High-airtightness fire gate valve

A high airtight and fire-fighting technology, applied in shaft seals, valve devices, valve details, etc., can solve problems such as transmission medium pollution, and achieve the effects of overcoming failure, safety and excellent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

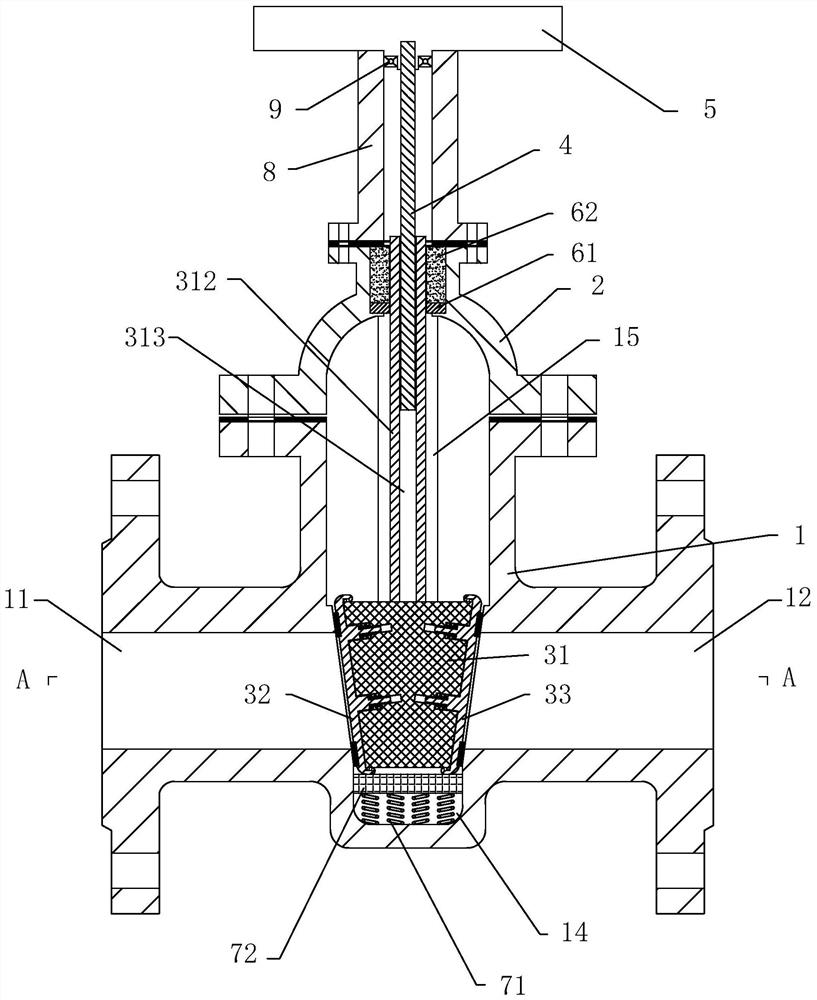

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

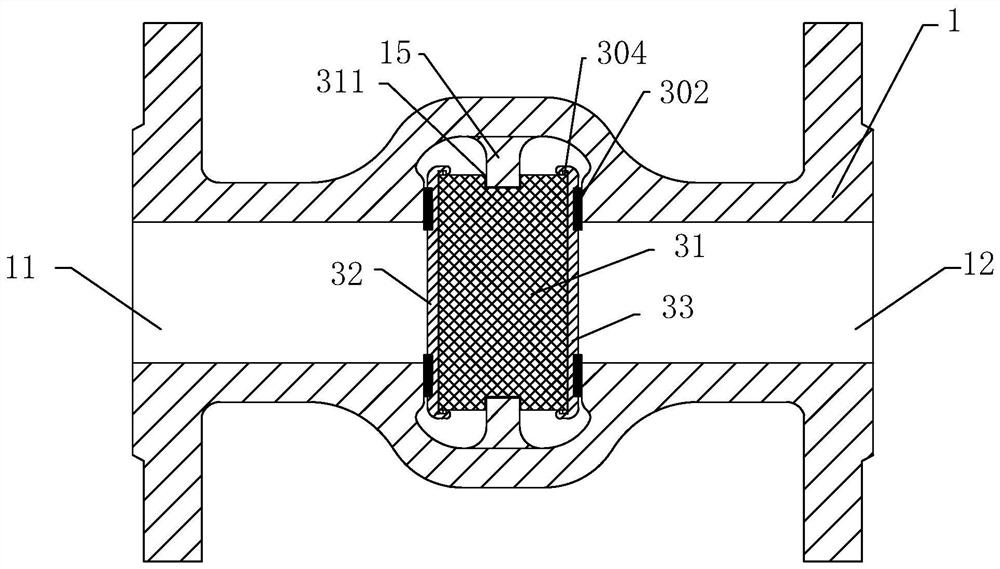

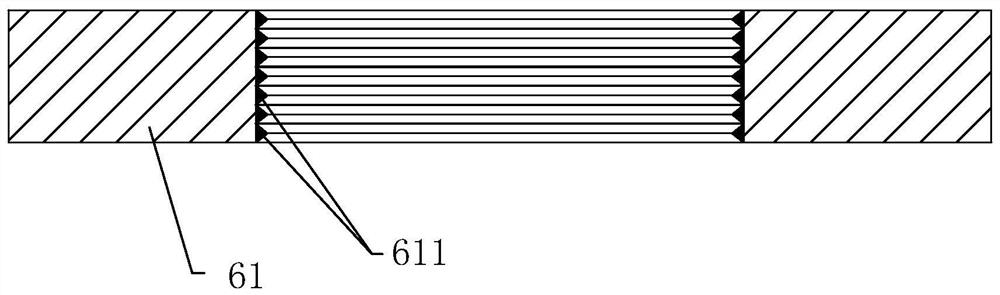

[0026] refer to Figure 1 to Figure 6 , this embodiment provides a highly airtight fire gate valve, including a valve body 1, a valve cover 2, a gate assembly 3, a valve stem 4 and a hand wheel 5, and the valve cover 2 is installed on the top of the valve body 1 by bolts , the valve body 1 is provided with a feed port 11 and a discharge port 12 arranged coaxially, and between the feed port 11 and the discharge port 12 is a flow channel 13 for medium circulation, and the gate assembly 3 Set in the flow channel to block the flow channel 13, the bottom of the flow channel 13 is provided with a gate groove 14, the lower end of the valve stem 4 penetrates into the valve body 1 from the valve cover 2 and is screwed with the gate assembly 3 Connected, the upper end of the valve rod 4 is fixedly connected with the handwheel 5.

[0027] Define the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com