Method for preparing titanium niobium zirconium tin biomedical titanium alloys by discharge plasma sintering

A discharge plasma and biomedical technology, which is applied in the field of preparing titanium, niobium, zirconium and tin biomedical titanium alloys, can solve undiscovered problems, achieve short sintering time, fast heating and cooling speed, and improve composition segregation and tissue inhomogeneity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

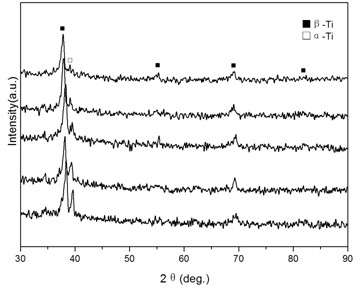

[0018] Example 1: The process steps of the method for preparing titanium niobium zirconium tin biomedical titanium alloy by spark plasma sintering are:

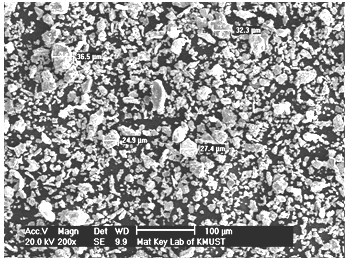

[0019] (1) According to the mass percentage (wt.%) of Ti64%, Nb24%, Zr4%, and Sn8%, weigh a total of 25 grams of Ti, Nb, Zr, and Sn metal powders with a purity of 99.9% and an average particle size of 45 μm;

[0020] (2) Put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 6 Pa, and then perform ball milling and mixing for 6 hours to obtain mixed metal powder;

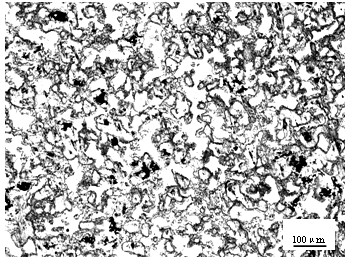

[0021] (3) Put the mixed metal powder into a cylindrical graphite mold with an inner diameter of 20mm, then put it into a spark plasma sintering furnace, and apply an axial pressure of 40 MPa through the punches at both ends of the graphite mold, and the system is vacuumed to Sinter after 2 Pa, heat up to 1100°C sintering temperature at a speed of 100°C / min, keep it warm for 5 minutes, keep an axial pressure of 40 MPa during ...

Embodiment 2

[0027] Example 2: The process steps of the method for preparing titanium niobium zirconium tin biomedical titanium alloy by spark plasma sintering are:

[0028] (1) According to the mass percentage (wt.%) of Ti73%, Nb22%, Zr4%, and Sn2%, weigh a total of 25 grams of Ti, Nb, Zr, and Sn metal powders with a purity of 99.9% and an average particle size of 40 μm;

[0029] (2) Put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 10Pa, and then ball mill and mix the powder for 6 hours to obtain the mixed metal powder;

[0030] (3) Put the mixed metal powder into a cylindrical graphite mold with an inner diameter of 20mm, then put it into a spark plasma sintering furnace, and apply an axial pressure of 40 MPa through the punches at both ends of the graphite mold, and the system is vacuumed to Sinter after 2 Pa, heat up to 1100°C sintering temperature at a speed of 100°C / min, keep it warm for 5 minutes, keep an axial pressure of 40 MPa throug...

Embodiment 3

[0034] Example 3: The process steps of the method for preparing titanium niobium zirconium tin biomedical titanium alloy by spark plasma sintering are:

[0035] (1) According to the mass percentage (wt.%) of Ti69%, Nb23%, Zr3%, and Sn5%, weigh a total of 25 grams of Ti, Nb, Zr, and Sn metal powders with a purity of 99.9% and an average particle size of 10 μm;

[0036] (2) Put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 8 Pa, and then perform ball milling and mixing for 12 hours to obtain mixed metal powder;

[0037] (3) Put the mixed metal powder into a cylindrical graphite mold with an inner diameter of 20 mm, and then put it into a spark plasma sintering furnace, and apply an axial pressure of 30 MPa through the punches at both ends of the graphite mold, and the system is vacuumed to After sintering at 4 Pa, heat up to 1000°C sintering temperature at a speed of 80°C / min, keep it warm for 8 minutes, and keep an axial pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com