Coal pulverizing system

A pulverizing system and pulverizing silo technology, applied in the direction of block/powder fuel preparation, combustion method, lighting and heating equipment, etc., can solve the problem of compaction of powder storage, low superheat of steam fire protection device, danger of occurrence, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

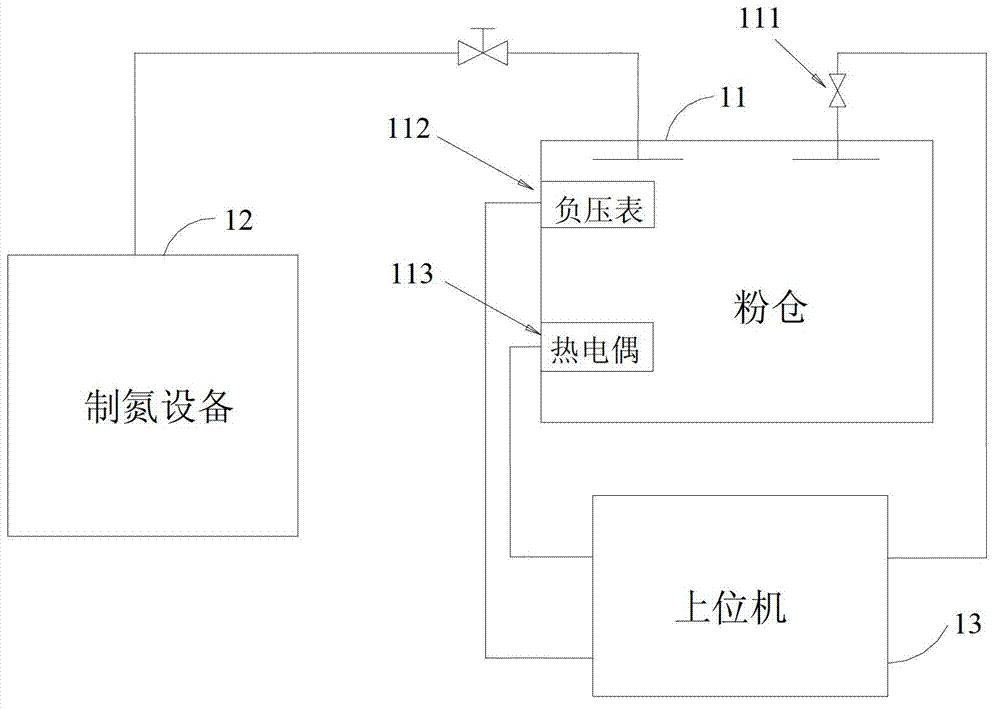

[0021] Such as figure 1 As shown, it is a schematic structural diagram of an embodiment of the powder making system of the present invention, including a powder bin 11, the powder bin includes an upper cover, and a nitrogen making device 12 is also included;

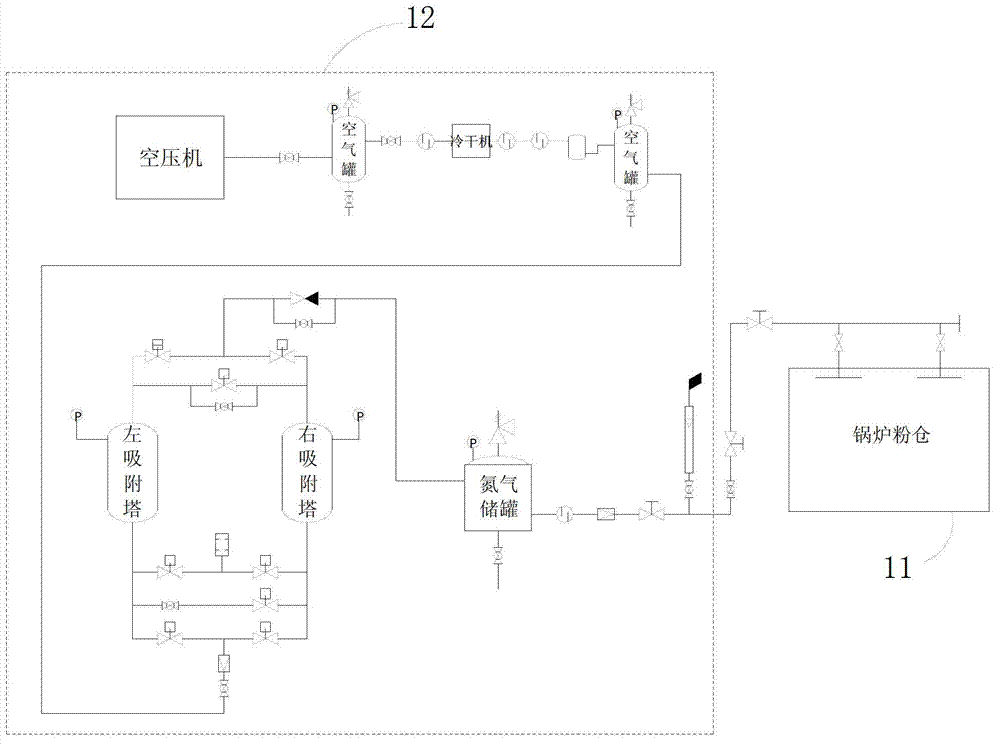

[0022] The upper cover of the powder bin 11 is provided with a nitrogen filling port, and the outlet of the nitrogen making device 12 is connected to the nitrogen filling port of the powder bin 11 through a pipeline; multiple nitrogen filling ports can be set, and can be arranged in the powder bin At the side position of the upper cover, each pipeline is horizontally inserted into the nitrogen filling port of the upper cover, which can prevent the coal powder from flying after the nitrogen gas rushes into the powder bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com