Special fireproof mortar of plastic extrusion plate

A technology of extruded plastic board and mortar, which is applied in the field of fireproof mortar, can solve the problems of fire hazards and the difficulty of adding flame retardants to meet the requirements of B1 flame retardancy, etc.

Inactive Publication Date: 2010-04-21

北京艺高世纪科技股份有限公司

View PDF0 Cites 39 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical applications, it is difficult to meet the requirements of B1 flame retardant by simply adding flame retardants; and in the storage and use of external wall insulation projects, it is very easy to cause fire hazards due to the complicated conditions on the construction site and many fire sources.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] raw material

Embodiment 3

[0020] raw material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

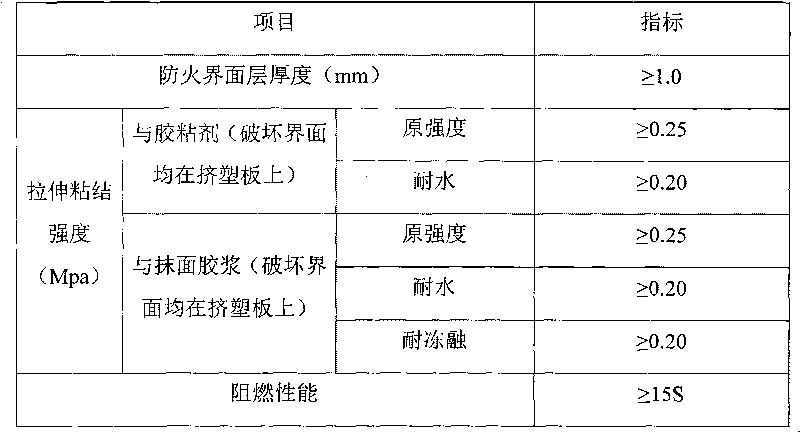

The invention relates to special fireproof mortar of a plastic extrusion plate. A fireproof protection layer is formed at the surface of the plastic extrusion plate, can act as the function of isolating oxygen and enables the oxygen not to directly contact with the extrusion molding plate, thereby avoiding the generation of a combustion reaction. The mortar comprises the following components: 20-50% of cement, 20-60% of sand, 2-10% of dispersible emulsion powder, 0-40% of inorganic composite material and 0.5-10% of organic composite material.

Description

technical field [0001] The invention relates to the field of building materials, in particular to a fireproof mortar for preventing and reducing fire hazards during storage and construction of extruded boards in building external heat preservation projects. Background technique [0002] Extruded board is a kind of thermal insulation material with excellent performance, which is widely used in external thermal insulation and internal systems of external walls. However, due to its flammable performance, it is very easy to cause fires on complex construction sites. Recently, fire accidents of building exterior wall insulation materials and systems have occurred one after another in China, which have caused extremely serious losses to the country and people's lives and property, and also caused greater social and political impacts, which have aroused widespread concern from all walks of life. [0003] Combustion can only be carried out under certain conditions, that is, the thre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B28/04C04B28/08C04B28/06C04B14/06

Inventor 宋德强田辉

Owner 北京艺高世纪科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com