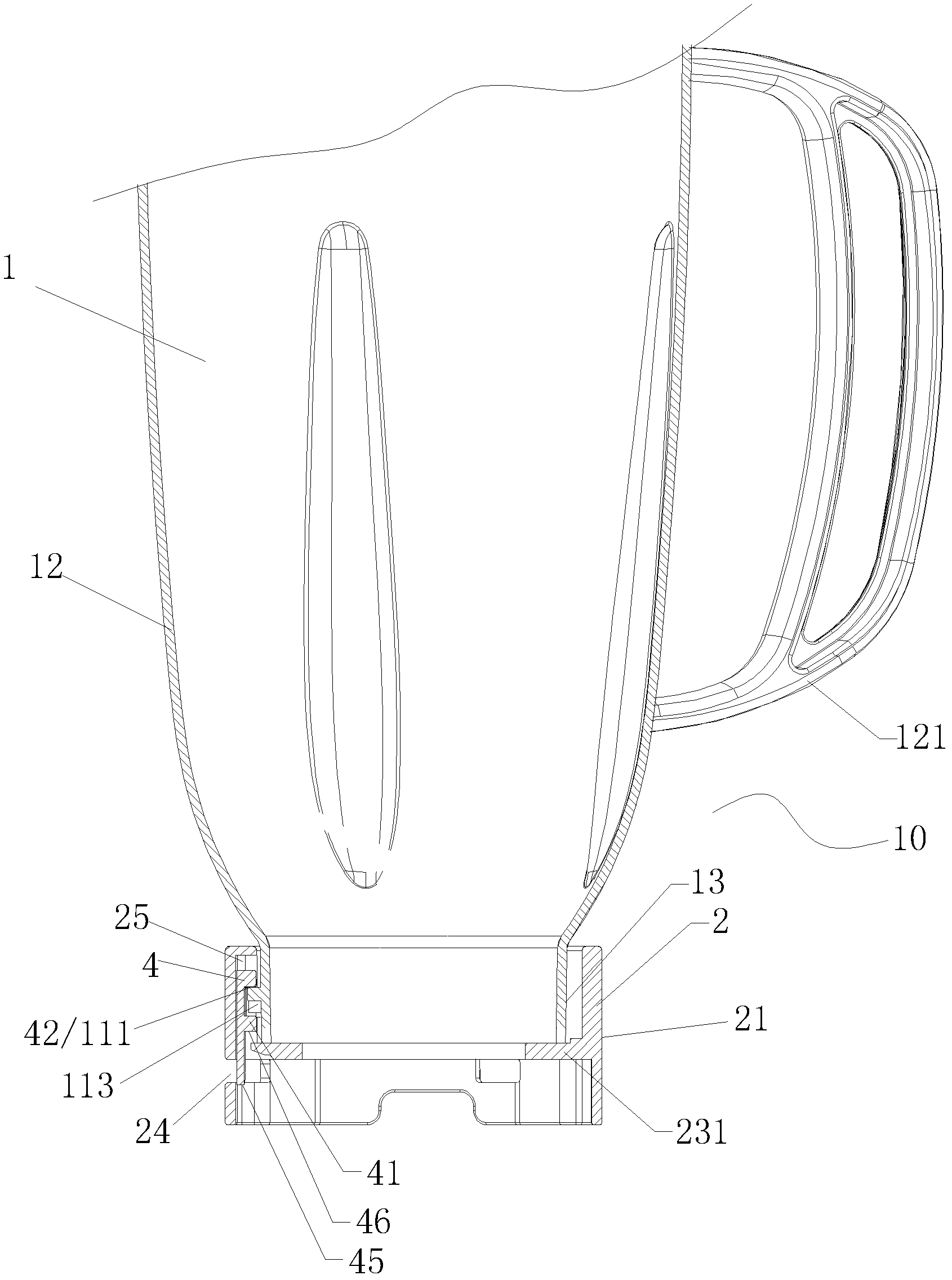

[0022] The invention discloses a locking mechanism of a food processor, please refer to Figure 1 to Figure 8 As shown, it includes a first structural member 1, a second structural member 3 and a connecting member 2, and the connecting member 2 is screwed with the first structural member 1 and the second structural member 3 in a convenient and separable manner. connection; the first structural member 1 and the connecting member 2 are composed into a first structural assembly 10; wherein: it also includes at least one locking block 4 installed on the connecting member 2, and the locking block 4 includes three Two working positions: initial position, first position and second position; when the connecting member 2 is separated from the first structural member 1 and the second structural member 3, the locking block 4 is in the initial position and locked The block 4 is supported and connected by the support structure of the connector 2; when the first structural member 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com