Self-loading and unloading heavy-load shelf with adjustable layer interval

A self-loading, heavy-duty technology, applied in the field of shelves, can solve the problems of reducing the use of special loading and unloading equipment, the inability of heavy goods, and the difficulty of spacing adjustment, so as to reduce labor intensity, ensure safety, and meet storage requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

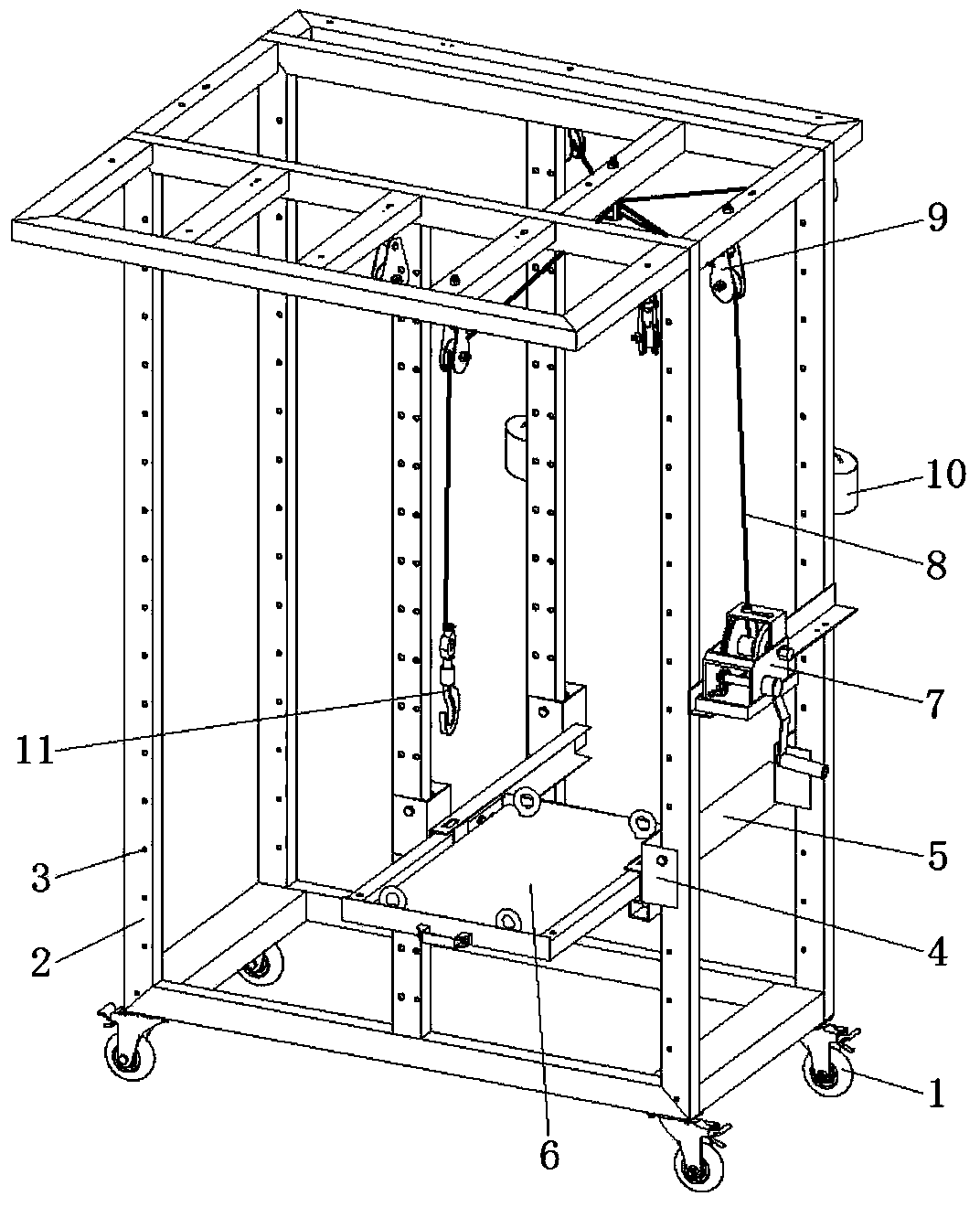

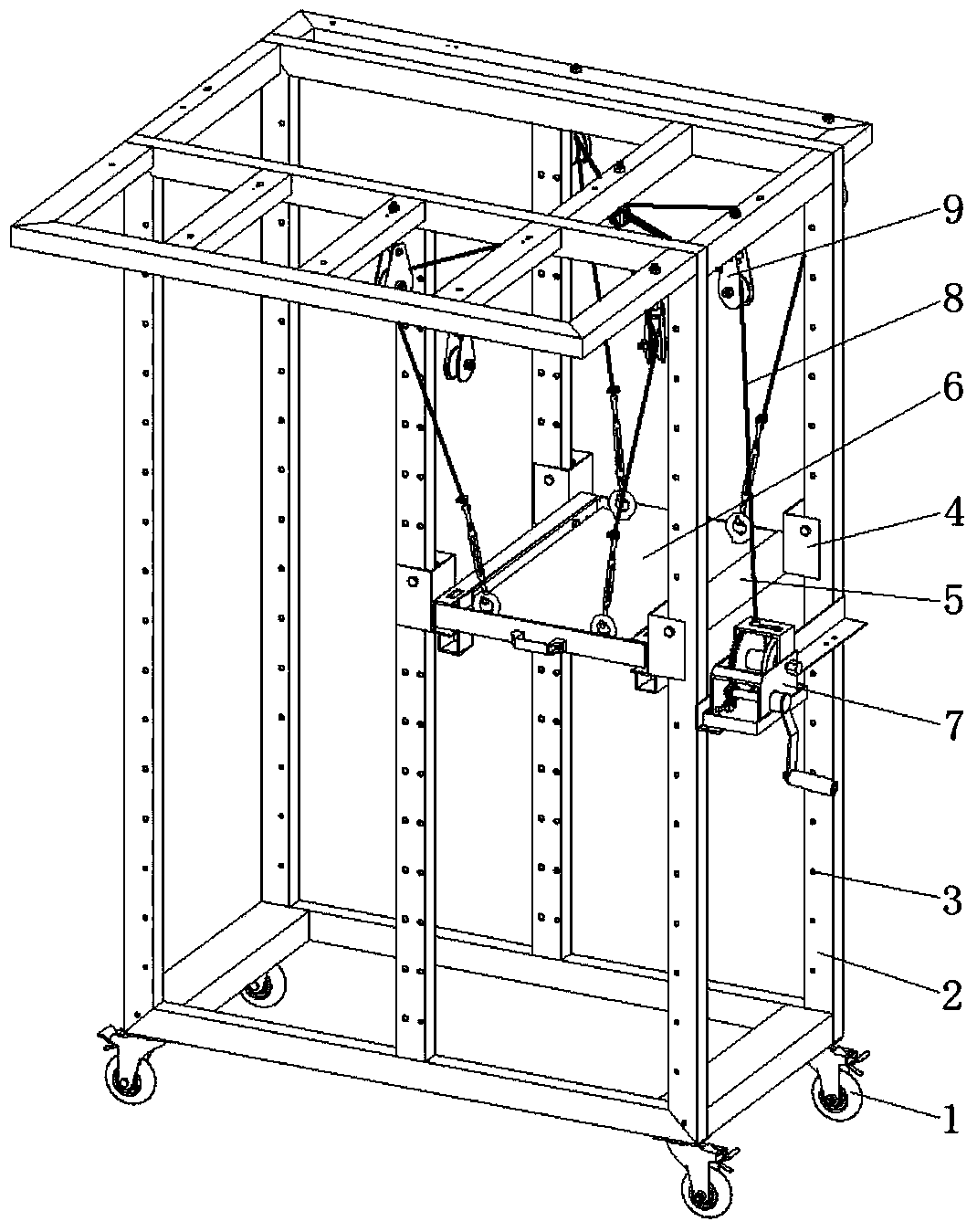

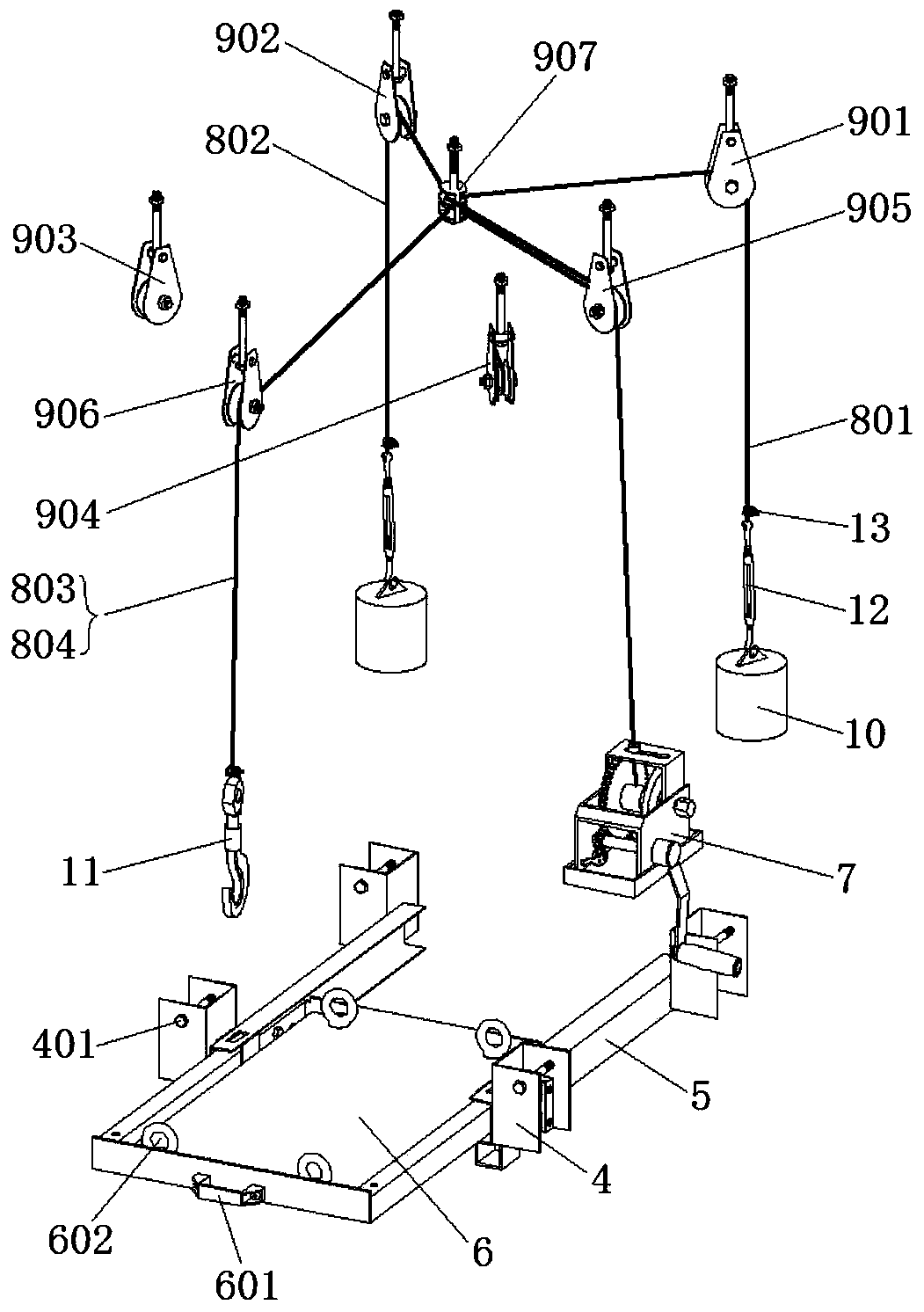

[0037] combine Figure 1 to Figure 4 , a self-loading and unloading heavy-duty shelf with adjustable layer intervals in this embodiment includes a main frame 2, a layer frame, a manual winch 7, a wire rope 8, a pulley block 9, a weight 10 and a lifting hook 11, and the main frame 2 A plurality of adjustment holes 3 are arranged at intervals along the height direction of the vertical column. In this embodiment, the distance between two adjacent adjustment holes 3 is 5 cm to 15 cm, and the shelf is fixed to the main frame 2 through the adjustment holes 3. On the top, the adjustment hole 3 is used to install the shelf, and at the same time play a role in adjusting the height of the shelf. In this embodiment, the shelf includes a rolling lifting sliding sleeve 4, a heavy-duty slide rail 5 and a tray 6, the heavy-duty slide rail 5 is arranged on both sides of the tray 6, and the heavy-duty slide rail 5 passes through the rolling rollers located at its two ends. The lifting sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com