Anti-aging flame-retardant cable insulation material

A technology for flame-retardant cables and insulating materials, applied in the field of cable materials, can solve problems such as poor flame-retardant performance and cables are prone to aging, and achieve long service life, good anti-aging effect, and the effect of preventing combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

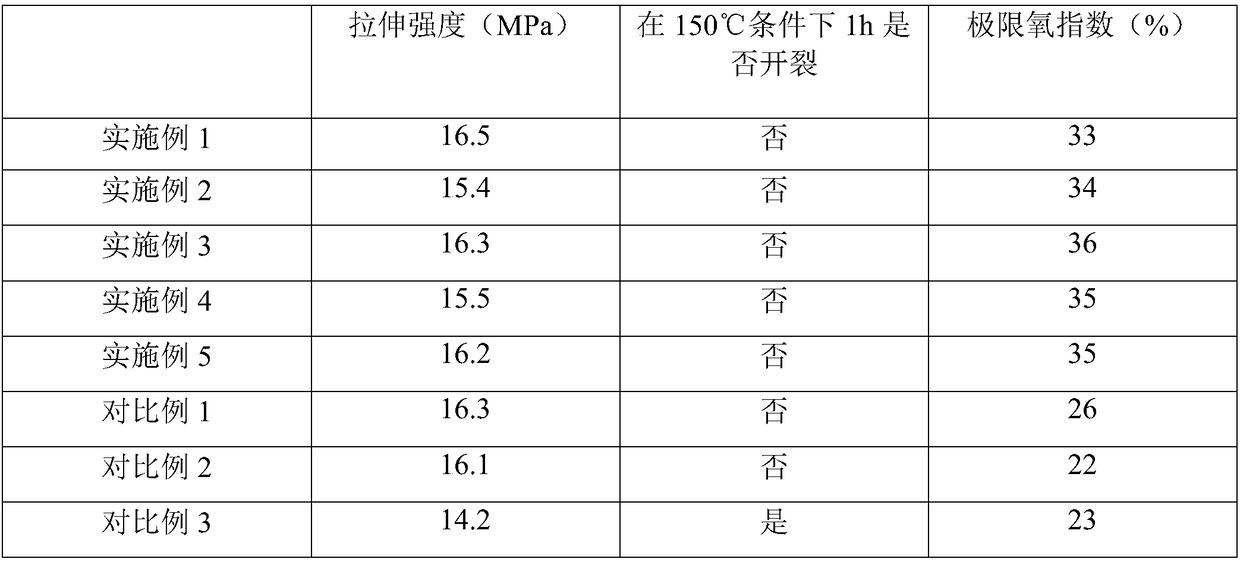

Examples

Embodiment 1

[0018] An anti-aging flame-retardant cable insulation material is characterized in that it comprises the following components by weight:

[0019] 60 parts of polyvinyl chloride resin, 20 parts of modified talcum powder, 1 part of didodecanyl thiodipropionate anti-aging agent, 2 parts of azelaic acid ester plasticizer, 1 part of benzophenone stabilizer , 0.5 parts of polysiloxane antibacterial agent, 4 parts of phthalic acid, 3 parts of melamine polyphosphate, 0.2 parts of barium sulfate.

[0020] The preparation method of described modified talcum powder is: add talcum powder to the water of 20 times of talcum powder weight, stir and mix evenly, then add the carboxymethyl chitosan that viscosity is 100cps, the mixture of carboxymethyl chitosan and talcum powder The weight ratio is 1:2, the temperature is raised to 50°C, and the stirring is continued for 1 hour. After standing for 4 hours, the modified talc powder is obtained by filtering and drying in sequence.

Embodiment 2

[0022] An anti-aging flame-retardant cable insulation material is characterized in that it comprises the following components by weight:

[0023] 65 parts of polyvinyl chloride resin, 24 parts of talcum powder, 1 part of didodecanyl thiodipropionate antiaging agent, 2 parts of azelaic acid ester plasticizer, 1 part of benzophenone stabilizer, poly 0.6 parts of siloxane antibacterial agent, 4 parts of phthalic acid, 3 parts of melamine polyphosphate, 0.3 parts of barium sulfate.

[0024] The preparation method of described modified talcum powder is: talcum powder is added in the water of 24 times of talcum powder weight, stir and mix evenly, then add the carboxymethyl chitosan that viscosity is 150cps, the carboxymethyl chitosan and talcum powder The weight ratio is 1:2, the temperature is raised to 55°C, the stirring is continued for 1 hour, and after standing for 5 hours, the modified talc powder is obtained by filtering and drying successively.

Embodiment 3

[0026] An anti-aging flame-retardant cable insulation material is characterized in that it comprises the following components by weight:

[0027] 70 parts of polyvinyl chloride resin, 25 parts of talcum powder, 2 parts of didodecanyl thiodipropionate anti-aging agent, 2.5 parts of azelaic acid ester plasticizer, 2 parts of benzophenone stabilizer, poly 0.7 parts of siloxane antibacterial agent, 5 parts of phthalic acid, 4 parts of melamine polyphosphate, 0.4 part of barium sulfate.

[0028] The preparation method of described modified talcum powder is: add talcum powder to the water of 26 times of talcum powder weight, stir and mix evenly, then add the carboxymethyl chitosan that viscosity is 160cps, the mixture of carboxymethyl chitosan and talcum powder The weight ratio is 1:3, the temperature is raised to 56°C, and the stirring is continued for 2 hours. After standing for 6 hours, the modified talc powder is obtained by filtering and drying in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com