Fire-resistant engineering plastic and preparation method thereof

A technology of engineering plastics and fire resistance, which is applied in the field of fire resistance engineering plastics and its preparation, can solve the problems of insufficient flame retardancy and insufficient flame retardancy of engineering plastics, and achieve the effect of flame retardancy reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

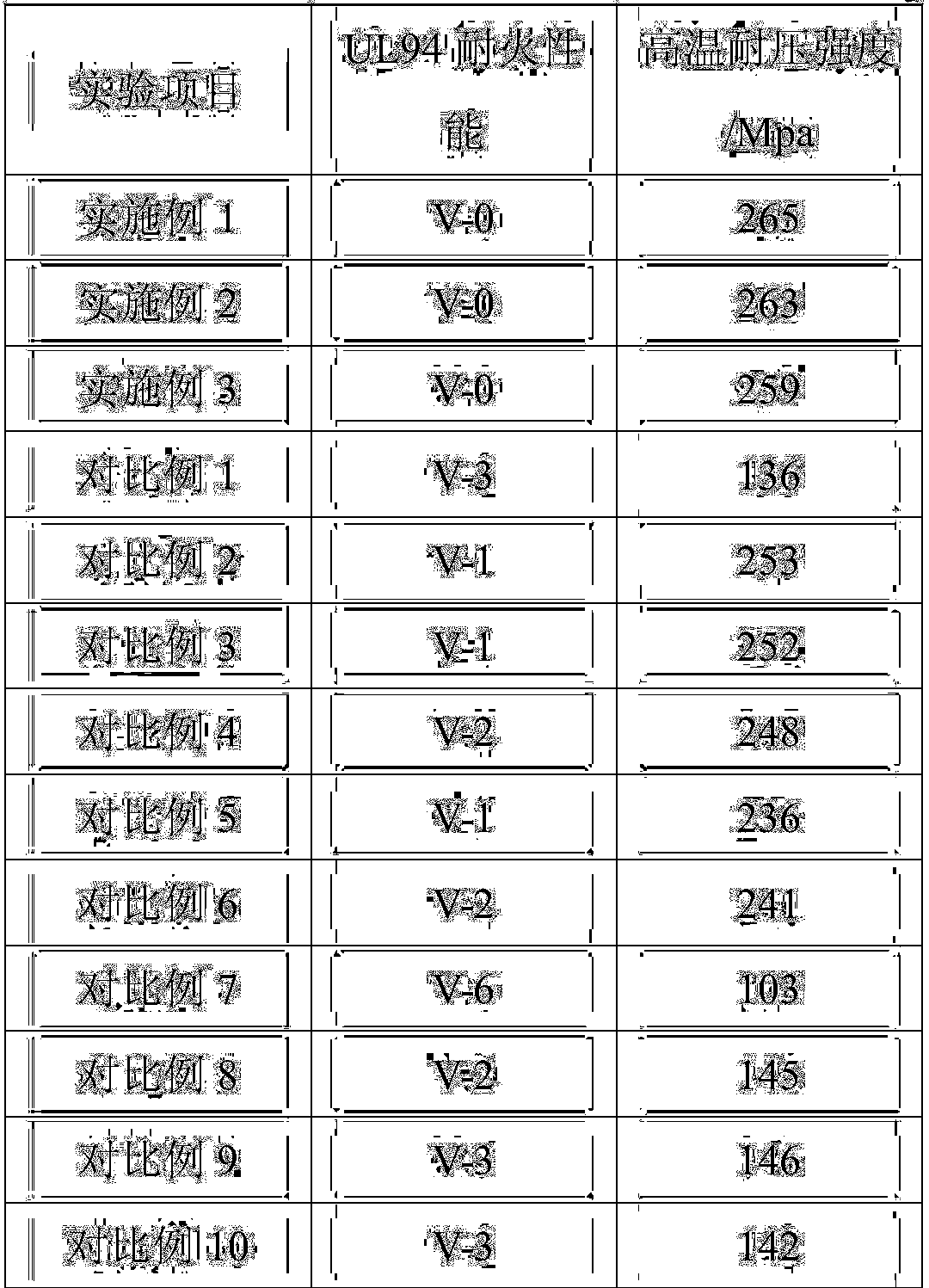

Examples

preparation example Construction

[0028] The preparation method of described refractory engineering plastics, comprises the following steps:

[0029] S1. Mix ethylene-propylene rubber, styrene-butadiene rubber and ammonium polyphosphate evenly, heat up to 120-130°C, keep warm for 10-30min, then stir at 1500-2500r / min for 10-30min, cool to room temperature to obtain the base material, then Add vinyltriethoxysilane and hexachlorocyclotriphosphazene to the base material, mix evenly, raise the temperature to 110-130°C, and keep it warm for 10-20min to obtain the modified base material;

[0030] S2. Mix polycarbonate and fluorocarbon resin evenly, heat up to 110-130°C, keep warm for 20-40min, then add white carbon black, organic modified montmorillonite, silicon hydrogen group, cellulose ether, carbon black N330 , glass fiber, sodium silicate, chlorinated paraffin, simethicone, expanded vermiculite, accelerator TMDT, zinc oxide, stearic acid, antioxidant RD, mix evenly, and stir at 850-1050r / min for 1-2h, Then con...

Embodiment 1

[0033] A kind of said refractory engineering plastics, in parts by weight, comprising the following raw materials: 20 parts of polycarbonate, 6 parts of organically modified montmorillonite, 10 parts of modified flame retardant, 4.5 parts of nano silicon dioxide, glass 3 parts of fiber, 7702 parts of light stabilizer, 3.5 parts of polyethylene glycol, 6 parts of ethylene bis stearamide, 7.5 parts of white carbon black, 6 parts of di(2,3-dichloropropyl) octyl phosphate, 6 parts of tri(new 3.5 parts of pentanediol phosphate)methylamine, 2 parts of silsesquioxane, 6 parts of vinyltriethoxysilane, and 10 parts of hexachlorocyclotriphosphazene.

[0034] The modified flame retardant is prepared according to the following process: by weight, 10 parts of cross-linked polyacrylonitrile-styrene copolymer, 4.5 parts of polypropylene, 3 parts of potassium persulfate and 3.5 parts of polyaryl phosphate are mixed Evenly, then heat up to 70°C, keep warm for 3 hours to get the core, then add ...

Embodiment 2

[0040] A kind of said refractory engineering plastics, in parts by weight, comprising the following raw materials: 15 parts of polycarbonate, 8 parts of organically modified montmorillonite, 9 parts of modified flame retardant, 6 parts of nano silicon dioxide, glass 1 part of fiber, 7703 parts of light stabilizer, 2 parts of polyethylene glycol, 8 parts of ethylene bis stearamide, 6 parts of white carbon black, 9 parts of di(2,3-dichloropropyl) octyl phosphate, 9 parts of tri(new Pentylene glycol phosphate) methylamine 2 parts, silsesquioxane 3 parts, vinyltriethoxysilane 4 parts, hexachlorocyclotriphosphazene 12 parts.

[0041] The modified flame retardant is prepared according to the following process: 8-12 parts by weight of cross-linked polyacrylonitrile-styrene copolymer, 3-6 parts of polypropylene, 1-5 parts of potassium persulfate and 2-5 parts Mix one part of polyaryl phosphate evenly, then heat up to 60-80°C, keep warm for 2-4h to get core, then add 4-8 parts of silan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com