Preparation method of special chlorinated paraffin for surface treatment of fabric

A chlorinated paraffin and surface treatment technology, which is applied in the field of preparation of chlorinated paraffin for fabric surface treatment, can solve the problems of inability to achieve good flame retardant effect, difficult fabric quality improvement, poor flame retardant effect, etc., and achieve good flame retardant Effects of protection, improvement of softness, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

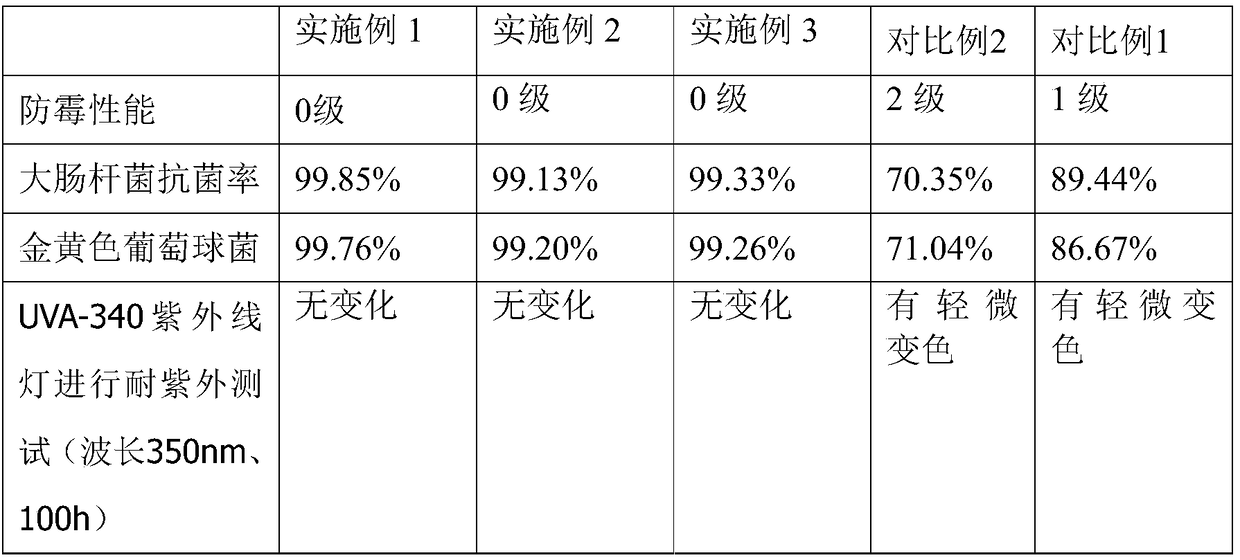

Examples

Embodiment 1

[0016] A preparation method of special chlorinated paraffin for fabric surface treatment, comprising the following steps:

[0017] (1) Take 1 part by weight of hexabromocyclododecane, add it to 6 times the weight of absolute ethanol, stir evenly, add 16 parts by weight of triethanolamine, slowly raise the temperature to 70°C, and keep stirring for 30 minutes , to remove ethanol by distillation to obtain modified triethanolamine;

[0018] (2) Get 110 parts by weight of solid paraffin, join it in chloroform of 1.6 times its weight, stir evenly, add 10 parts by weight of phosphoric acid, ultrasonic 1 hour, distill and remove chloroform, obtain phosphoric acid modified paraffin;

[0019] (3) Get the above-mentioned phosphoric acid modified paraffin, send it into the reactor, feed chlorine, adjust the temperature of the reactor to 80°C, react until the specific gravity of the liquid is 1.30, discharge, add 20 parts by weight of pentaerythritol, and increase the temperature to 90°C...

Embodiment 2

[0024] A preparation method of special chlorinated paraffin for fabric surface treatment, comprising the following steps:

[0025] (1) Take 2 parts by weight of hexabromocyclododecane, add it to 10 times the weight of absolute ethanol, stir evenly, add 20 parts by weight of triethanolamine, slowly raise the temperature to 75°C, and keep stirring for 40 minutes , to remove ethanol by distillation to obtain modified triethanolamine;

[0026] (2) Get 130 parts by weight of solid paraffin, join in the chloroform of its weight 2 times, stir evenly, add the phosphoric acid of 17 parts by weight, ultrasonic 2 hours, distill and remove chloroform, obtain phosphoric acid modified paraffin;

[0027] (3) Get the above-mentioned phosphoric acid modified paraffin, send it into the reactor, feed chlorine, adjust the temperature of the reactor to 120°C, react until the liquid specific gravity is 1.55, discharge, add 24 parts by weight of pentaerythritol, raise the temperature to 95°C, add 0...

Embodiment 3

[0032] A preparation method of special chlorinated paraffin for fabric surface treatment, comprising the following steps:

[0033] (1) Take 1 part by weight of hexabromocyclododecane, add it to 8 times the weight of absolute ethanol, stir evenly, add 19 parts by weight of triethanolamine, slowly increase the temperature to 72 ° C, keep stirring for 32 minutes , to remove ethanol by distillation to obtain modified triethanolamine;

[0034] (2) Get 120 parts by weight of solid paraffin, join it in chloroform of 1.7 times its weight, stir evenly, add 18 parts by weight of phosphoric acid, ultrasonic 1 hour, distill and remove chloroform, obtain phosphoric acid modified paraffin;

[0035] (3) Get the above-mentioned phosphoric acid modified paraffin, send it into the reactor, feed chlorine, adjust the temperature of the reactor to 110°C, react until the liquid specific gravity is 1.50, discharge, add 22 parts by weight of pentaerythritol, raise the temperature to 92°C, add 0.22 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com