Small-diameter integrated wooden pillar and manufacturing method thereof

A production method and technology of small-diameter materials, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of reduced strength, easy dislocation, and low strength, and achieve the effects of improved compressive strength, good economic benefits, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

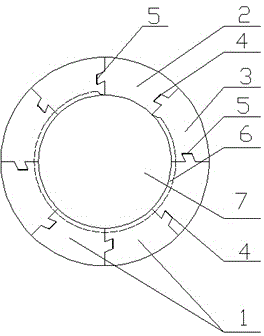

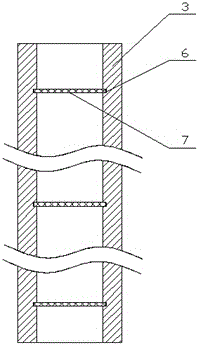

[0028] Example 1. A small-diameter timber-integrated wooden post, constituted as figure 1 with Figure 3-6 As shown, including inserting slat 2 and slat 3, the sides of inserting slat 2 and slat 3 are provided with tongue and groove 4 and tenon 5, and inserting slat 2 and slat 3 are connected end to end to form a ring-shaped slat group 1. During production, glue is applied to the contact surfaces of the slat 3 and the insert slat 2, the tenon groove 4 and the tenon 5, and the slat 3 and the insert slat 2 are connected end-to-end through the tenon and groove 4 and the tenon 5 to form a ring-shaped plate Strip group 1. Because the sides of the insert slat 2 and the slat 3 are provided with a tenon 4 and a tenon 5, the wooden bar 3 and the insert slat 2 are connected by the tenon 4 and the tenon 5, and the assembly of the tenon 4 and the tenon 5 It is relatively simple, and the mortise 4 and the mortise 5 are not easy to dislocate when assembled, and there is no need for surf...

Embodiment 2

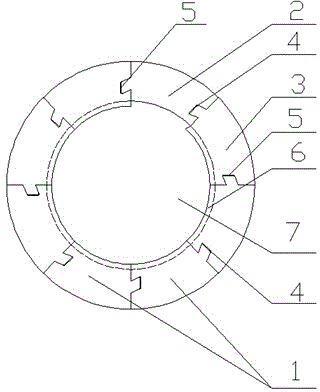

[0043] Embodiment 2. A kind of small-diameter wood integrated wooden column, constitutes as Figure 2-6 As shown, including inserting slat 2 and slat 3, the sides of inserting slat 2 and slat 3 are provided with tongue and groove 4 and tenon 5, and inserting slat 2 and slat 3 are connected end to end to form a ring-shaped slat group 1. During production, glue is applied to the contact surfaces of the slat 3 and the insert slat 2, the tenon groove 4 and the tenon 5, and the slat 3 and the insert slat 2 are connected end-to-end through the tenon and groove 4 and the tenon 5 to form a ring-shaped plate Strip group 1. Because the sides of the insert slat 2 and the slat 3 are provided with a tenon 4 and a tenon 5, the wooden bar 3 and the insert slat 2 are connected by the tenon 4 and the tenon 5, and the assembly of the tenon 4 and the tenon 5 It is relatively simple, and the mortise 4 and the mortise 5 are not easy to dislocate when assembled, so there is no need for surface ro...

Embodiment 3

[0058] Example 3. A small-diameter timber-integrated wooden post, constituted as figure 1 with Figure 3-6 As shown, including inserting slat 2 and slat 3, the sides of inserting slat 2 and slat 3 are provided with tongue and groove 4 and tenon 5, and inserting slat 2 and slat 3 are connected end to end to form a ring-shaped slat group 1. During production, glue is applied to the contact surfaces of the slat 3 and the insert slat 2, the tenon groove 4 and the tenon 5, and the slat 3 and the insert slat 2 are connected end-to-end through the tenon and groove 4 and the tenon 5 to form a ring-shaped plate Strip group 1. Because the sides of the insert slat 2 and the slat 3 are provided with a tenon 4 and a tenon 5, the wooden bar 3 and the insert slat 2 are connected by the tenon 4 and the tenon 5, and the assembly of the tenon 4 and the tenon 5 It is relatively simple, and the mortise 4 and the mortise 5 are not easy to dislocate when assembled, so there is no need for surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com