Patents

Literature

335results about How to "Not easy to misplace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

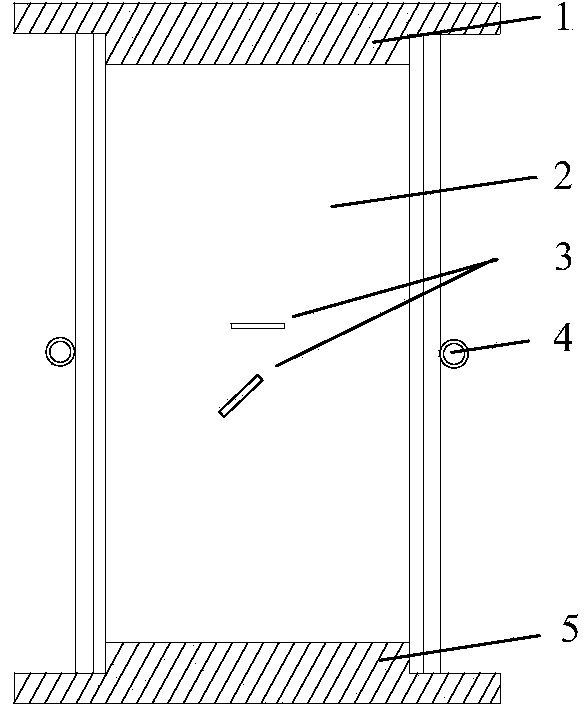

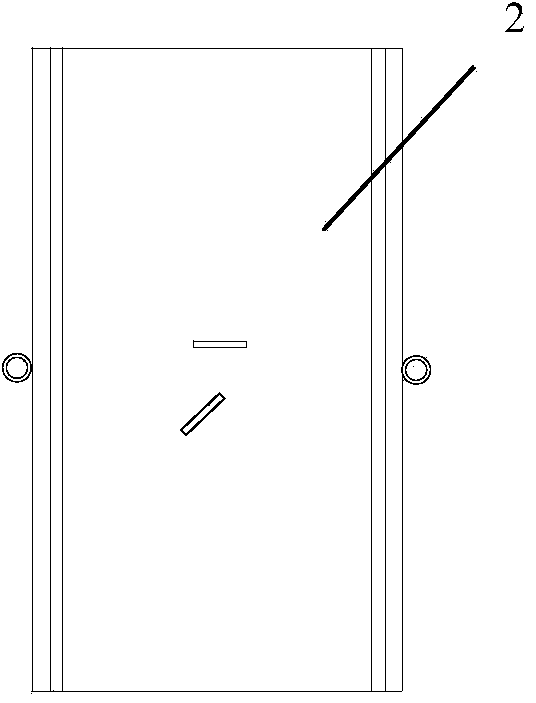

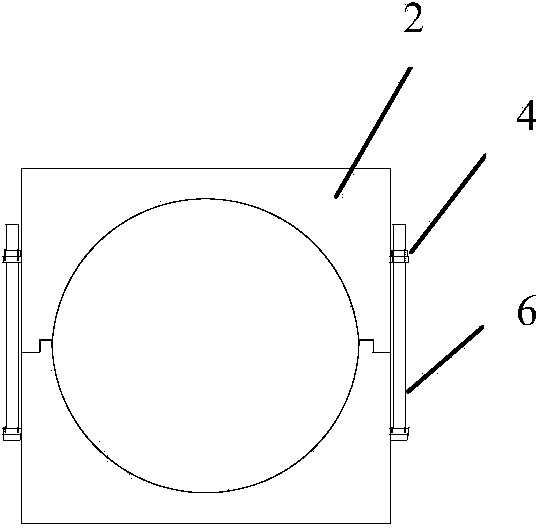

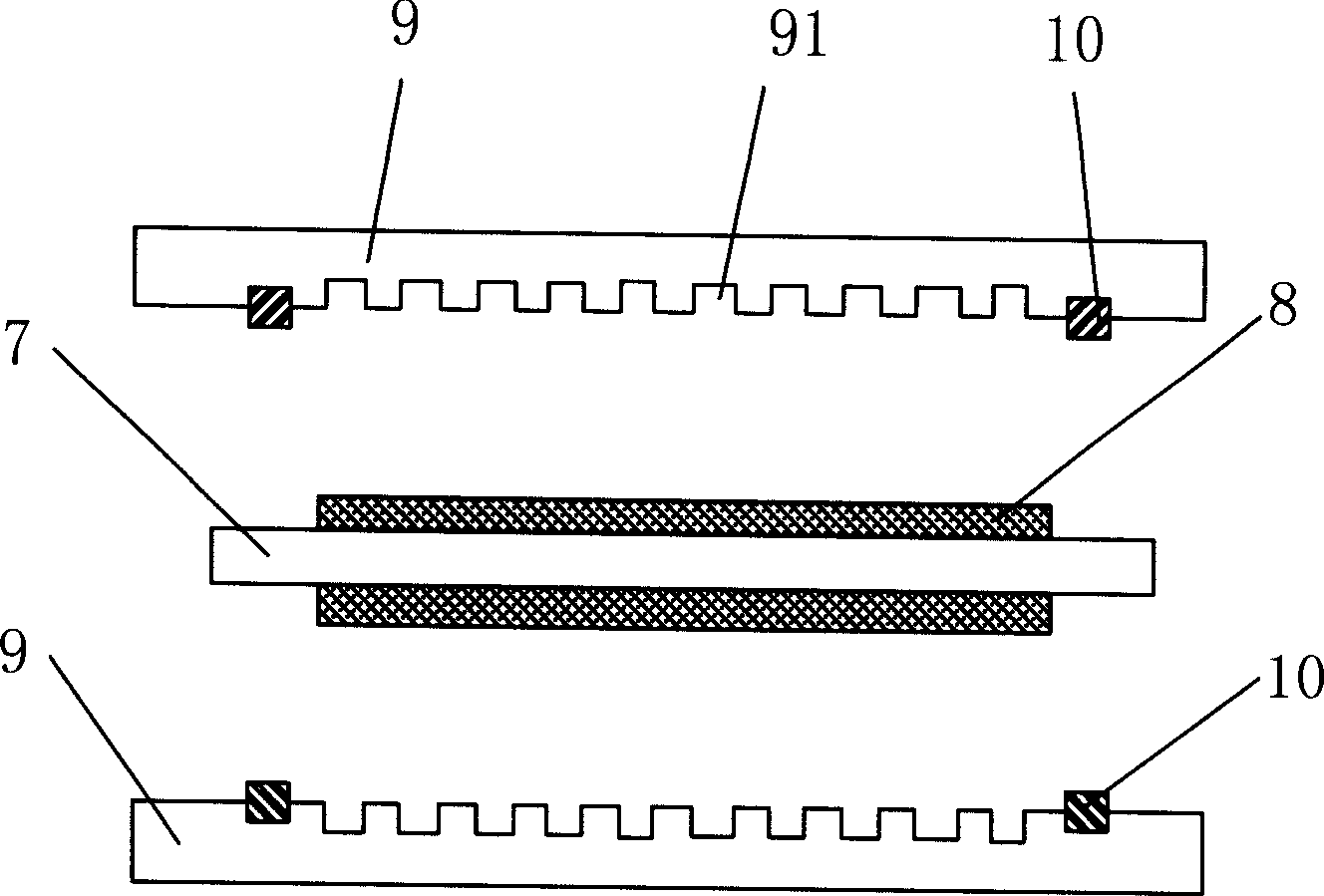

Rock test piece die for triaxial compression test on intermittent double-fracture rock

ActiveCN103900882AEasy to processSimple structurePreparing sample for investigationEngineeringTriaxial compression

The invention discloses a rock test piece die for triaxial compression test on an intermittent double-fracture rock. The rock test piece die for the triaxial compression test on the intermittent double-fracture rock comprises a base and a middle frame die arranged on the base, wherein a gland is arranged on the top of the middle frame die; the middle frame die consists of two modules which are symmetrically buckled together and are provided with semicircular slots; fixing lugs are symmetrically arranged on the side walls of the two modules respectively; a bolt for integrally fixing the two modules is sleeved with the fixing lugs in a penetrating manner; rectangular wide slots for enabling a rectangular steel sheet to penetrate through and be positioned between the two modules are formed in the middle parts of the two modules. Compared with the prior art, the rock test piece die has the advantages of simple structure, easiness in machining, convenience in dismounting and mounting and fracture positioning accuracy; the precision and the efficiency for preparing a intermittent fracture rock material test piece.

Owner:CHINA UNIV OF MINING & TECH

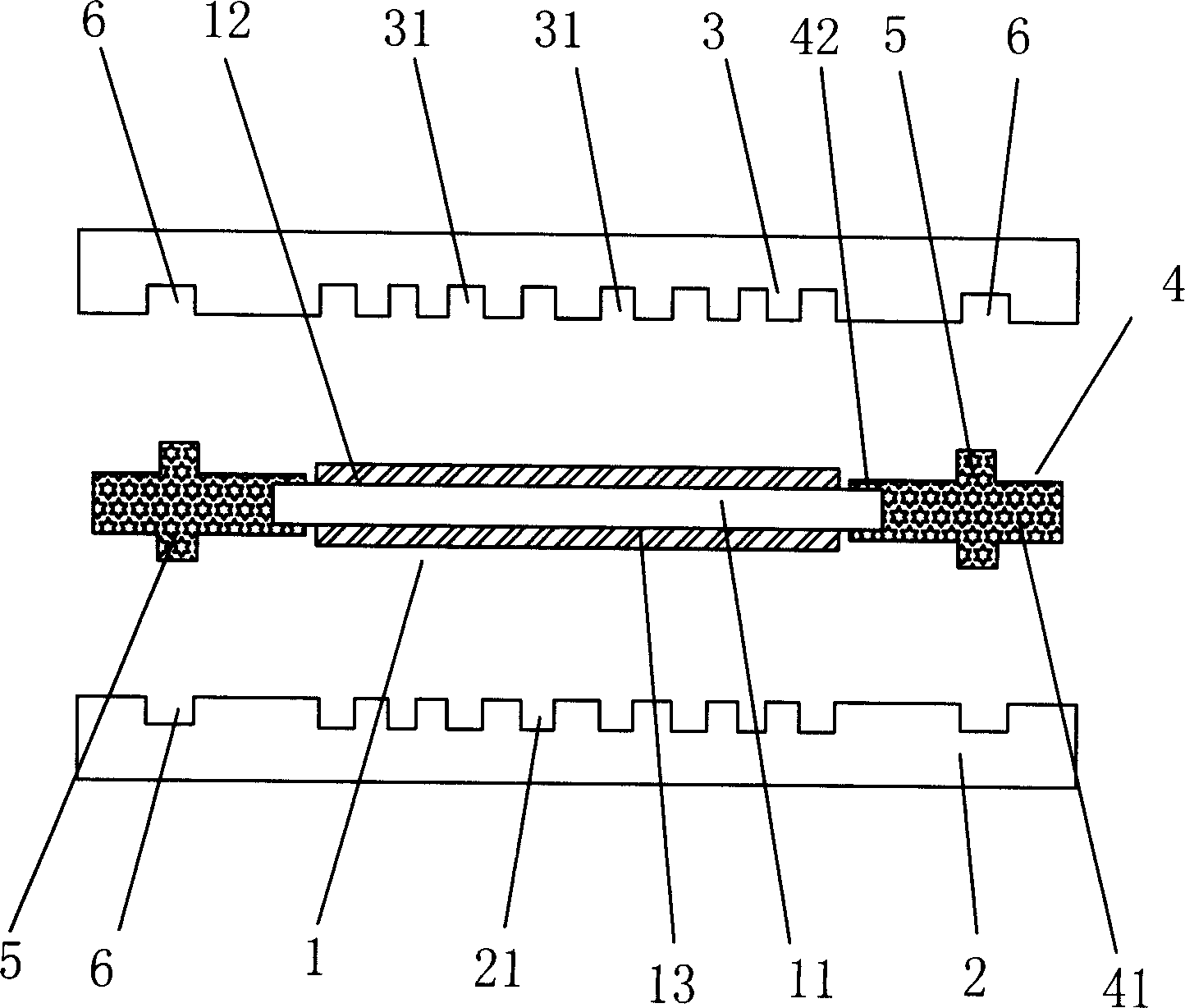

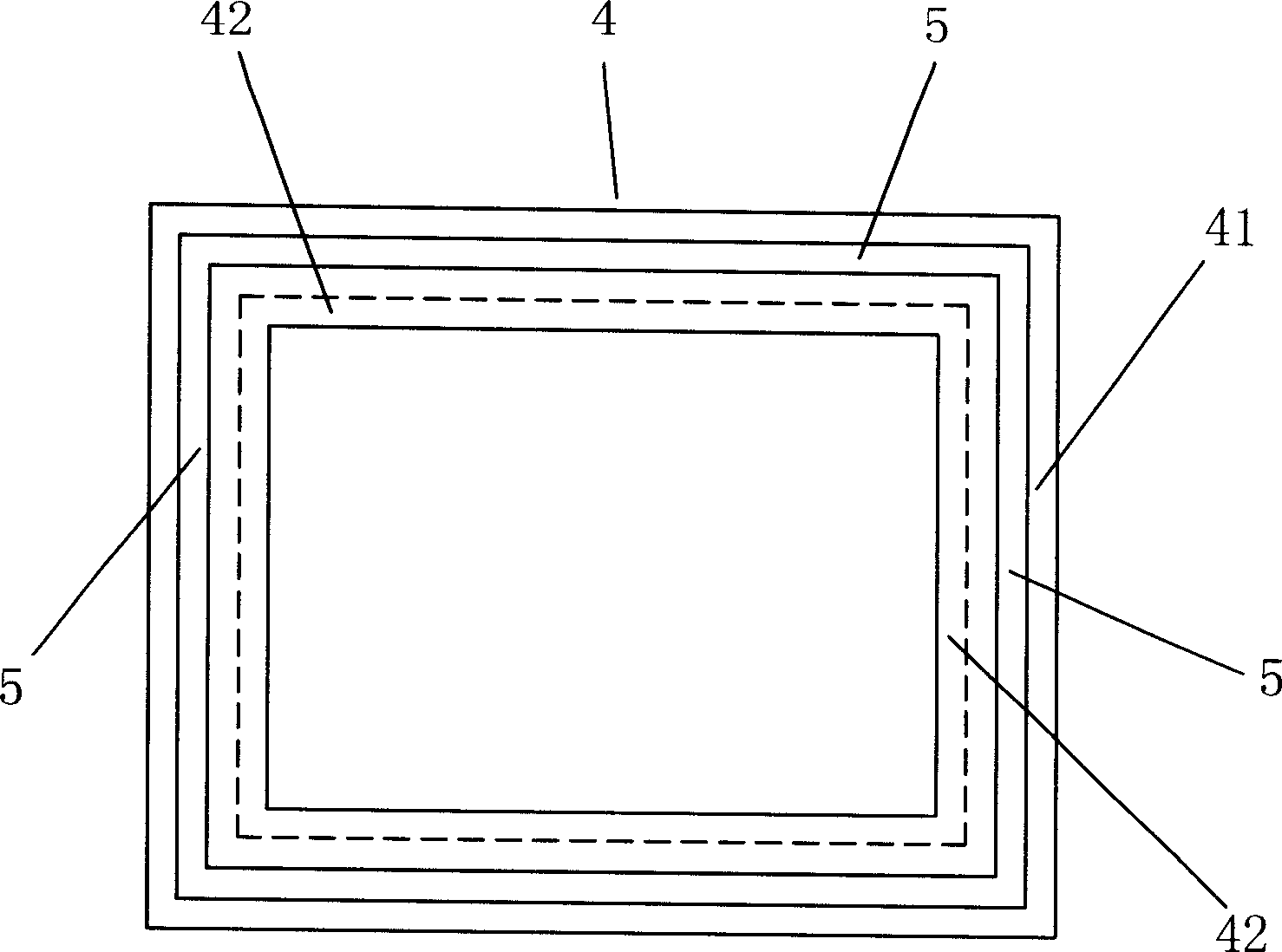

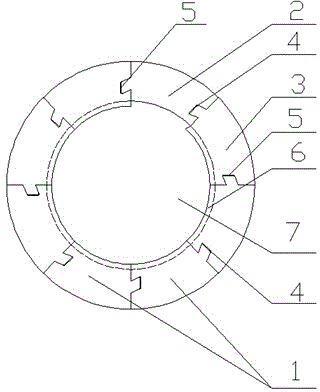

Sealing device of proton exchanging film fuel cell unit

InactiveCN1858926AImprove sealingNot easy to slideSolid electrolyte fuel cellsSealing/support meansProtonEngineering

This invented sealing device of a proton exchange film fuel battery unit includes a membrane electrode component, a sealing element, an anode diversion pole plate and a cathode diversion pole plate clamping said membrane electrode component, which includes a proton exchange film and an anode and a cathode adhered at its either side, the sealing element jackets on the circumference of the film and joints with it having a first locating piece facing to the side of the diversion pole plate and a second locating piece matching to and corresponding to the first locating piece is set on the pole plate and the first one is a hump formed from the surface of the sealing element and the second one is a sealing groove formed from the surface of the pole plate facing to the membrane electrode, in which, the two diversion pole plates will not slide due to the design of the two locating pieces.

Owner:BYD CO LTD

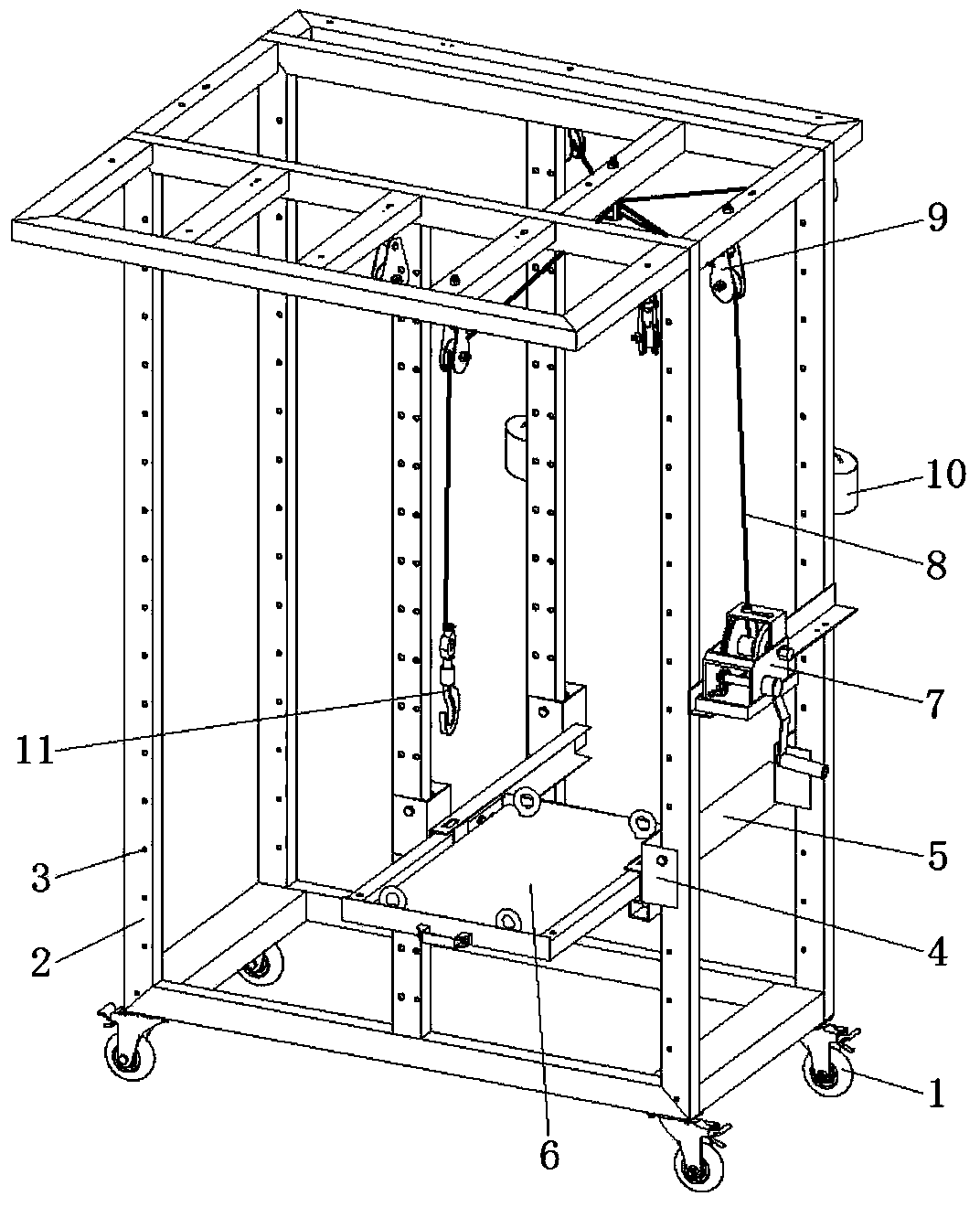

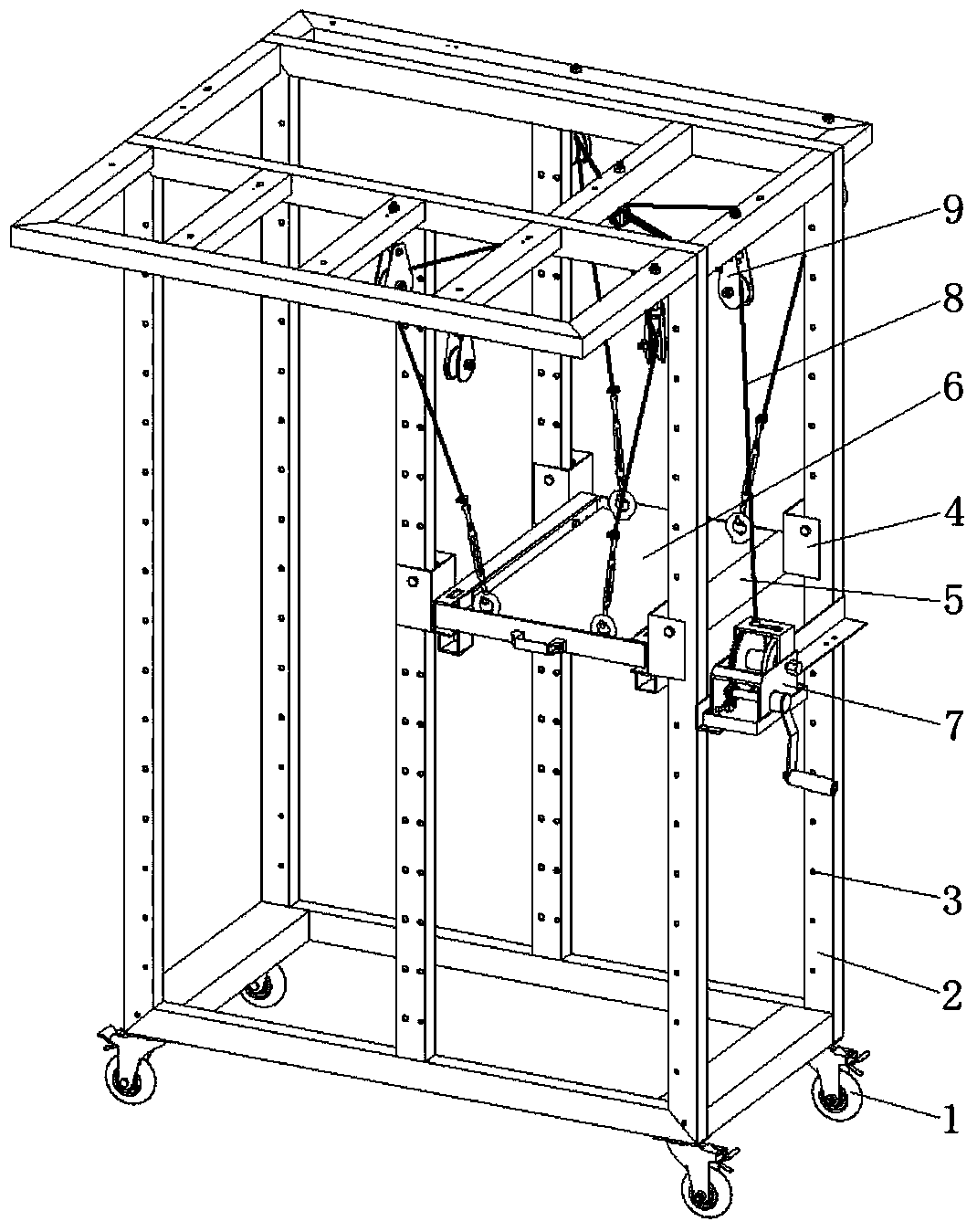

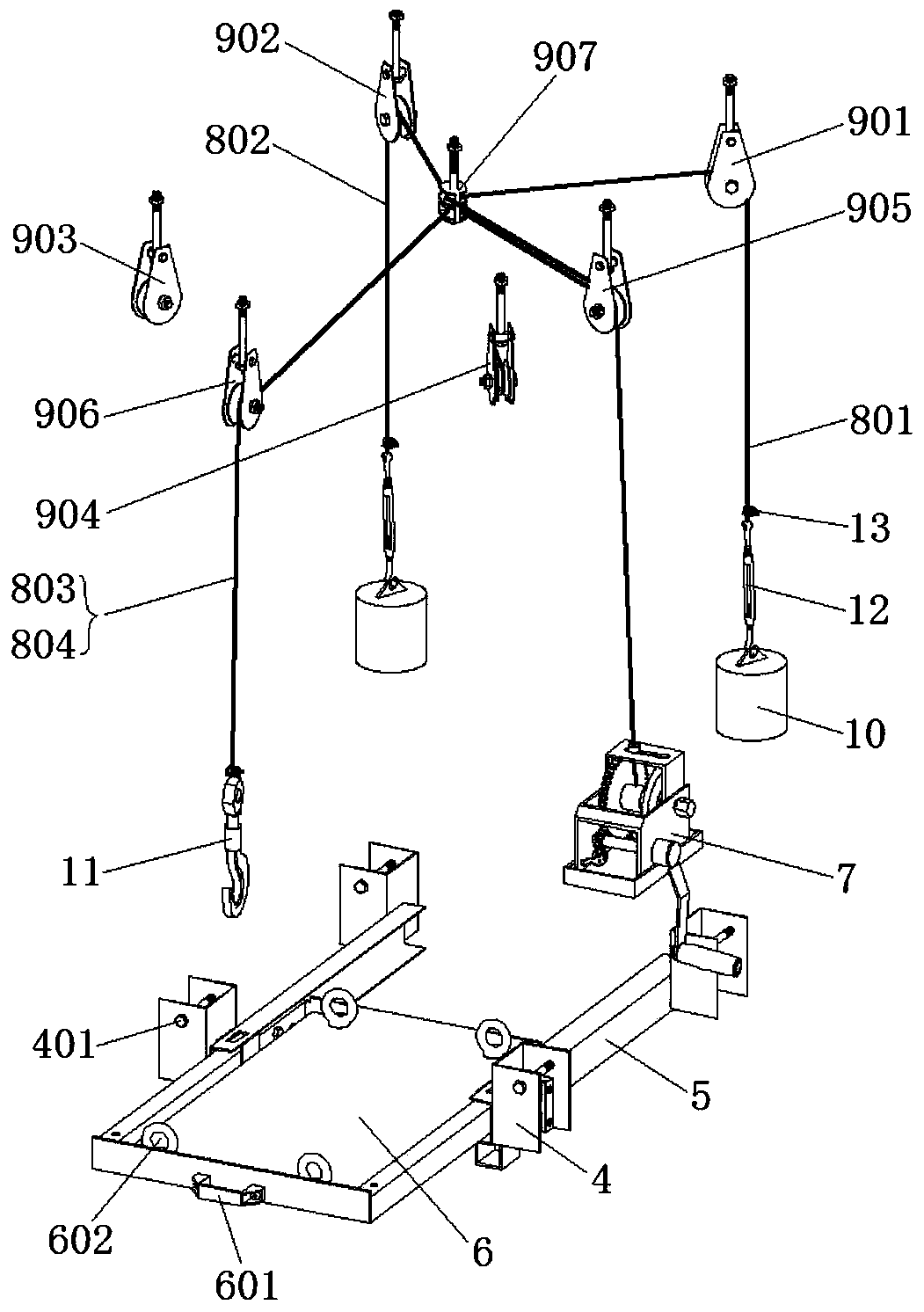

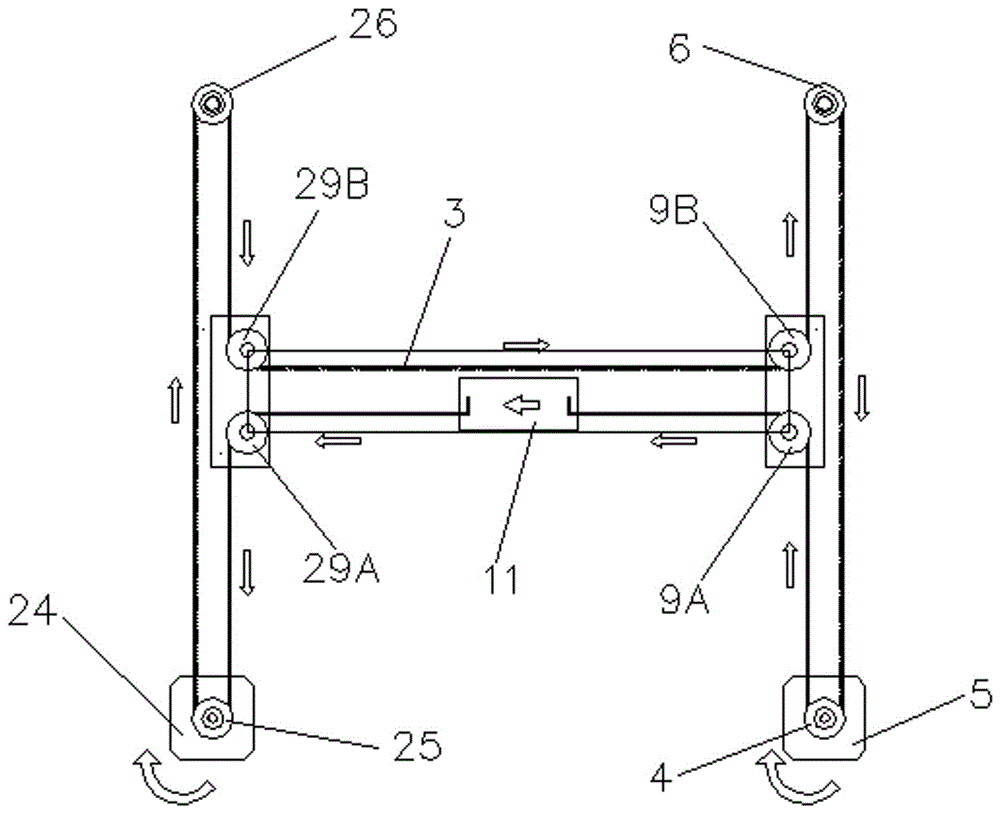

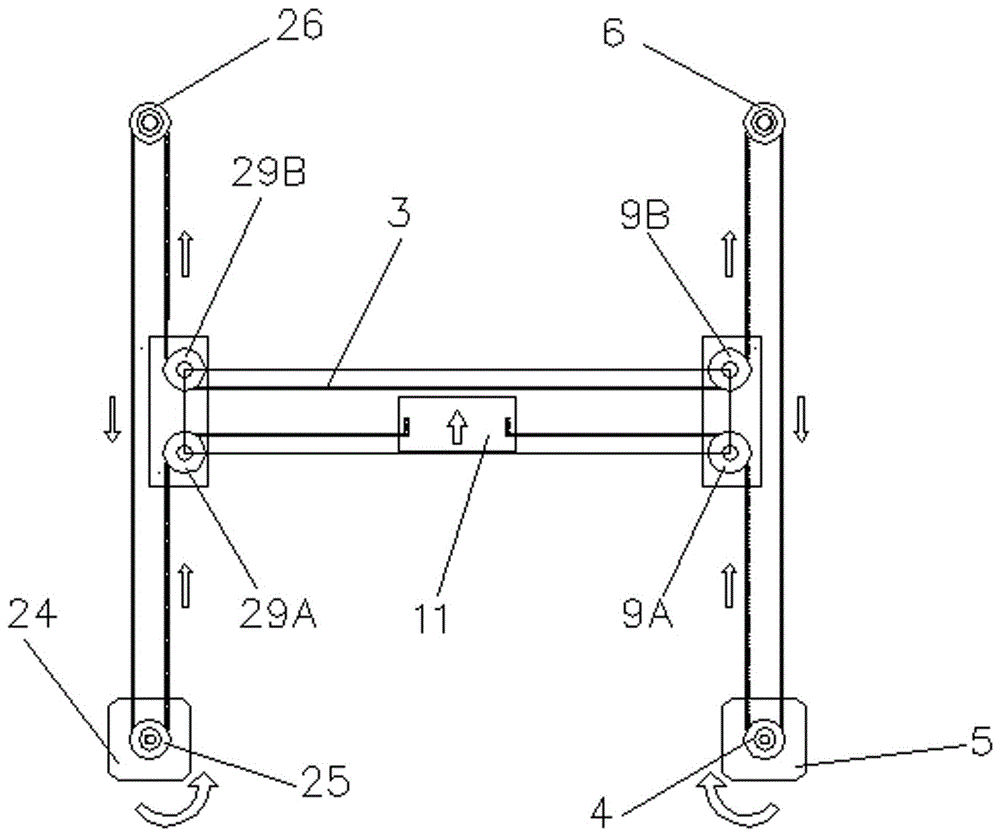

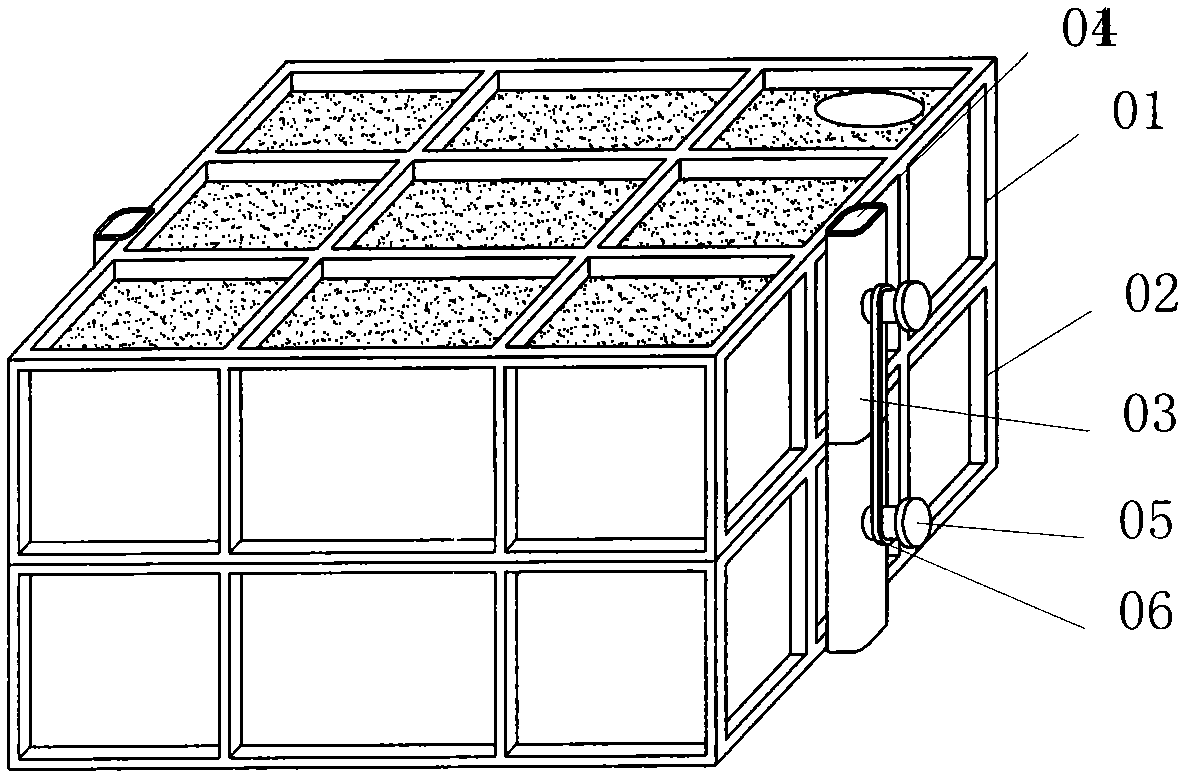

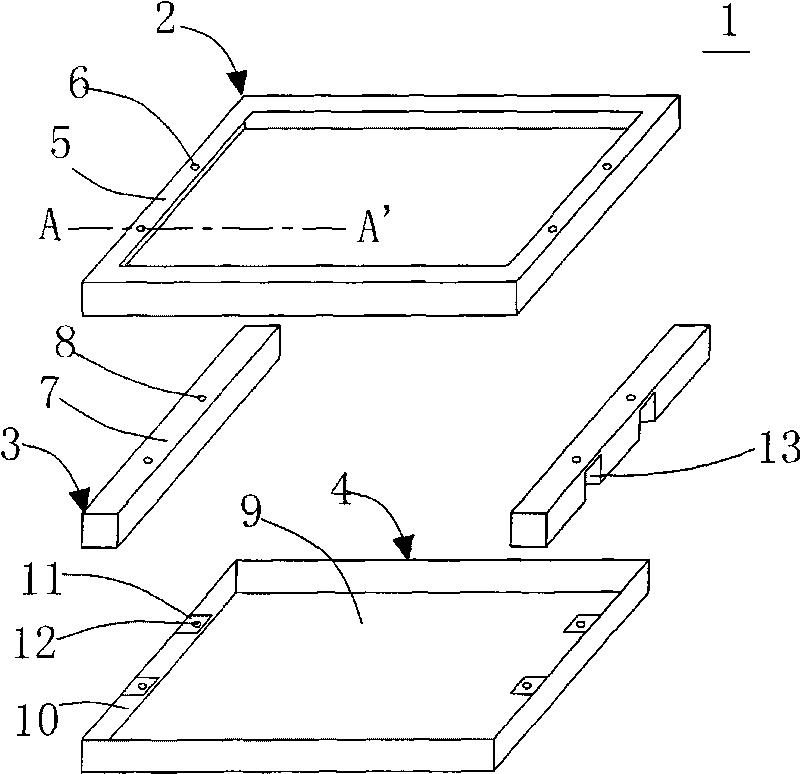

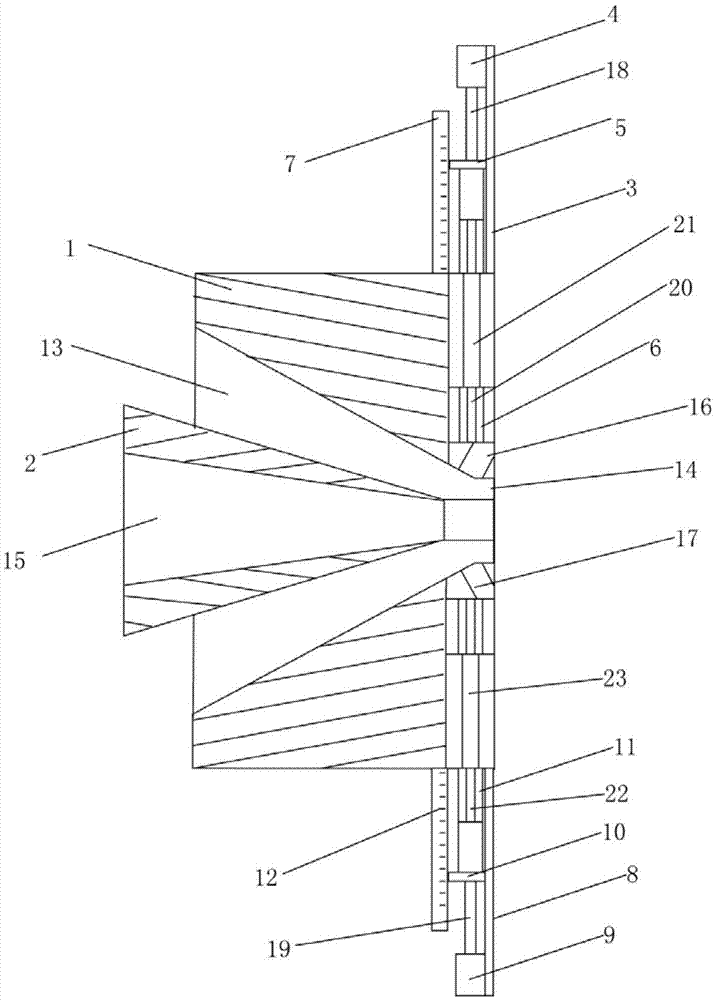

Self-loading and unloading heavy-load shelf with adjustable layer interval

ActiveCN104210796ARealize spacing adjustmentAchieve mechanical propertiesWinding mechanismsStorage devicesBlock and tackleWinch

The invention discloses a self-loading and unloading heavy-load shelf with an adjustable layer interval, and belongs to the field of shelves. The self-loading and unloading heavy-load shelf comprises a main framework, a layered frame, a manual winch, steel wire ropes, a pulley block, a heavy object and a lifting hook, wherein the layered frame comprises rolling lifting sliding sleeves, heavy-load slide rails and a tray; the heavy-load slide rails are arranged on both sides of the tray, and are arranged on vertical columns of the main framework through the rolling lifting sliding sleeves arranged at the two ends of the heavy-load slide rails; the manual winch is fixed on one side of the main framework, and four steel wire ropes are led out of the manual winch; after the steel wire ropes pass through the pulley block on the top of the main framework, two of the steel wire ropes are combined together and are connected with the hoisting hook, and the other two steel wire ropes are connected with the heavy object; hoisting rings are arranged on the four corners of the tray respectively and are correspondingly connected with the four steel wire ropes, and the tray is lifted or lowered through the manual winch. By adopting the self-loading and unloading heavy-load shelf, the height of a laminate can be adjusted under the condition that the laminate is under load; moreover, loading and unloading of heavy goods can be realized, and the self-loading and unloading heavy-load shelf is particularly suitable for storing heavy goods.

Owner:常州东吉路国际贸易有限公司

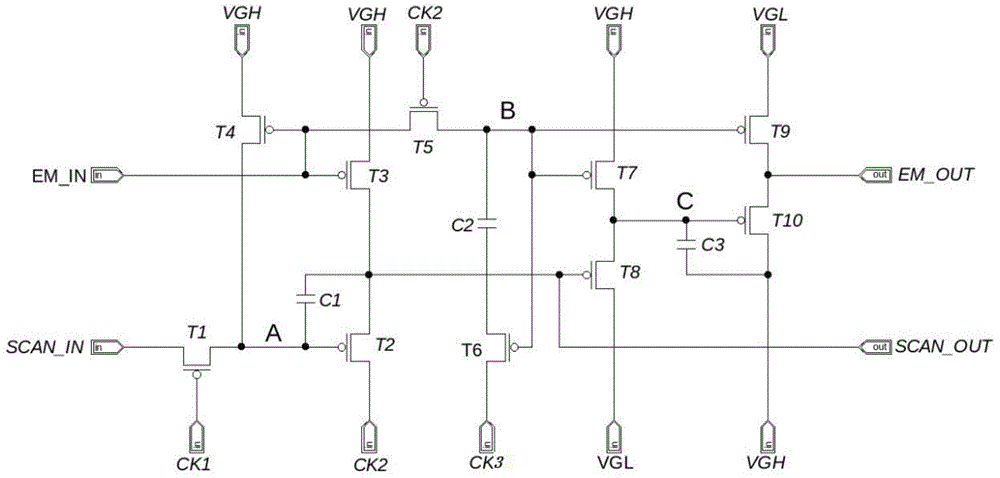

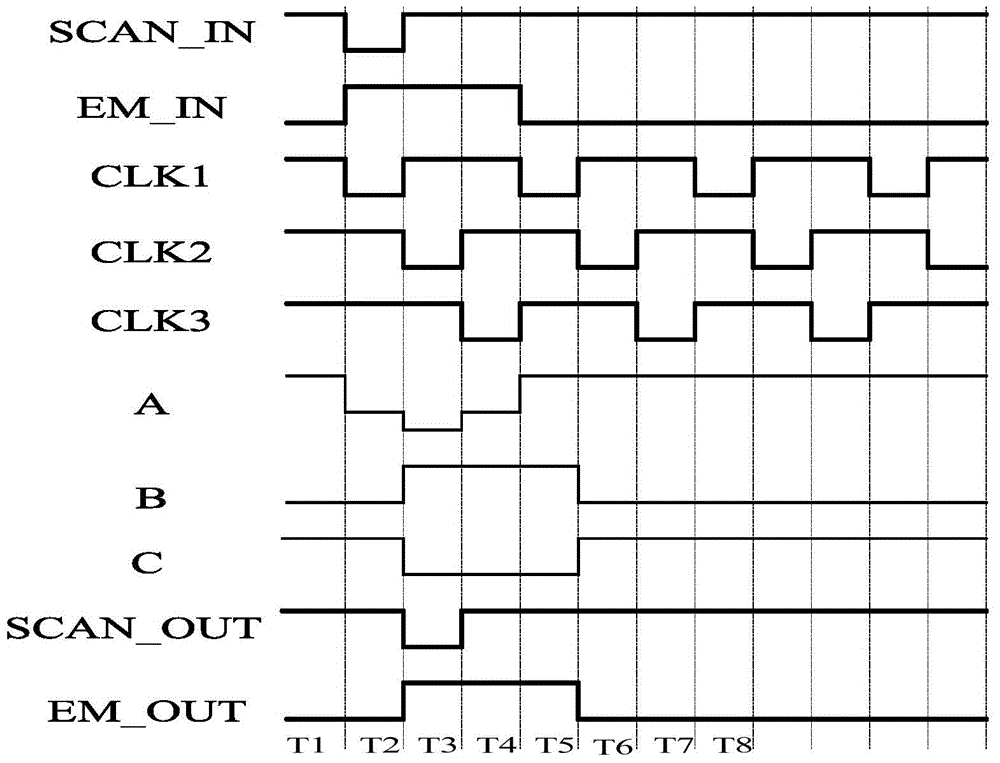

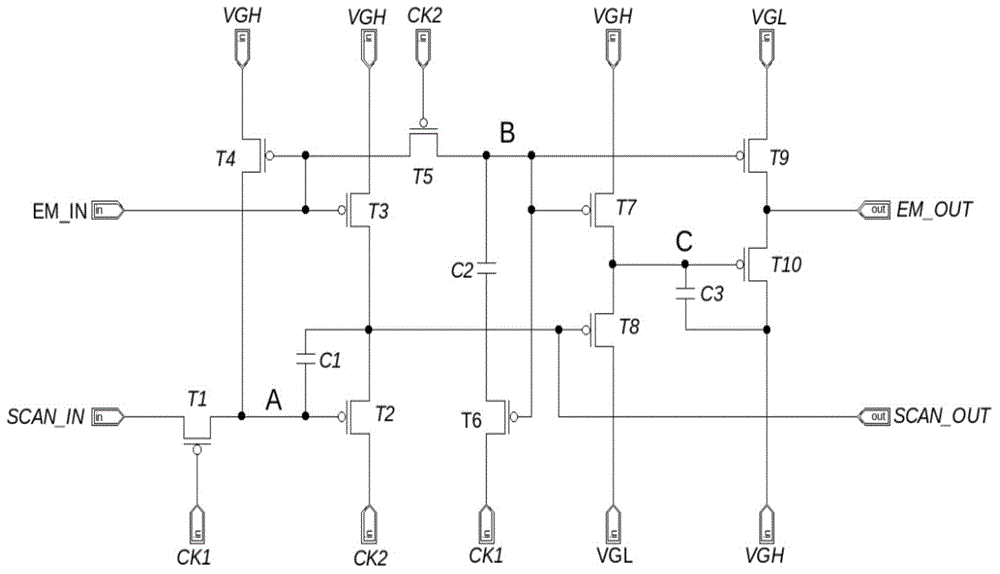

GOA unit circuit and GOA circuit

ActiveCN105223746AReduce the numberConducive to narrow bezel designStatic indicating devicesNon-linear opticsCapacitanceCapacitor

The invention discloses a GOA unit circuit comprising first to tenth film transistors, first to third capacitors, a SCAN signal input end, an EM signal input end, a SCAN signal output end, an EM signal output end, first to third clock signal ends, a high level end, a low level end, and A to C circuit nodes. The invention also discloses a GOA circuit; the number of film transistors and capacitors needed by the GOA unit circuit can be reduced, and the output signal is stable with no offset.

Owner:TRULY HUIZHOU SMART DISPLAY

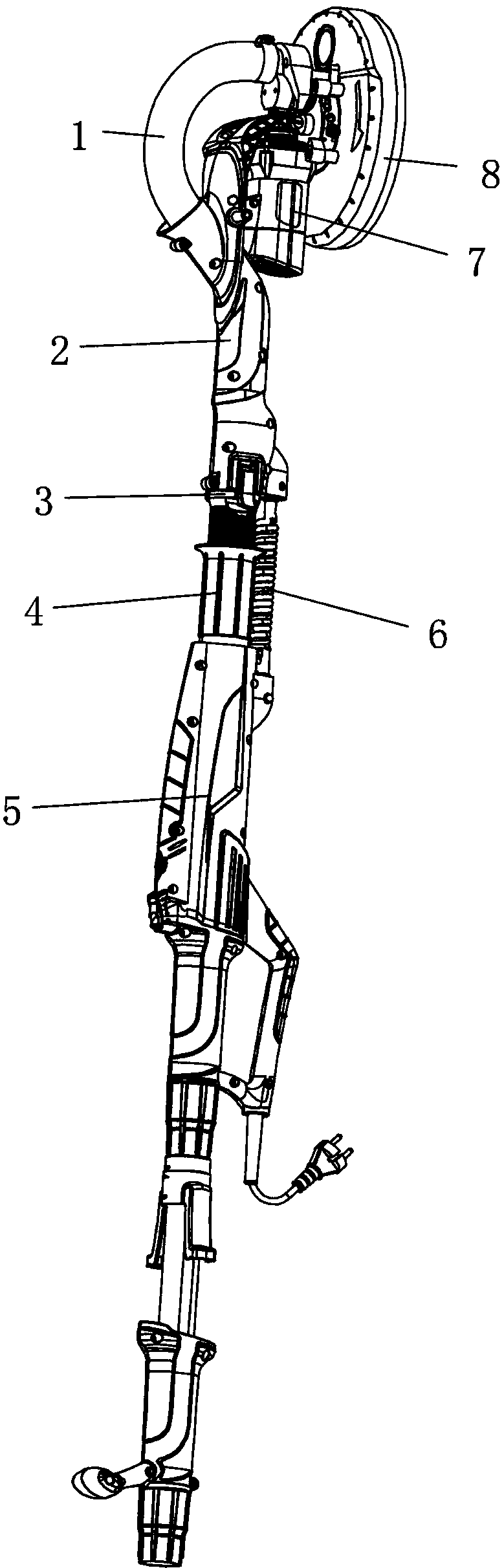

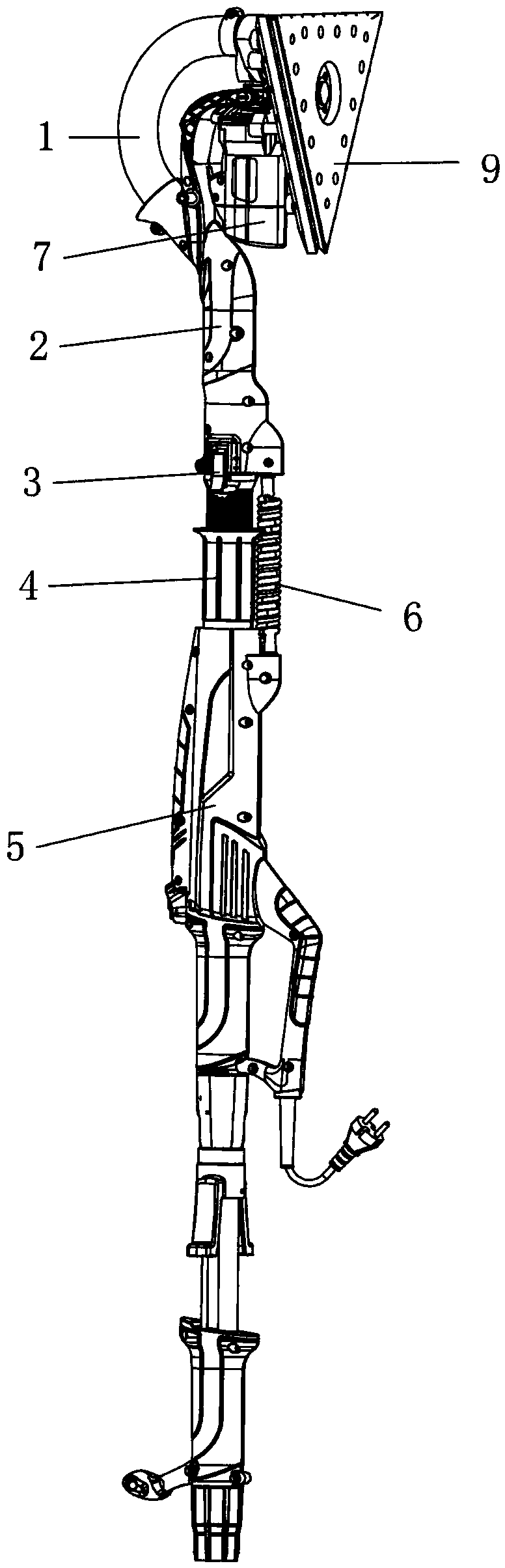

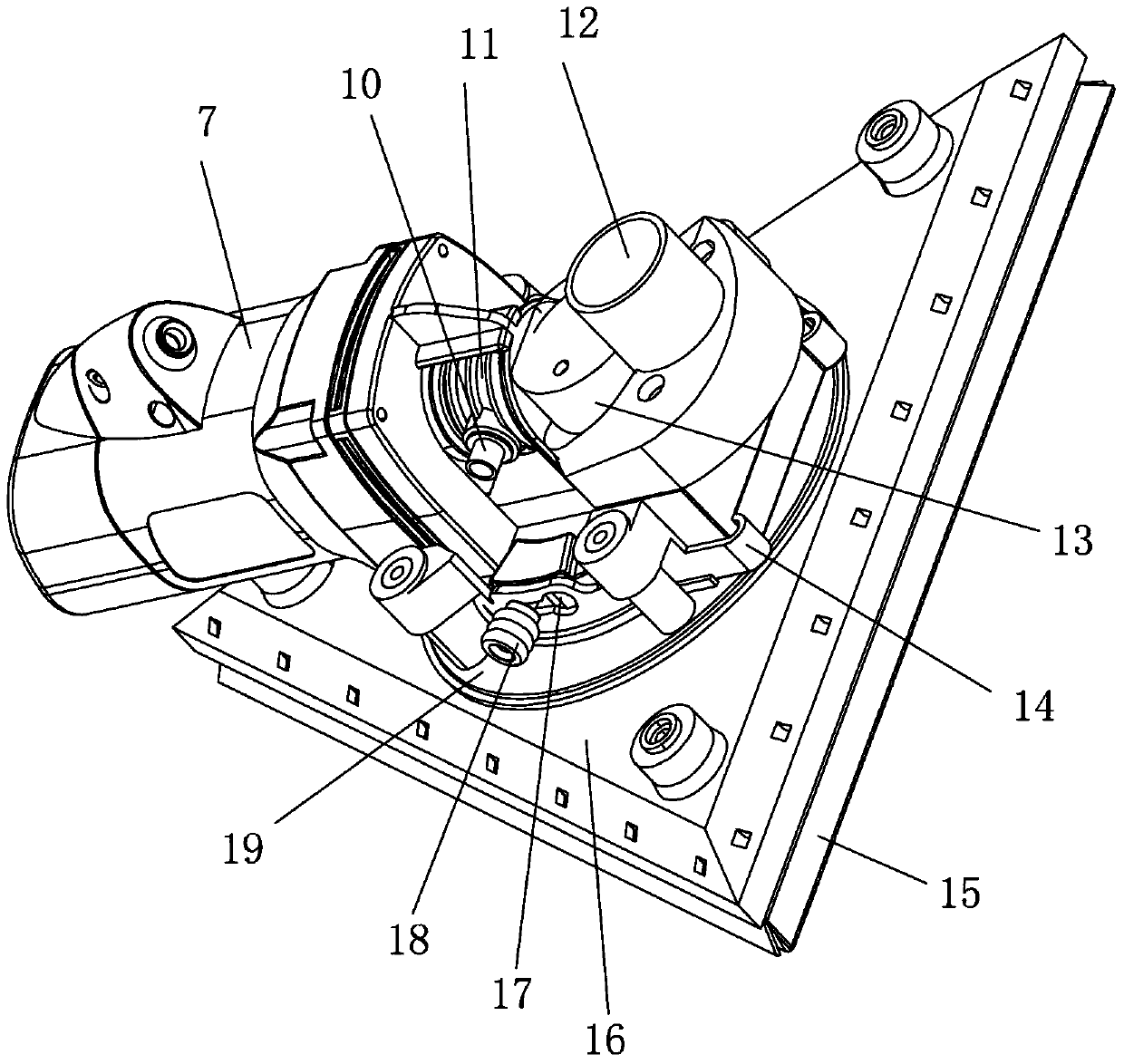

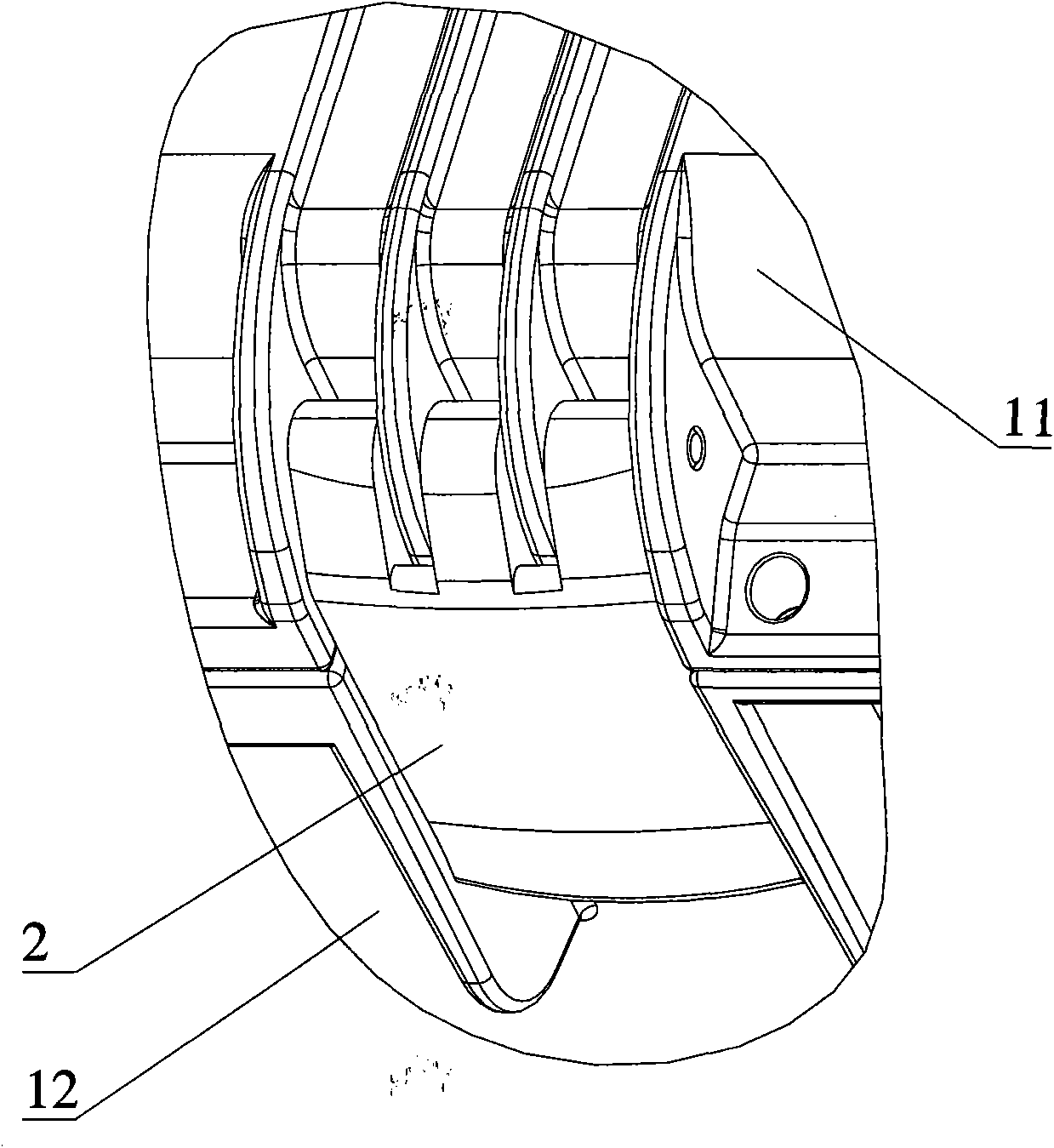

Wall polisher

ActiveCN103991015AOutstanding and Beneficial Technical EffectsQuick switchGrinding headsPlane surface grinding machinesEngineeringDISC assembly

The invention relates to the technical field of electric tools, in particular to a wall polisher. The wall polisher comprises an operating handle, a motor and a polishing head. The polishing head comprises a top cover, a base and abrasive disc assemblies. A transmission mechanism for transmitting the torque of the motor to the abrasive disc assemblies is arranged between the top cover and the base. An output shaft of the transmission mechanism is an eccentric shaft or a concentric shaft. An abrasive disc of each abrasive disc assembly is installed at the lower end of the eccentric shaft or the concentric shaft. The base is internally provided with a rotating disk, one side of the rotating disk is provided with a shifting handle, the rotating disk is provided with one or more limiting holes, the top cover is fixedly provided with a positioning rod stretching into the limiting holes, and the limiting holes can clamp or loosen the positioning rod through the rotation of the rotating disk. According to the wall polisher, the two different abrasive disk assemblies are usually prepared, the output shaft of the transmission mechanism of one abrasive disk is the eccentric shaft, the other output shaft of the transmission mechanism of the other abrasive disk is the concentric shaft, different abrasive disk assemblies can be rapidly switched, and therefore the wall corner can be polished very conveniently.

Owner:傅月华 +1

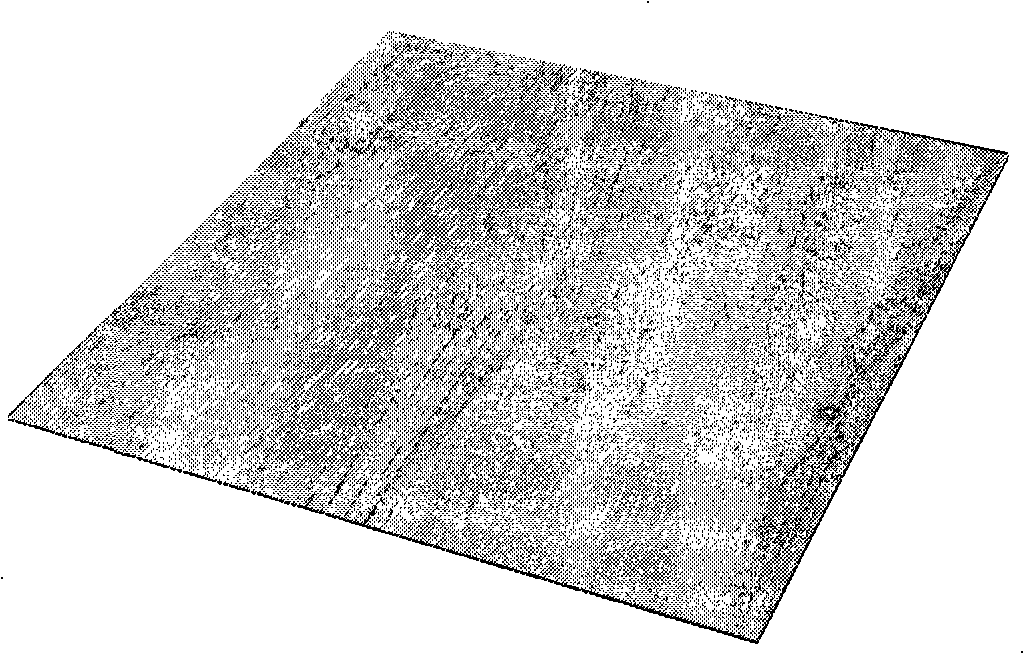

Simulation synchronously impressing patterns and facing artificial board production process

ActiveCN101259626AReflect completeSimple methodLamination ancillary operationsNatural patternsHigh rateEngineering

The invention discloses a manufacturing method of an emulational synchronous lines marked facing man-made panel which consists of the following steps: patterns can be obtained by shooting or according to real objects to design the patterns, and the patterns are decomposed into corresponding two parts by using the technology of computer image processing; a grounding pattern is printed on decoration paper, and a texture pattern is made to be a corresponding solid relief sculpture as a die mold; the decoration paper which is printed with the grounding pattern and other planks that are necessary to lead the facing man-made panel to be folded according to requirements; the die mold is corresponding to the decoration paper with the grounding pattern according to an original real object, and the folded planks are thermally pressed by the die mold; dye needed is coated on the surface of the sinking position of the plank pressed, and the emulational synchronous lines marked facing man-made panel can be obtained by removing the dye on the convex part and solidifying the dye. The emulational synchronous lines marked facing man-made panel uses the method to separate plane patterns on the real object patterns from the patterns which can reflect the solid effect, and the method has the advantages of low cost and high rate of finished products when the emulational man-made plate with the solid effect is made.

Owner:POWER DEKOR GROUP

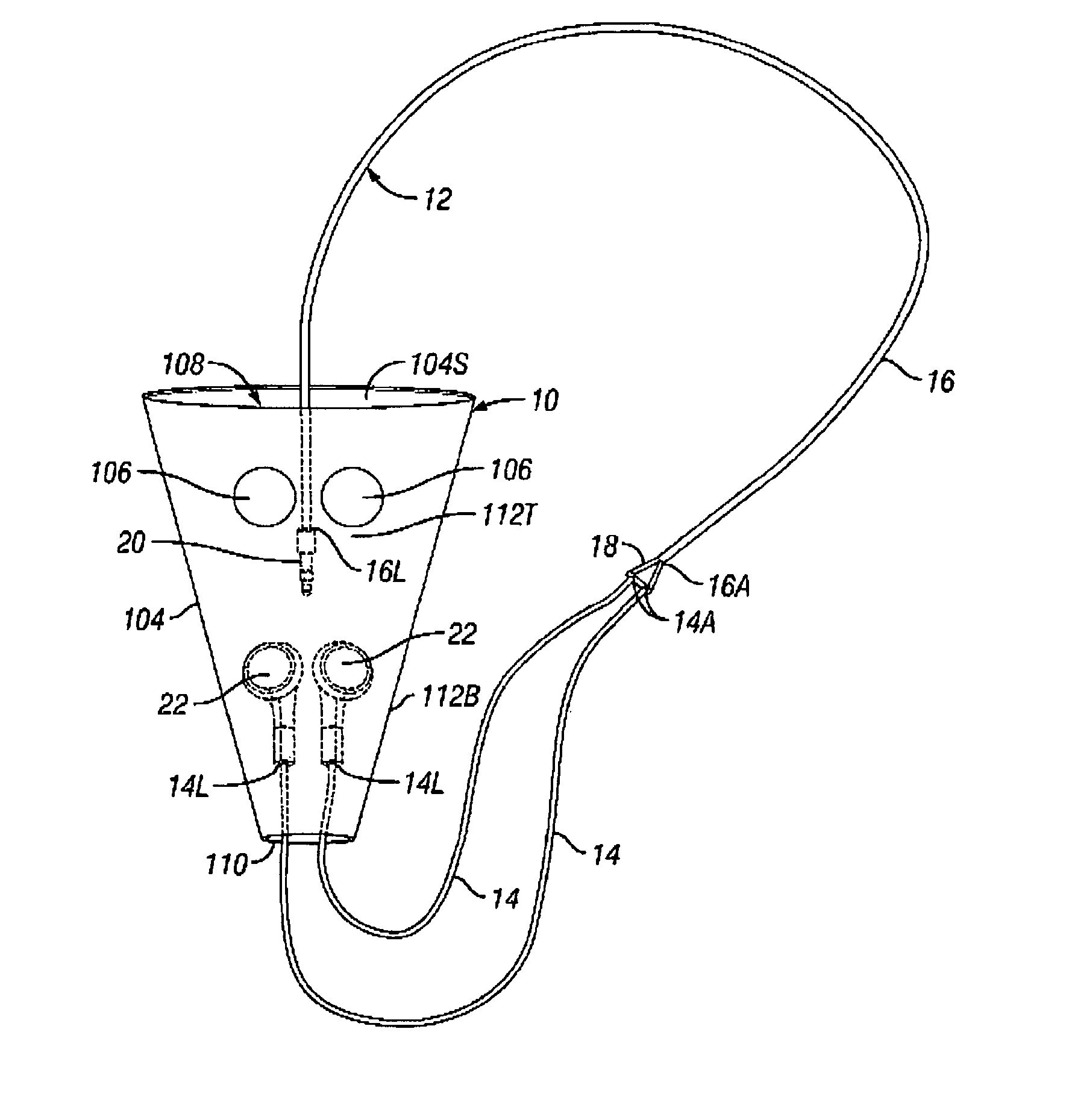

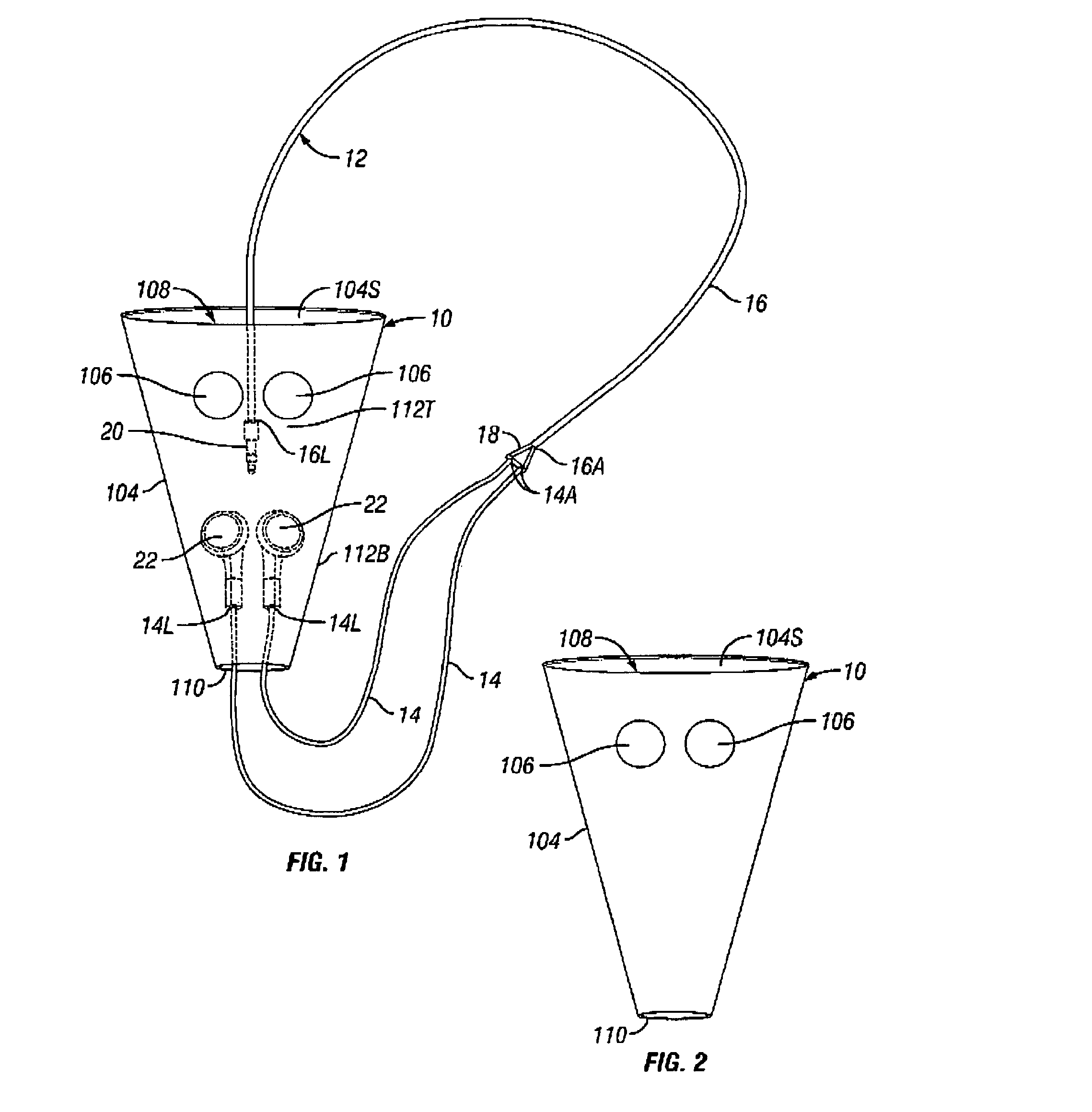

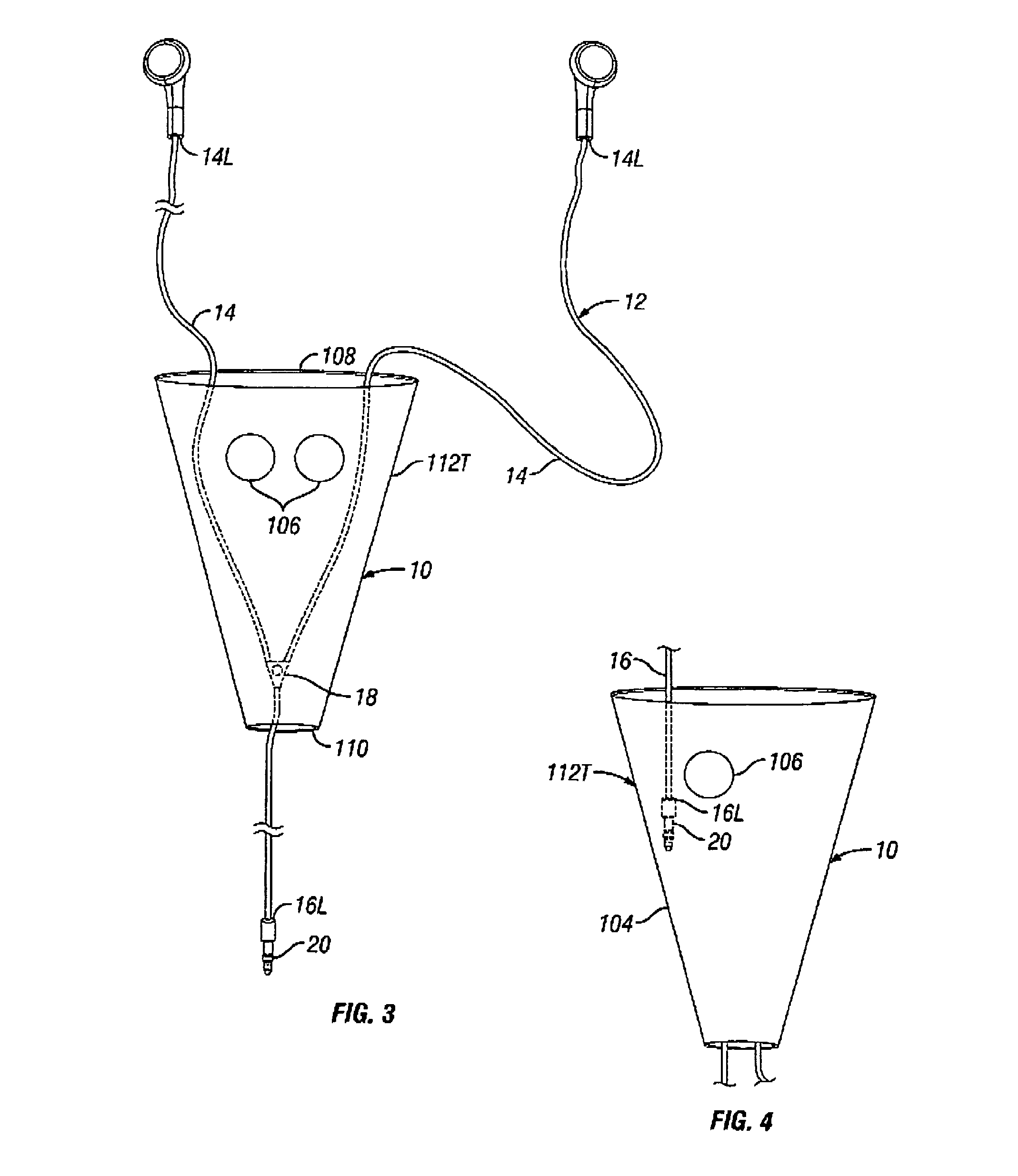

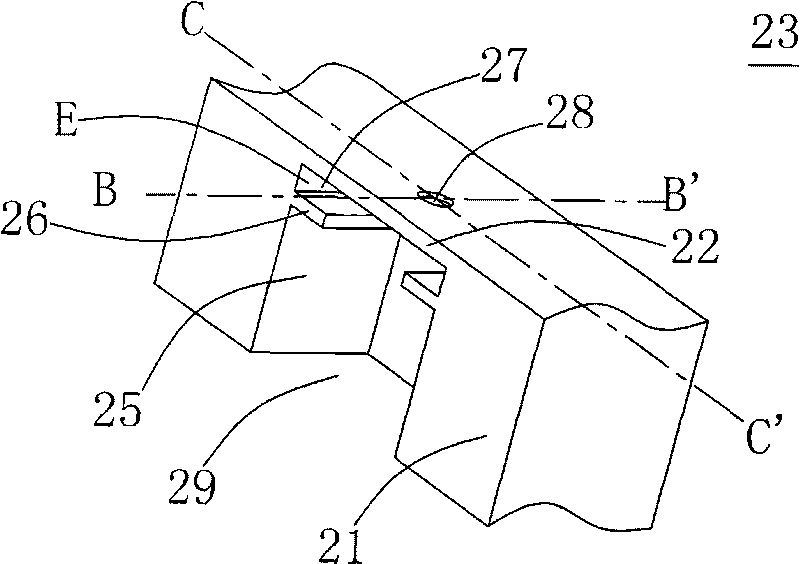

Cord management method and sleeve for ends of Y-shaped cords

InactiveUS8147270B1Quickly untangles minor tanglingNot easy to misplaceSnap fastenersRopes and cables for vehicles/pulleyClosed loopFastener

A sleeve for storing a Y-shaped cord without tangling and a method of managing a Y-shaped cord by grouping a plurality of the cord loose ends in the sleeve, each into a separate portion, forming a closed loop. The sleeve is triangular-shaped, having a conical sidewall with an open top end and an open bottom end. Inside the sleeve, the ends of the cord are separated by at least one fastener. The closed loop makes it less likely that the cord will tangle with other objects or with itself. If the cord does tangle when in the closed loop, the topology of the closed loop makes untangling the cord simpler and quicker than if the ends were loose. When using the Y-cord, the sleeve remains on the cord, not interfering with the cord functioning and not easily lost.

Owner:WESCOTT JEFFREY

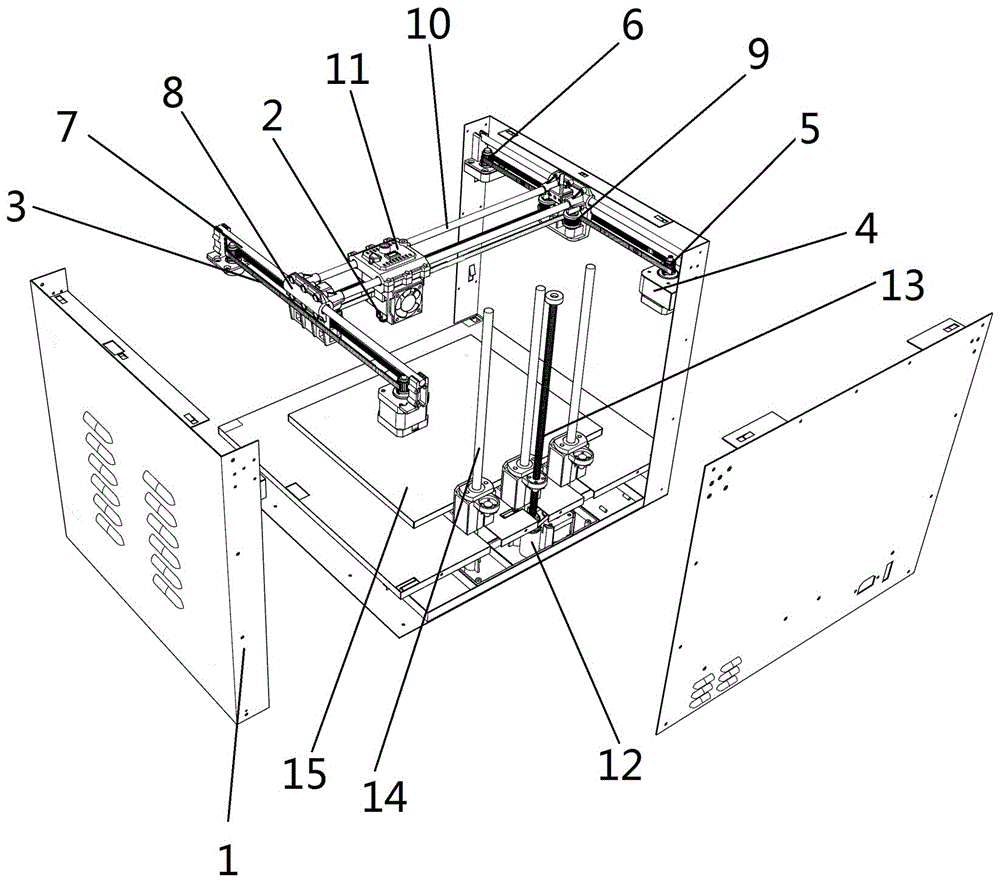

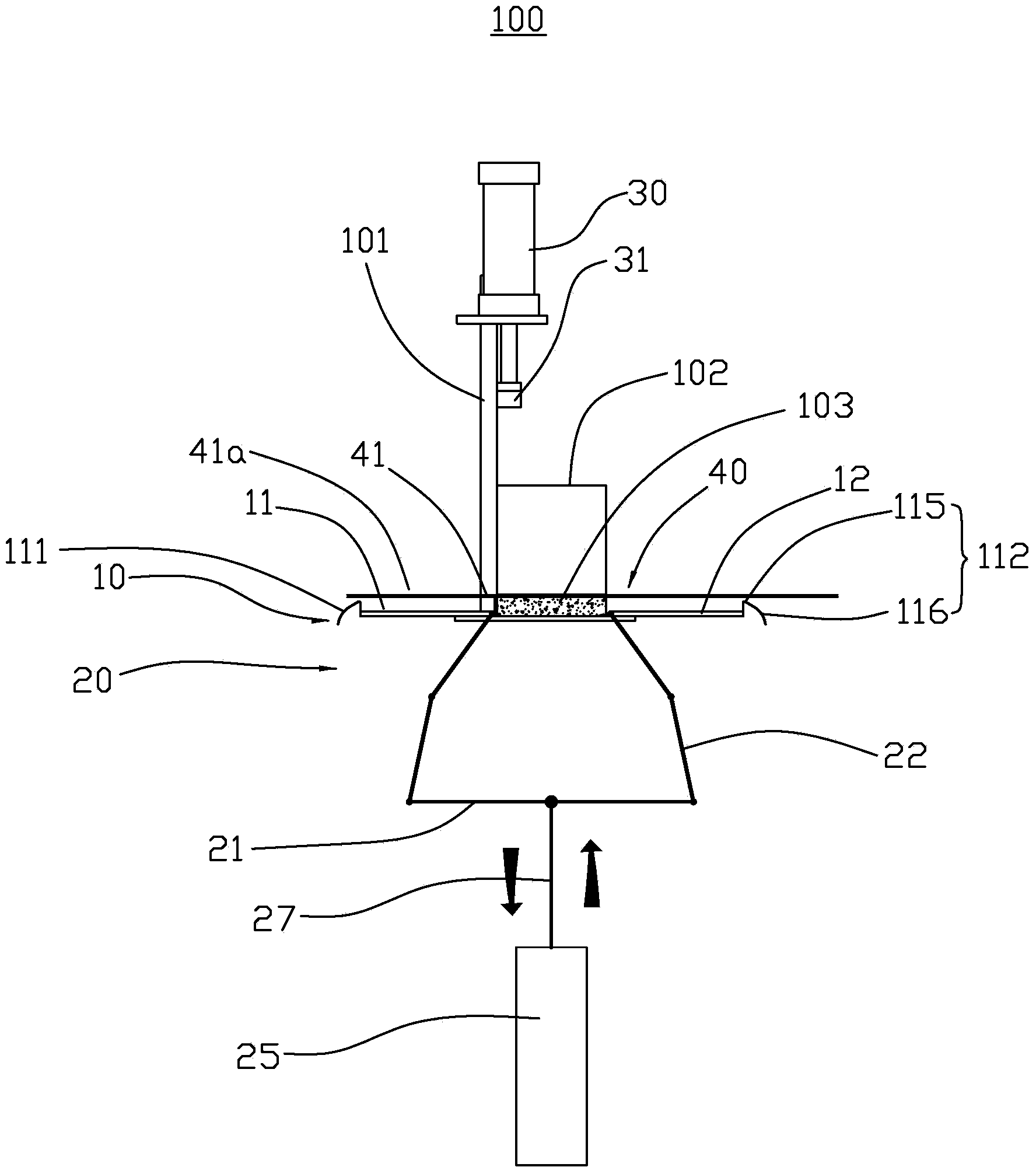

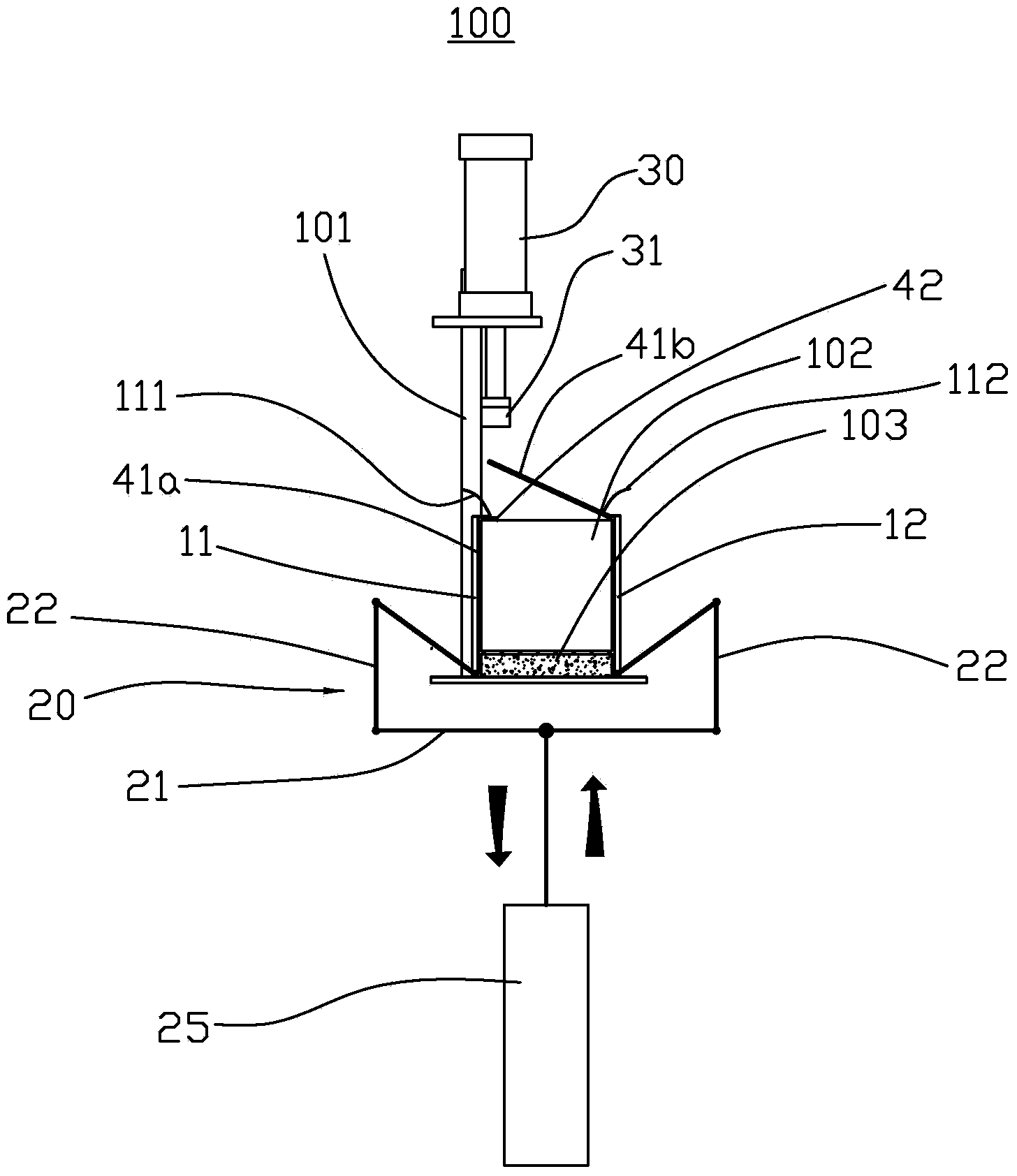

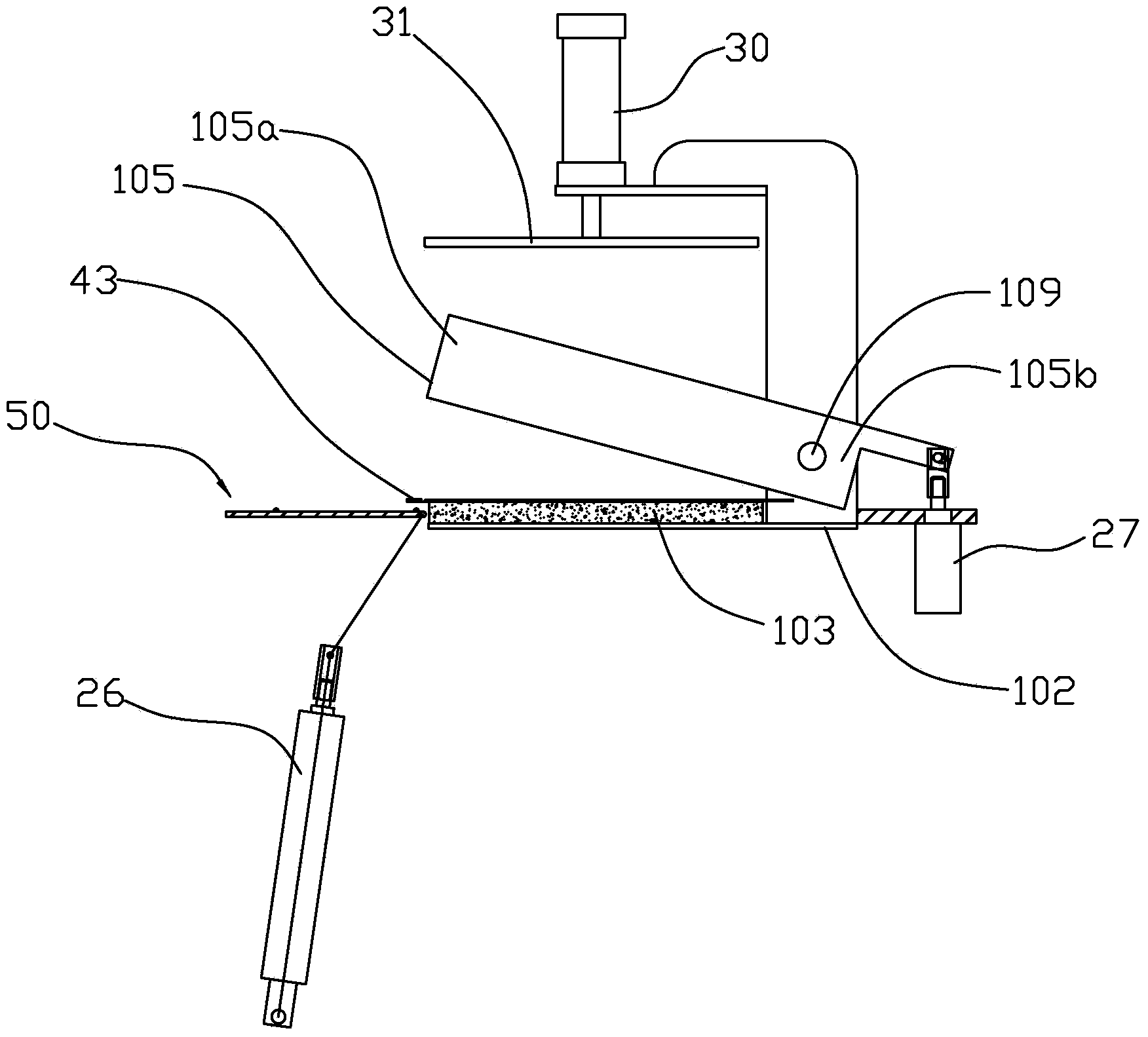

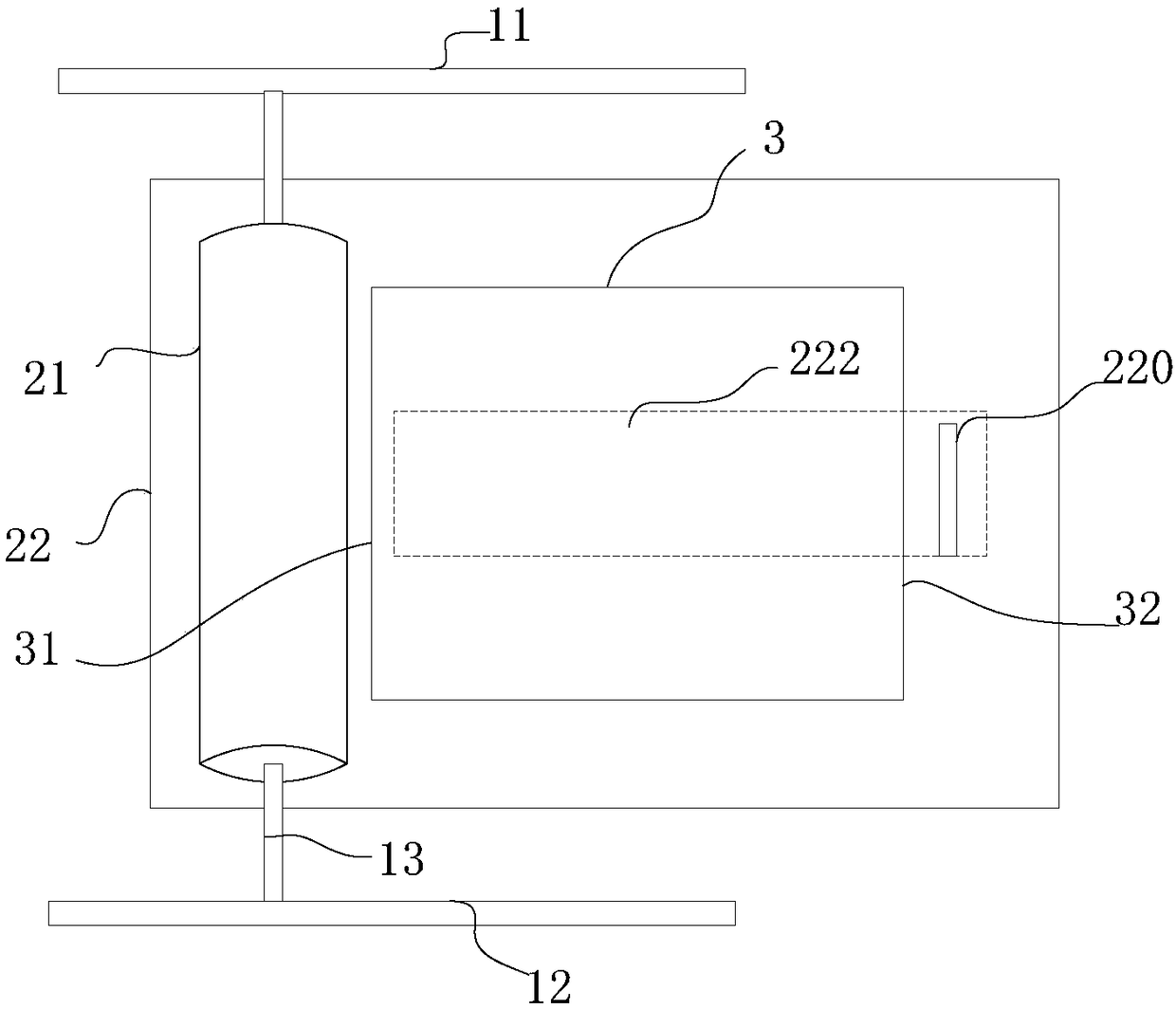

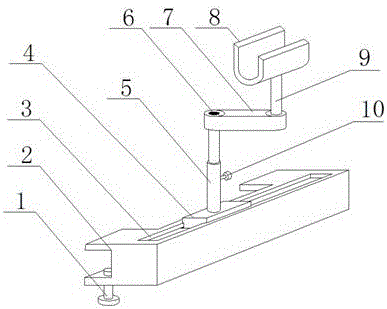

3D printer, special horizontal movement mechanism and horizontal movement method of 3D printer

InactiveCN105922599ASimple structureEasy to installAdditive manufacturing apparatusEngineering3d printer

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

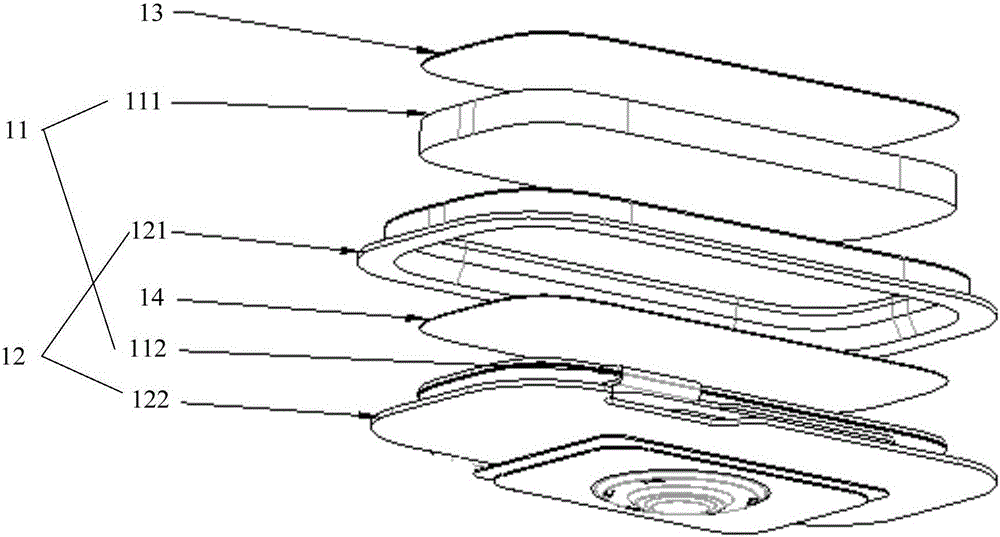

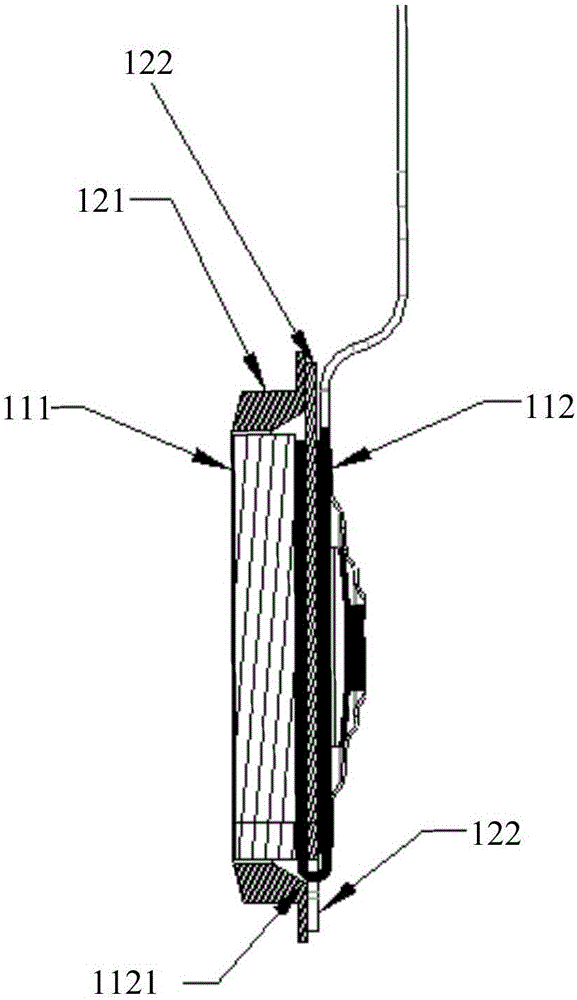

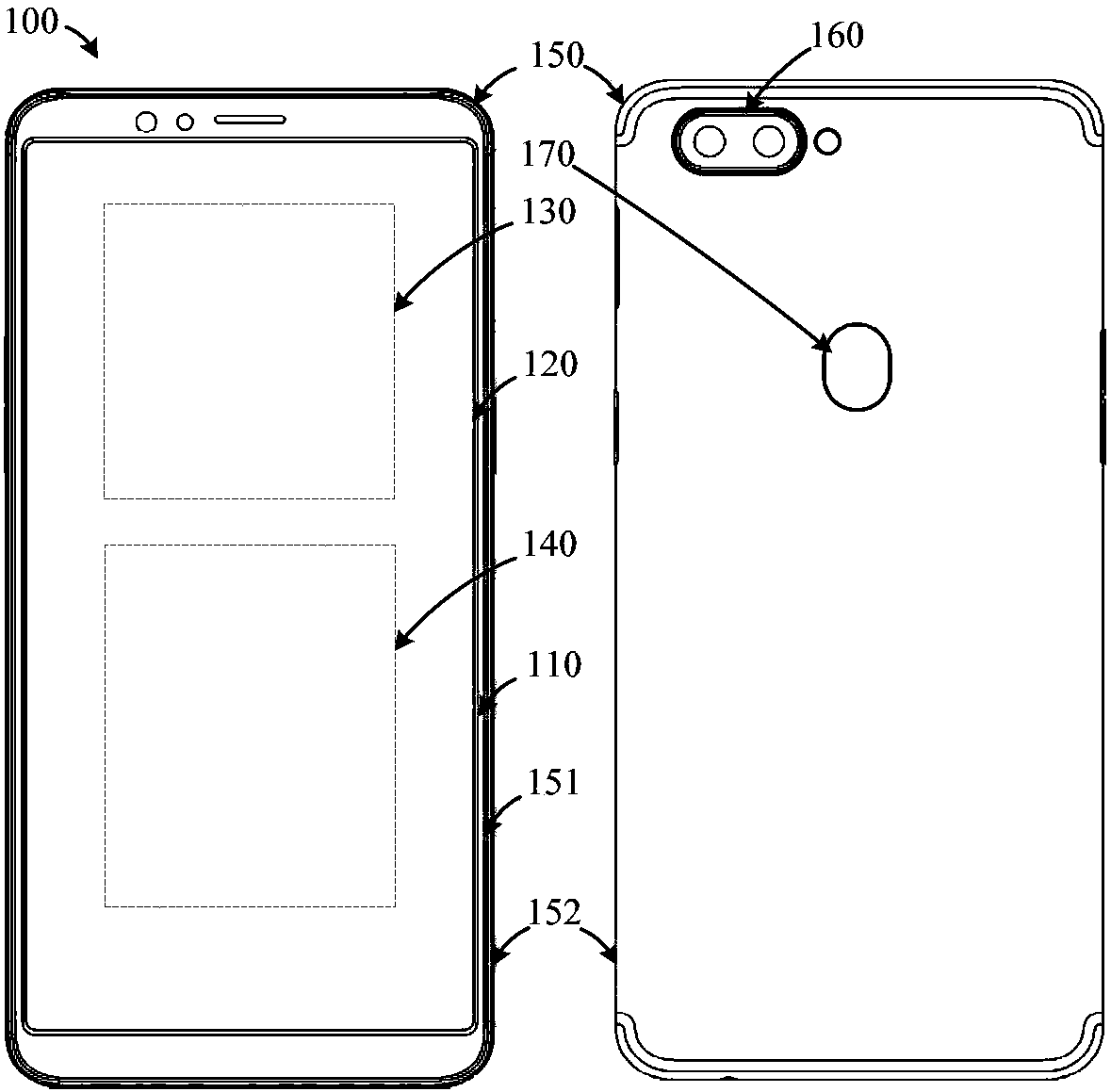

Key device and electronic apparatus

ActiveCN105893958ANot easy to misplaceExtended service lifePrint image acquisitionFingerprintElectric devices

The embodiment of the invention discloses a key device and an electronic apparatus. The key device comprises a fingerprint-sensing module and a support assembly supporting the fingerprint-sensing module. The support assembly comprises a support base plate and a support side plate fixedly connected with the support base plate. The fingerprint-sensing module comprises a fingerprint-sensing chip and a circuit board. The first surface of the circuit board is fixedly connected with the support base plate. The first surface of the fingerprint-sensing chip is fixedly connected with the second surface of the circuit board. The fingerprint-sensing chip is electrically connected with the circuit board.

Owner:LENOVO (BEIJING) CO LTD

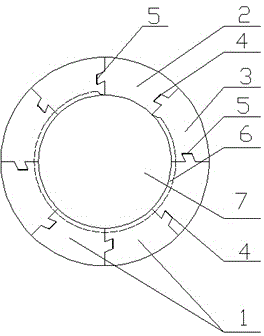

Loop-pile cutting circular machine

ActiveCN103938357ASolve the problem of uneven hair surface and hair end hookIncrease weaving speedCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

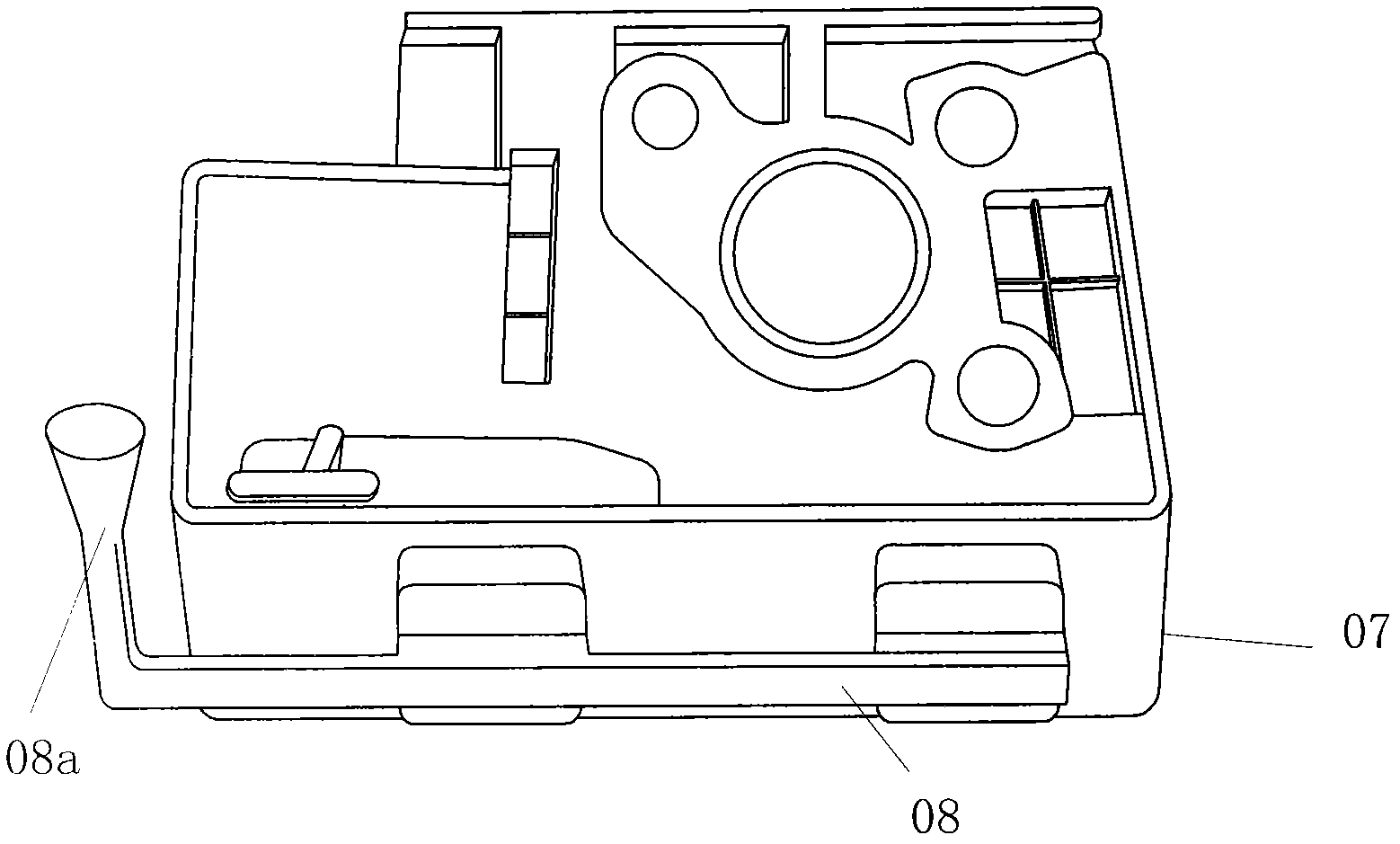

Casting mold for single cylinder diesel body, external casting mold for horizontal parting multi-cylinder diesel body and cast parts, and energy-saving low-carbon casting process of external casting mold

The invention provides an energy-saving low-carbon casting process for a single cylinder diesel body, which comprises manufacture of the mold, wherein a resin sand and triethylamine curing technique is used during the manufacture of an external mold; a mold gate is located at a spindle hole of the diesel body; and an exhaust port is arranged on a balance axle hole of the diesel body. By using thenovel process provided by the invention, defects of the single cylinder diesel production in the prior art, such as low quality, low efficiency, high energy consumption, serious pollution and intensive labor, can be solved. The invention also provides the mold used in the process. The invention further provides an external casting mold for the horizontal parting multi-cylinder diesel body and thecast parts, and the casting process of the external casting mold.

Owner:平遥县嵘兴机械制造有限公司

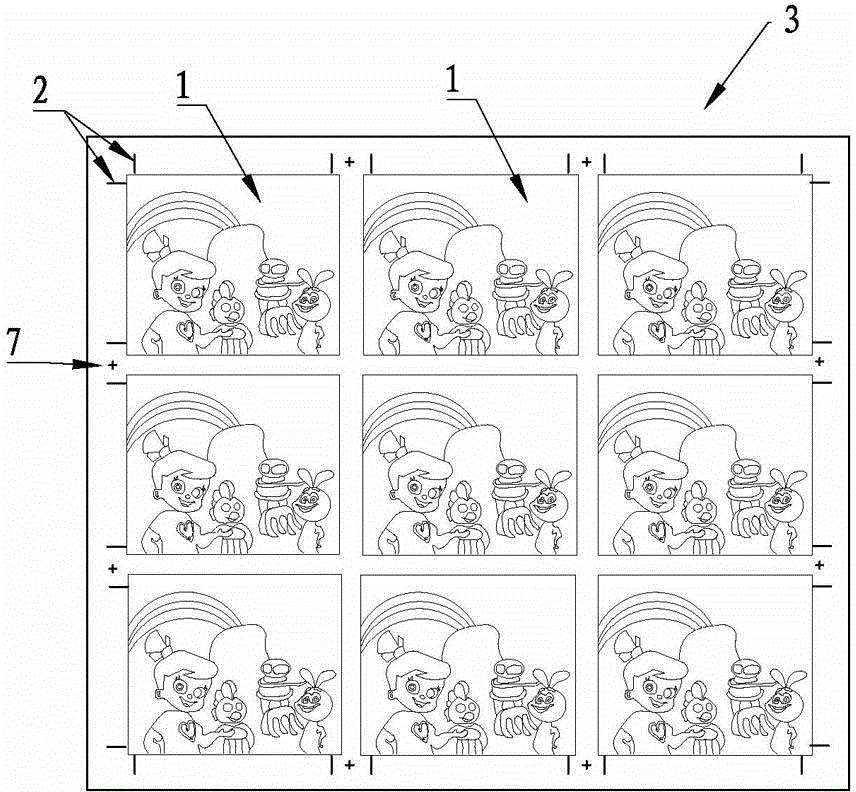

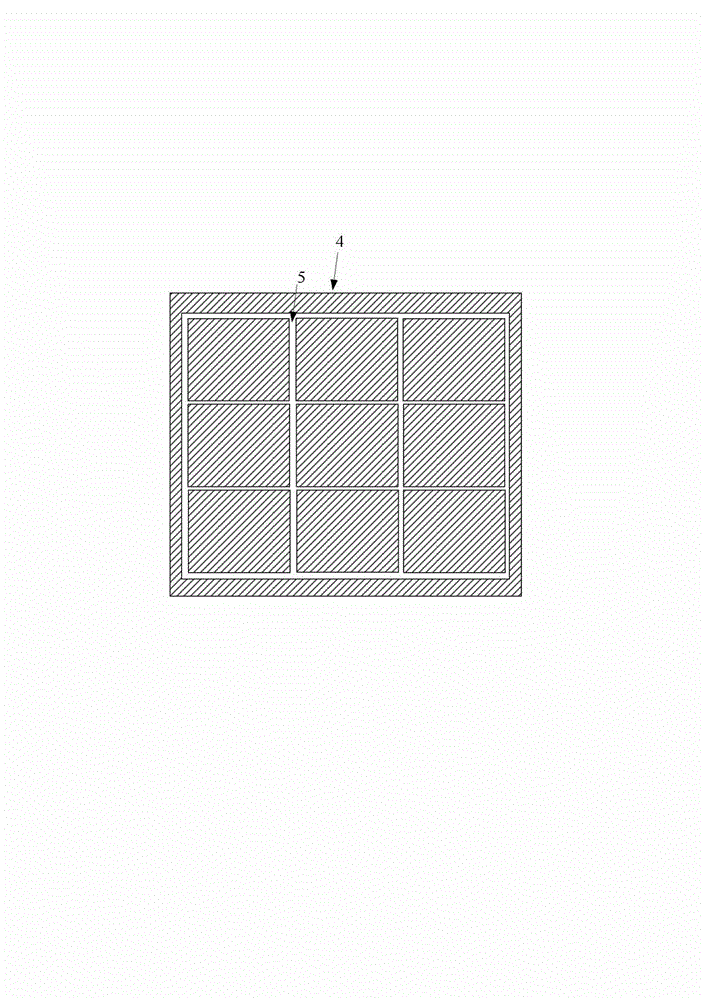

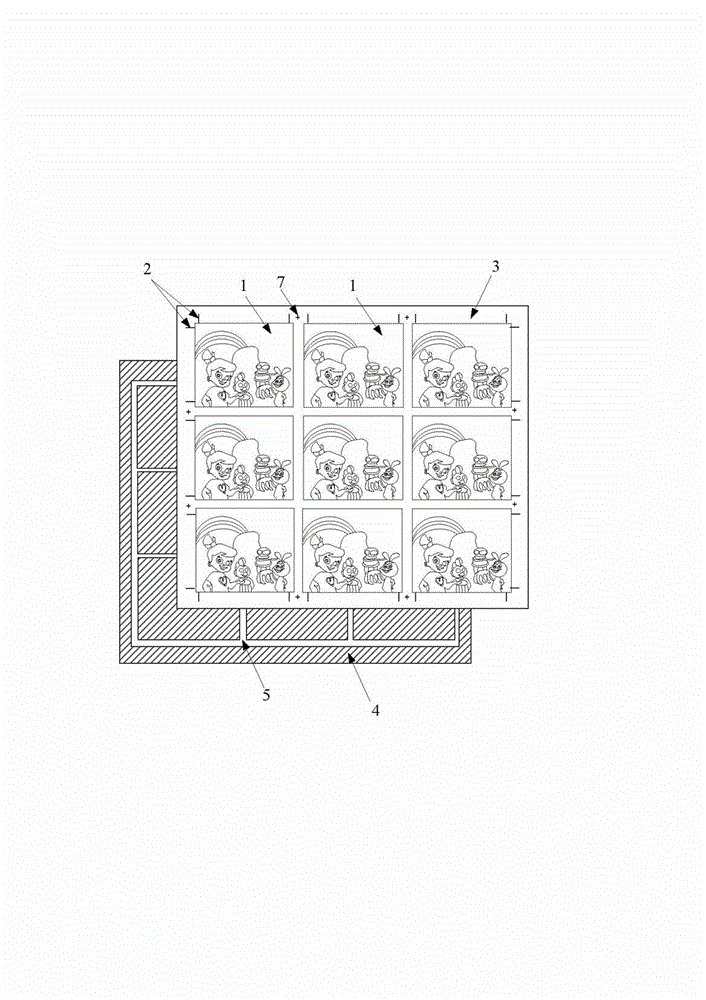

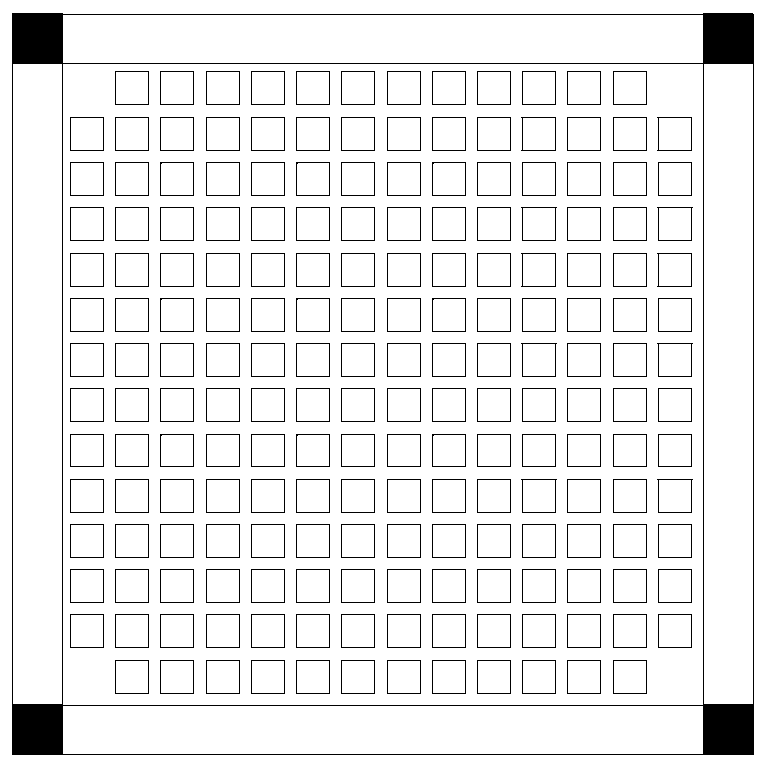

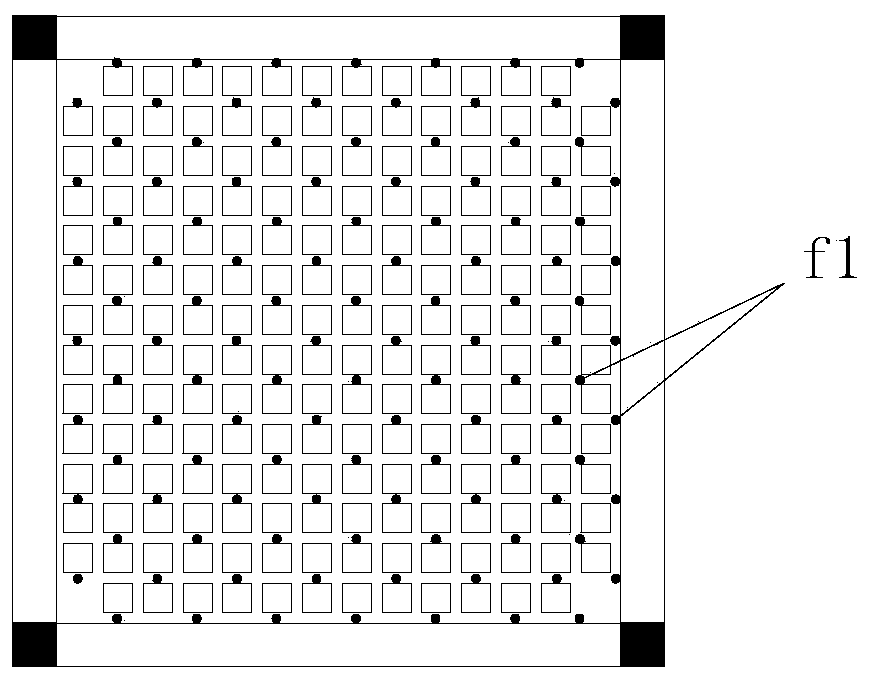

Production process of paper puzzle and paper puzzle

InactiveCN102743865ANot easy to misplaceNot easy to loseIndoor gamesPulp and paper industryComplete type

The invention relates to the field of production processes of puzzles, in particular to a production process of a paper puzzle and the paper puzzle. The production press of the paper puzzle comprises the following steps of: splicing a pattern according to the size of the puzzles and the dimension of a computerized paper, and reserving a spacing between every two puzzles; completing type setting, and making trimming line marks; printing the computerized paper to obtain a finished printed sheet; silkscreening glue on the position of a base, which corresponds to the periphery of the paper puzzle; oppositely mounting and compacting the finished printed sheet and the base with the glue completely silkscreened; after the glue is dried, and die-cutting the finished printed sheet; and cutting the finished printed sheet to obtain single puzzles. In the invention, because glue positions corresponding to the periphery of the paper puzzle are silkscreened with the glue, the peripheries of the single cut puzzles are fixed, only a puzzle part is die-cut and penetrated through a die-cutting procedure, the base is not penetrated, and the base fixes the paper puzzle from the bottom, and therefore, puzzle units of the paper puzzle are difficult to displace and lose; and the paper puzzle produced by utilizing the production process of the paper puzzle prevents the puzzle units from being displaced and lost.

Owner:DONGGUAN JIEDAXING PRINTING

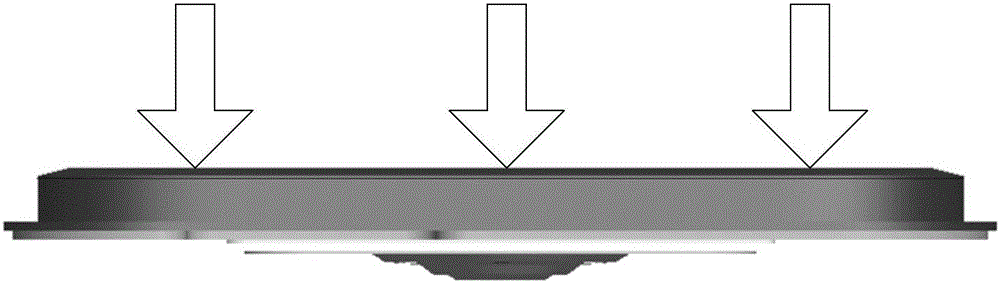

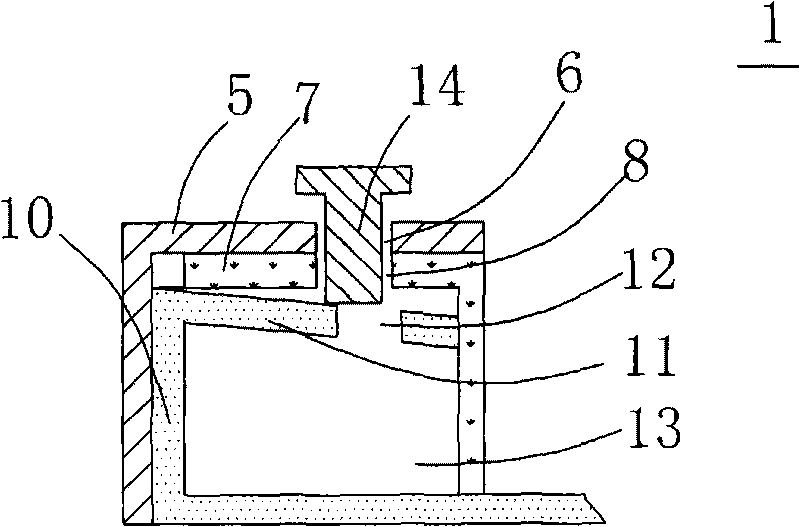

Backlight module and display device

InactiveCN101761834AEasy to assembleImprove product yieldNon-linear opticsLight fasteningsBackplaneEngineering

The invention provides a backlight module and a display device. The backlight module comprises a back plate and a supporting seat, wherein the back plate comprises a bottom plate, a side plate and a lug, and the lug is provided with a first through hole; the supporting seat comprises a chamfer and a supporting plate; the chamfer extends to the interior of the supporting seat from the side face of the supporting plate facing the side plate; a top plate is arranged above the chamfer and provided with a second through hole corresponding to the first through hole; the supporting plate is arranged on the side wall forming the chamfer and parallel to the top plate, and the supporting plate, the top plate and the side wall form an accommodating area and an opening; and the lug is inserted in the accommodating area and combines and fixes the supporting seat and the back plate through a fixing piece, the first through hole and the second through hole. The lug of the back plate of the backlight module is arranged in the accommodating area of the supporting seat and supported by the supporting plate so that the lug is not easy to generate displacement caused by the action of external force during locking and fixing a bolt, and the locking and fixing of the lug with a lamp holder and a frame is not easy to generate a misplacement condition so as to be beneficial to assembling and improving the product yield.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

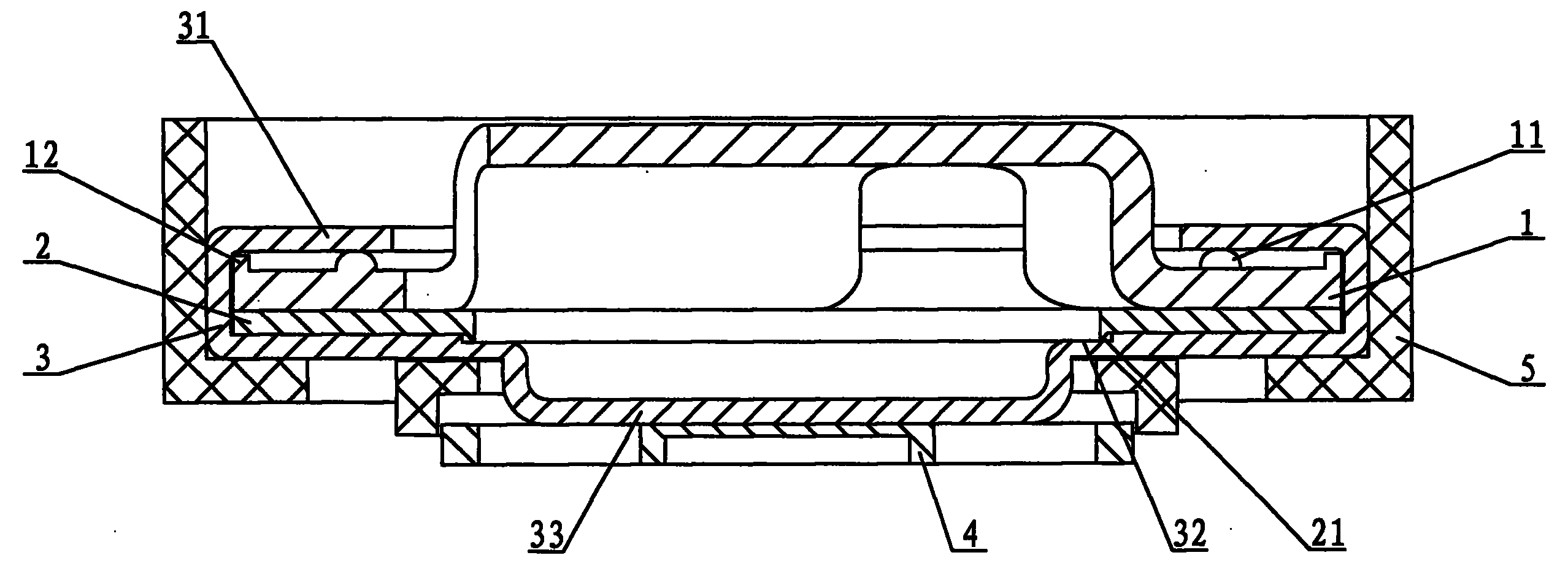

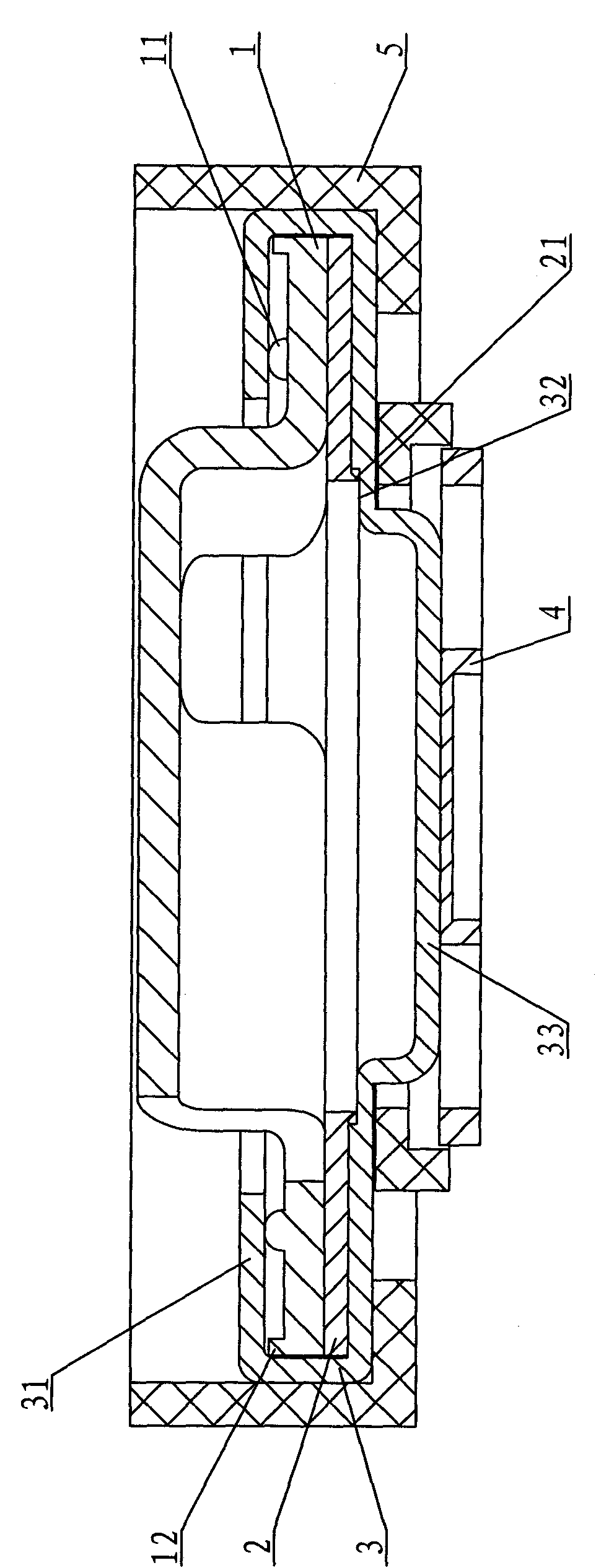

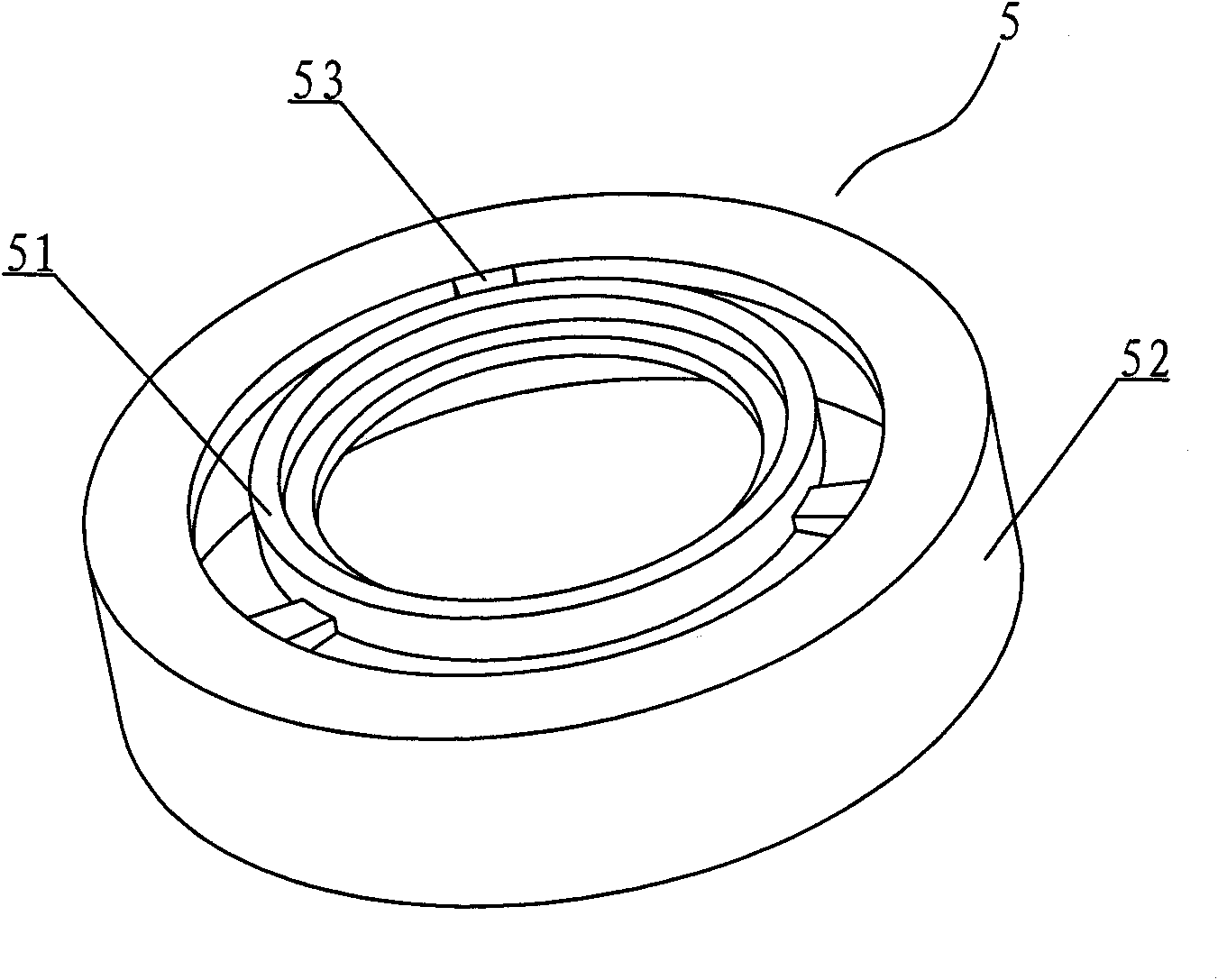

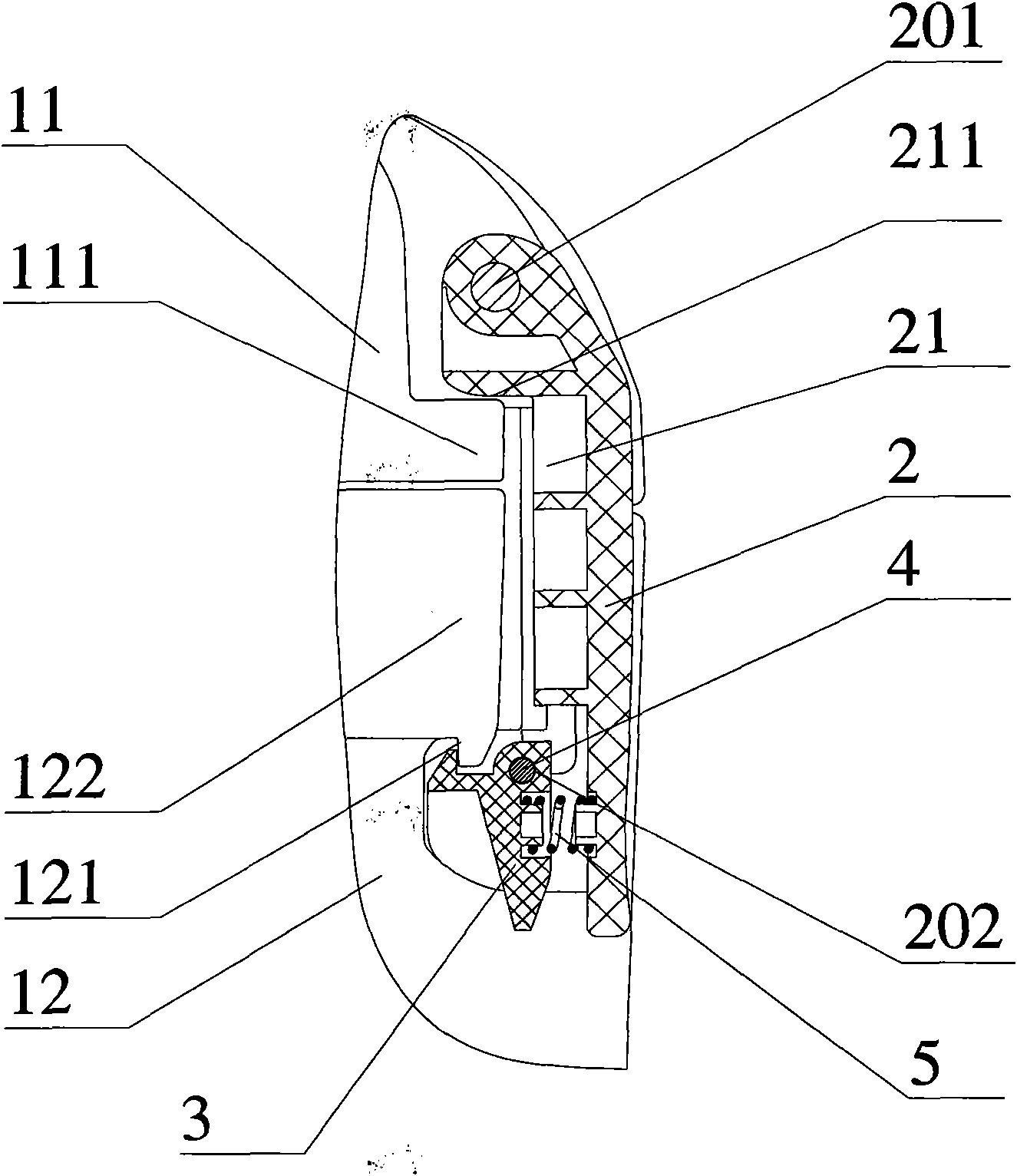

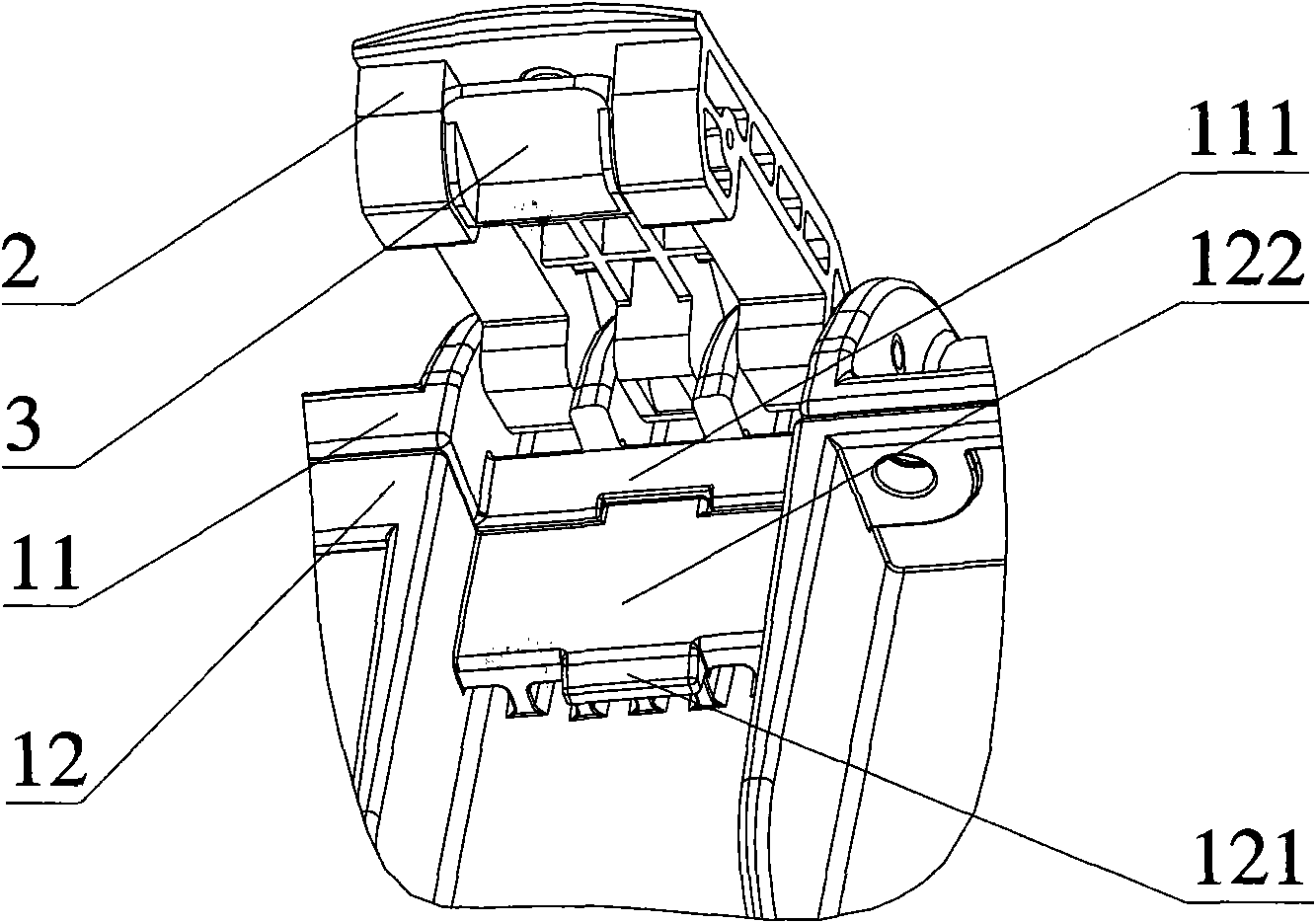

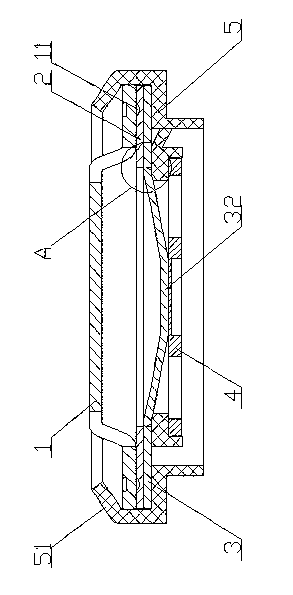

Explosion-proof cap of micro-resistance cylindrical lithium ion battery

InactiveCN101814589ANo explosion hazardImprove securityVent arrangementsCell lids/coversVena contracta diameterInternal resistance

The invention relates to an explosion-proof cap of a micro-resistance cylindrical lithium ion battery. The explosion-proof cap comprises an upper cap, a gasket, an explosion-proof membrane with a wall body, an orifice plate and a sealing ring. A plurality of air holes are arranged on the upper cap. The wall body of the explosion-proof membrane is bent and wraps the gasket and the upper cap in the cavity of the explosion-proof membrane. After the explosion-proof membrane wraps the gasket and the upper cap, the explosion-proof membrane is embedded in the sealing ring coated with glue. The orifice plate is embedded at the bottom surface of the sealing ring. The orifice plate is welded with the explosion-proof membrane through laser spot welding. A circular welding platform which protrudes downward is arranged on the bottom surface of the explosion-proof membrane. A prestressed pressure relief ring is formed between the circular welding platform and the bottom surface of the explosion-proof membrane. In combination with the cutting of the prestressed pressure relief ring along a sharp spiny flanged edge in the gasket, the flanging of the cap edge of the upper cap and the tight welding between a convex welding spot on the cap edge and the bent wall body of the explosion-proof membrane, the invention realizes that the explosion-proof membrane can be exploded open when being turned over and the overall internal resistance of the cap is reduced, and has the advantages that the structure is simple, compact and stable, the deformation and the misplacement are not apt to occur, the internal resistance of the cap is low, the battery performance is high, the explosion-proof membrane can be normally exploded open to relieve pressure after the explosion-proof membrane is turned over, the explosion-proof performance is stable and the service life is long.

Owner:TAIXING ZHENGXING ELECTRON

Locking device used for box body

ActiveCN102599709AImprove protectionEasy to unlockBuilding locksOther accessoriesEngineeringMechanical engineering

Owner:扬州哈登塑料技术有限公司

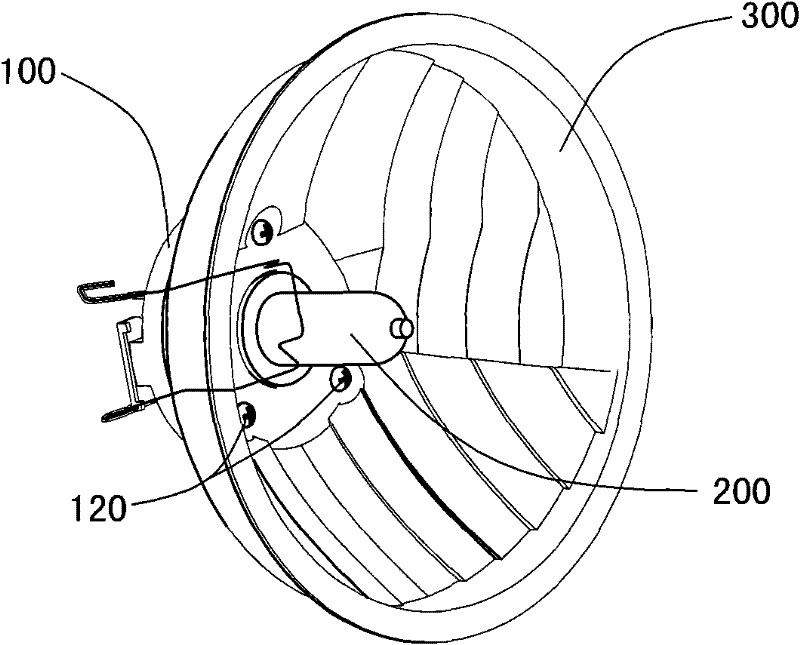

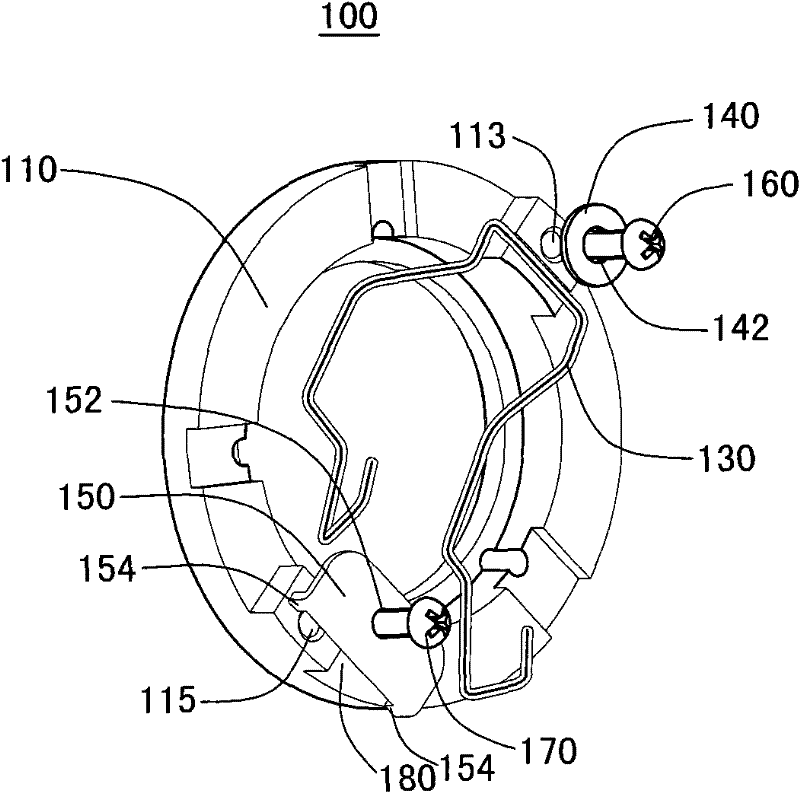

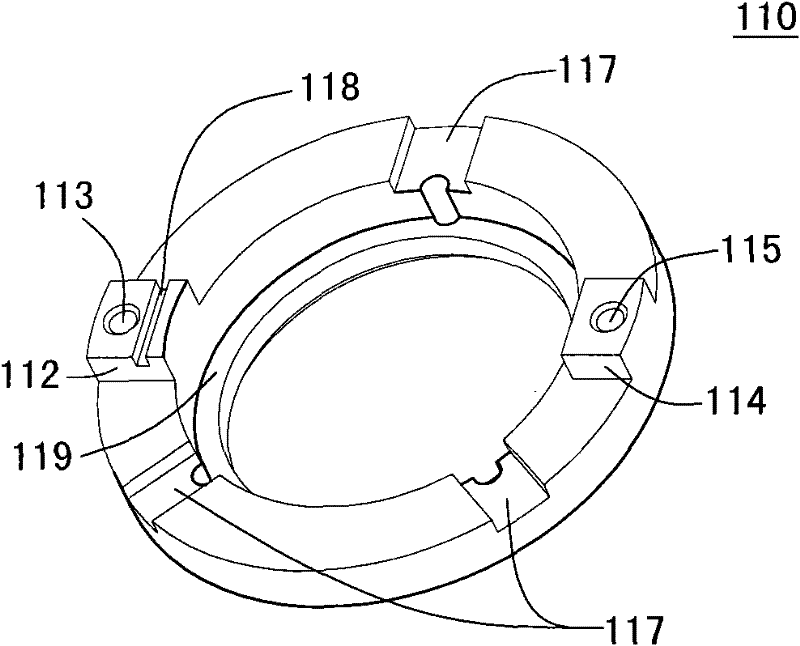

Lamp bulb fixing device and lamp

ActiveCN102444871AAccurate light distributionLight distribution stabilityLight fasteningsEngineeringFastener

The invention discloses a lamp bulb fixing device and a lamp. The lamp bulb fixing device is used for fixing a lamp bulb which comprises a lamp bulb back seat and being matched with a reflector fixing fastener to fix a reflector. The lamp bulb fixing device comprises a lamp holder bracket, a lamp holder fixing spring, a spring shim, a spring pressure sheet, a first fastener for fixing the spring shim and a second fastener for fixing the spring pressure sheet. The lamp bulb back seat is clamped and fixed on the lamp holder bracket by the lamp holder fixing spring. The front side of the lamp holder bracket is provided with a reflector fixing hole matched with the reflector fixing fastener. The lamp bulb fixing device has convenient and simple mounting mode. The reflector is fixed on a lamp bulb fixing structure through the reflector fixing fastener and the reflector fixing hole and meanwhile, the lamp bulb back seat is clamped and fixed on the lamp holder bracket by the lamp holder fixing spring, so that a lamp bulb and the reflector are fixed together and are difficult to misplace or deflect, and thus, the lamp bulb is accurate and stable to distribute light.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Power type lithium ion battery cover and welding process thereof

InactiveCN103296227AImprove safety performanceNo explosion hazardCell component detailsWelding apparatusLithium electrodeEngineering

The invention relates to a power type lithium ion battery cover and a welding process thereof. An upper cover, a gasket and an anti-explosion film are embedded into a sealing ring; a pore plate and the anti-explosion film are subjected to laser spot welding; more than two downward convex welding points are uniformly arranged on the lower surface of the edge of the upper cover, and the convex height of the welding points is greater than the thickness of the gasket; the upper cover is sequentially in resistance welding with the gasket and the bottom surfaces in a cavity of the anti-explosion film through the more than two convex welding points; the bottom face of the anti-explosion film is provided with an annular pressure-relief notching groove; the wall of an inner hole of the gasket corresponds to the annular pressure-relief notching groove. The upper cover is sequentially in resistance welding with the gasket and the bottom surfaces in the cavity of the anti-explosion film along the downward convex welding points, is matched with the inner hole of the gasket and corresponds to the anti-explosion film with the annular pressure-relief notching groove in the bottom face, so as to reduce the inner resistance of the whole battery cover and stabilize anti-explosion pressure relief. The power type lithium ion battery cover is simple in connection structure, stable in connection, low in deformation and malposition possibility and low in whole inner resistance; by adoption of the power type lithium ion battery cover, the battery has high performance, stable anti-explosion performance, high safety performance and long service life.

Owner:TAIXING ZHENGXING ELECTRON

Adjustable extrusion mold

InactiveCN106938529AExpand the scope of processingEasy to adjustExtrusion diesExtrusion mandrelsEngineeringExtrusion

The invention belongs to the field of extrusion equipment, in particular relates to an adjustable extrusion mold. The adjustable extrusion mold is characterized in that an extrusion port is provided with a first adjusting block on one side and a second adjusting block on the other side; the middle part of a first pushing plate is arranged on a first lead screw for connection, and one side thereof is slidingly arranged on a first slide way; one end of a first pushing column is connected with the first pushing plate, and the other end thereof penetrates through an outer mold to connect with the first adjusting block; a first dividing ruler is fixed on the outer side of the outer mold, and is positioned on the other side of the first pushing plate; the middle part of a second pushing plate is arranged on a second lead screw for connection, and one side thereof is slidingly arranged on a second slide way; one end of a second pushing column is connected with the second pushing plate, and the other end thereof penetrates through the outer mold to connect with the second adjusting block; and a second dividing ruler is fixed on the outer side of the outer mold, and is positioned on the other side of the second pushing plate.

Owner:TIANJIN DEV AREA JINPENG PLASTICS PROFILE MFG CO LTD

Small-diameter integrated wooden pillar and manufacturing method thereof

The invention discloses a small-diameter integrated wooden pillar and a manufacturing method thereof. The small-diameter integrated wooden pillar comprises inserted battens (2) and battens (3), wherein the side surfaces of the inserted battens (2) and the battens (3) are respectively provided with a mortise (4) and a tenon (5); the inserted battens (2) and the battens (3) are connected end to end, so that a ring-shaped batten group (1) can be formed. The small-diameter integrated wooden pillar is easy to assemble and cannot be in dislocation easily, does not need surface planing treatment, is good in fire resistance, high in strength and low in cost, and can meet the demand of a wood structure.

Owner:贵州剑河园方林业投资开发有限公司

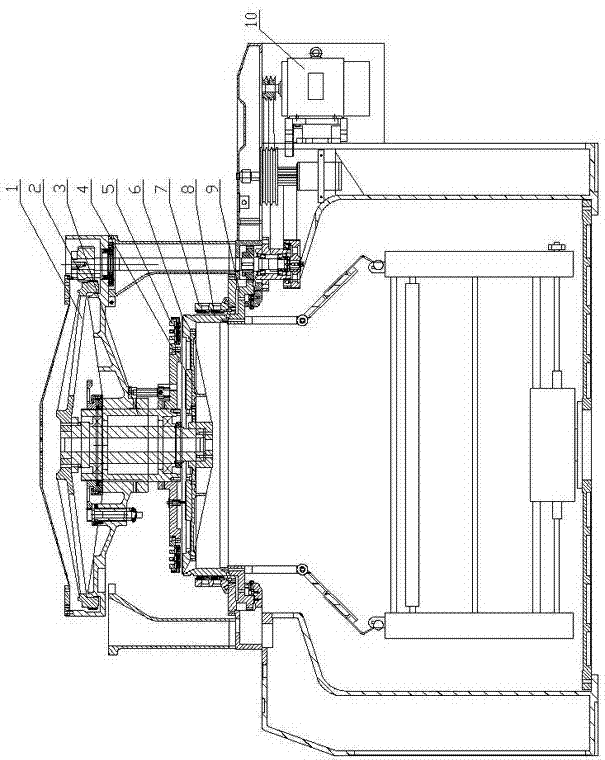

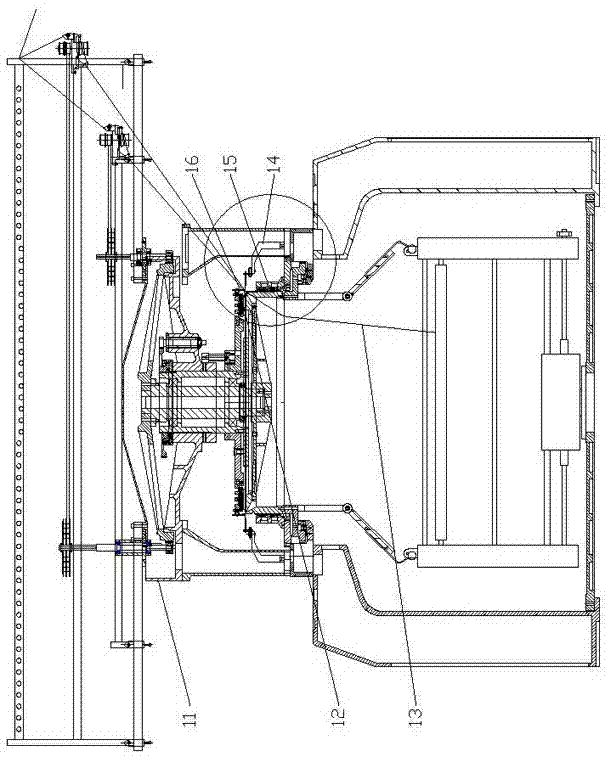

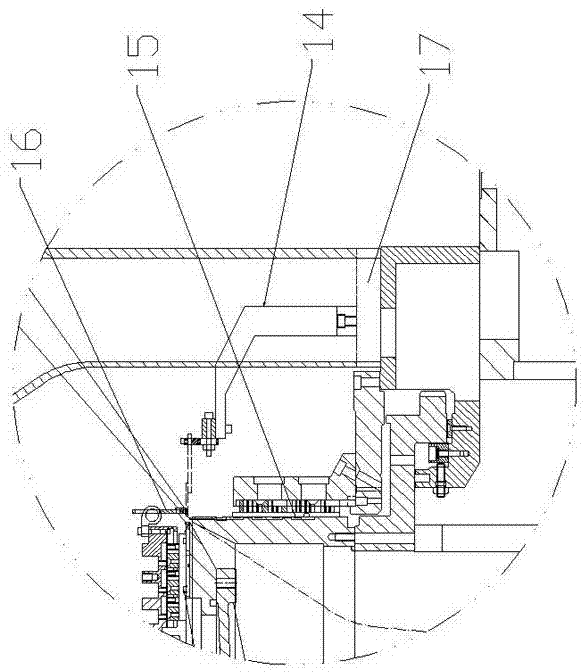

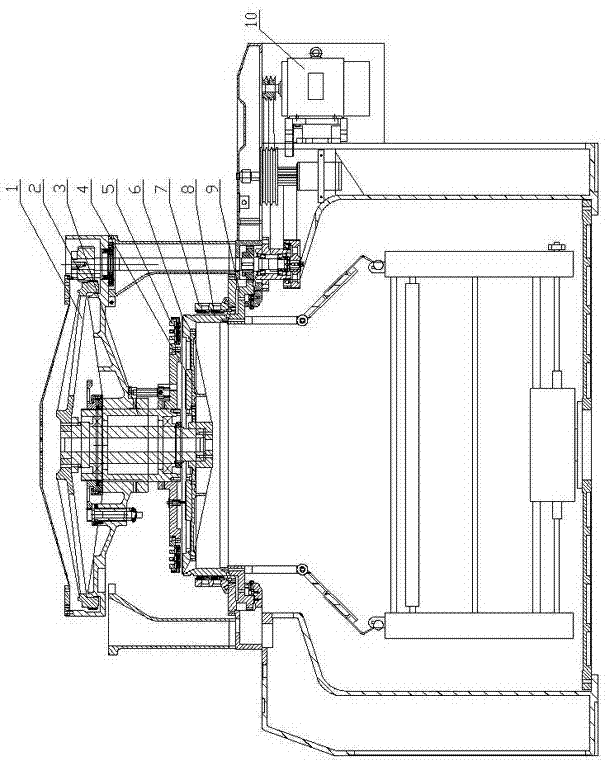

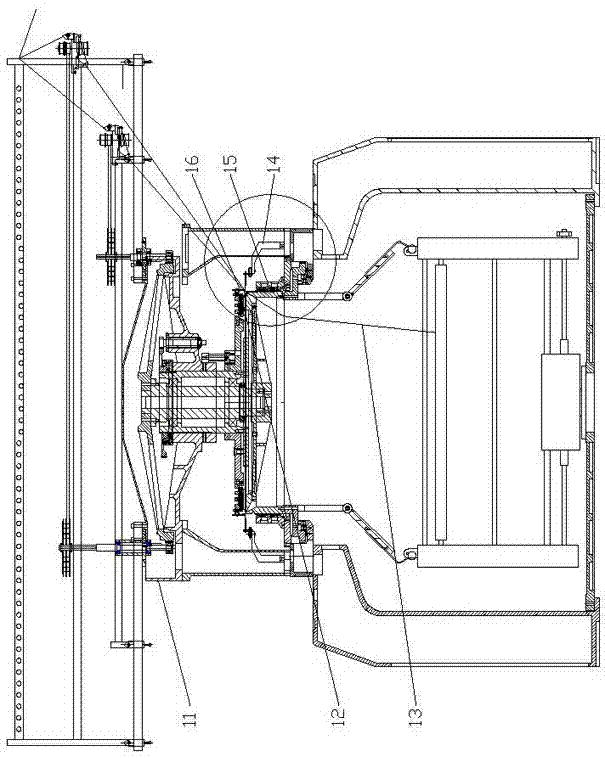

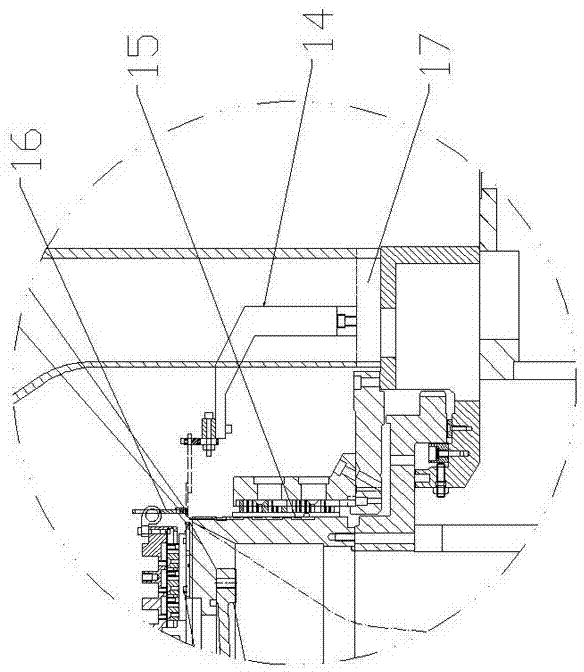

Quick stereoscopic packaging machine

ActiveCN103481543ANot easy to misplaceEasy to operateBoxes/cartons making machineryEngineeringForming processes

The invention provides a quick stereoscopic packaging machine which is used for packaging box face plates. Each box face plate to be packaged comprises a plurality of side face plates which are integrally connected with one another in a folded manner. The packaging machine which is a forming machine comprises a framework and a connecting bar mechanism. A box inner mold, a lower support part, a side face plate overturning assembly and a pressure mechanism are arranged on the framework, the side face plate overturning assembly is positioned on two sides of the lower support part, the pressure mechanism is positioned above the box inner mold, and a gap is formed between the lower support part and the box inner mold, so that the certain box face plate to be packaged can be supported by the gap and clings to the lower side surface of the box inner mold; the side face plate overturning assembly is arranged on the framework in an overturning manner, and the connecting bar mechanism and the side face plate overturning assembly are connected with each other to push the side face plates of the certain box face plate to be packaged to be overturned, so that the side face plates can cling to the box inner mold; the pressure mechanism is used for pressing the certain box face plate which clings to the box inner mold to form a box. The quick stereoscopic packaging machine which is the forming machine has the advantages that the connecting bar mechanism pushes the side plate overturning assembly to overturn, so that encircling operation can be automatically performed on the box, actions are coherent and quick in an integral forming procedure, and the box can be quickly and automatically formed.

Owner:JINCAI PRINTING & PACKAGING

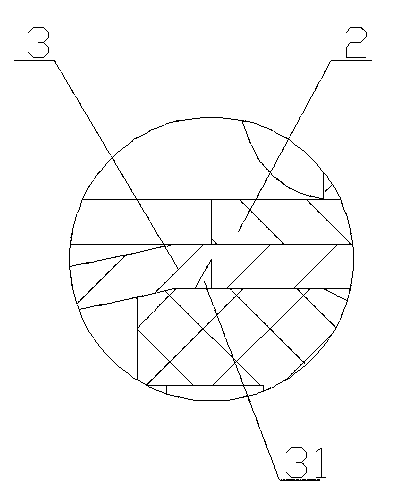

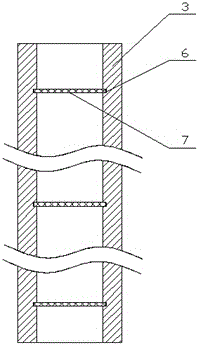

Vanadium flow cell seal ring and ionic membrane integrated assembly and electric pile

ActiveCN102394281ANot easy to misplaceImprove sealingFuel cells groupingCell component detailsEngineeringIon

The invention relates to a vanadium flow cell seal ring and ionic membrane integrated assembly and an electric pile. The vanadium flow cell seal ring and ionic membrane integrated assembly comprises an ionic membrane and a seal ring which are integrated. The electric pile comprises a first frame plate, a second frame plate and the seal ring and ionic membrane integrated assembly, wherein the first frame plate and the second frame plate are provided with seal ring clamping grooves; the lower end of the seal ring in the seal ring and ionic membrane integrated assembly is installed in the seal ring clamping groove arranged on the first frame plate, and the upper end of the seal ring is protruded out of the end surface of the seal ring clamping groove of the first frame plate; the second frame plate is covered on the seal ring and ionic membrane integrated assembly; and the upper end part of the seal ring is clamped into the seal ring clamping groove arranged on the second frame plate. In the invention, the seal ring and an ionic membrane are directly designed into an integrated structure on the first frame plate and the second frame plate, so that the seal ring and ionic membrane integrated assembly has a better sealing effect, and the phenomena of liquid leakage and mixture of positive liquid and negative liquid are avoided, therefore, the performance of a vanadium battery can be more stable.

Owner:TIANJIN BINHAI ENERGY STORAGE TECH

Loop-pile cutting circular machine

ActiveCN103938357BIncrease weaving speedHigh densityCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

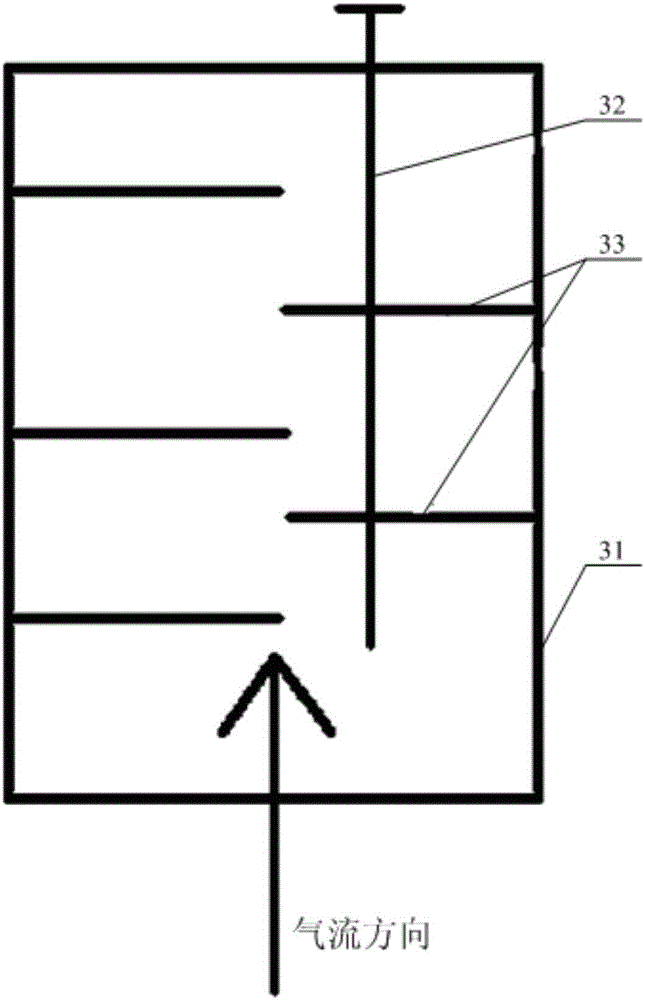

Gas heating device

InactiveCN106595043ARealize disassembly and replacementRealize maintenance workAir heatersOhmic-resistance heating detailsGas heatingElectrical and Electronics engineering

The invention discloses a gas heating device. The gas heating device comprises an insulation shell. A heating chamber is arranged inside the insulation shell. A gas inlet enabling the heating chamber and an external gas inlet pipe to communicate is formed in the bottom of the insulation shell. A gas outlet enabling the heating chamber and an external gas outlet pipe to communicate is formed in the top of the insulation shell. A partition plate is arranged in the middle of the heating chamber in the vertical direction. A plurality of heating pipes which sequentially penetrate through the side walls of the heating chamber and the partition plates in the horizontal direction are arranged on the lateral portion of the insulation shell, and the heating pipes are sequentially arranged in the vertical direction. Wiring terminals which are connected with an external power distribution cabinet are arranged at the outer ends of the heating pipes. According to the gas heating device, internal assemblies are arranged reasonably, working noise is low, and online replacement or maintenance of the heating pipes can be achieved.

Owner:YANGGU XIANGGUANG COPPER

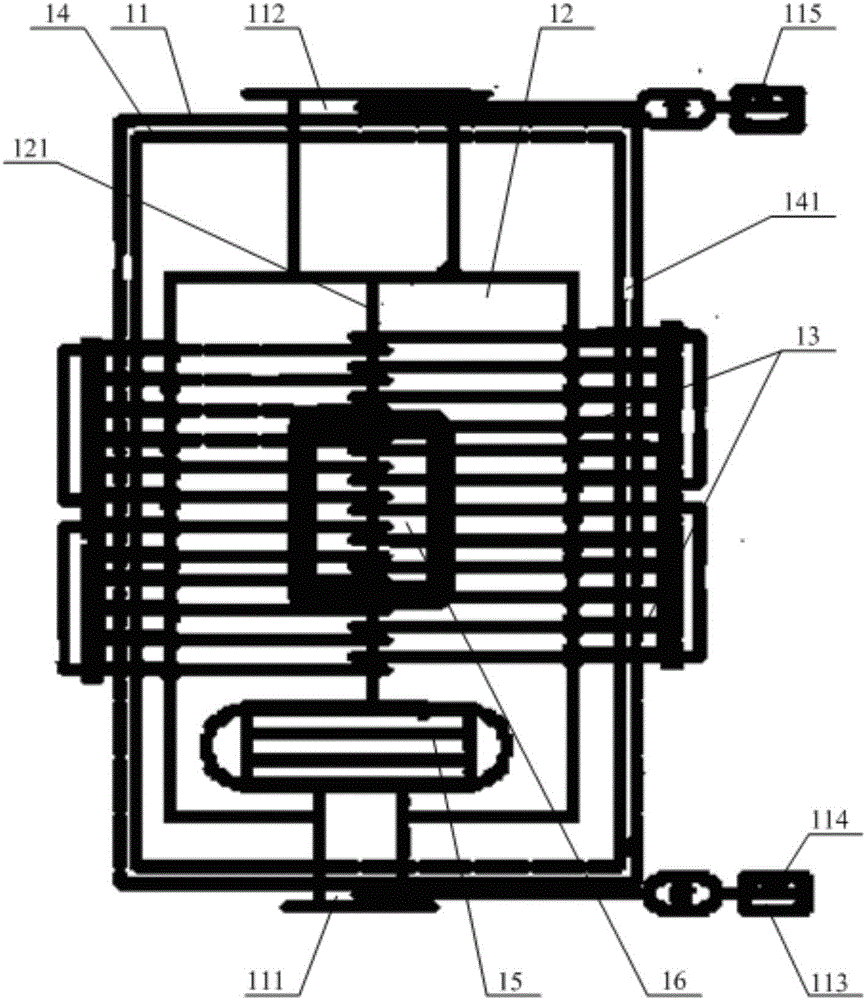

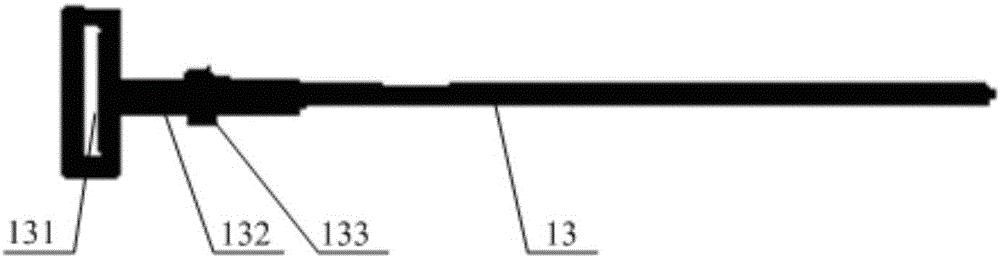

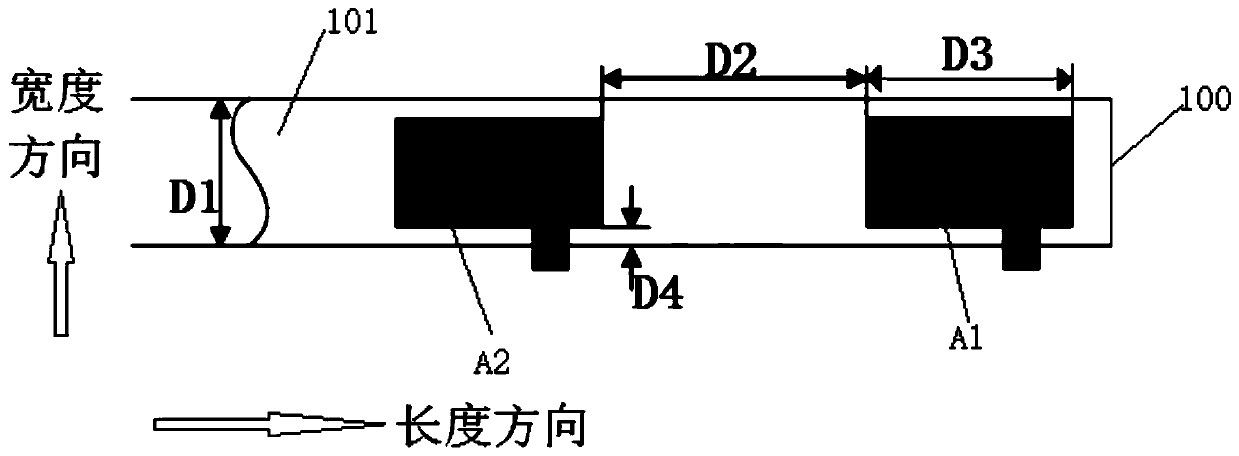

Lithium ion battery and preparation method thereof

ActiveCN110380129AImprove stabilityImprove securityFinal product manufactureSecondary cellsElectrical batteryEngineering

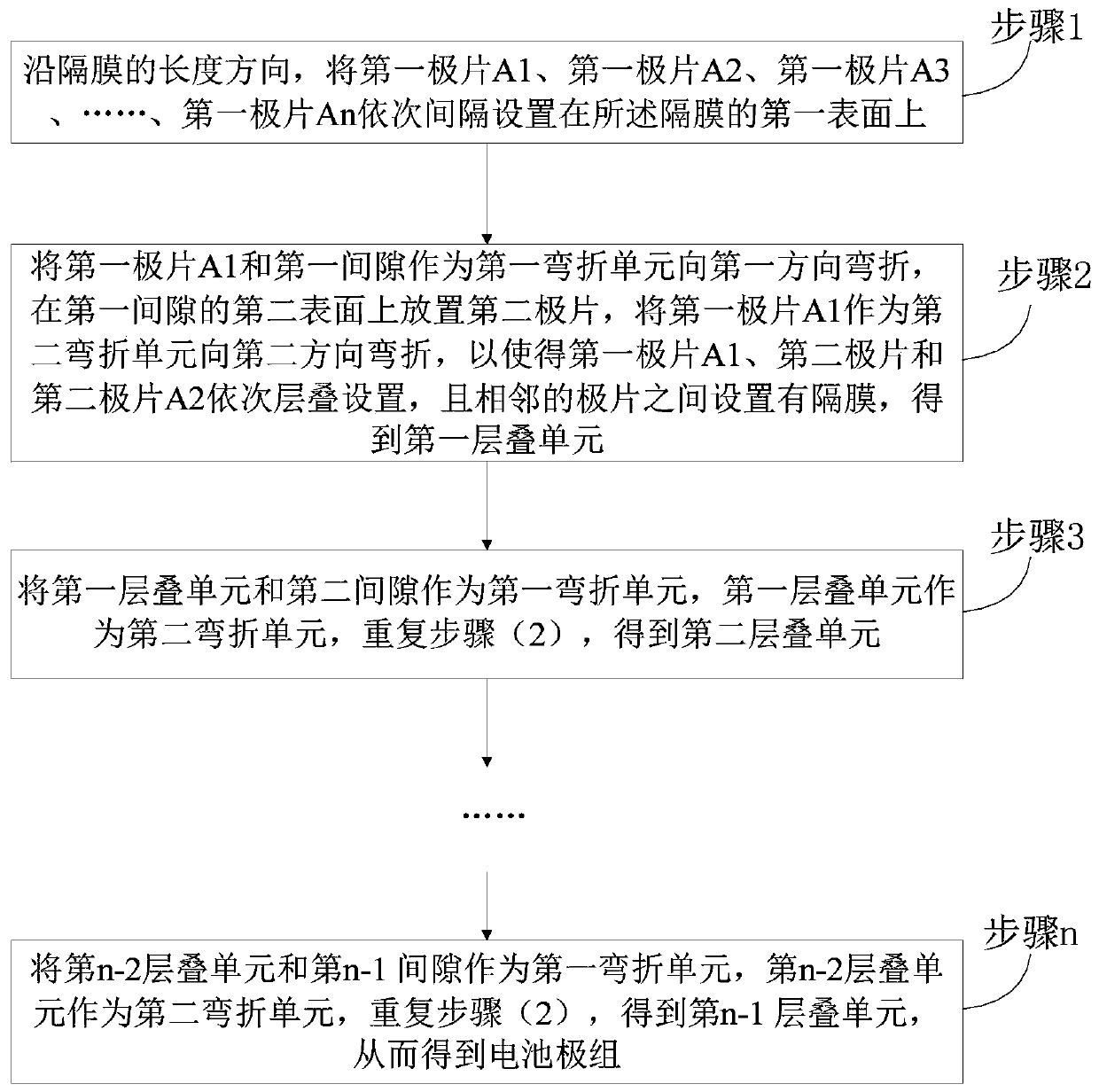

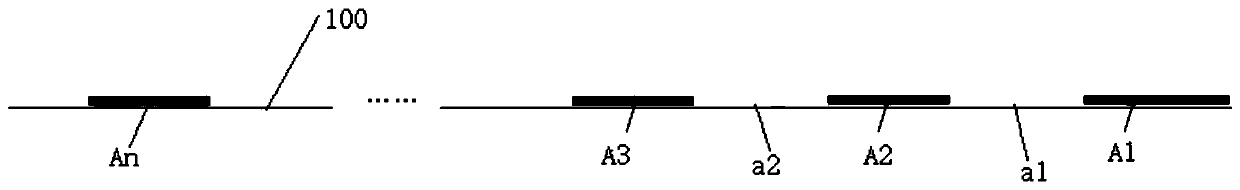

The invention provides a lithium ion battery and a preparation method thereof. The method comprises the steps of 1, arranging a first pole piece A1, a first pole piece A2, a third pole piece A3,..., and a first pole piece An on the first surface of a diaphragm at intervals in sequence along the length direction of a diaphragm; 2, taking the first pole piece A1 and a first clearance as a first bending unit which is bent towards a first direction, placing a second pole piece on the second surface of the first clearance, taking the first pole piece A1 as a second bending unit which is bent towards a second direction, and acquiring a first laminated unit; 3, taking the first laminated unit and a second clearance as a first bending unit, taking the first laminated unit as a second bending unit,repeating the step 2 to obtain a second laminated unit; ...; n, taking the (n-2)th laminated unit and the (n-1)th clearance as a first bending unit, taking the (n-2)th laminated unit as a second bending unit, repeating the step 2 to obtain a (n-1)th laminated unit, and thus obtaining a battery pole set. Therefore, the stacking time of the pole pieces can be reduced, and the preparation efficiencyof the lithium ion battery can be improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

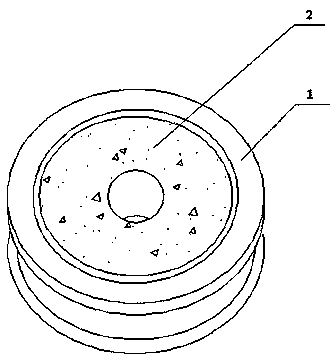

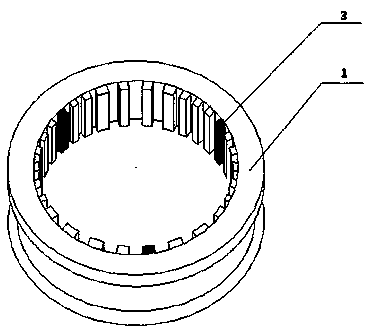

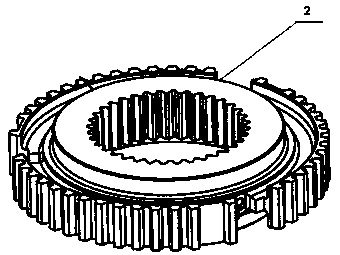

Synchronizer assembly for truck and machining technology thereof

InactiveCN109027035AImprove toughnessImprove wear resistanceMechanical actuated clutchesHobbingEngineering

The invention relates to a synchronizer assembly for a truck and a machining technology thereof, and belongs to the technical field of truck synchronizer and machining thereof. The synchronizer assembly comprises a gear sleeve and a gear core. The gear core is embedded in the gear sleeve, and the gear core and the gear sleeve are fixed and limited through a limiting device. The limiting device iscomposed of a sliding block, a sliding block mounting groove and an elastic element, and the sliding block is installed in the sliding block mounting groove through the elastic element. The sliding block mounting groove is formed in the gear sleeve. Gear teeth matched with the sliding block mounting groove are arranged on the outer surface of the sliding block. The machining technology comprises the following steps that the gear sleeve and the gear core are subjected to the processes such as normalizing, rough turning, finishing turning, gear hobbing, gear shaping and anti-rust oil applying, then are subjected to carburizing heat treatment, and then are subjected to polishing, ultrasonic cleaning, assembling, anti-rust oil applying and packaging, and a finished product is obtained. The prepared synchronizer assembly has the advantages that synchronize axial movement is not prone to occurring, the service life is long, abrasion is not prone to occurring, and the strength is high.

Owner:福建省真发齿轮股份有限公司

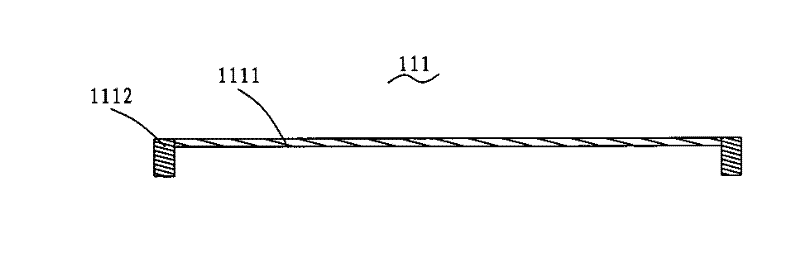

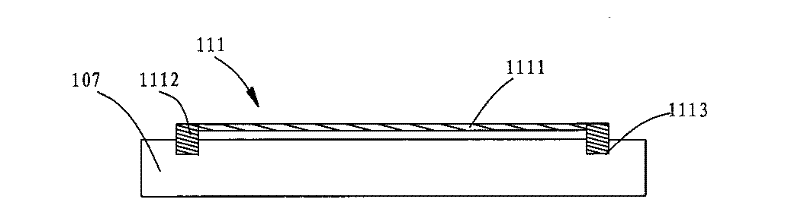

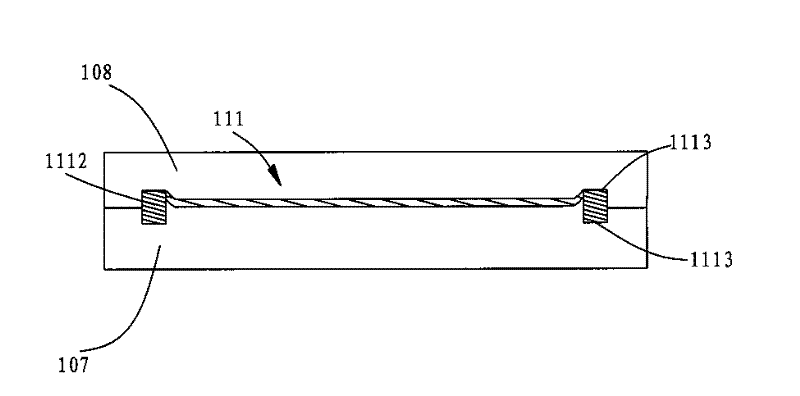

Flexible screen bending test device

InactiveCN108106948ANot easy to misplaceImprove test stabilityMaterial strength using steady bending forcesEngineeringMechanical engineering

Owner:苏州吉赛电子科技有限公司

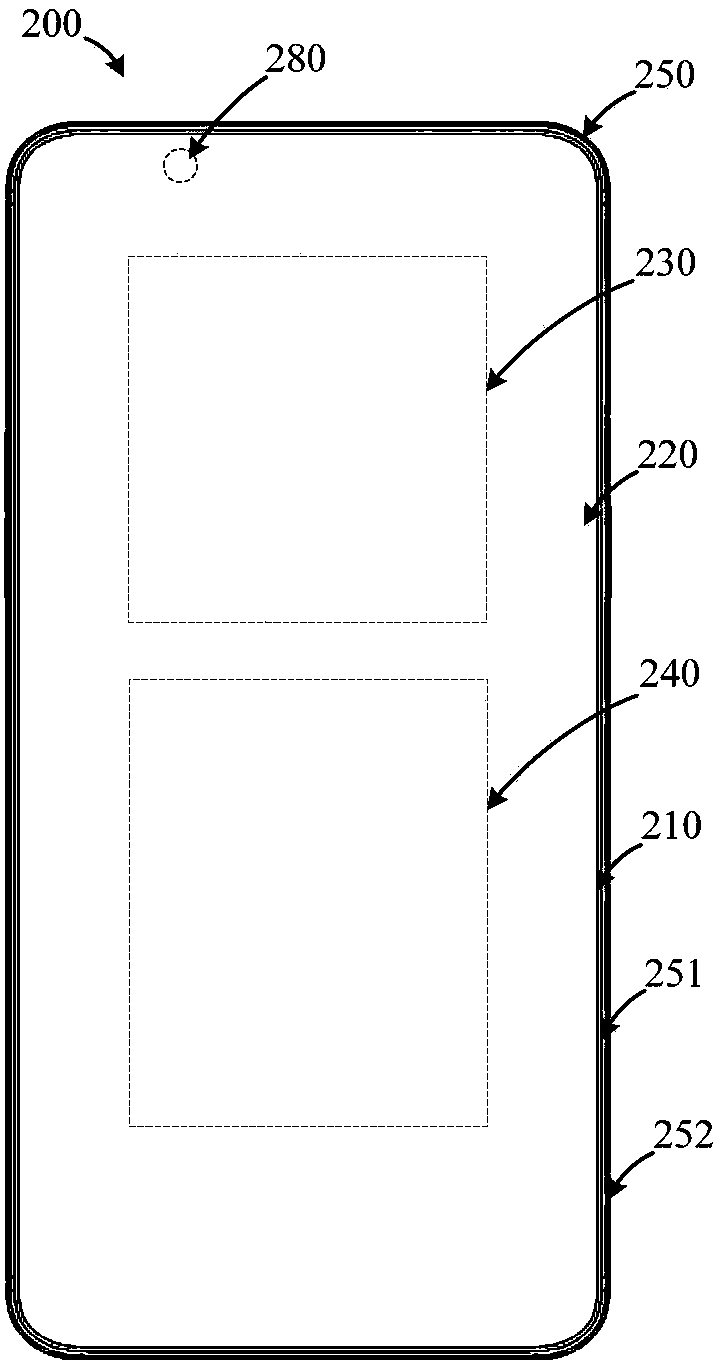

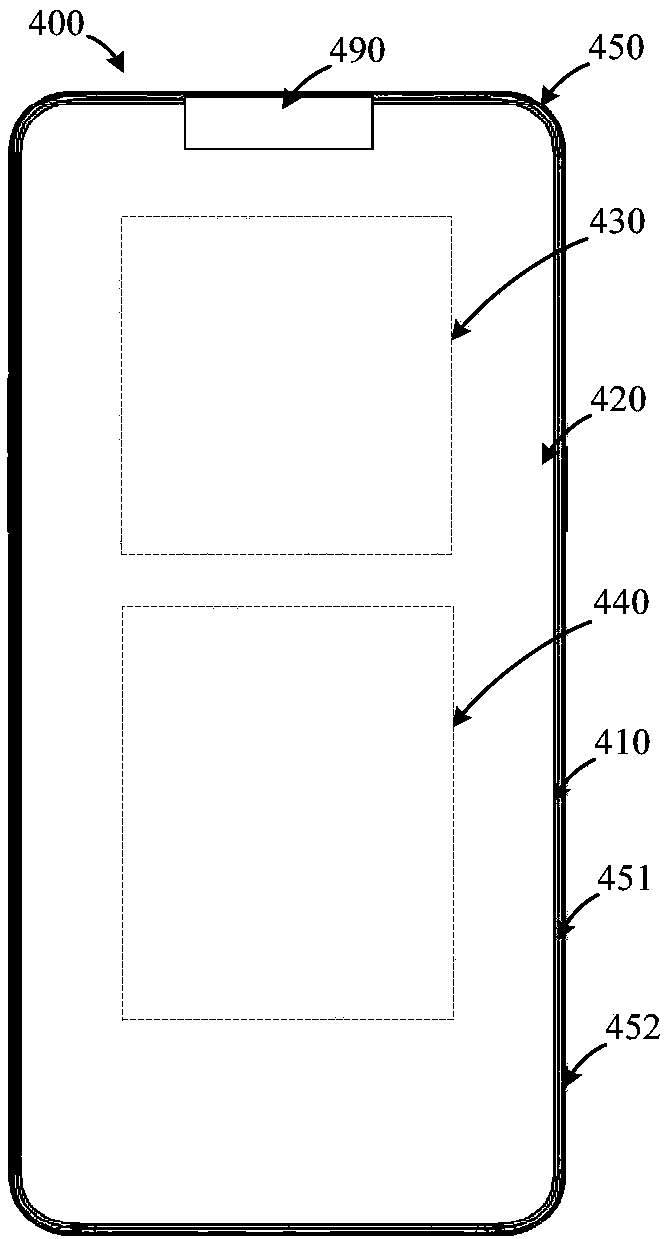

Display screen component, display screen component assembling method and electronic equipment

ActiveCN108254958AImprove waterproof performancePrecise positioningSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveComputer engineering

The embodiment of the invention provides a display screen component, a display screen component assembling method and electronic equipment. The display screen component assembling method comprises thesteps that a first gasket is connected to a cover plate; a second gasket is connected to a backlight module; the first gasket is connected with the second gasket so as to make the cover plate, a display screen and the backlight module sequentially clamped between the first gasket and the second gasket; the periphery of the backlight module and the periphery of the display screen are subjected tofirst dispensing processing to form a first waterproof adhesive, and the periphery of the backlight module and the periphery of the display screen are in seal joint through the first waterproof adhesive; the first gasket and the second gasket are removed to form a first notch in the first waterproof adhesive; second dispensing processing is conducted at the first notch position, a second waterproof adhesive is formed, and the second waterproof adhesive and the first waterproof adhesive are fixedly connected to form a whole waterproof adhesive structure. Accordingly, the waterproof property ofthe display screen component can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Limb bracket

Owner:谭秀香

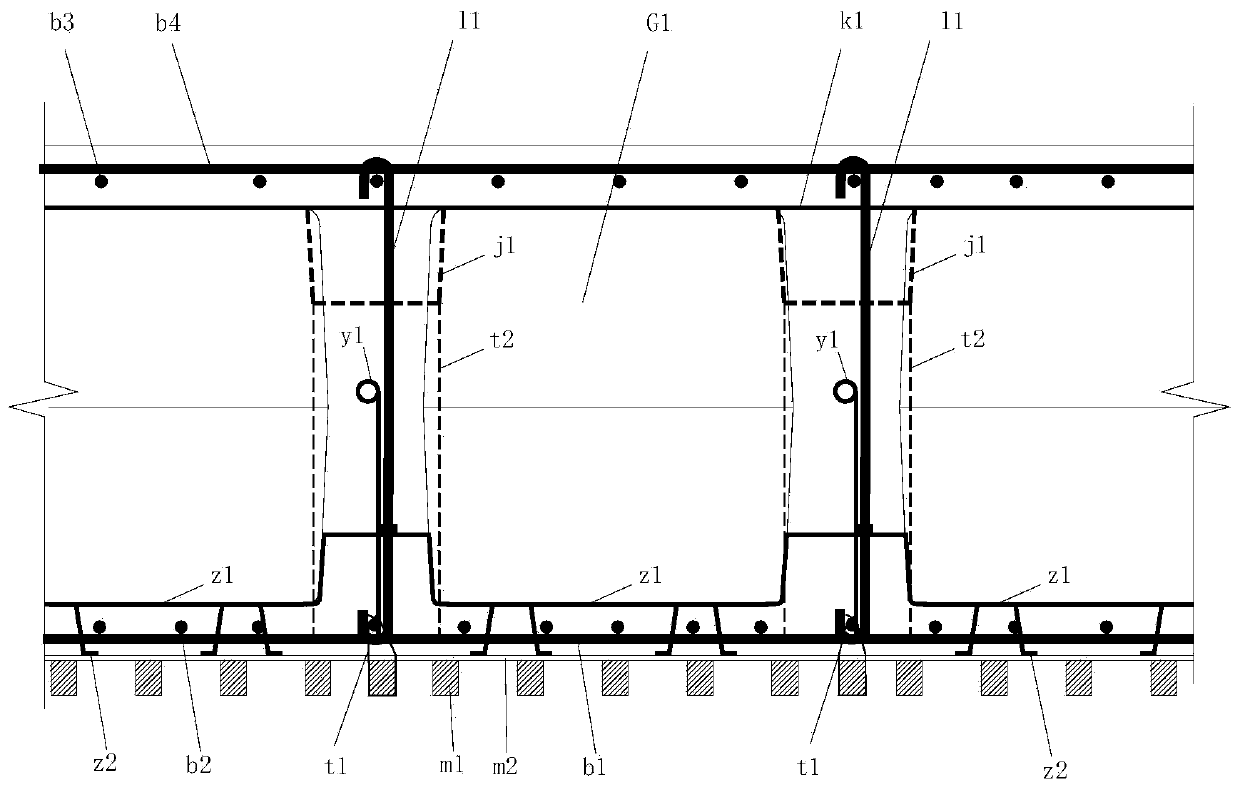

Prestress thick plate hollow floor construction method

The invention relates to a prestress thick plate hollow floor construction method. The method comprises the steps: according to hollow floor design parameters, deepening the geometric dimension and arrangement parameters of a built-in hollow square box; determining arrangement parameters of an anti-floating tie bar; mounting a formwork; locating a hidden beam, a column cap, a multi-ribbed beam, ahigh-injection alloy square box and a reserved embedded facility and performing scribing; installing the hidden beam, column cap ribs, a plate bottom reinforcing steel bar, prestressed ribs and the reserved embedded facility; connecting the plate bottom reinforcing steel bar with the bottom template; laying a hollow square box bottom positioning device; laying a hollow square box; laying an anti-floating steel bar layer, and placing an upper positioning device; connecting the upper positioning device with the plate bottom reinforcing steel bar; placing a plate top reinforcing steel bar cushionblock, laying plate top reinforcing steel bars on the plate top reinforcing steel bar cushion block and performing binding, and tying the plate top reinforcing steel bars and the plate bottom reinforcing steel bars through tie bars; pouring concrete, and performing vibrating and maintaining; performing prestress tensioning, grouting and anchor sealing; and dismantling the formwork. The construction quality of the prestress hollow floor can be improved, and the field construction difficulty is reduced.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

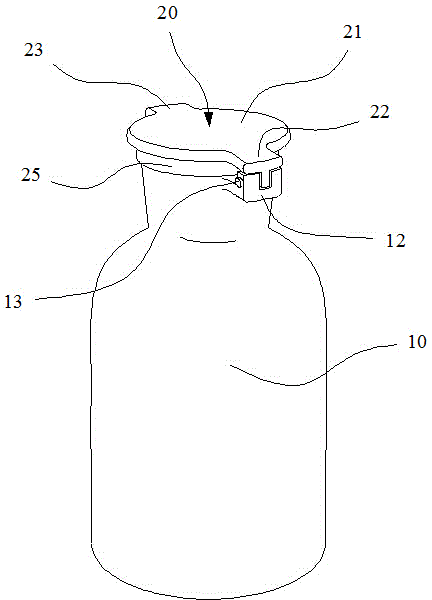

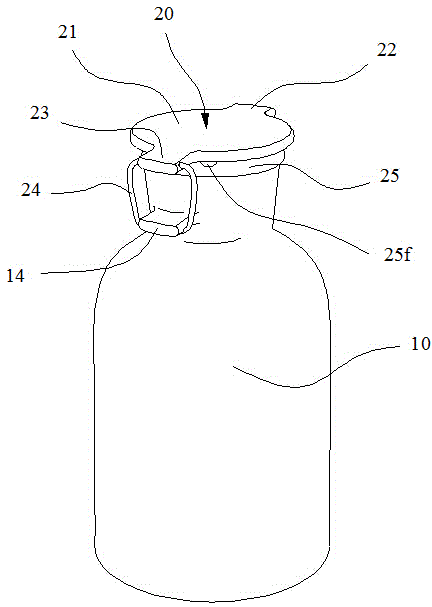

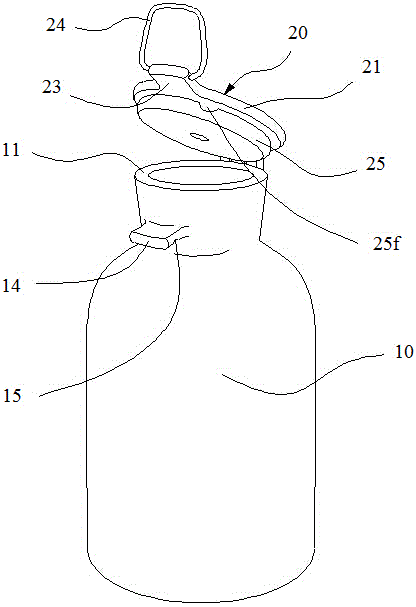

De-oxidant seal bottle

InactiveCN104528151AEasy to storeAvoid failureLaboratory glasswaresSealingEngineeringAtmospheric pressure

The invention provides a de-oxidant seal bottle. When a bottle cap is snapped at a bottle opening, a downward drawing force can be formed to extrude and attached the edge of a seal pad on the bottle cap to the bottle opening of a bottle body, and the upper end of a seal strut of the seal pad is promoted to be embedded in a vertical extension section of a second ventilation through hole in the capsule wall of the top of the seal pad to seal the second ventilation through hole. A snapping ring is withdrawn from a protrusion portion of the bottle body and is held to lift a stretching portion of the bottle cap upwards to enable the bottle cap to rotate upwards around the connection mounting portion, the upper end of the seal strut can be pulled out of the second ventilation through hole, and accordingly, the seal effect is lost, the acting force for 'absorbing' the bottle cap due to the atmospheric pressure difference in and out of the bottle disappears along with the losing of the sealing effect, and the bottle cap of the seal bottle can be opened easily. By means of the seal bottle, the problems that frosted-opening glass bottles, wood-cork glass bottles and the like are inconvenient to save and use when being used for storing de-oxidants in the prior art are well solved.

Owner:CHONGQING YUEFA COMMODITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com