Method for preparing functionally-graded dental implant by metal 3D printing

A functionally gradient and dental implant technology, which is applied in dentistry, dental implants, dental restorations, etc., can solve problems such as leakage, looseness, and poor mechanical bonding, and achieve stress shielding effects, high strength requirements, and overcoming poor contact. The effect of fastness and fretting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

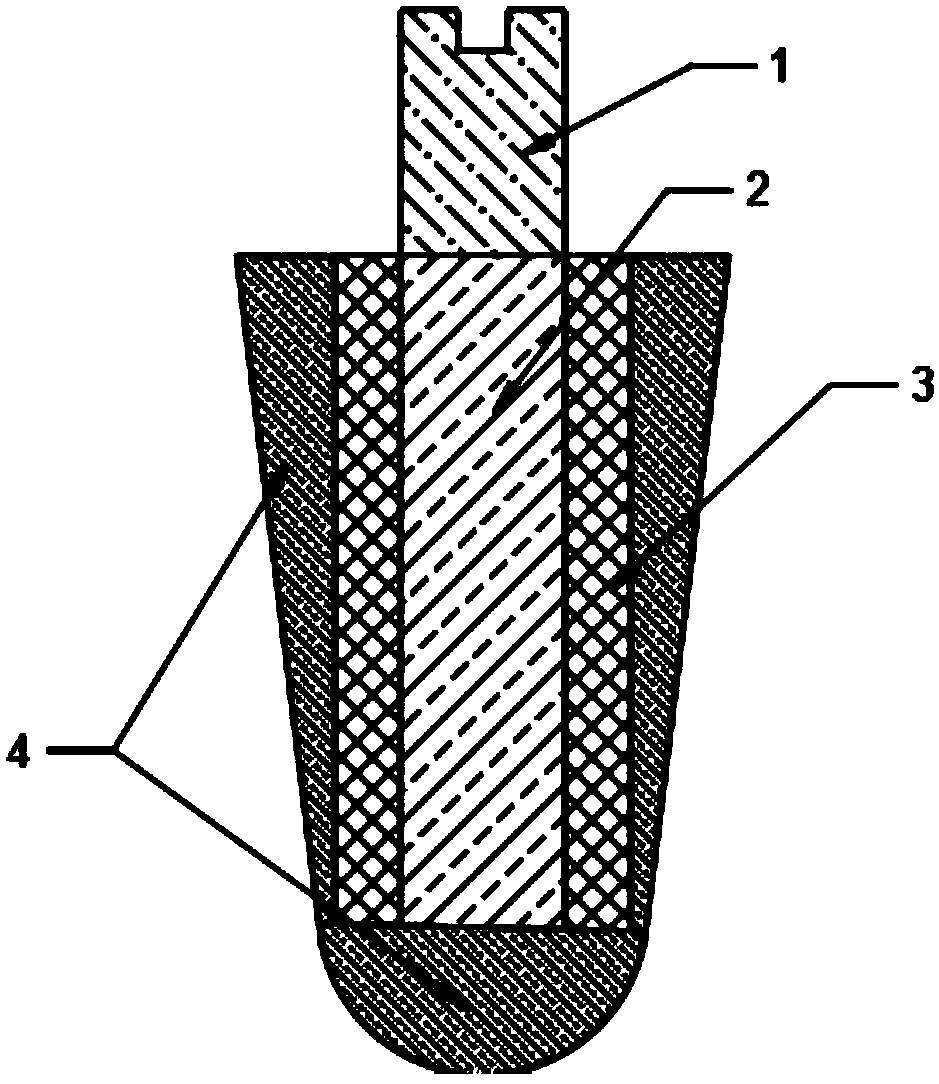

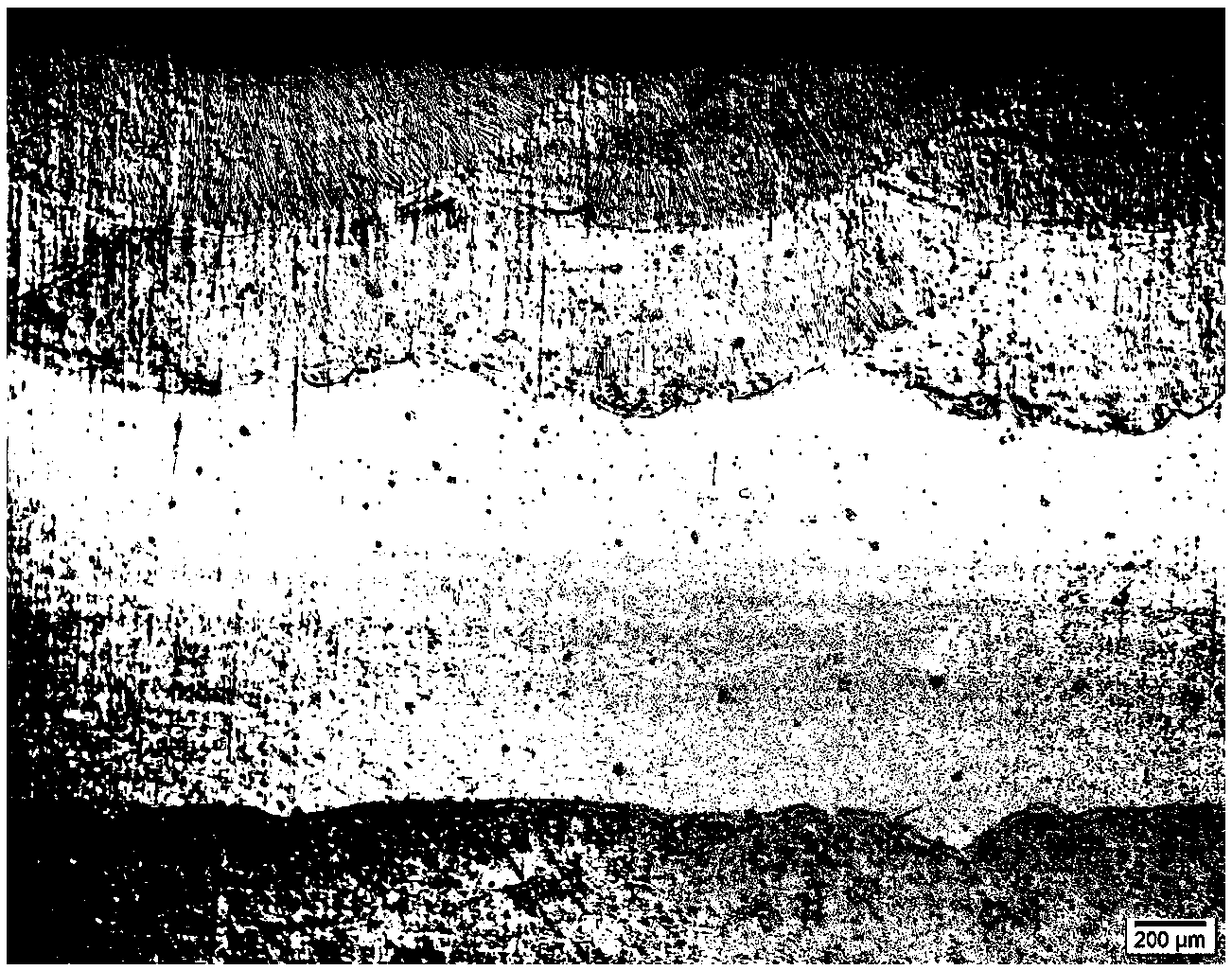

[0021] In this embodiment, the basic three-dimensional shape data of the dental implant body is obtained first by using medical imaging technology, and the three-dimensional shape data of the abutment are added to reconstruct a complete three-dimensional model of the dental implant.

[0022] The Ti6Al4V and β titanium alloy powders used in this example have an average particle size of 100 μm, wherein the titanium alloys are respectively Ti6Al4V and the promising β titanium alloy-"rubber metal" TNTZO, namely Ti-39Nb-3Ta-2Zr-0.35Owt. % alloy powder. Before manufacturing, the powder is baked in a vacuum heating oven for about 1 hour to remove the moisture contained in the powder to improve the fluidity of the powder.

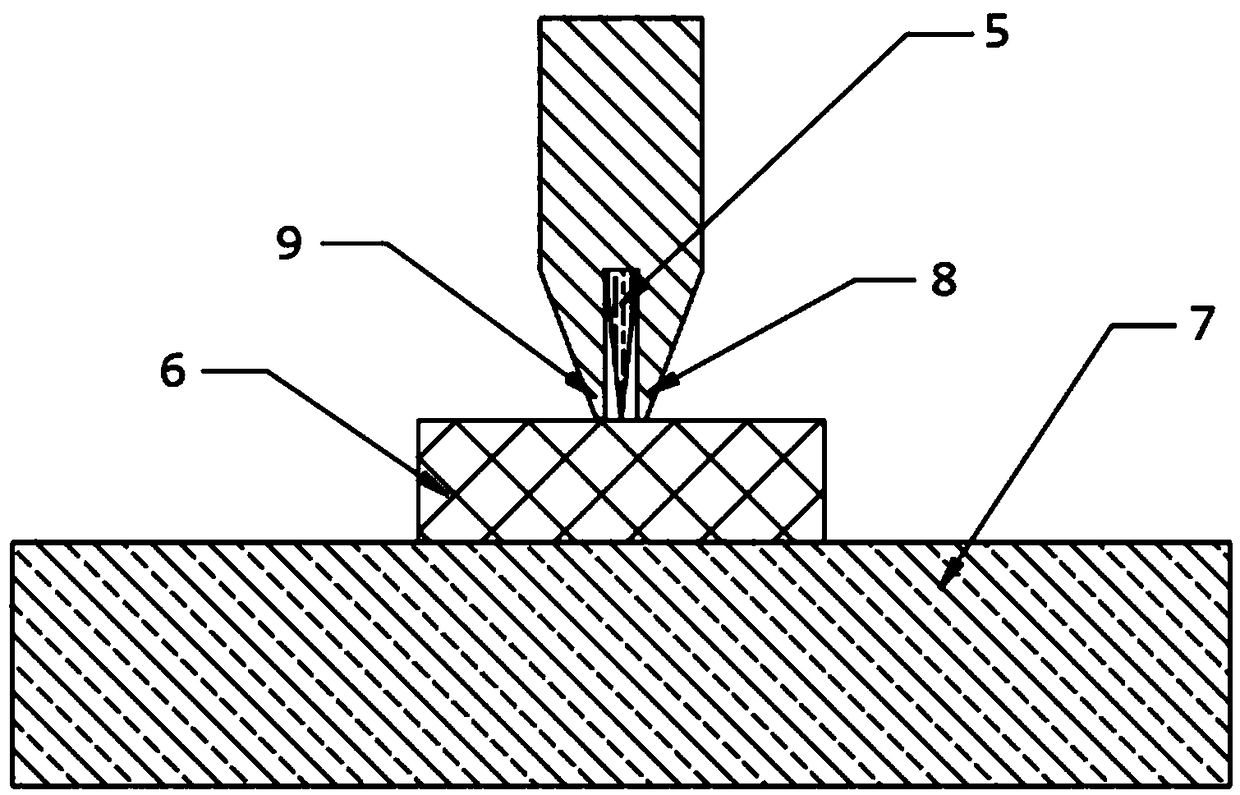

[0023] Such as figure 2 As shown, the specific steps of this embodiment are as follows: according to the set printing program, the selected laser power is 900W, the spot diameter is 1mm, and the energy size is Gaussian distribution; the scanning speed of the lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com