Patents

Literature

62results about How to "Act as an oxygen barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

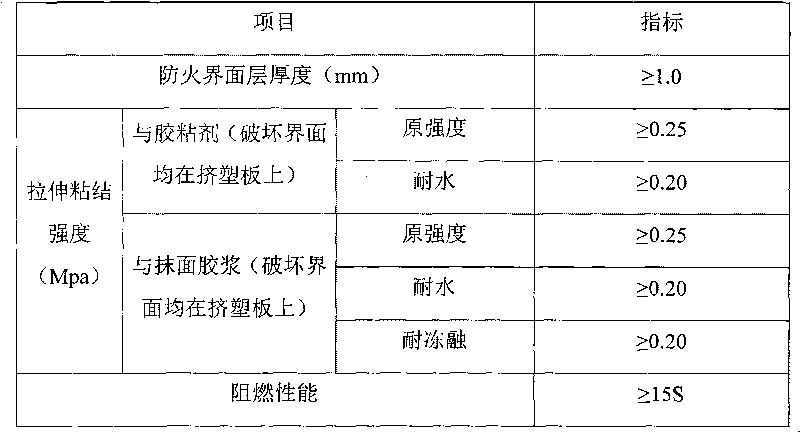

Special fireproof mortar of plastic extrusion plate

The invention relates to special fireproof mortar of a plastic extrusion plate. A fireproof protection layer is formed at the surface of the plastic extrusion plate, can act as the function of isolating oxygen and enables the oxygen not to directly contact with the extrusion molding plate, thereby avoiding the generation of a combustion reaction. The mortar comprises the following components: 20-50% of cement, 20-60% of sand, 2-10% of dispersible emulsion powder, 0-40% of inorganic composite material and 0.5-10% of organic composite material.

Owner:北京艺高世纪科技股份有限公司

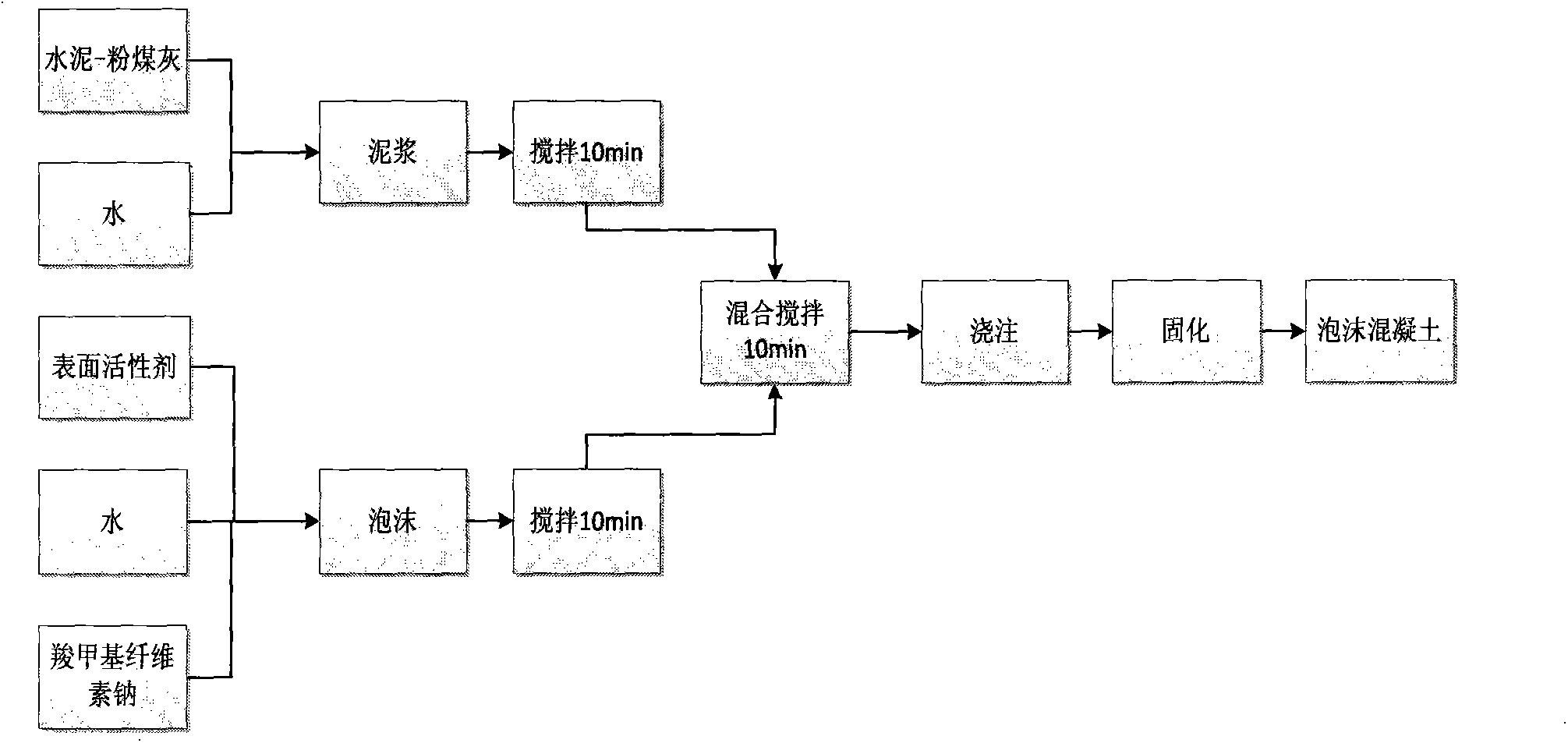

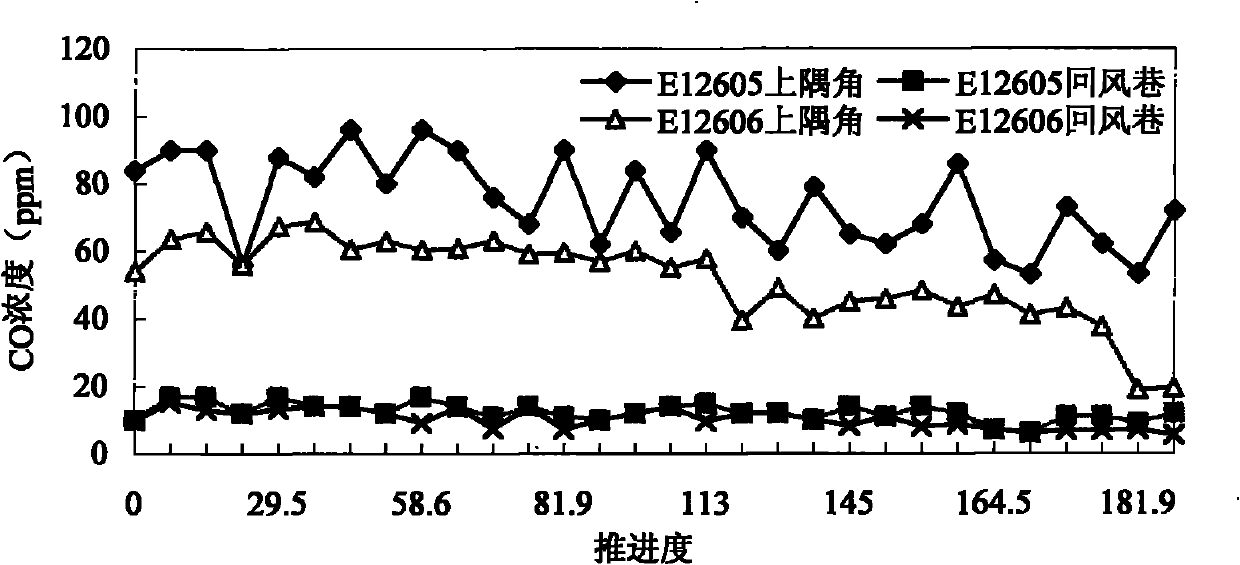

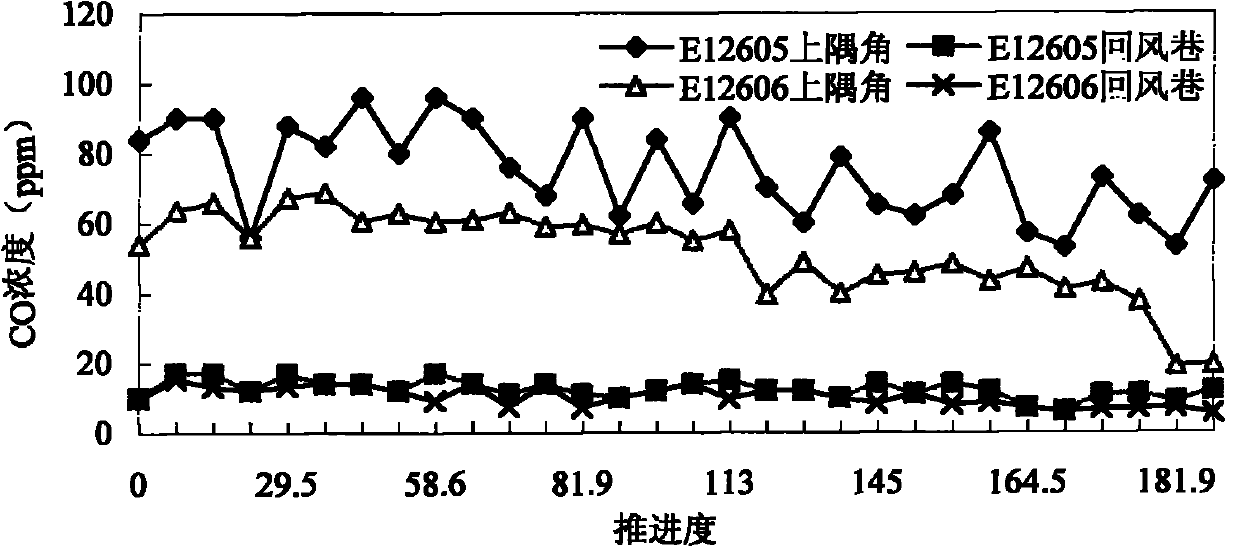

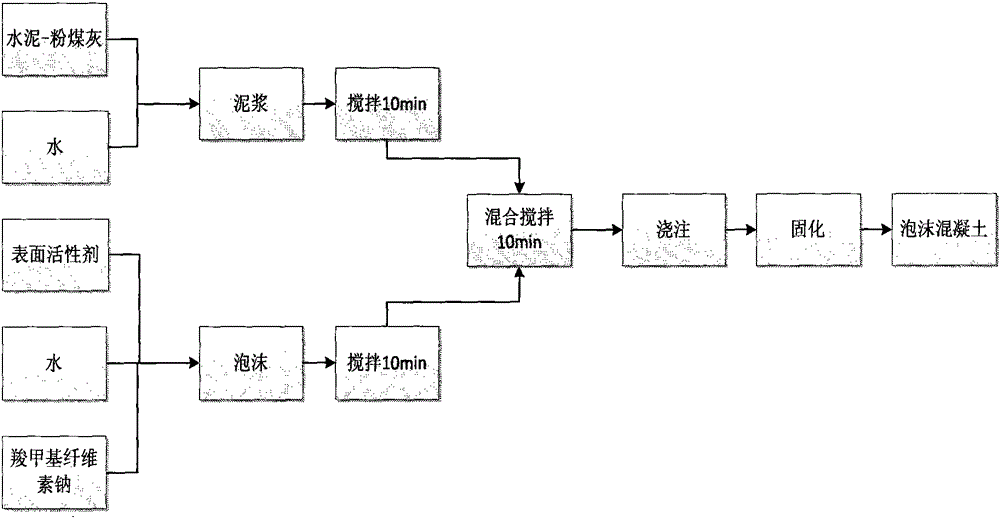

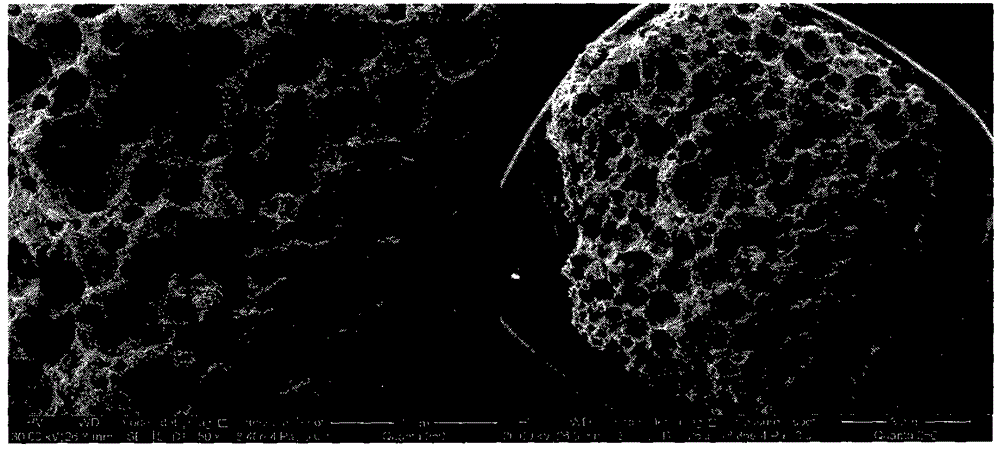

Pulverized fuel ash-cement foam material for controlling spontaneous combustion of coal and preparation method of pulverized fuel ash-cement foam material

ActiveCN103964766APrevent spontaneous combustionLow costCeramicwareSpontaneous combustionPulverized fuel ash

The invention discloses a pulverized fuel ash-cement foam material for controlling the spontaneous combustion of coal and a preparation method of the pulverized fuel ash-cement foam material. The pulverized fuel ash-cement foam material is prepared from the following components by weight: 10-40 % of sulfoaluminate superfine cement, 10-40 % of pulverized fuel ash, 0.5-0.9 % of carboxymethyl cellulose, 0.1-0.6 % of sodium fluoride, 0.2-0.6 % of melamine, 0.1-0.4 % of aluminum sulfate, 0.3-0.6 % of lauryl sodium sulfate, 0.4-0.6 % of sodium dodecyl benzene sulfonate, 0.5-0.8 % of saponin and the balance of water. The foam material is high in expansion rate of foam, long in stabilizing time, low in rate of water loss, good in plugging performance, and very suitable for extinguishment underground a coal mine. The pulverized fuel ash-cement foam material has the advantages of being low in cost, good in plugging performance, high in strength, simple to construct and the like.

Owner:胡相明

Inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in goaf of coal mine

InactiveCN101766877AAvoid contactStop spontaneous combustionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention discloses an inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in a goaf of a coal mine, which belongs to the field of fire prevention and extinguishment in the goaf of the coal mine. The inorganic salt type inhibitor consists of sodium bicarbonate, calcium bicarbonate, calcium chloride, magnesium chloride, sodium chloride and zinc chloride according to a certain proportion by weight. The average inhibiting rate of the inorganic salt type inhibitor can achieve 85%, and the inhibiting effect is ideal. When in use, the inhibitor is covered on the surface of the residual coal in the goaf, thereby achieving the effects of preventing and controlling the spontaneous combustion of a coal layer in the region for a long time. The dusting method of the inorganic salt type inhibitor for fire prevention and extinguishment is safe and stable, the process flow is simple, the operation is convenient, the initial investment is low, and the using cost is relatively low. The fire prevention and extinguishment technology of the inorganic salt type inhibitor which has thermal instability and can release inert gas carbon dioxide has broad application prospects in the work of preventing and controlling the spontaneous combustion fire disasters of the coal layers. The inorganic salt type inhibitor is applicable to the fire prevention and extinguishment in the goaf of the coal mine.

Owner:UNIV OF SCI & TECH BEIJING

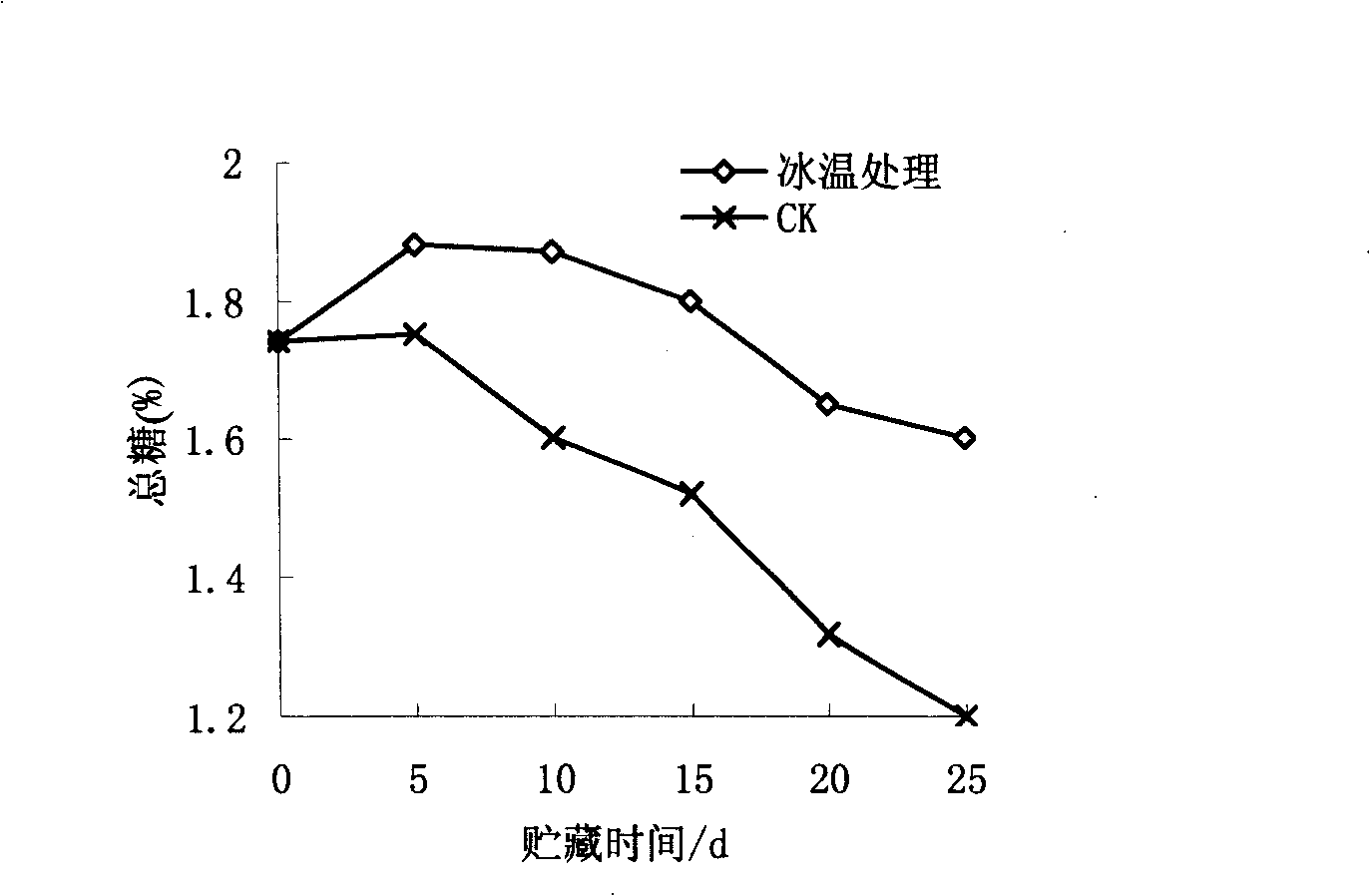

Preservation fresh-keeping method for white gold needle mushroom

InactiveCN101258869AInhibitory activityReduced activityFruits/vegetable preservation by freezing/coolingFruits/vegetable preservation by dehydrationFood additiveUltimate tensile strength

The invention discloses a storing and fresh preserving method for white flammulina velutipes, which pertains to the technical field of storage and fresh preservation of agricultural commodity. The method comprises the steps of: (1) harvesting, finishing and grading of the white flammulina velutipes; (2) preparation of anti-browning inhibitors and the treatment thereof; (3) treatment of low temperature and dryness; (4) vacuum packaging; (5) storage at ice temperature until delivering out of a storehouse and distributing to the market. The white flammulina velutipes stored by the method is characterized by reducing the rotting rate, enzymatic browning and the respiration rate, lengthening the preservation period which reaches 20 to 30 days, keeping the original color, fragrance, taste, shape and nutrition, etc., and reaching a commodity rate over 95 percent. The anti-browning inhibitors are the food additives which are permitted by the country and are safe and reliable. The method of the invention can be widely applied in the fields of production, storage and fresh preservation and operation of the flammulina velutipes.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

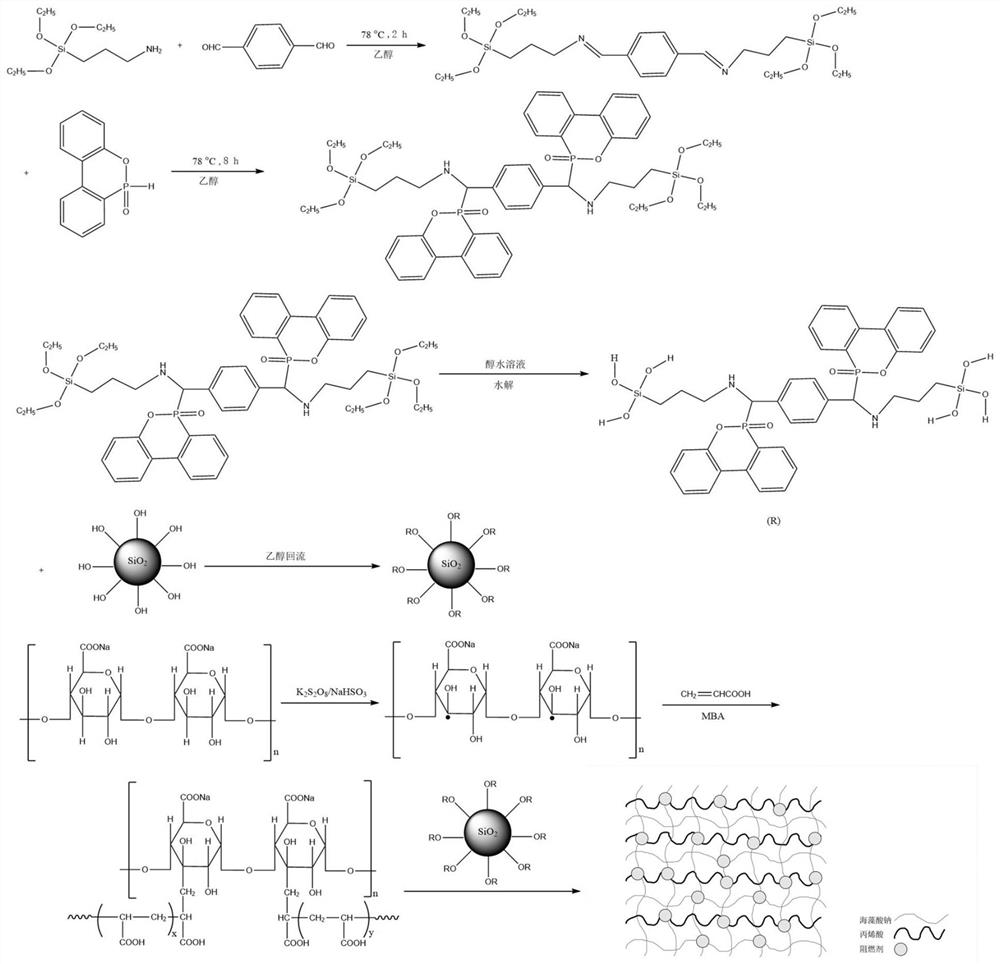

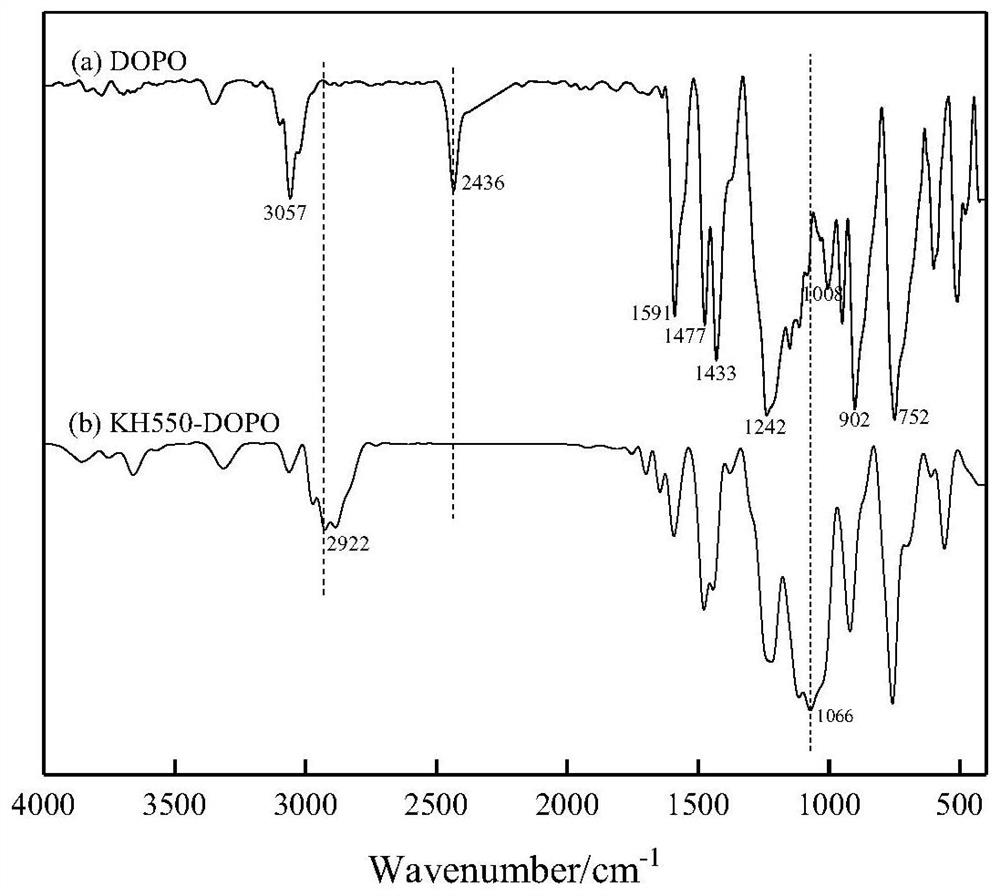

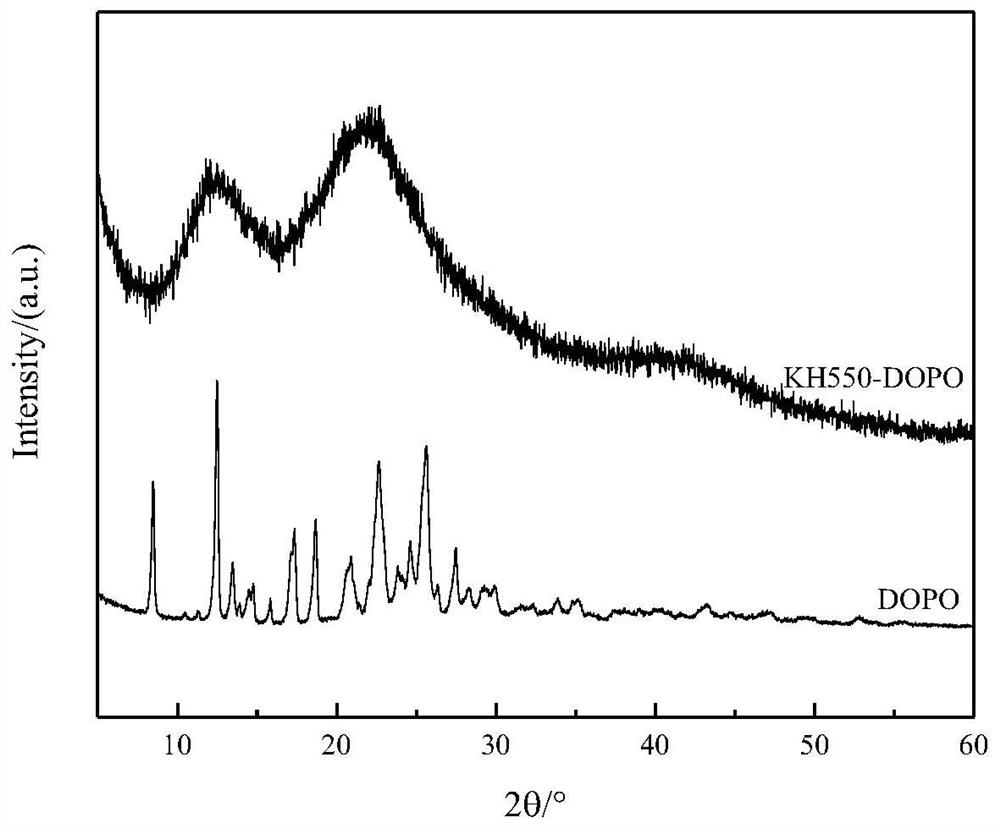

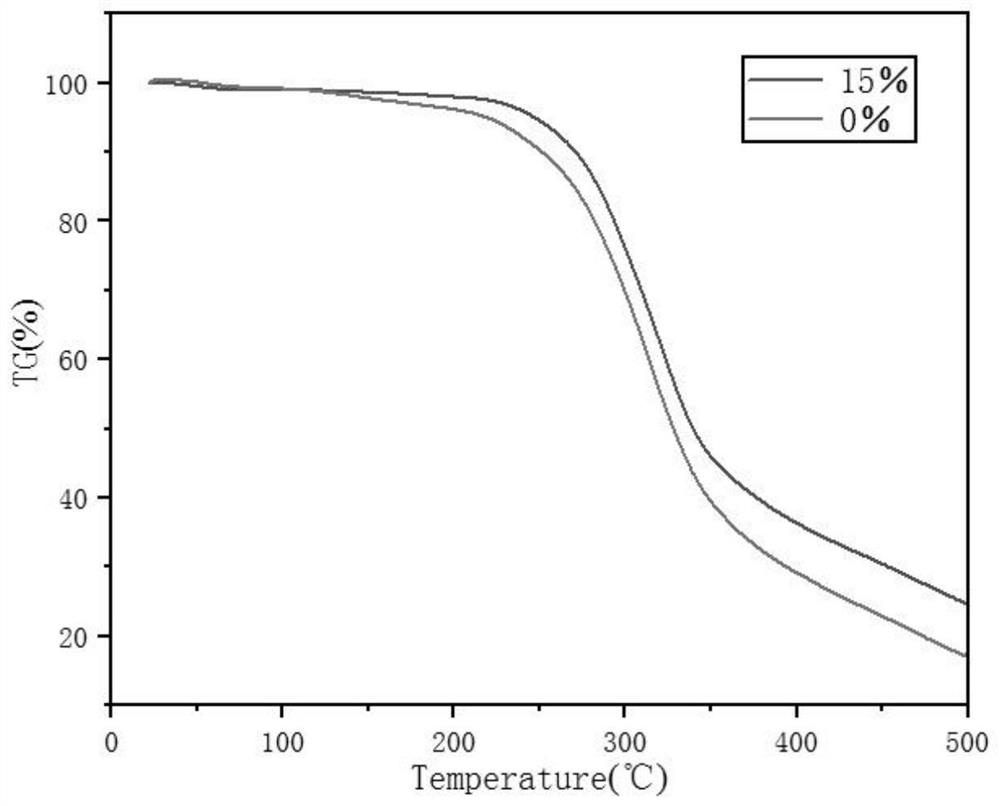

Nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and preparation method thereof

ActiveCN111849270AAvoid breakingNot easy to driftFireproof paintsOther chemical processesSilanesActive agent

The invention belongs to the field of coal flame-retardant dust suppressants. The invention specifically discloses a nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and apreparation method thereof. The nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant comprise the following components: 0.08 to 0.12 part of a phosphorus-based flame retardant, 0.10 to 0.14 part of a nitrogen-containing silane coupling agent, 0.01 to 0.05 part of an aldehyde compound, 100.0 to 200.0 parts of a solvent, 0.18 to 0.36 part of a silicon flame retardant, 0.1-0.4 part of a pH regulator, 83.0 to 125.0 parts of deionized water, 57.0 to 95.0 parts of alcohol, 1.0 to 2.0 parts of a natural polymer, 10.0 to 20.0 parts of a monomer, 4.0 to 8.0 parts of a pH buffer agent, 0.1 to 0.4 part of an initiator, 0.02 to 0.08 part of a cross-linking agent, 0.2 to 0.4 part of a surfactant and 0.2 to 1.0 part of a plasticizer. The preparation method comprises the following steps: grafting a nitrogen-containing silane coupling agent onto phosphorus flame retardant molecules by using an aldehyde compound, then hydrolyzing the silicon-based flame retardant, carrying outdehydration reaction between hydroxyl groups on the hydrolyzed silicon-based flame retardant and surface hydroxyl groups on the silicon-based flame retardant to obtain a nitrogen-phosphorus-silicon synergistic flame retardant, and finally organically combining the nitrogen-phosphorus-silicon synergistic flame retardant with dust suppression components such as a natural polymer, a monomer, glycerol and a surfactant in the same system through a polymer free radical polymerization reaction, so that the flame retardant has flame retardance and dust suppression properties.

Owner:SHAANXI UNIV OF SCI & TECH

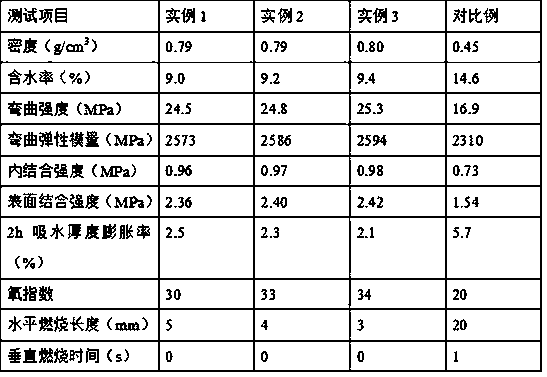

Preparation method of refractory moisture-proof wheat straw board

InactiveCN108372570AImprove thermal stabilityStop the spreadWood veneer joiningDomestic articlesAdhesivePotassium

The invention relates to the technical field of artificial board preparation, and in particular relates to a preparation method of a refractory moisture-proof wheat straw board. The preparation methodprovided by the invention comprises the following step of taking rice straw and wheat straw as raw materials to prepare modified straw fragments, and adding methyl triethoxysilane into a flame retardant material, processing to obtain silica gel microencapsulated ammonium polyphosphate, mixing a modified soybean protein adhesive with the silica gel microencapsulated ammonium polyphosphate to obtain a flame retardant adhesive, and finally, bonding and hot-pressing wheat straw board layers to obtain the wheat straw board. According to the preparation method provided by the invention, a silica gel microencapsulated ammonium polyphosphate is prepared by wrapping ammonium polyphosphate with the silica gel, thus improving the thermal stability of ammonium polyphosphate. In addition, ammonium polyphosphate can co-decompose with the protein adhesive in a high temperature combustion process to form metaphosphoric acid, and prevent oxygen and heat from further diffusing into the polyurethane foam, thus improving the refractory and flame retardant properties of the wheat straw board; methoxy groups and amine substances in the protein adhesive react to form potassium methyl silicate, and forma waterproof mineral film on the surface of the straw board, and broad application prospect is obtained.

Owner:许水仙

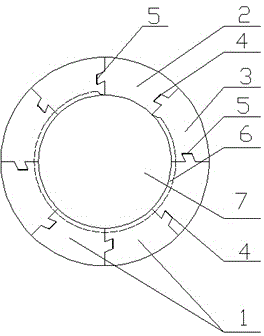

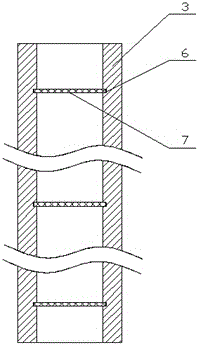

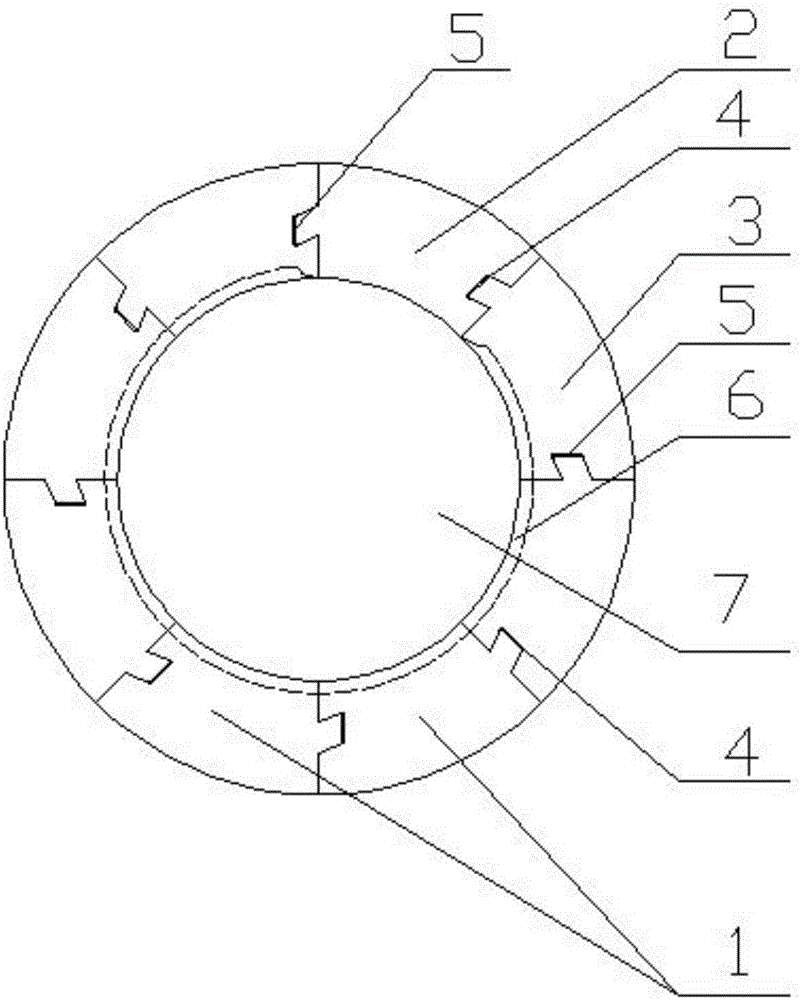

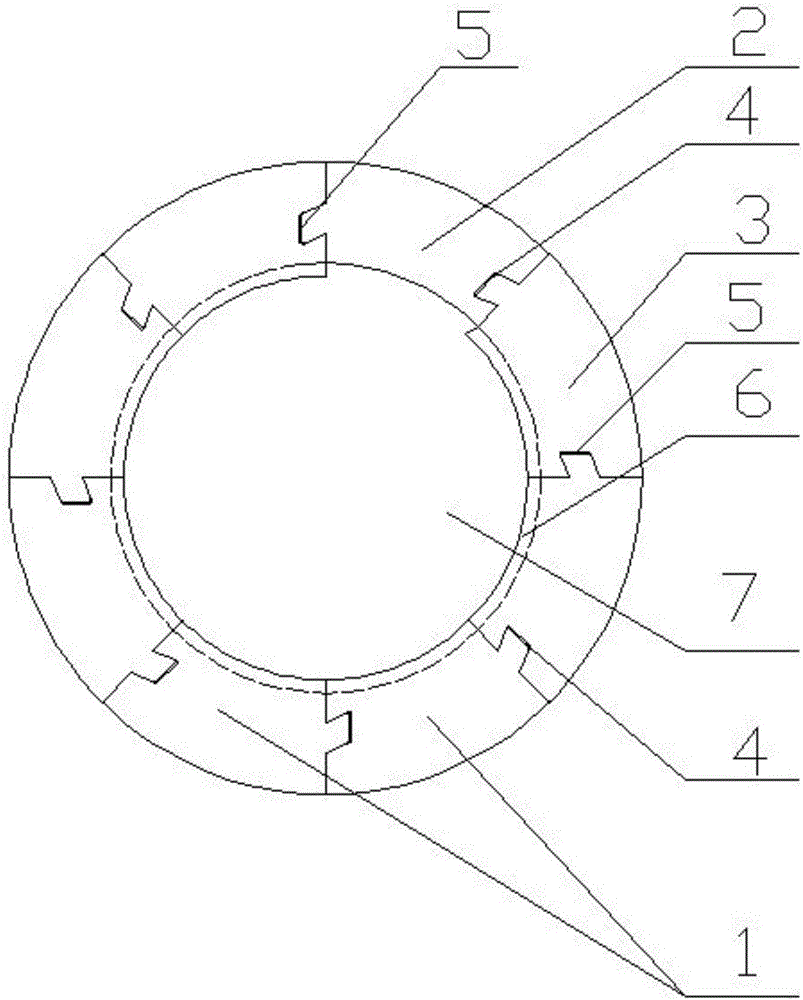

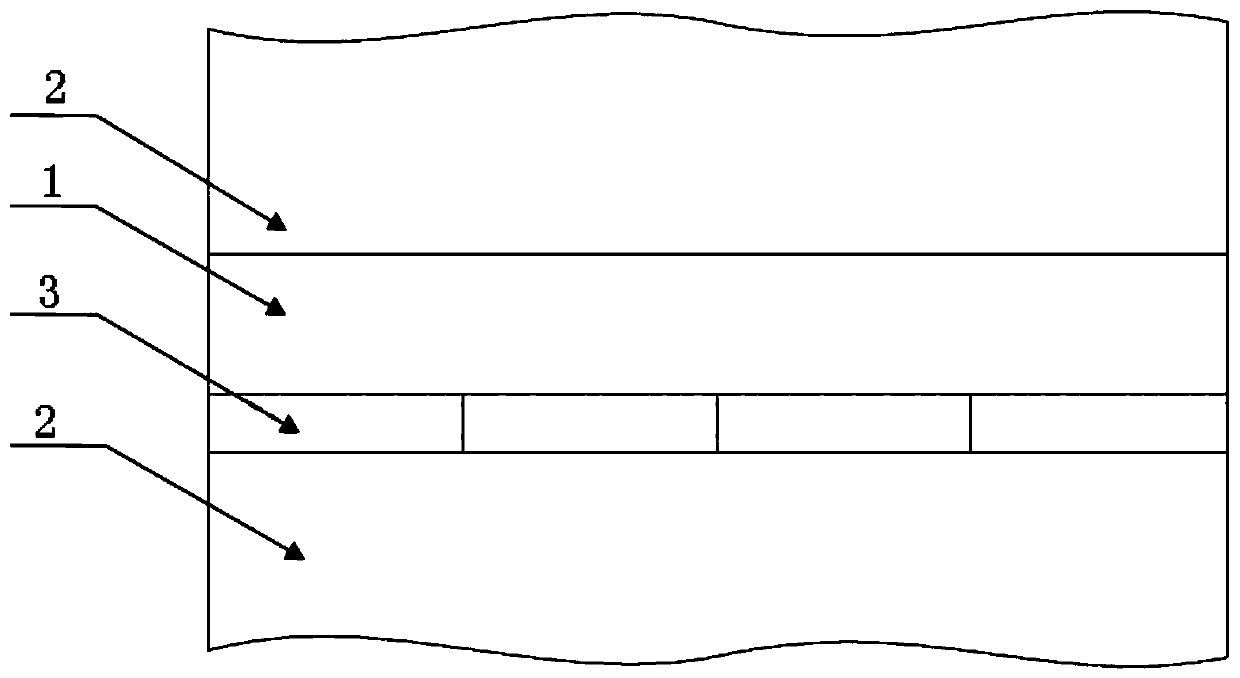

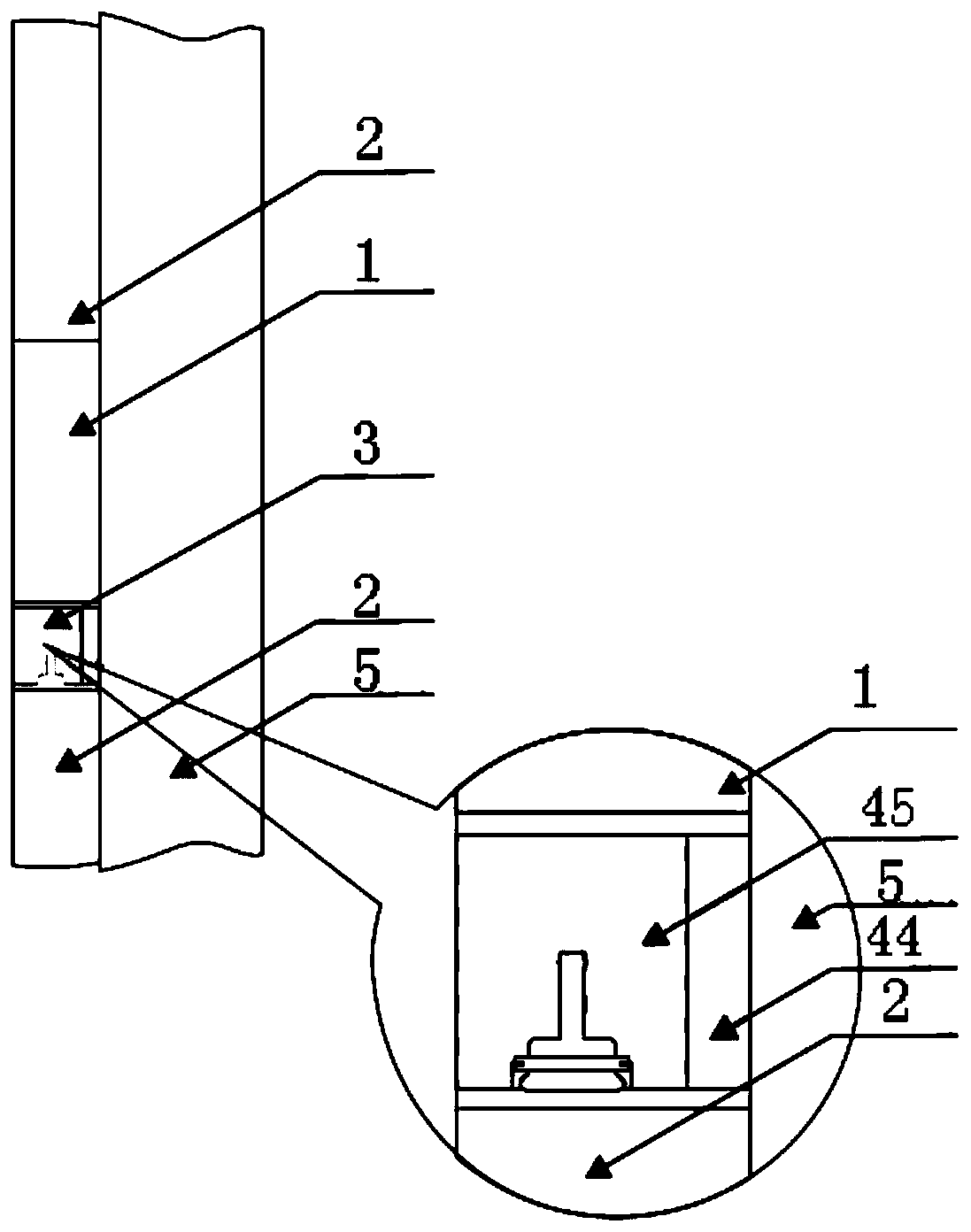

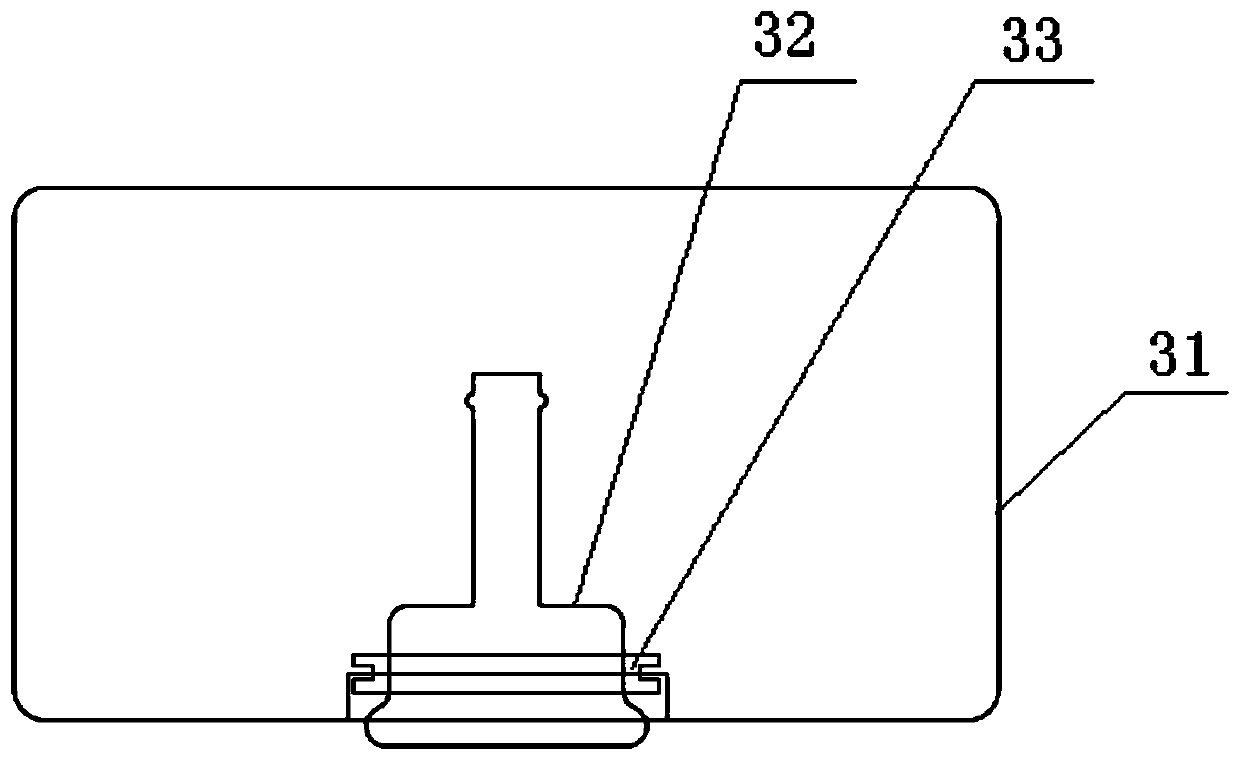

Small-diameter integrated wooden pillar and manufacturing method thereof

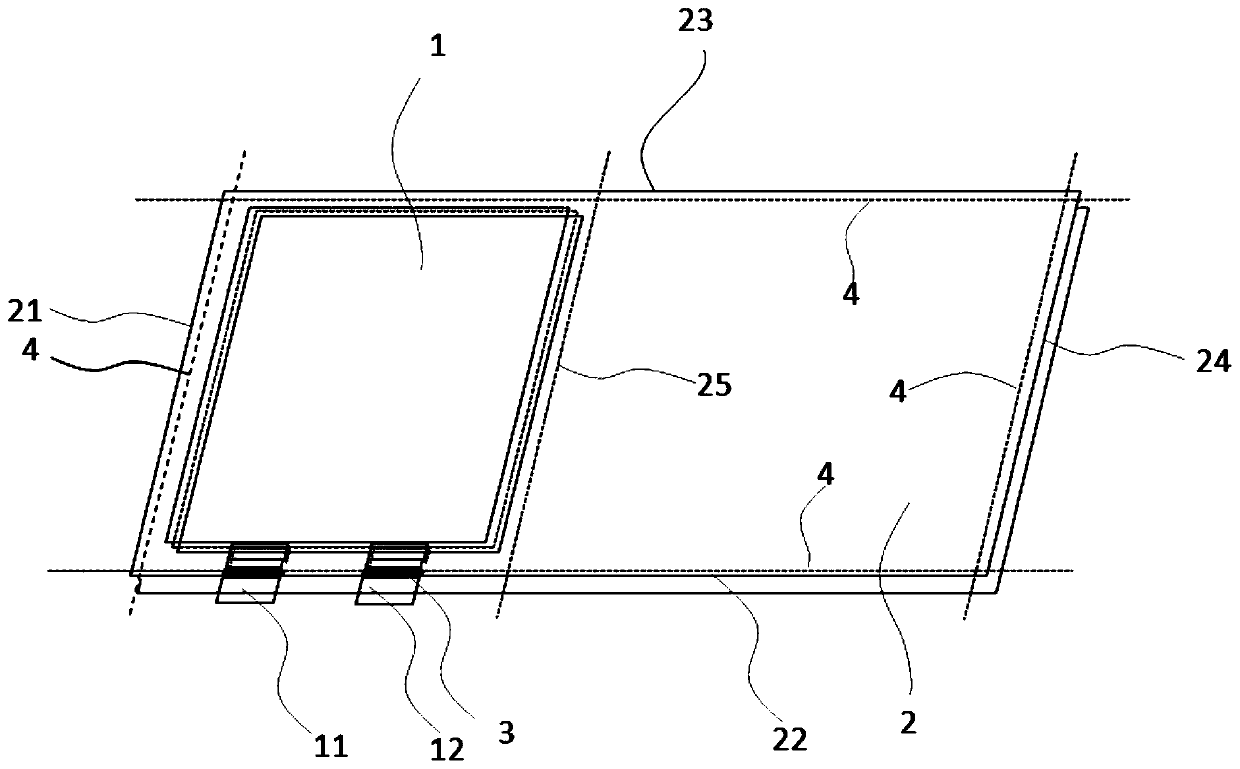

The invention discloses a small-diameter integrated wooden pillar and a manufacturing method thereof. The small-diameter integrated wooden pillar comprises inserted battens (2) and battens (3), wherein the side surfaces of the inserted battens (2) and the battens (3) are respectively provided with a mortise (4) and a tenon (5); the inserted battens (2) and the battens (3) are connected end to end, so that a ring-shaped batten group (1) can be formed. The small-diameter integrated wooden pillar is easy to assemble and cannot be in dislocation easily, does not need surface planing treatment, is good in fire resistance, high in strength and low in cost, and can meet the demand of a wood structure.

Owner:贵州剑河园方林业投资开发有限公司

Gaseous propellant fire extinguishing agent for aircraft dry chamber extinguishment

The invention discloses a gaseous propellant fire extinguishing agent for aircraft dry chamber extinguishment. The gaseous propellant fire extinguishing agent is prepared by the following steps: weighing 15-86 parts of solid fuel, 5-50 parts of an oxidizing agent, 1-5 parts of an adhesive, 5-40 parts of a coolant, 5-40 parts of a fire extinguishing agent, and 0.1-2 parts of a lubricant and 0.1-2 parts of a catalyst, uniformly mixing the raw materials, drying, grinding, mixing and preparing. The gaseous propellant fire extinguishing agent disclosed by the invention has the characteristics of being good in stability, high in emission efficiency, high in fire extinguishing efficiency and low in cooling rate. The defects that an existing propellant gas producing agent is bad in stability, high in temperature, bad in fire extinguishing performance and the like are overcome, and the fire extinguishing agent has the very high application prospect in the aircraft dry chamber extinguishment.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA +1

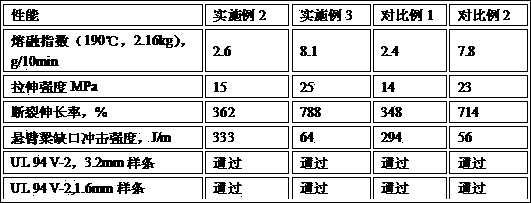

Environment-friendly adding type polyethylene flame-retardant masterbatch and preparation method thereof

ActiveCN103509263AHigh flame retardant efficiencyReduce smoke densityMasterbatchEnvironmental resistance

The invention discloses an environment-friendly adding type polyethylene flame-retardant masterbatch. The masterbatch comprises the following raw materials by mass: 10 parts of carrier resin, 15 parts of chlorinated polyethylene, 28 parts of decabromodiphenylethane, 10 parts of antimony trioxide, 3-10 parts of TBC (tri-N-butyl citrate) flame retardant, 12 parts of flame retardant synergist, 5-15 parts of MCA (melamine cyanurate) flame retardant, 8 parts of lubricating agent and 1 part of antioxidant. The polyethylene flame-retardant masterbatch is environment-friendly, non-toxic, clean and sanitary. The flame retardant efficiency is obvious; the processing performance is excellent; when the masterbatch is used for producing polyethylene products, the addition is low, so that the production cost for the polyethylene material can be greatly reduced; the polyethylene flame-retardant masterbatch is suitable for development of enterprises.

Owner:GUANGDONG JUSHI CHEM CO LTD

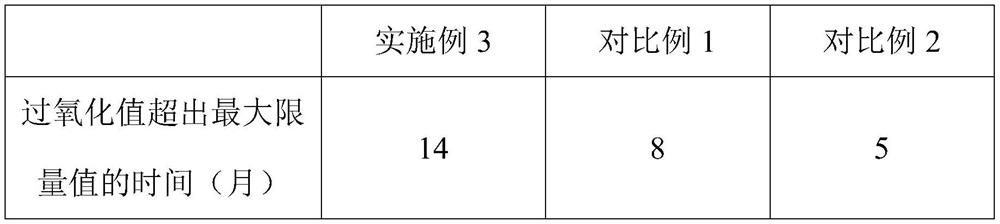

Method for retaining freshness of fresh cocoons

InactiveCN102965738AImprove drying rateGood fresh-keeping effectSilk filament obtainingDesiccantPreservative

The invention provides a method for retaining freshness of fresh cocoons and relates to a preservation method. The method comprises the following steps: placing inactivated fresh cocoons into a tent with six sealed surfaces; removing oxygen-enriched air from the tent; introducing carbon dioxide; and circularly air-drying, wherein water in a recycling gas channel is absorbed by a drying agent, the temperature in the tent is adjusted to be 10 to 25 DEG C, the fresh cocoons in the tent is circularly dried and the water of pupae in the circularly dried fresh cocoons is reduced to 15 percent. The invention researches and develops a new method for retaining freshness of the fresh cocoons, so that a fresh cocoon silk reeling process can be performed successfully and the problems of high energy consumption and atmospheric pollution in the traditional cocoon drying process. The device, the drying agent and the carbon dioxide adopted by the method are low in cost and pollution-free; the carbon dioxide is recycled, so the cost is saved greatly; a preservative is not added in the whole process, so guarantee is brought for the pupa processing, the silk quality is not changed and silk reeling is promoted.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Processing method of nut roasted food

InactiveCN112690332AImprove bindingImprove antioxidant capacityFood ingredient as antioxidantFood freezingBiotechnologyAntioxidant

The invention discloses a processing method of nut roasted food, which comprises the following steps: S1, soaking nut kernels in water for a certain period of time; S2, freezing the soaked nut kernels under high pressure, and then unfreezing and drying the frozen nut kernels to obtain pretreated nut kernels; and S3, soaking the pretreated nut kernels in an antioxidant solution, and then performing drying and baking so as to obtain the nut roasted food. According to the processing method disclosed by the invention, the oxidation resistance of the nut roasted food can be improved, nutrient and flavor substances in the food can be well reserved, and the prepared nut roasted food is pure in taste, rich in fragrance and long in shelf life, and has good market potential.

Owner:WUHU FEIYUE FOOD

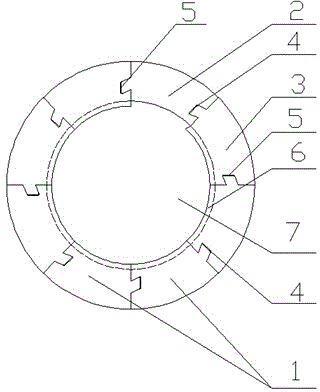

Small dimension integrated wooden pillar and production method thereof

InactiveCN106013616AEasy to assembleNot easy to misplaceStrutsWood working apparatusEngineeringUltimate tensile strength

The invention discloses a small dimension integrated wooden pillar and a production method thereof. The small dimension integrated wooden pillar comprises an insert lath (2) and a lath (3), a mortise (4) and a tenon (5) are arranged on each of the side surfaces of the insert lath (2) and the lath (3), the insert lath (2) and the lath (3) are connected end to end, and thus an annular lath group (1) is formed. The small dimension integrated wooden pillar is simple to assemble, dislocation is hardly caused, surface does not need to be rounded, flame retardance is good, strength is high, cost is low, and demand for wood structures also can be met.

Owner:贵州剑河园方林业投资开发有限公司

Continuous culture process of anaerobe strain

The invention discloses a continuous culture method for anaerobic strains which take polyvinyl alcohol complex gel as embedding material. The method comprises the following steps: a) mixing: 5 to 15mL caproic acid bacteria suspension fluid is added into 90mL polyvinyl alcohol complex gel solution in an anaerobic box; after being stirred evenly, the mixture is poured into a culture dish and paved into a plate; b) freezing and cutting into blocks: the mixture is frozen for 48 hours at the temperature of minus 20 DEG C, after taking shape, the mixture is taken out and cut into blocks with a boundary dimension of 12mm*10mm*12mm; c) culture: then the mixture is cultured in sodium acetate medium at the temperature of 37 DEG C. The method can realize continuous culture with simple operation and significant function of increasing the caproic acid bacteria and decreasing emulsion, so the method is suitable for extensive large industrialized production.

Owner:周剑平

Phosphorated-crosslinked-graphene flame-retardant composite material and preparation method thereof

The invention discloses a phosphorated-crosslinked-graphene flame-retardant composite material. The phosphorated-crosslinked-graphene flame-retardant composite material is prepared from the following raw materials in parts by weight: 1-2 parts of lauryl mercaptan, 0.1-0.2 part of diisocyanate, 6-7 parts of ammonium polyphosphate, 2-3 parts of phosphorus oxychloride, 6-7 parts of phenol, 18-25 parts of graphene oxide, 1-2 parts of tri(hydroxymethyl)propane, 17-20 parts of 2,4-xylenol, 0.03-0.1 part of aluminum chloride, 0.4-1 part of triallyl isocyanurate and 110-120 parts of polyvinyl chloride. The composite material disclosed by the invention has very good flame retardance; after the graphene oxide is subjected to organic modification, the dispersity of the graphene oxide among polyvinyl chloride can be effectively improved, and thus, the stability and strength of the finished product are improved.

Owner:商立华

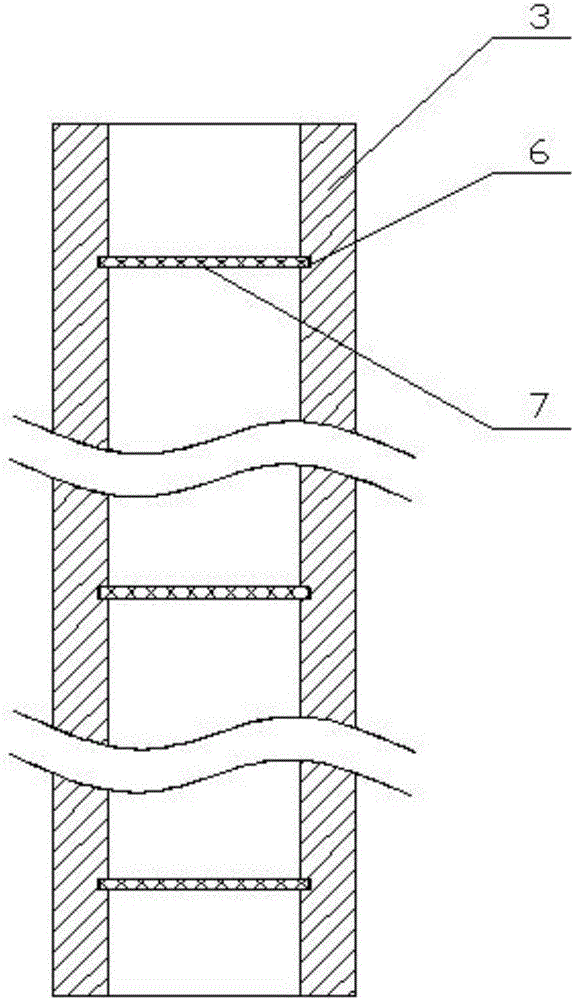

Preparation method of high water, oxygen and high temperature-resistant cell

ActiveCN110048167AReduce manufacturing costReduce consumptionFinal product manufactureJackets/cases materialsPower batteryAmbient humidity

The invention discloses a preparation method of a high water, oxygen and high temperature-resistant cell, and belongs to the field of preparation of lithium ion batteries. The surface of the cell is coated with an Al2O3 / PET / CPP insulating film composed of Al2O3, PET and CPP, and the insulating film can effectively resist water, oxygen and high temperature. The coating function of the Al2O3 / PET / CPPinsulating film makes that the prepared roll core reduces the control requirements on the ambient humidity in the post-charging and activation process after the heat sealing is completed, carried outunder normal temperature and humidity conditions, which greatly reduces the energy consumption during the cell preparation process and reduces the manufacturing cost of the power battery. Moreover, since the outer layer of the Al2O3 / PET / CPP insulating film is an Al2O3 layer having good performance of high temperature resistance, so that the prepared cell can still work normally at a high temperature, thereby improving the service life and safety performance of the power battery.

Owner:合肥国轩精密涂布材料有限责任公司

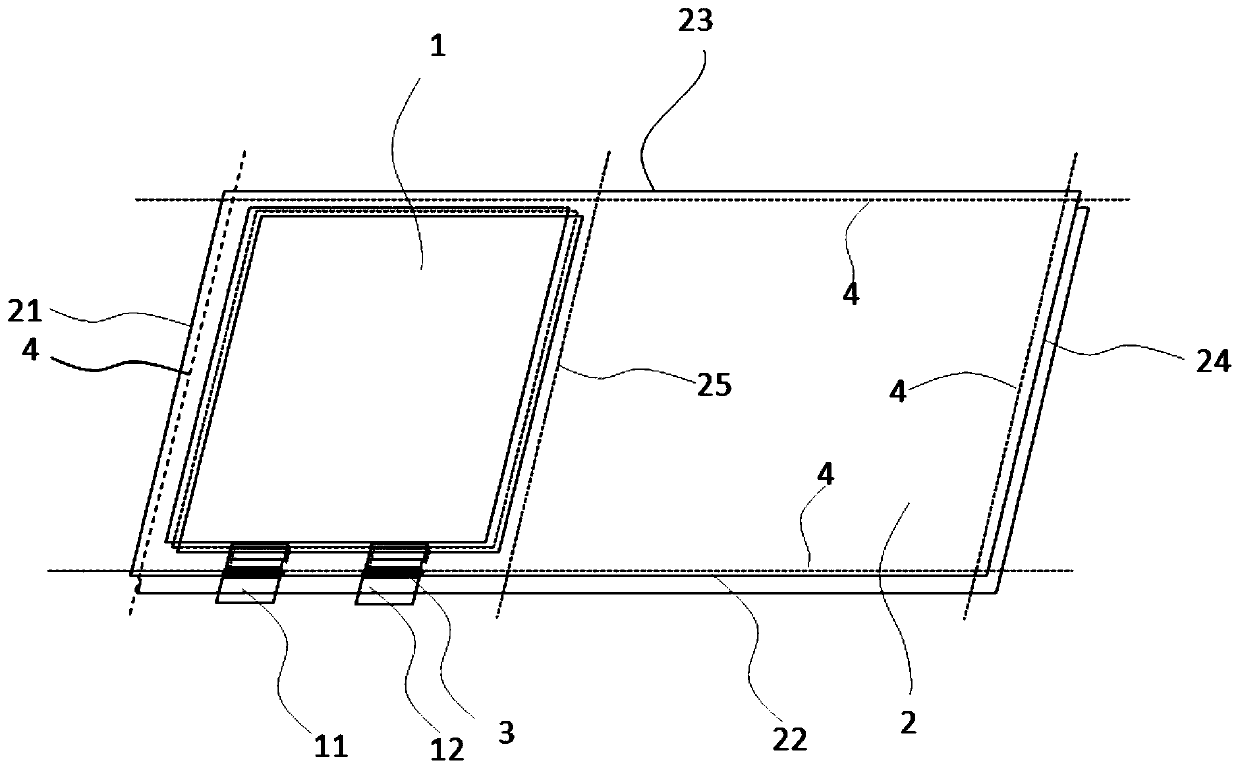

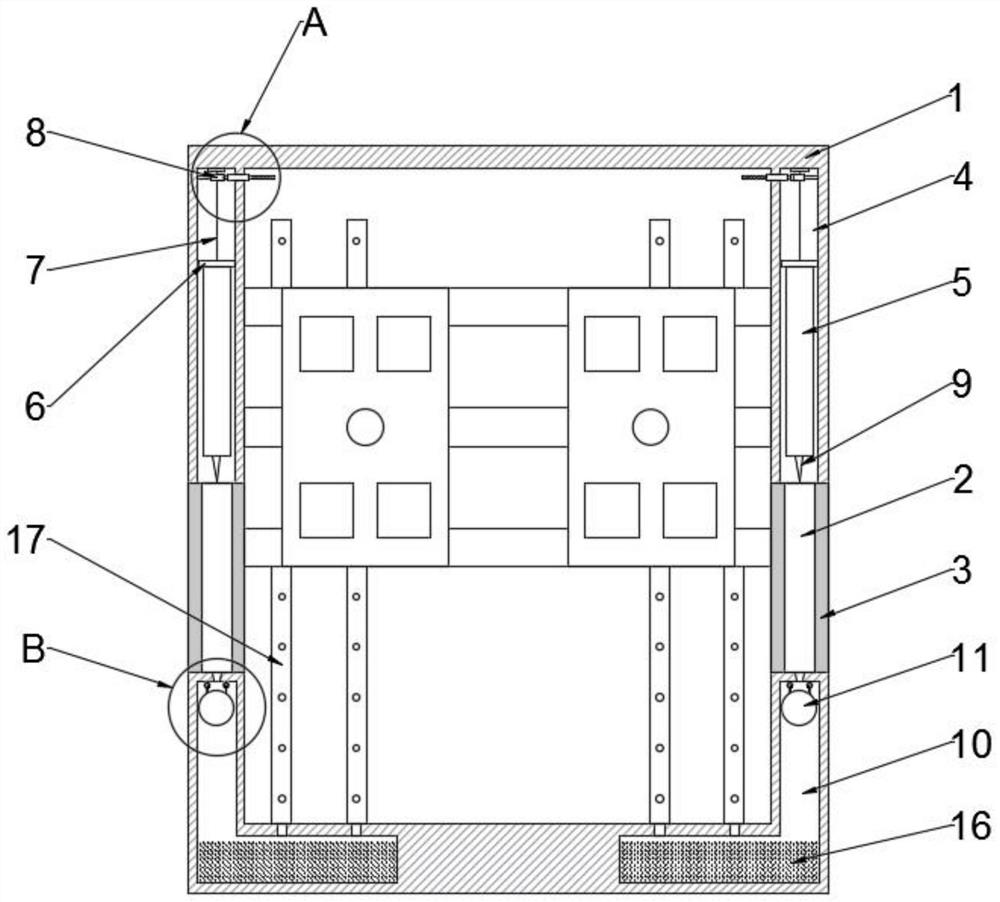

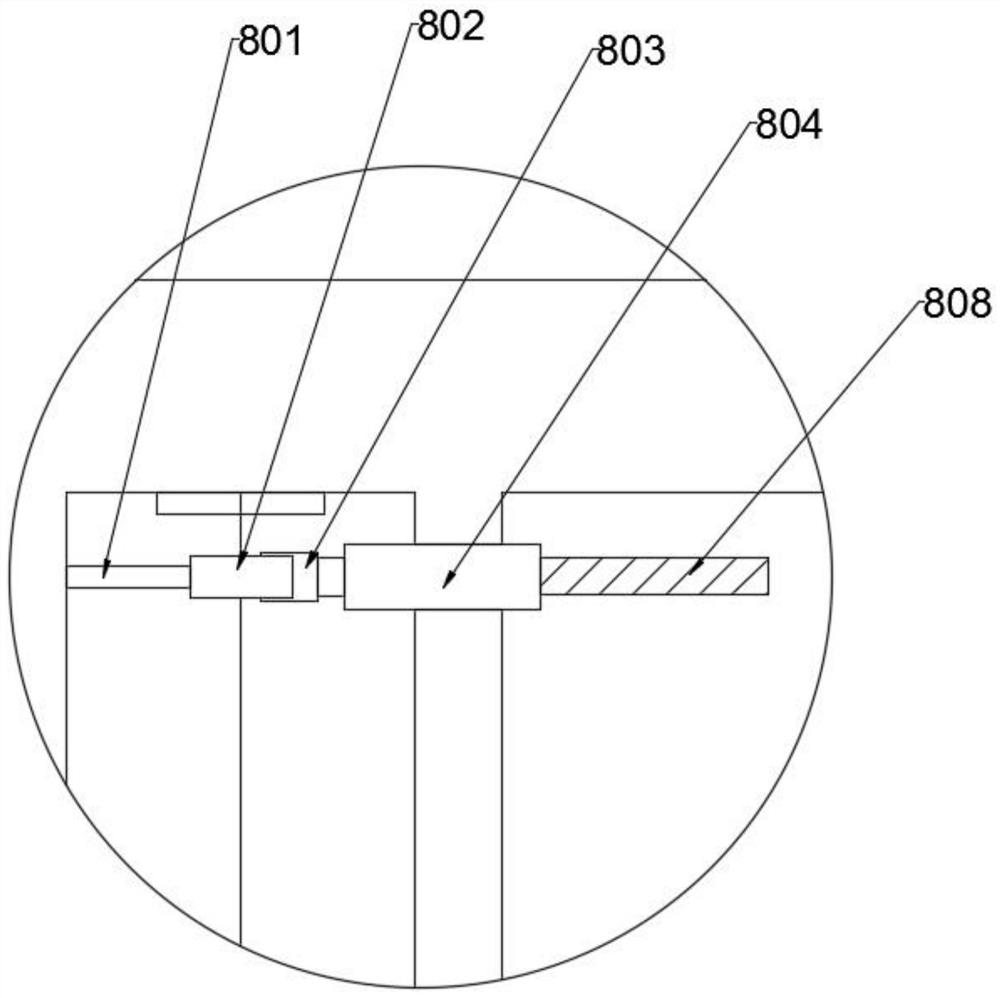

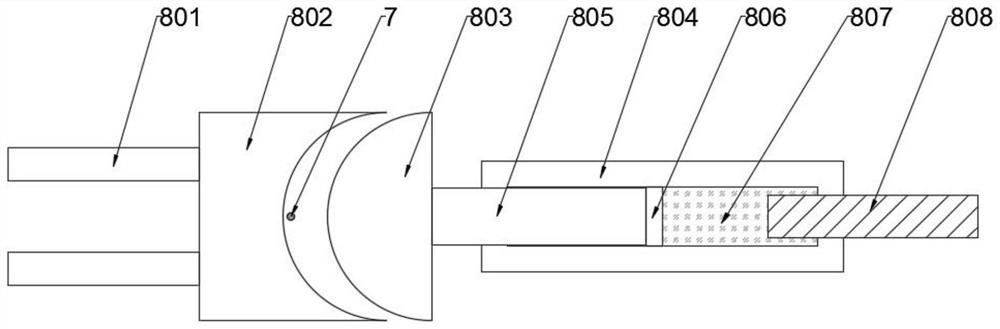

Outdoor power distribution cabinet with high protection performance

InactiveCN112271565ATimely self-controlImprove the protective effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectric power equipmentStructural engineering

The invention discloses an outdoor power distribution cabinet with high protection performance, which belongs to the technical field of power equipment and comprises a cabinet body, ventilation squareholes are symmetrically formed in the left side wall and the right side wall of the cabinet body, and first cavities are formed in the left side wall and the right side wall of the cabinet body and located on the upper sides of the ventilation square holes. A fireproof sealing plate is arranged in the first cavity, the size of the fireproof sealing plate is matched with that of the ventilation square hole, a sealing cover plate is fixed to the top end of the fireproof sealing plate, a hanging rope is connected to the top end of the sealing cover plate, the top end of the hanging rope is hungat the inner top end of the first cavity, and a hanging rope cutting-off structure is arranged at the inner top of the first cavity; and the ventilation square holes can be automatically blocked whenopen fire is generated in the power distribution cabinet, so that the interior of the cabinet body is sealed, the effect of isolating oxygen is achieved, the situation that the fire behavior is increased due to continuous circulation of air is avoided, timely self-control of the power distribution cabinet when open fire occurs is achieved, and the protection performance and the safety of the powerdistribution cabinet are effectively improved.

Owner:潘玉霞

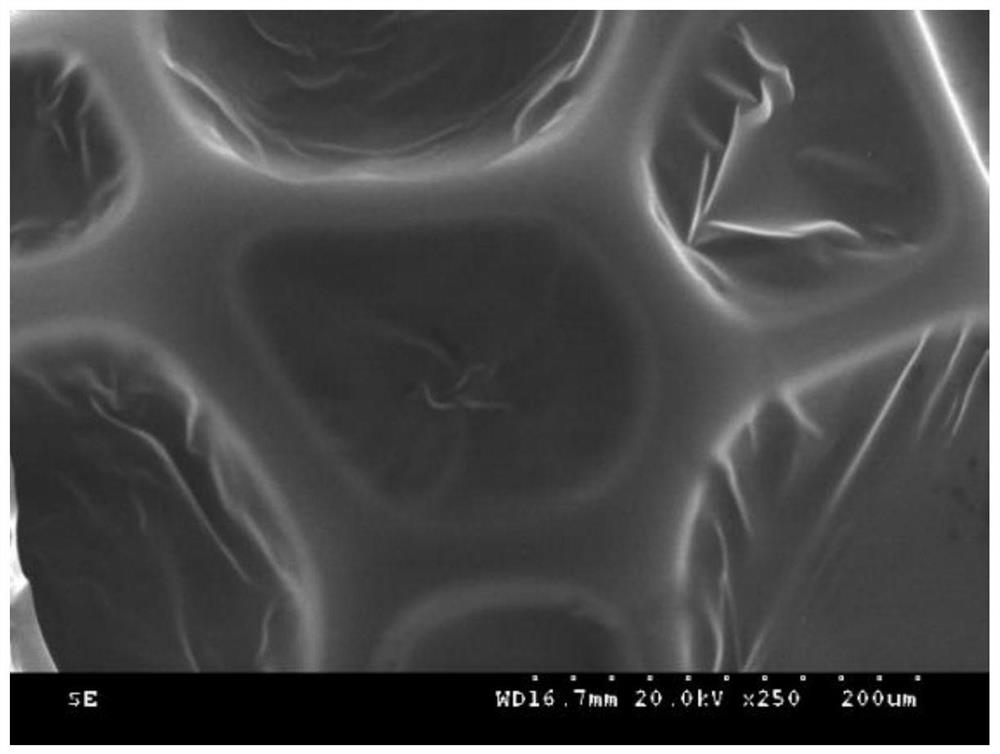

Preparation method of flame-retardant foam composite board

ActiveCN108247804AImprove thermal stabilityLow thermal conductivityNon-macromolecular adhesive additivesWood veneer joiningCross-linkPolymer science

The invention relates to the technical field of preparation of building materials, in particular to a preparation method of a flame-retardant foam composite board. According to the preparation method,methyl triethoxysilane is added to an alkalified flame retardant to obtain silica gel microencapsulated ammonium polyphosphate; a modified soybean protein adhesive and the silica gel microencapsulated ammonium polyphosphate are mixed to obtain a flame-retardant adhesive; and a polyurethane foam board and a bamboo fiberboard are subjected to bonding and hot-pressing to obtain the foam composite board. Through the method, ammonium polyphosphate is cladded with silica gel; and in the burning process, metaphosphoric acid is used for dehydrating the polyurethane foam board to form a compact carbonlayer on the surface to prevent oxygen and heat from further diffusing to the interior of polyurethane foam, so that the flame retardant property of the foam composite board is improved. Formaldehydehas the functions of a stabilizing agent and a cross-linking agent; and meanwhile, the stability of modified soybean protein has the inhibition effect on release of the formaldehyde, and noxious formaldehyde cannot be released. Accordingly, the polyurethane foam board and the bamboo fiberboard are bonded more tightly. The flame-retardant foam composite board has broad application prospects.

Owner:唐山市丰润区展硕保温建材有限公司

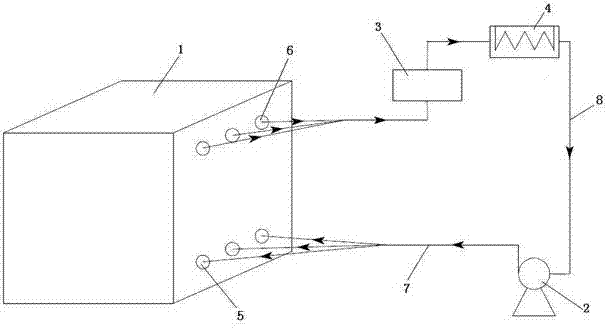

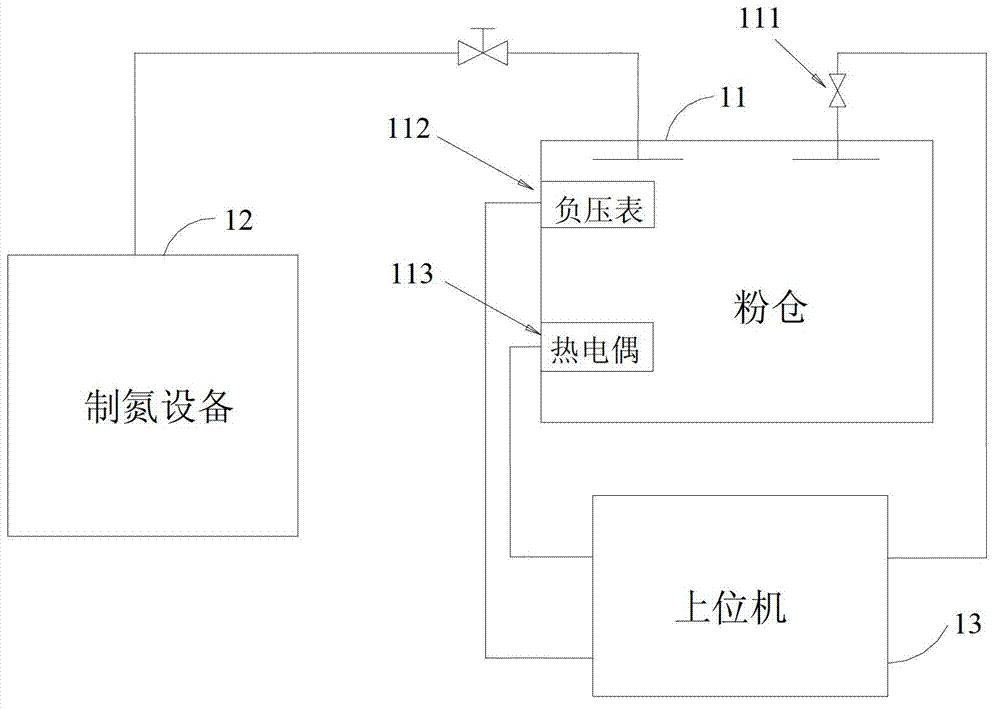

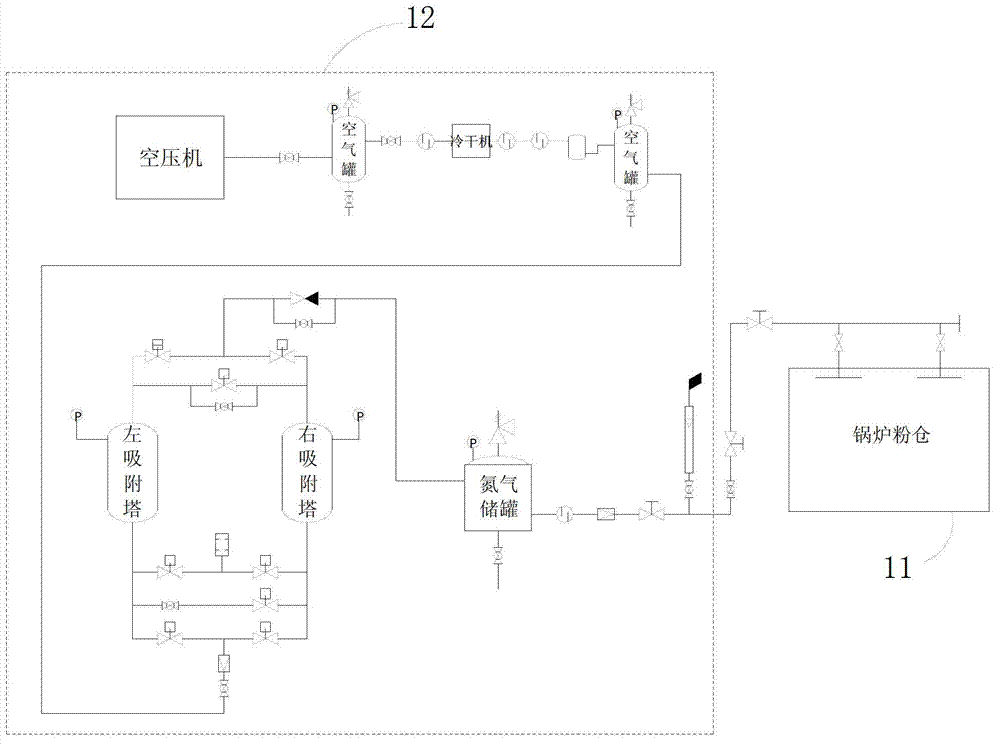

Coal pulverizing system

ActiveCN102927579AImprove securityImprove reliabilityDispersed particle separationLump/pulverulent fuel preparationEngineeringNitrogen source

The invention discloses a coal pulverizing system which comprises a coal powder cabin. The coal powder cabin comprises an upper cover, wherein further comprises nitrogen generating equipment. A nitrogen charging inlet is arranged on the upper cover of the coal powder cabin, and the outlet of the nitrogen generating equipment is connected with the nitrogen charging inlet of the coal powder cabin through pipe lines. The coal pulverizing system uses the nitrogen generating equipment as a flame protection device, and continuous nitrogen sources can be provided for the coal powder cabin of a pulverized coal boiler. Nitrogen can be produced under normal temperature, process is simple, energy consumption is small and cost is low. The nitrogen enters the coal powder cabin through pipe lines, and can reduce oxygen content, plays a role of oxygen isolation and carries out inerting to the internal portion of the coal powder cabin, and forms a good nitrogen protection layer; and meanwhile coal powder can be prevented from low temperature clotting, and has no smoldering danger. The safety performance and the reliability of the coal pulverizing system are greatly improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

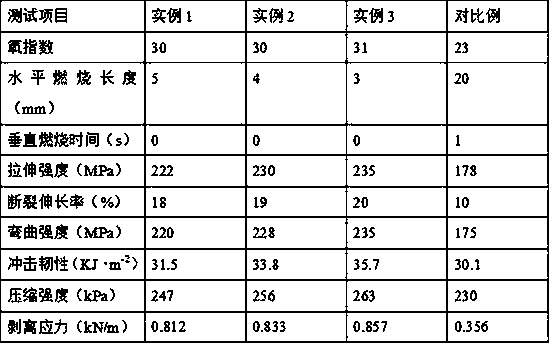

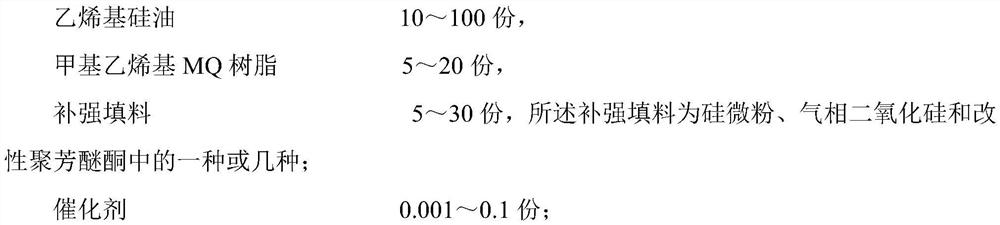

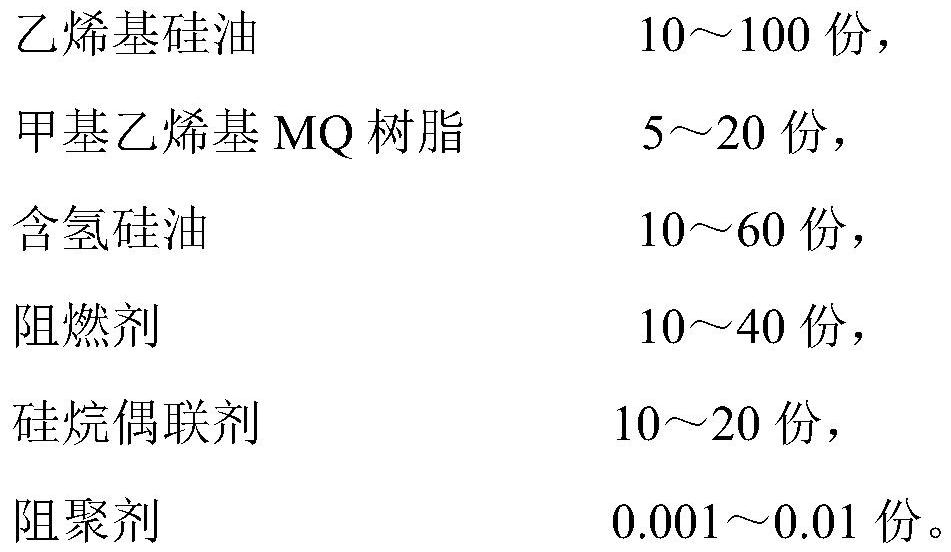

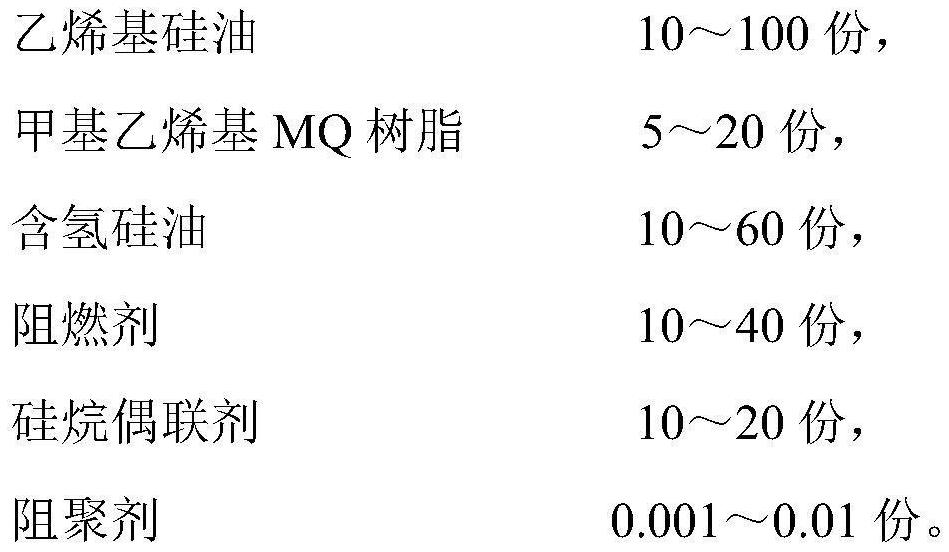

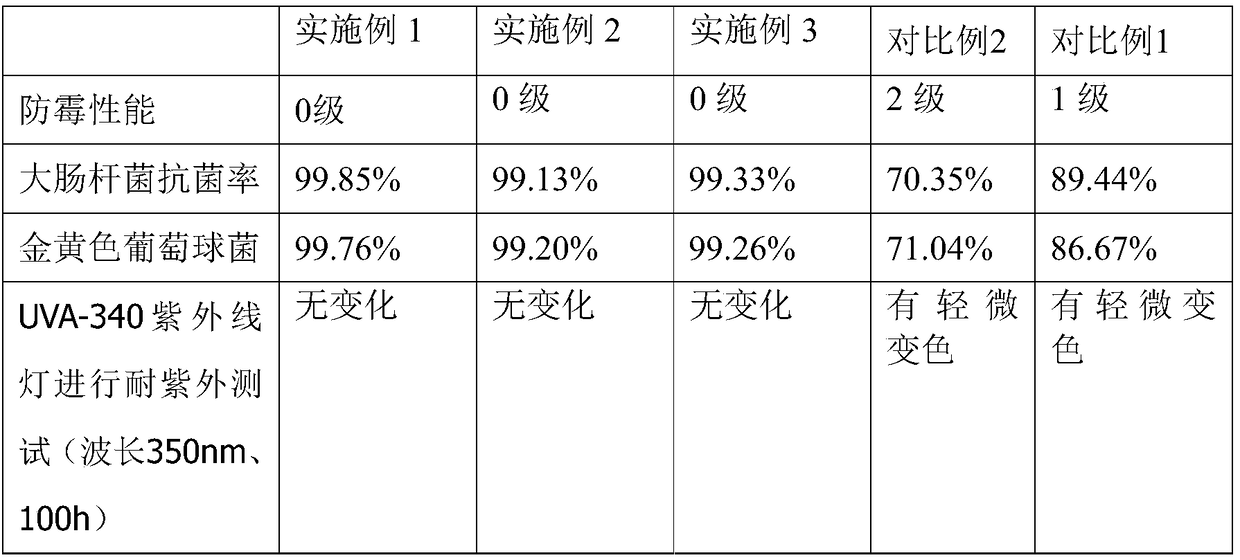

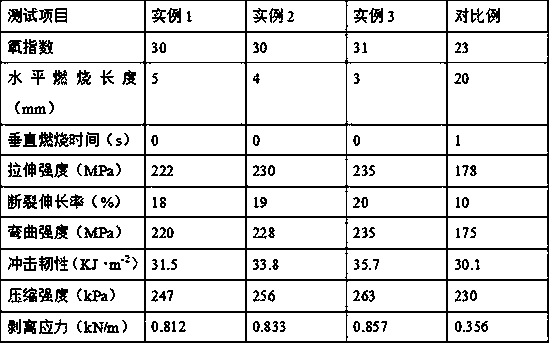

Organic silicon pouring sealant and preparation method thereof

PendingCN112778968AImprove the tracking coefficient compared toInhibition formationNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses an organic silicon pouring sealant which comprises two components including a component A and a component B. The component A comprises vinyl, methyl vinyl MQ resin, a reinforcing filler and a catalyst. The component B comprises vinyl silicone oil, methyl vinyl MQ resin, hydrogen-containing silicone oil, a flame retardant, a silane coupling agent and a polymerization inhibitor. The preparation method comprises the following steps of: adding vinyl silicone oil, methyl vinyl MQ resin and a catalyst into a reaction kettle, dispersing at a low speed, adding a reinforcing filler, dispersing at a high speed, and defoaming in vacuum to obtain a component A; and adding vinyl silicone oil, methyl vinyl MQ resin and a polymerization inhibitor into a reaction kettle, dispersing at a low speed, adding hydrogen-containing silicone oil and a silane coupling agent, dispersing at a low speed, adding a flame retardant, dispersing at a high speed, and defoaming in vacuum to obtain a component B; The comparative tracking coefficient (CTI) of the organic silicon pouring sealant is larger than or equal to 600V, and the organic silicon pouring sealant is free of oil leakage, excellent in flame retardant property, small in viscosity and easy to pour.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

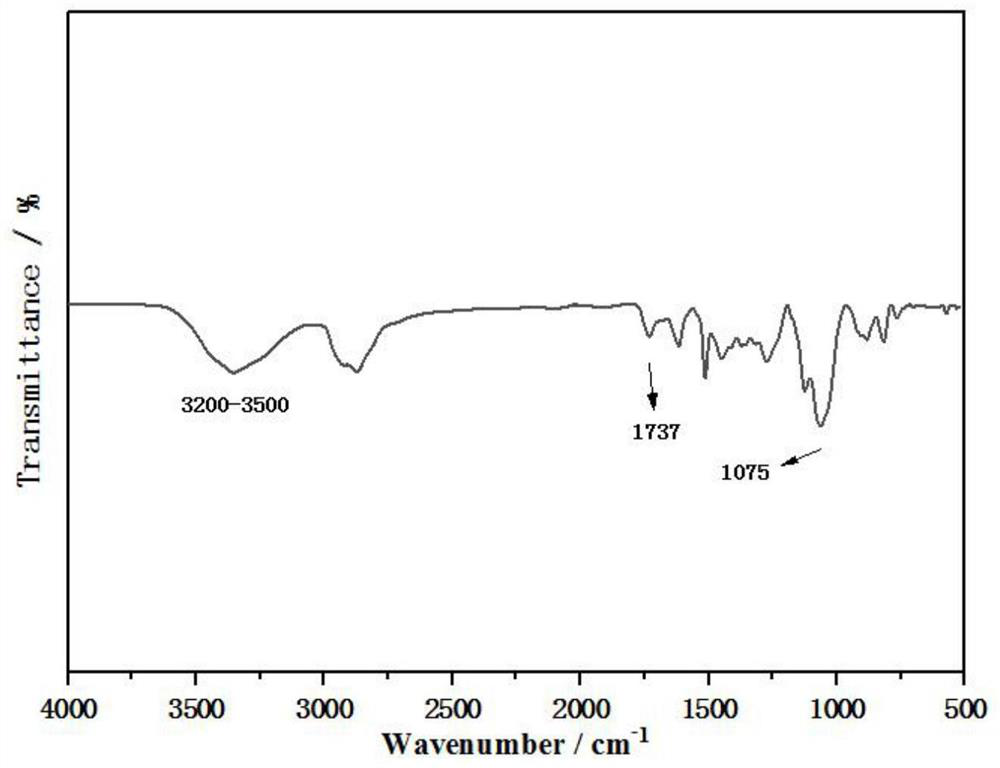

Preparation method of special chlorinated paraffin for surface treatment of fabric

ActiveCN109233903AHeat insulationAct as an oxygen barrierPetroleum chemical modificationPentaerythritolPhosphate

The invention discloses a preparation method of special chlorinated paraffin for the surface treatment of a fabric. The preparation method comprises the following steps: treating solid paraffin by adopting phosphoric acid, then preparing chlorinated paraffin by adopting a chlorine method, then blending the chlorinated paraffin and pentaerythritol, performing the catalytic reaction in the presenceof p-methylbenzene sulfonic acid, thus obtaining phosphate modified chlorinated paraffin, then dispersing the phosphate modified chlorinated paraffin into dimethyl carbonate, and blending with modifying ester amine to react, thus obtaining the quaternization modifying chlorinated paraffin. Triethanolamine is treated by adopting hexabromocyclododecane, so that the surface hydrophobic performance ofthe fabric is effectively improved; and the quaternization modified chlorinated paraffin is used for treating the fabric, so that the softness, electrostatic resistance, sterilization performance, and yellowing resistance of the fabric can be effectively improved.

Owner:ANHUI XINGXIN CHEM TECH

A kind of preparation method of flame retardant foam composite board

ActiveCN108247804BImprove thermal stabilityLow thermal conductivityNon-macromolecular adhesive additivesWood veneer joiningAdhesive cementPolymer science

The invention relates to the technical field of preparation of building materials, in particular to a preparation method of a flame-retardant foam composite board. According to the preparation method,methyl triethoxysilane is added to an alkalified flame retardant to obtain silica gel microencapsulated ammonium polyphosphate; a modified soybean protein adhesive and the silica gel microencapsulated ammonium polyphosphate are mixed to obtain a flame-retardant adhesive; and a polyurethane foam board and a bamboo fiberboard are subjected to bonding and hot-pressing to obtain the foam composite board. Through the method, ammonium polyphosphate is cladded with silica gel; and in the burning process, metaphosphoric acid is used for dehydrating the polyurethane foam board to form a compact carbonlayer on the surface to prevent oxygen and heat from further diffusing to the interior of polyurethane foam, so that the flame retardant property of the foam composite board is improved. Formaldehydehas the functions of a stabilizing agent and a cross-linking agent; and meanwhile, the stability of modified soybean protein has the inhibition effect on release of the formaldehyde, and noxious formaldehyde cannot be released. Accordingly, the polyurethane foam board and the bamboo fiberboard are bonded more tightly. The flame-retardant foam composite board has broad application prospects.

Owner:唐山市丰润区展硕保温建材有限公司

Method for preparing corrosion-resistant antistatic coating

InactiveCN108559387AHigh UV absorptionImprove antioxidant capacityAnti-corrosive paintsPolyurea/polyurethane coatingsOxygenElectron

The invention discloses a method for preparing a corrosion-resistant antistatic coating and belongs to the technical field of coating preparation. When a high polymer material and other non-conductivebase materials is coated with the corrosion-resistant antistatic coating disclosed by the invention, tin powder is first deposited on the surface layer of the base material so as to form a tin metallayer. Therefore, when the tin metal layer is complexed, oxygen and other substances are effectively prevented from entering the metal surface, and a single-molecule hole-electron conductive layer isformed on the covering metal base surface. According to the method disclosed by the invention, mixed coumarin powder, fresh lemon peel and ammonium hydroxide are mixed and fermented to perform acidification precipitation, 2,3-epoxypropyltrimethylammonium chloride is added, the coumarin powder is fermented to produce coumarin, and an effect of promoting cured cross-linking can be achieved. Due to increase of the degree of crosslinking, the ageing degradation ability of resins is decreased, anti-aging and corrosion-resistant effects are achieved, and graphite, carbon black and other highly antioxidant substances can prevent the coating from being corroded. Moreover, the wear resistance and conductivity of the coating are improved, and the application prospects are wide.

Owner:郦璋

Thermal insulation material prepared by degrading waste polyurethane, and preparation method of thermal insulation material

PendingCN113583206AImprove degradation rateHigh strengthPlastic recyclingPolyurethane elastomerPolymer science

The invention relates to a thermal insulation material prepared by degrading lignin and waste polyurethane, and a preparation method thereof. According to the method, firstly, lignin extracted from a papermaking waste liquid is subjected to alkalization treatment, then a blending system of old polyurethane elastomer and lignin subjected to alkalization treatment is degraded, recovered and reused, no three wastes are discharged in the recovering process, and the environment is protected. According to the invention, the prepared rigid polyurethane thermal insulation product has excellent performances of high compression strength, good elasticity, good thermal stability, good thermal insulation performance and the like; the recycling rate of the waste polyurethane elastomer is close to 100%, the cost of a polyurethane rigid foam product is greatly reduced, a new practical way is opened up for the application of recycling the waste polyurethane elastomer to prepare polyhydric alcohol; and the performance of the polyurethane recycled material is modified by utilizing the excellent structure of lignin, so that a new way is opened up for the utilization of lignin extracted from papermaking waste liquid.

Owner:SHANGHAI HECHENG POLYMER TECH CO LTD

Flame retardant foam plastic and preparation method thereof

ActiveCN108559193AReduce the temperatureSuppress generationDimethyl methylphosphonatePolymer science

The invention discloses flame retardant foam plastic and a preparation method thereof, and relates to the technical field of foam plastic preparation. The plastic is prepared from, by weight, 76-84 parts of polystyrene, 12-16 parts of flame retardants, 5-8 parts of binder, 6-9 parts of lubricant, 4-8 parts of foaming agent and 0.5-0.8 part oftalc, the flame retardant is formed by mixing a mixtureA and a mixture B according to the mass ratio of 1:2, the mixture A is formed by mixing anhydrous phosphoric acid, tris(2-chloroethyl) phosphate and dimethyl methylphosphonate at a mass ratio of 2:1:1, and the mixture B is obtained by mixing decabromodiphenylethane and magnesium hydroxide at a mass ratio of 1:2. The plastic solves the problem that foam plastic has poor flame retardancy, and the flame retardant which is a mixture of the mixture A and the mixture B is added to raw materials, thereby improving the flame retardancy of the foam plastic.

Owner:青岛文宝泡塑包装有限公司

Fire extinguishing device and automatic fire extinguishing isolation belt with fire extinguishing device

PendingCN110639141AAchieve destructionPlay a role in coolingFire rescueBoring toolsTemperature controlAutomatic fire suppression

The invention discloses a fire extinguishing device. The fire extinguishing device comprises a barrel body and an exploder. A through hole is formed in the bottom of the barrel body, the exploder is fixed to the position of the through hole in a sealed manner through an elastic silica gel sealing ring, a fire extinguishing agent is sealed in the barrel body, the exploder is used for exploding andbreaking when heated or subjected to flame attacks, and the fire extinguishing agent flows out after the through hole is opened. A temperature control powder exploder is adopted as the exploder, and powder violently expanding when encountering high temperature is sealed in the exploder. 4,4'-oxydibenzenesulfonyl hydrazide is adopted as the powder. The fire extinguishing device further comprises anouter shell body. A through hole opposite to the exploder is formed in a bottom panel of the outer shell body. The invention further discloses an automatic fire extinguishing isolation belt with thefire extinguishing device. The fire extinguishing device is arranged below the fireproof isolation belt, the situation that when a heat insulating material on the lower face catches fire, the exploderexplodes, and the fire extinguishing agent in the barrel body flows out to the heat insulating material catching fire is achieved, the effect of isolating oxygen and reducing the temperature is achieved, fire behaviors are prevented from spreading upwards rapidly, enough time is conveniently gained for fire extinguishing and crowd evacuating, and the life and property safety of people is protected.

Owner:王宝龙

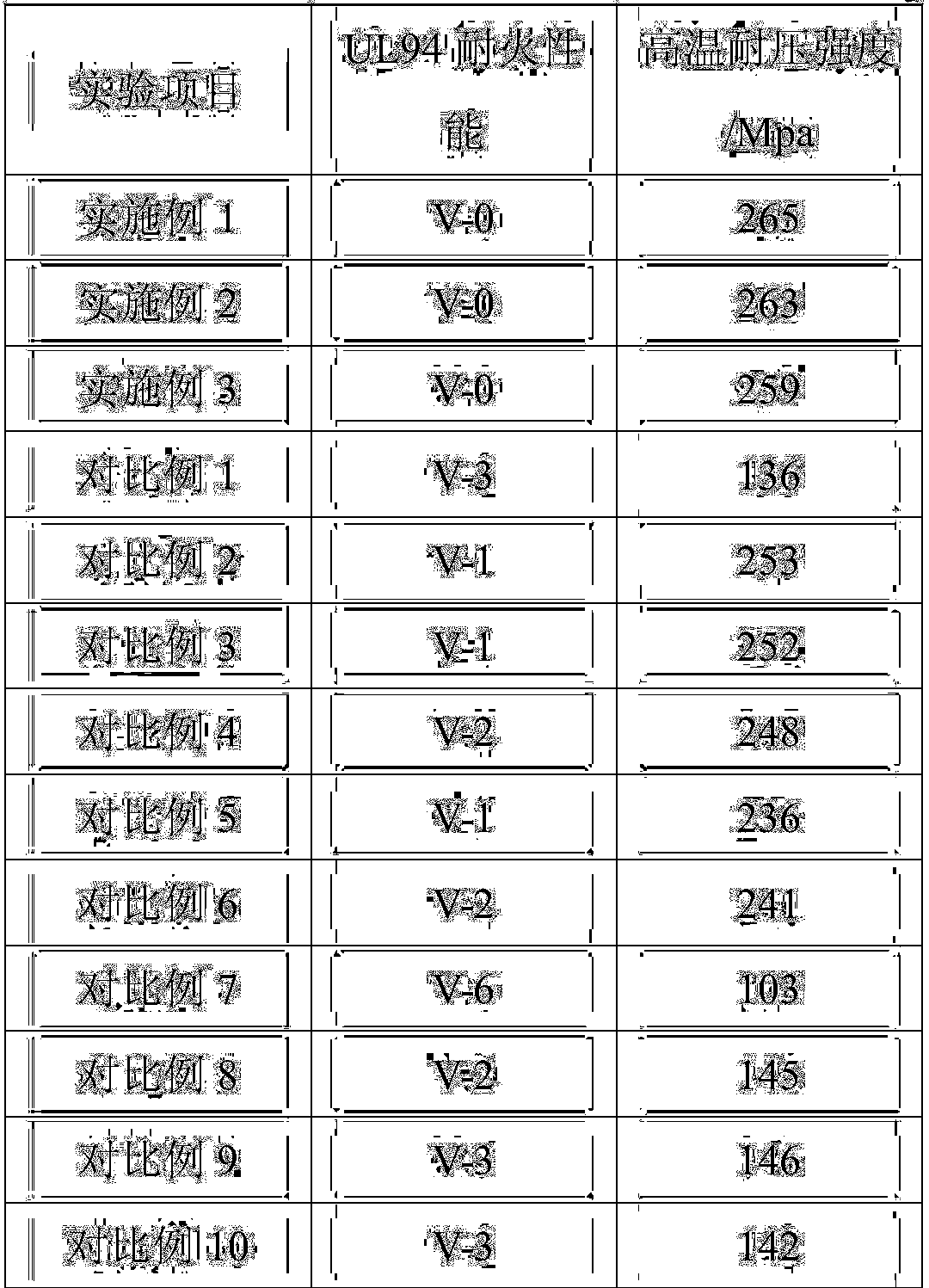

Fire-resistant engineering plastic and preparation method thereof

The invention discloses a fire-resistant engineering plastic, and belongs to the technical field of plastic material preparation. The fire-resistant engineering plastic is prepared from polycarbonate,organic modified montmorillonite, a modified flame retardant, nano silica, glass fibers, a light stabilizer 770, polyethylene glycol, N,N-ethylene bis-stearamide, white carbon black, di(2,3-dichloropropyl)octyl phosphate, tri(neoamylic dialcohol phosphate)methylamine, silsesquioxane, vinyltriethoxysilane and phosphonitrilic chloride trimer. The fire-resistant engineering plastic is prepared by preparing a base material, preparing a modified material and then mixing the main material and the modified material. The prepared engineering plastic has excellent fire resistance.

Owner:长沙如洋环保科技有限公司

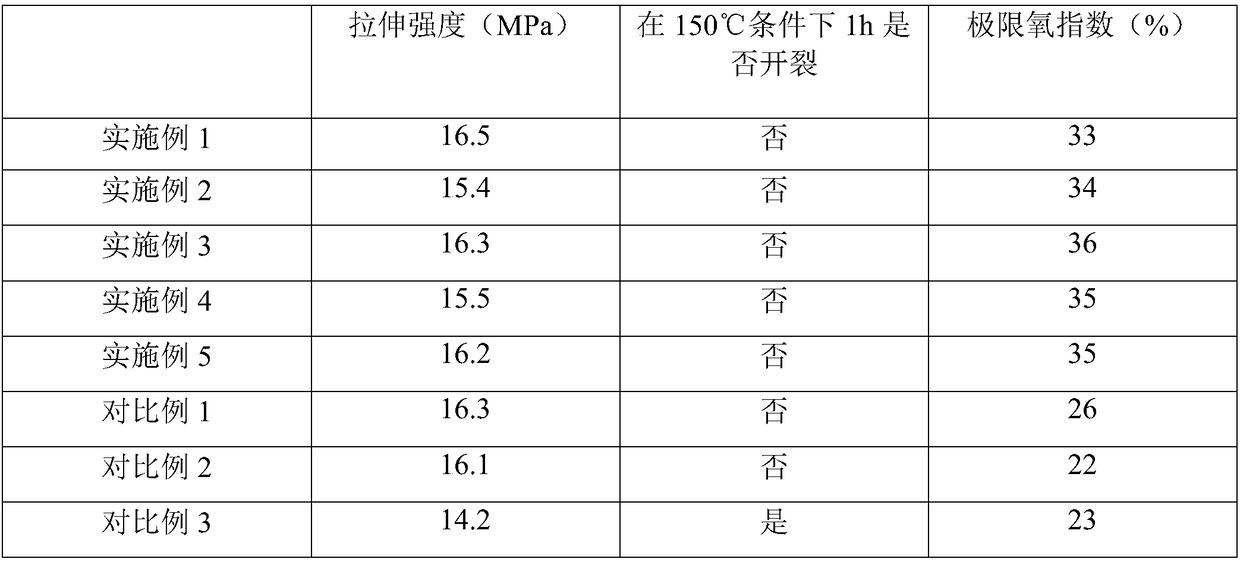

Anti-aging flame-retardant cable insulation material

The invention relates to the technical field of a cable material, and discloses an anti-aging flame-retardant cable insulation material. The cable insulation material comprises the following components in parts by weight: 60 to 80 parts of polyvinyl chloride resin, 20 to 30 parts of modified powdered steatile, 1 to 3 parts of an anti-aging agent of dilauryl thiodipropionate, 2 to 3 parts of a sebacate plasticizer, 1 to 3 parts of a benzophenone stabilizer, 0.5 to 1 part of a polysiloxane antibacterial agent, 4 to 6 parts of phthalic acid, 3 to 5 parts of melamine pyrophosphate, and 0.2 to 0.6parts of barium sulfate. The cable insulation material has good flame resistance and age-proof performance.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

Fly ash-cement foam material for preventing coal spontaneous combustion and preparation method thereof

ActiveCN103964766BPrevent spontaneous combustionLow costFire extinguisherSpontaneous combustionPulverized fuel ash

The invention discloses a pulverized fuel ash-cement foam material for controlling the spontaneous combustion of coal and a preparation method of the pulverized fuel ash-cement foam material. The pulverized fuel ash-cement foam material is prepared from the following components by weight: 10-40 % of sulfoaluminate superfine cement, 10-40 % of pulverized fuel ash, 0.5-0.9 % of carboxymethyl cellulose, 0.1-0.6 % of sodium fluoride, 0.2-0.6 % of melamine, 0.1-0.4 % of aluminum sulfate, 0.3-0.6 % of lauryl sodium sulfate, 0.4-0.6 % of sodium dodecyl benzene sulfonate, 0.5-0.8 % of saponin and the balance of water. The foam material is high in expansion rate of foam, long in stabilizing time, low in rate of water loss, good in plugging performance, and very suitable for extinguishment underground a coal mine. The pulverized fuel ash-cement foam material has the advantages of being low in cost, good in plugging performance, high in strength, simple to construct and the like.

Owner:胡相明

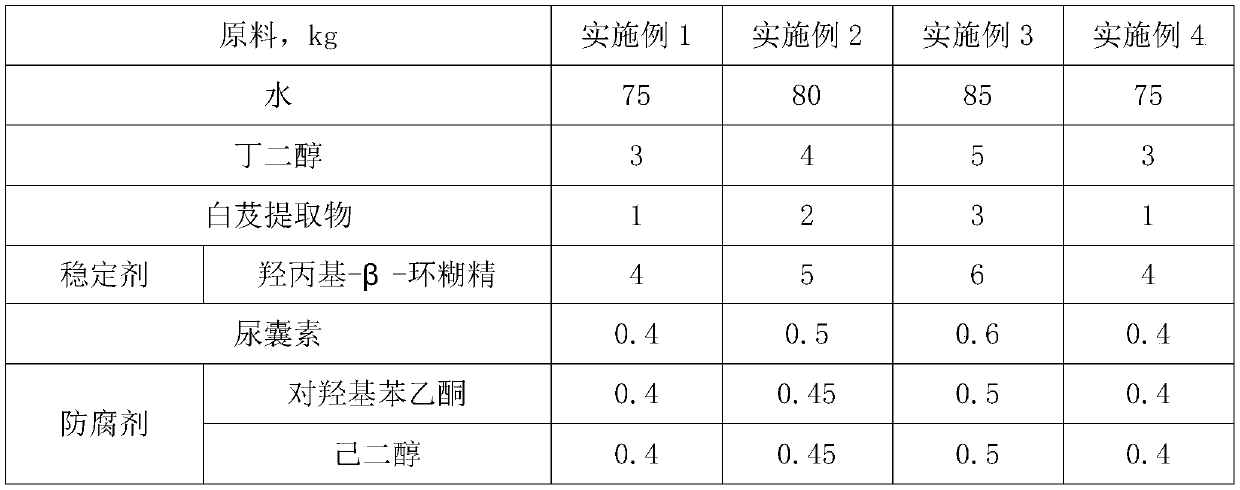

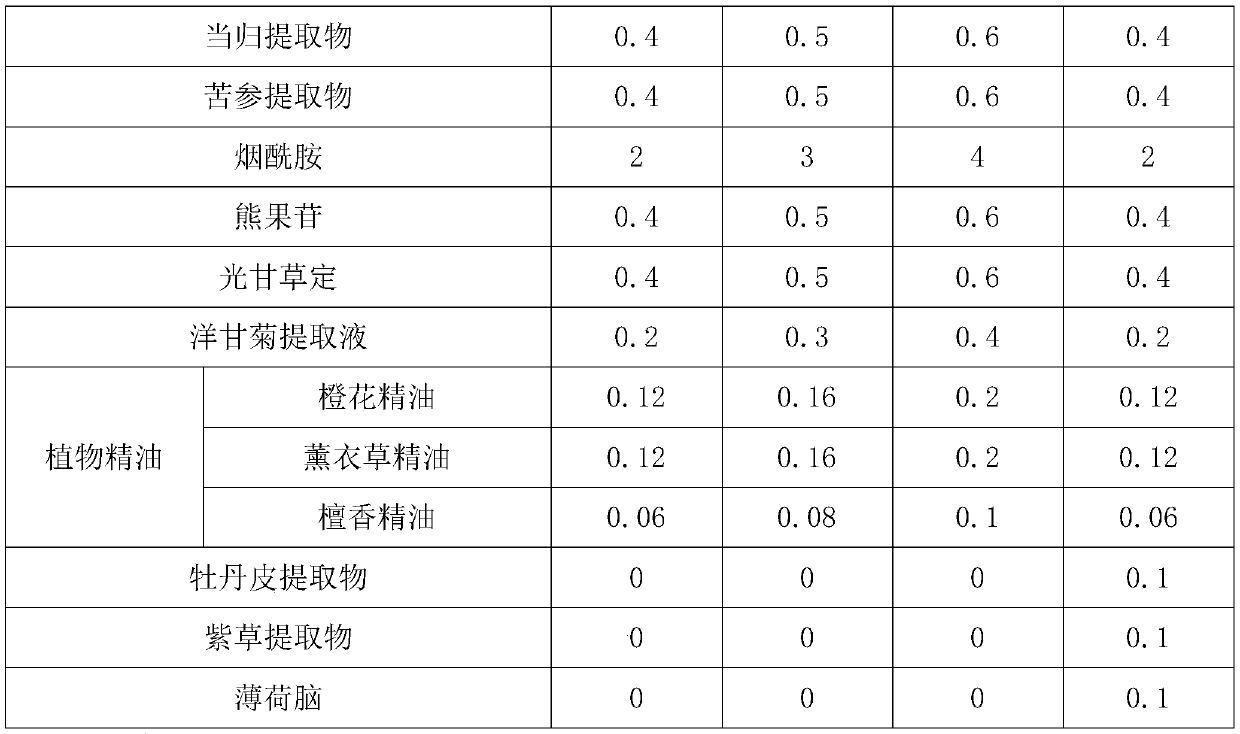

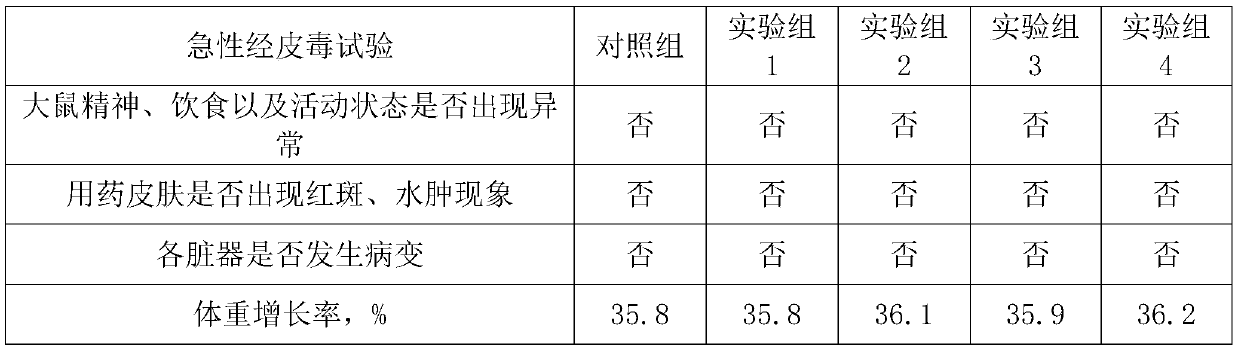

Bletilla striata gelatin repairing emulsion and preparation and application methods thereof

InactiveCN110269830ARevitalize new lifeLighten acne marksCosmetic preparationsToilet preparationsBletilla striataNicotinamide

The invention discloses a bletilla striata gelatin repairing emulsion and preparation and application methods thereof and belongs to the technical field of cosmetics. The bletilla striata gelatin repairing emulsion is characterized by being prepared from, by weight, 75-85 parts of water, 3-5 parts of butanediol, 1-3 parts of a bletilla striata extract, 4-6 parts of a stabilizer, 0.4-0.6 part of allantoin, 0.8-1 part of a preservative, 0.4-0.6 part of a radix angelicae sinensis extract, 0.4-0.6 part of a radix sophorae flavescentis extract, 2-4 parts of nicotinamide, 0.4-0.6 part of arbutin, 0.4-0.6 part of glabridin, 0.2-0.4 part of a chamomile extraction solution and 0.3-0.5 part of plant essential oil. The bletilla striata gelatin repairing emulsion has the advantages of fading scars, relieving the itch, diminishing inflammation, relieving pain and relieving the mood.

Owner:浙江高妍科技有限公司

A kind of flame retardant coating and preparation method thereof

ActiveCN105694543BLow film forming temperatureImprove heat resistanceFireproof paintsPretreated surfacesPhosphateAdhesive

The invention relates to the field of flame retardant coating layers, and in particular, relates to a flame retardant coating layer applicable to the surface of a magnesium alloy and other lightweight alloys and a preparation method thereof. The flame retardant coating layer comprises the main components: an inorganic film-forming substance and an inorganic filler; the mass ratio of the inorganic film-forming substance to the inorganic filler is (35-65) to (35-65), the inorganic film-forming substance is a phosphate adhesive, and the inorganic filler is composed of a metal oxide, an alkali metal hydroxide and boric acid according to the mass ratio of (55-75) to (20-35) to (5-10). The flame retardant coating layer adopts the inorganic film-forming substance and the non-combustible filler, a proper auxiliary agent is added, and a reactive principle is applied, so that the coating layer can form a non-combustible dense inorganic 'glaze film layer' under a condition of flame or high temperature, and the effect of isolating oxygen gas is achieved. The flame retardant coating layer has the advantages of low film-forming temperature and good heat resistance, cannot be burnt when meeting fire, and can form the dense 'glaze film layer'; the surface of the magnesium alloy is coated with the flame retardant coating layer, and thus the flame retardancy of the magnesium alloy can be improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com