A kind of preparation method of flame retardant foam composite board

A flame-retardant foam and composite board technology, applied in the preparation of animal glue or gelatin, the joining of wooden veneers, chemical instruments and methods, etc., can solve the problems of easy peeling, easy detachment, and weak bonding, and achieve Effect of heat reduction and improvement of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

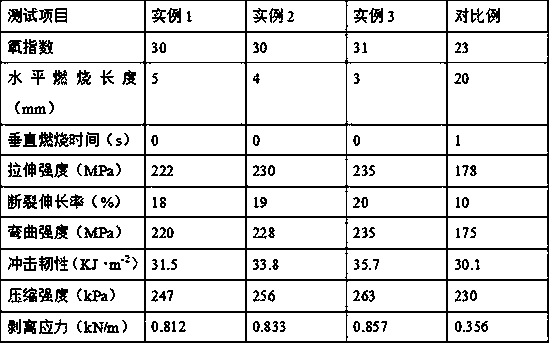

Examples

example 1

[0027] Add 200mL of distilled water to a four-necked flask with a stirrer and a reflux condenser, adjust the pH to 9 with a 40% sodium hydroxide solution, heat the four-necked flask to 90°C, add 60g of soybean powder, and heat-preserve After 50 minutes, add 10 g of phenol into the four-necked flask, cool down to 70 ° C, and heat-preserve for 15 minutes, continue to add 20 mL of formaldehyde solution with a mass fraction of 40% to the four-necked flask, react for 1 hour, and naturally cool to room temperature to obtain modified soybean protein Adhesive: put poplar wood in a wood crusher for 4 hours, pass through a 200-mesh sieve to get poplar wood powder, mix 20g poplar wood powder, 70g bamboo fiber, and 100mL water to get bamboo fiber pulp, inject the bamboo fiber pulp into a vacuum In the forming tank of the dehydration device, after air bubbling and stirring for 10 seconds, stand for vacuum dehydration for 5 minutes, and control the vacuum degree of dehydration to 70 Pa to ob...

example 2

[0029] Add 210mL of distilled water to a four-necked flask with a stirrer and a reflux condenser, adjust the pH to 9 with a 40% sodium hydroxide solution, heat the four-necked flask to 95°C, add 65g of soybean powder, and heat-preserve After 53 minutes, add 11 g of phenol into the four-necked flask, cool down to 73 ° C, and heat-preserve for 17 minutes, continue to add 22 mL of formaldehyde solution with a mass fraction of 40% to the four-necked flask, react for 1.5 hours, and naturally cool to room temperature to obtain modified soybeans Protein adhesive; poplar wood is put into a wood grinder and pulverized for 4.5 hours, passed through a 200-mesh sieve to obtain poplar wood powder, 25g poplar wood powder, 73g bamboo fiber, and 110mL water are mixed to obtain bamboo fiber pulp, and the bamboo fiber pulp is injected into the belt In a forming tank with a vacuum dehydration device, after air bubbling and stirring for 13 seconds, stand for vacuum dehydration for 6 minutes, and c...

example 3

[0031] Add 220 mL of distilled water to a four-necked flask with a stirrer and a reflux condenser, adjust the pH to 10 with a 40% sodium hydroxide solution, heat the four-necked flask to 100°C, add 70 g of soybean powder, and heat-preserve After 55 minutes, add 12 g of phenol into the four-necked flask, cool down to 75°C, heat-preserve for 20 minutes, continue to add 25 mL of formaldehyde solution with a mass fraction of 40% to the four-necked flask, react for 2 hours, and naturally cool to room temperature to obtain modified soybean protein Adhesive: put poplar wood into a wood crusher and pulverize for 5 hours, pass through a 200-mesh sieve to get poplar powder, mix 30g poplar wood powder, 75g bamboo fiber, and 120mL water to get bamboo fiber pulp, inject the bamboo fiber pulp into a vacuum In the forming tank of the dehydration device, after air bubbling and stirring for 15 seconds, stand for vacuum dehydration for 8 minutes, and control the vacuum degree during dehydration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com