Vanadium flow cell seal ring and ionic membrane integrated assembly and electric pile

A vanadium redox flow battery and sealing ring technology, which is applied to battery pack parts, fuel cell grouping, electrical components, etc., can solve problems such as falling, battery damage, and failure to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

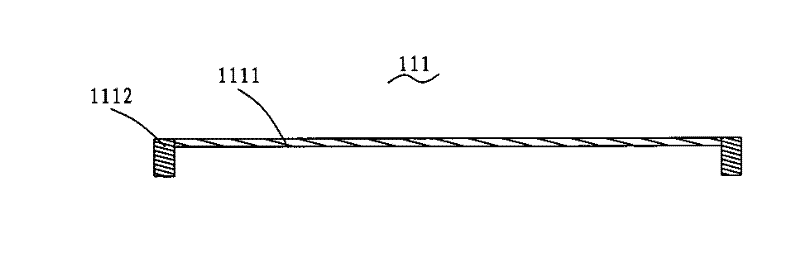

[0023] see figure 1 Schematic diagram of the sectional structure of the ionic membrane integrated structure of the present invention, as shown in the figure, the vanadium redox flow battery sealing ring ionic membrane integrated component 111 includes an ionic membrane 1111 and a sealing ring 1112, the ionic membrane 1111 and the sealing ring 1112 is a whole, wherein the height of the sealing ring 1112 is higher than the height of the sealing ring groove on the frame plate. In a preferred technical solution of the present invention, the height of the sealing ring 1112 is twice the height of the groove of the sealing ring on the frame plate.

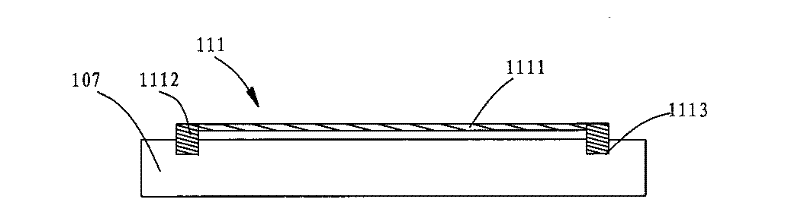

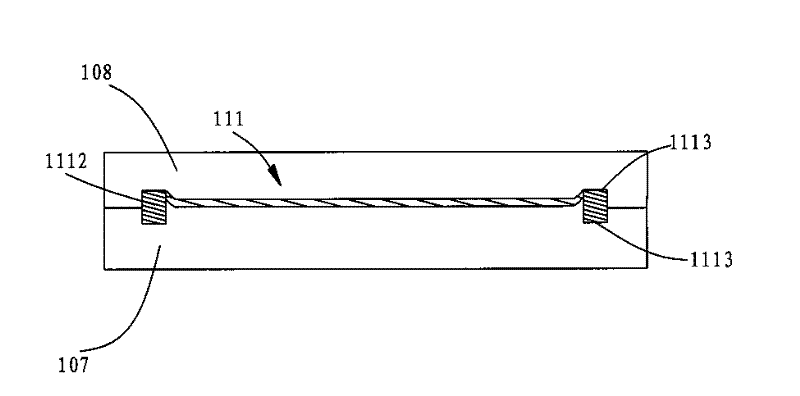

[0024] see figure 2 The schematic diagram of the assembly cross-sectional structure of the vanadium redox flow battery sealing ring ion membrane integrated assembly 111 and the first frame plate of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com