Graphene and vermiculite-based high-temperature-resistant anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and graphene, which is applied in anti-corrosion coatings, fire-proof coatings, anti-fouling/underwater coatings, etc. It can solve the problems of high pressure resistance and adhesion, unstable coating performance, and easy cracking of coating films, etc. Problems, to achieve the effect of simplifying construction difficulty, good temperature adaptation range, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

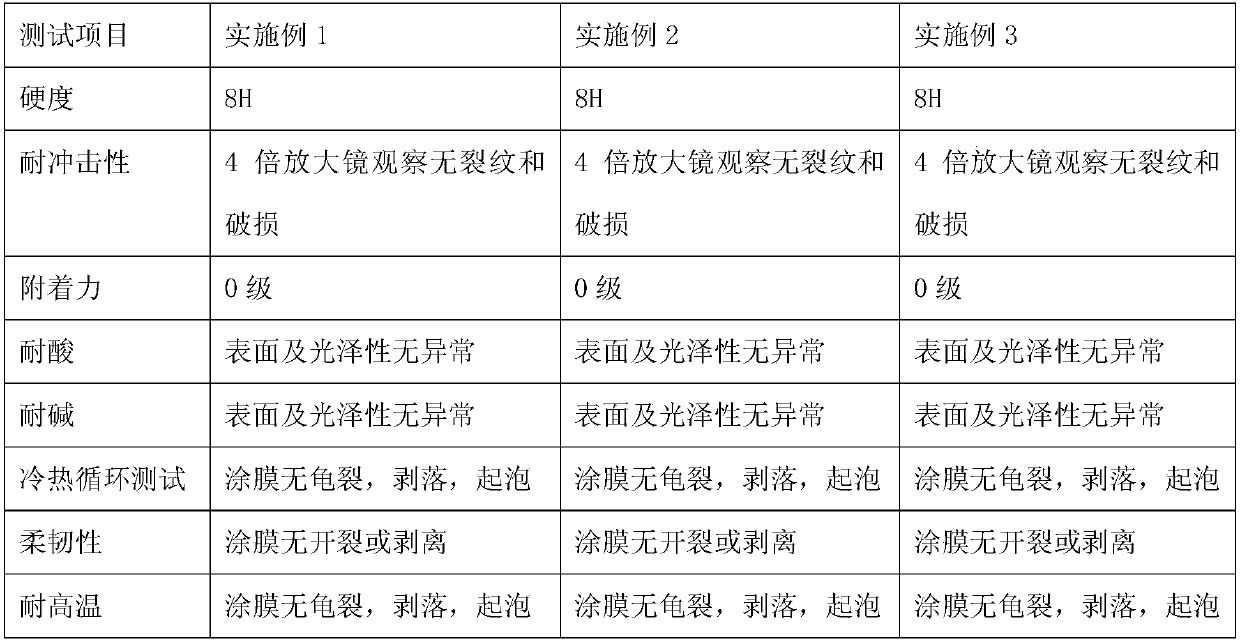

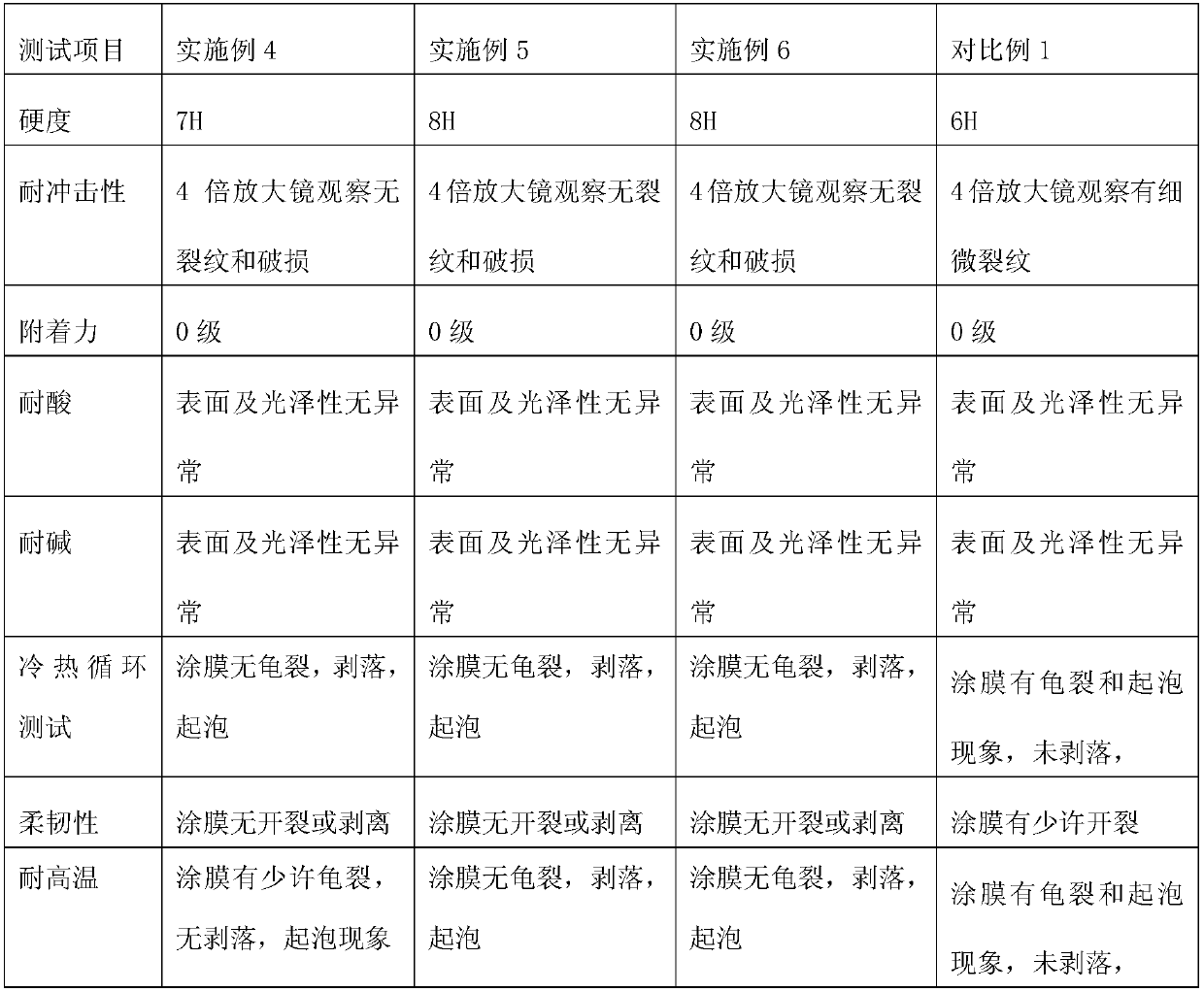

Embodiment 1

[0034] A kind of high temperature resistant anticorrosion coating based on graphene and vermiculite, comprises following composition according to mass percentage:

[0035] 5% bentonite, 5% vermiculite, 7% kaolin, 10% graphene, 6% corundum powder, 10% magnesium salt whisker, 15% titanium dioxide, 5% silicon acrylic emulsion, 37% inorganic binder.

[0036] It must mix vermiculite, graphene, titanium dioxide, and magnesium salt whiskers evenly, and then add coordination.

[0037] The inorganic binder includes the following components in terms of mass percentage: 10% sodium phosphate, 70% sodium silicate, 5% potassium silicate and 15% hydrophobically modified silica sol.

[0038]The hydrophobically modified silica sol is jointly modified by methyltrimethoxysilane and methylethoxysilicone oil. The amount of methyltrimethoxysilane and methylethoxy silicone oil is 1:5. The graphene includes single-layer graphene and multi-layer graphene, and the content of the multi-layer graphene ...

Embodiment 2

[0047] A kind of high temperature resistant anticorrosion coating based on graphene and vermiculite, comprises following composition according to mass percentage:

[0048] 6% bentonite, 10% vermiculite, 5% kaolin, 7% graphene, 4% corundum powder, 8% magnesium salt whisker, 17% titanium dioxide, 4% silicon acrylic emulsion, 39% inorganic binder.

[0049] It must mix vermiculite, graphene, titanium dioxide, and magnesium salt whiskers evenly, and then add coordination.

[0050] The inorganic binder includes the following components in terms of mass percentage: 10% sodium phosphate, 60% sodium silicate, 10% potassium silicate and 20% hydrophobically modified silica sol.

[0051] The hydrophobically modified silica sol is jointly modified by methyltrimethoxysilane and methylethoxysilicone oil. The amount of methyltrimethoxysilane and methylethoxy silicone oil is 1:4. The graphene includes single-layer graphene and multi-layer graphene, and the content of the multi-layer graphene...

Embodiment 3

[0054] A kind of high temperature resistant anticorrosion coating based on graphene and vermiculite, comprises following composition according to mass percentage:

[0055] 3% bentonite, 7% vermiculite, 3% kaolin, 13% graphene, 5% corundum powder, 7% magnesium salt whisker, 16% titanium dioxide, 6% silicon acrylic emulsion, 40% inorganic binder.

[0056] It must mix vermiculite, graphene, titanium dioxide, and magnesium salt whiskers evenly, and then add coordination.

[0057] The inorganic binder includes the following components in terms of mass percentage: 5% sodium phosphate, 70% sodium silicate, 10% potassium silicate and 15% hydrophobically modified silica sol.

[0058] The hydrophobically modified silica sol is jointly modified by methyltrimethoxysilane and methylethoxysilicone oil. The amount of methyltrimethoxysilane and methylethoxy silicone oil is 1:4. The graphene includes single-layer graphene and multi-layer graphene, and the content of the multi-layer graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com