Preparation method of non-formaldehyde adhesive for thermal insulation material

A technology of formaldehyde-free adhesives and thermal insulation materials, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve problems such as environmental and human health impacts, achieve cost reduction, high bonding strength, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

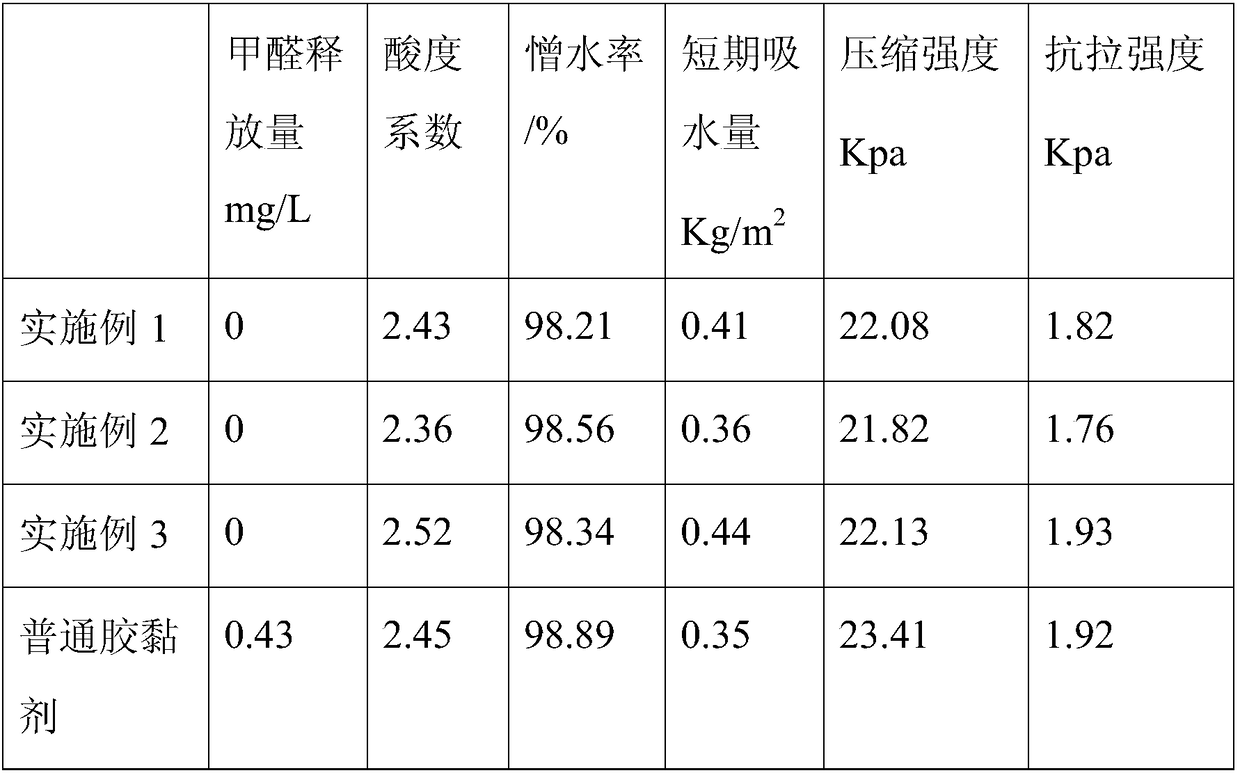

Examples

Embodiment 1

[0017] A method for preparing a formaldehyde-free adhesive for thermal insulation materials, the process comprising:

[0018] (1) Mix 10 parts of monobasic sugar and 2 parts of acid catalyst in parts by weight, start to stir, raise the temperature to 40°C, keep and fully dissolve, react at 80°C, add 20 parts of water into the reaction container and react for 20 minutes to obtain Formaldehyde-free adhesive mother liquor, monovalent sugars include fructose, glucose and galactose, the mixing ratio is 1:1:2, acid catalysts include hydrochloric acid and oxalic acid, and the mixing ratio is 1:1;

[0019] (2) Stir 100 parts of formaldehyde-free adhesive mother liquor, 0.1 part of silane coupling agent, 1 part of curing agent, and 0.5 part of water-repellent agent in parts by weight to obtain a non-formaldehyde-free adhesive that can be directly applied to thermal insulation materials. Aldehyde adhesive, silane coupling agent is vinyl trichlorosilane, curing agent is sodium hydroxide,...

Embodiment 2

[0021] A method for preparing a formaldehyde-free adhesive for thermal insulation materials, the process comprising:

[0022] (1) Mix 40 parts of monobasic sugar and 8 parts of acid catalyst in parts by weight, start stirring, raise the temperature to 55°C, keep and fully dissolve, react at 90°C, add 60 parts of water into the reaction container and react for 100 minutes Obtain the formaldehyde-free adhesive mother liquor, the monovalent sugar includes fructose, glucose and galactose, its mixing ratio is 1:1:2, and the acid catalyst is acetic acid;

[0023] (2) Stir 100 parts of formaldehyde-free adhesive mother liquor, 2 parts of silane coupling agent, 10 parts of curing agent, and 3 parts of water-repellent agent in parts by weight to obtain the non-formaldehyde adhesive that can be directly applied to thermal insulation materials. Aldehyde adhesive, silane coupling agent is vinyl trichlorosilane, curing agent is ammonium chloride, water repellent is modified methyl hydrogen...

Embodiment 3

[0025] A method for preparing a formaldehyde-free adhesive for thermal insulation materials, the process comprising:

[0026] (1) Mix 60 parts of monobasic sugar and 15 parts of acid catalyst in parts by weight, start stirring, raise the temperature to 60°C, keep and fully dissolve, react at 100°C, add 80 parts of water into the reaction vessel and react for 180 minutes Obtain the formaldehyde-free adhesive mother liquor, the monovalent sugar includes fructose, glucose and galactose, and its mixing ratio is 1:1:2, and the acid catalyst is tartaric acid and malic acid, and its mixing ratio is 1:2;

[0027] (2) Stir 100 parts of formaldehyde-free adhesive mother liquor, 3 parts of silane coupling agent, 20 parts of curing agent, and 5 parts of water-repellent agent in parts by weight to obtain the non-formaldehyde adhesive that can be directly applied to the insulation material. Aldehyde adhesive, the silane coupling agent is γ-chloropropyltrimethoxysilane, the curing agent is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com