Composite MC nylon steel core wheel casting equipment

A composite, nylon technology, applied in home appliances, other home appliances, household components, etc., can solve the problems of insufficient connection firmness, noise and unstable operation, and affect the normal use of elevators, so as to reduce vibration and noise, Strong firmness and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

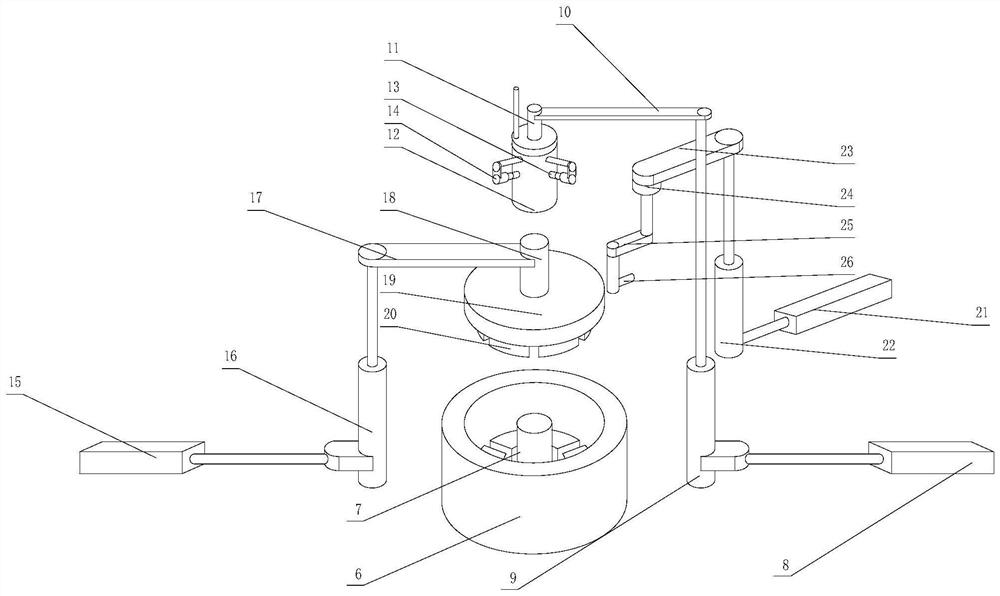

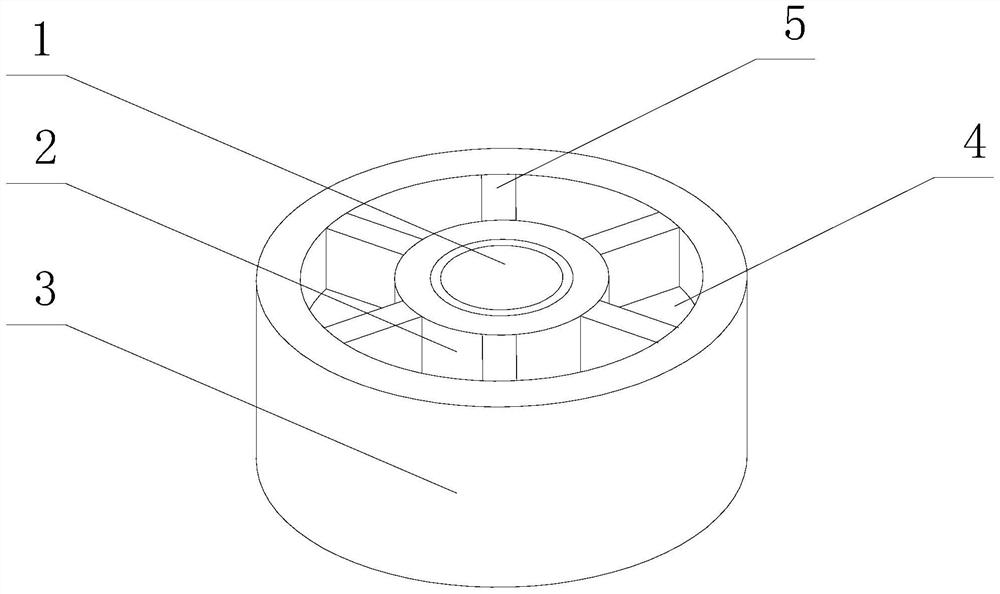

[0025] Such as Figure 1-Figure 2 As shown, a composite MC nylon steel core wheel casting equipment is provided in this embodiment, which includes a casting tank 6, a spacer cylinder 12, a cover plate 19 and two occupying units, and the casting tank 6 has a cylindrical Cavity, the top of the cavity is open, the cylinder 7 is fixed on the bottom wall of the cavity, the top of the cylinder 7 is located below the top of the cavity, and the cylinder 7 is arranged coaxially with the cavity;

[0026] The top of the limiting cylinder 12 is closed, the output end of the first horizontal moving device 8 is connected to the first lifting device 9, the output end of the first lifting device 9 is connected to the first connecting plate 10, and the first connecting plate 10 is provided with a second A connecting rod 11, the bottom end of the first connecting rod 11 is connected with the top wall of the limiting cylinder 12, the outer wall of the limiting cylinder 12 is fixed with a sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com