Production process of paper puzzle and paper puzzle

A production process, paper technology, applied in sports accessories, indoor games, etc., can solve the problems of dislocation of puzzle units, restricting production efficiency, easy to scattered puzzles, etc., to improve production efficiency, avoid dislocation and loss of puzzle units, and save manpower Effects of cost and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The production technology of paper jigsaw puzzle of the present invention mainly comprises the following steps:

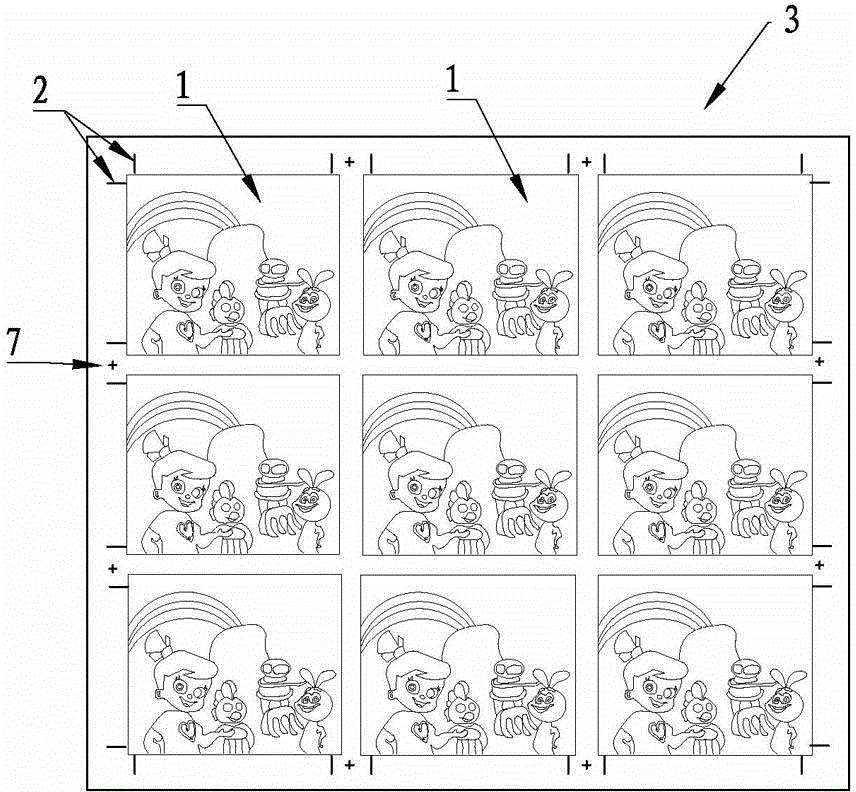

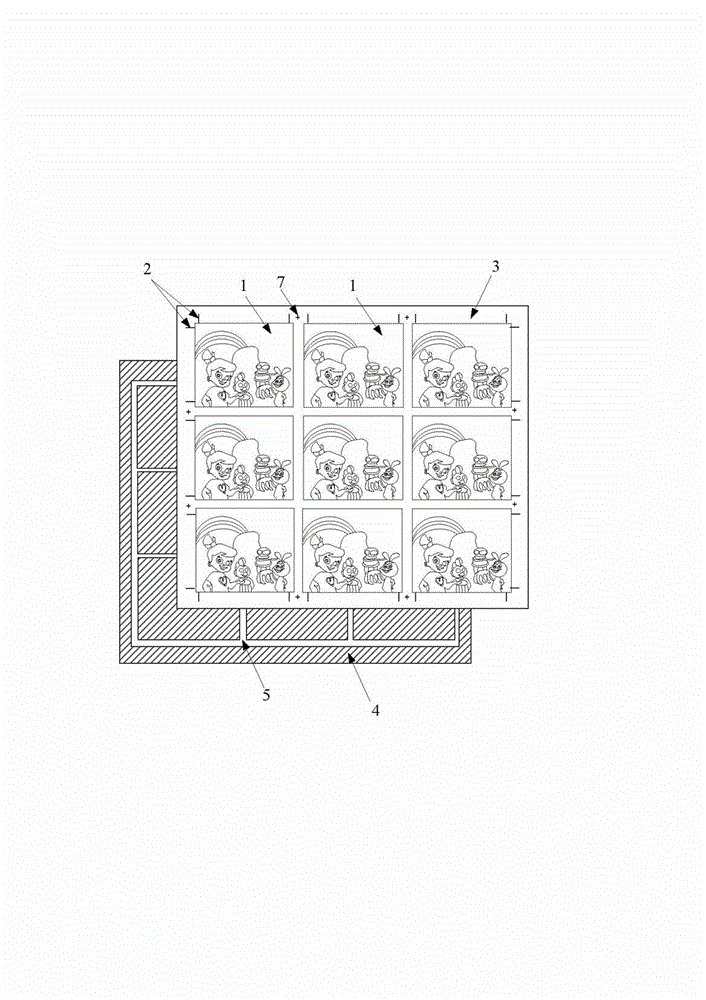

[0032] refer to figure 1 , step 1 according to spelling figure 1 The size of the machine and the size of the machine paper are assembled on the computer. figure 1 fight with figure 1 Reserve a space between; this step puts together multiple figure 1 fight together figure 1 fight with figure 1 The reserved space between them is 10-20mm. Preferably, the spacing may be 10 mm, 15 mm, or 20 mm.

[0033] spell figure 1 The pattern and size can be selected according to market demand, such as cartoon characters, architectural models, etc. The reserved spacing is 10-20mm to avoid cutting deviation and splitting figure 1 , causing fight figure 1 scrapped.

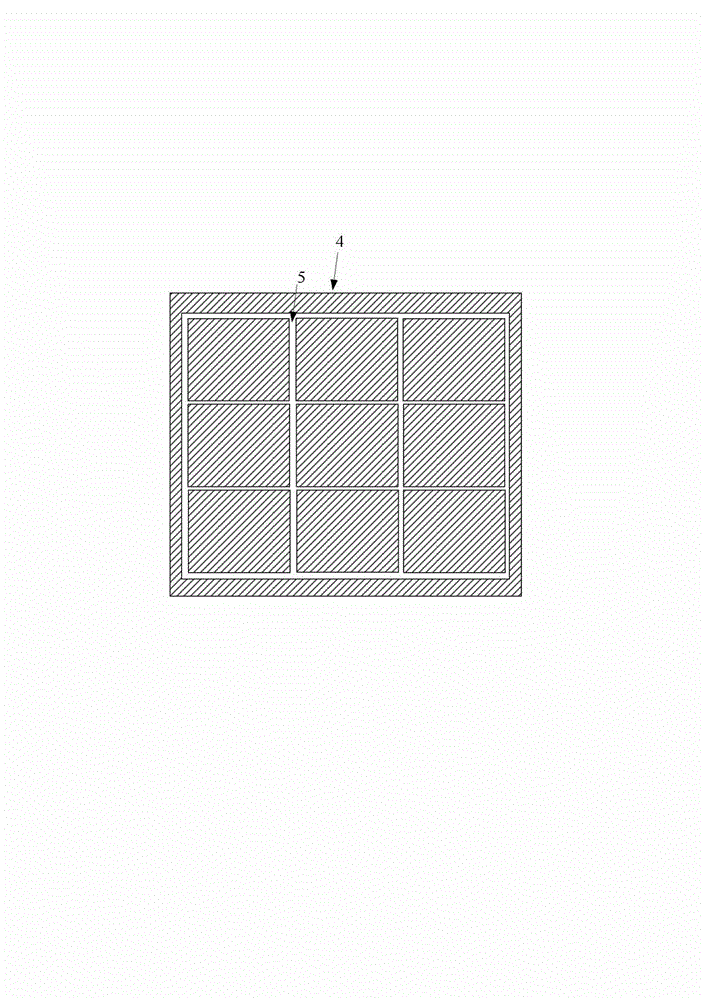

[0034] Step 2 Put the above spelled mold together figure 1 Make a typesetting, and mark t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com