Backlight module and display device

A technology for a backlight module and a display device, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc. Product yield, the effect of reducing material scrap and rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

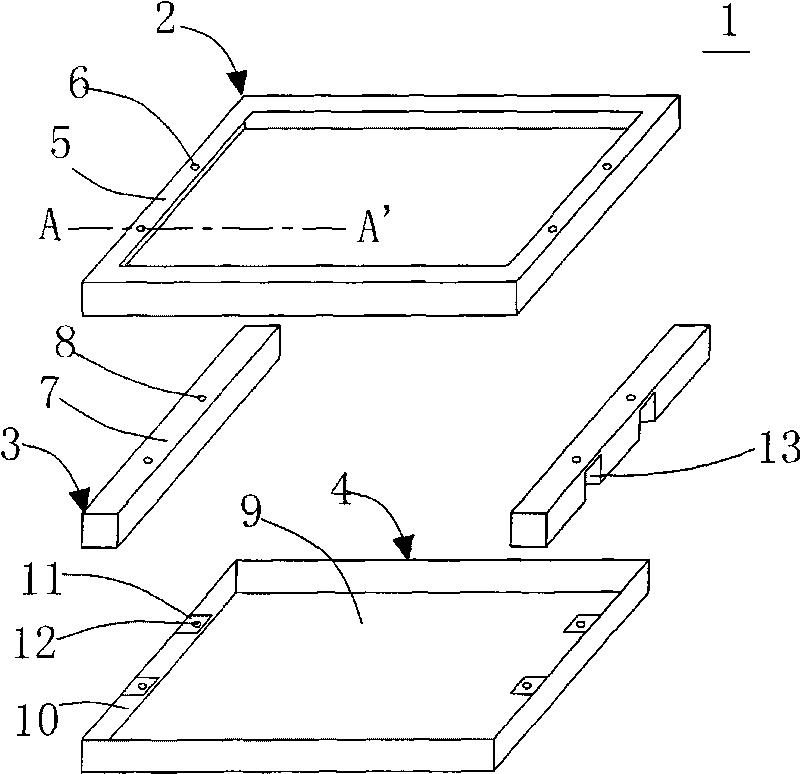

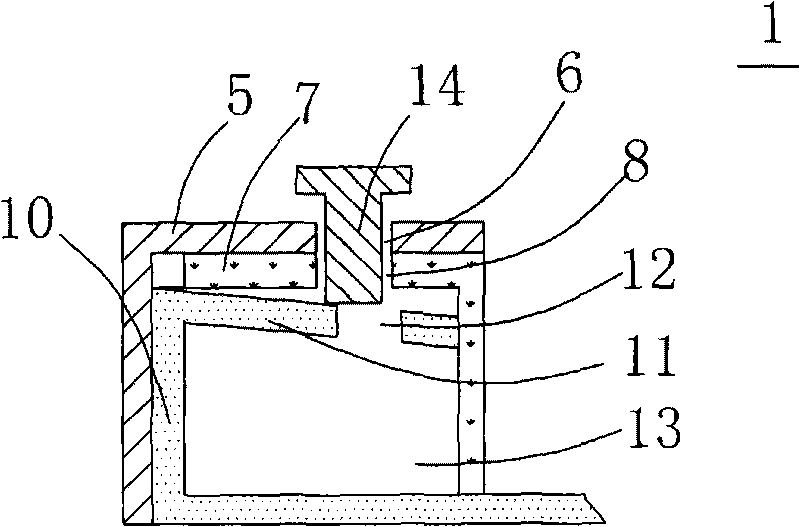

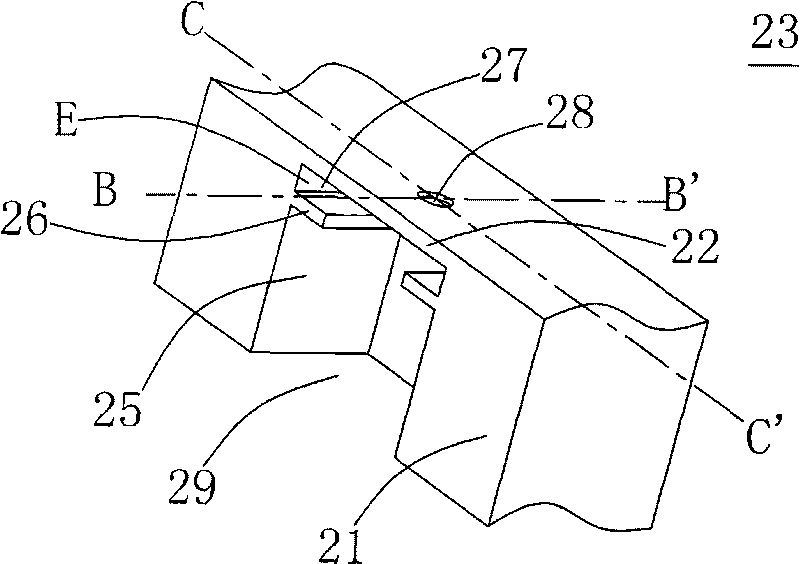

[0030] See image 3 , Figure 4 , Figure 5A as well as Figure 5B , image 3 Shown is a schematic diagram of a support base according to a first embodiment of the present invention, Figure 4 Shown is a schematic diagram of a backplane according to a first embodiment of the present invention, Figure 5A shown as image 3 The support seat in the Figure 4 The cross-sectional schematic diagram along the BB' line after the backplane is combined in Figure 5B shown as image 3 The support seat in the Figure 4 The schematic cross-sectional view along line CC' of the combined backplane in . The backlight module 20 provided by the present invention includes a backplane 24 and a supporting seat 23 . Since the structure of the light source, diffusion sheet, and prism sheet disposed in the backlight module 20 is the same as that of the prior art, and is not the focus of the present invention, it will not be described here. The back panel 24 includes a bottom panel 19 , a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com