Harness connector with barb for automatic transmission

A technology for automatic transmissions and harness connectors, applied in the installation of connecting parts, base/housing, etc., can solve problems such as inability to fix, complex assembly process, etc., achieve the effect of saving mold costs, optimizing process, and improving the pass rate of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

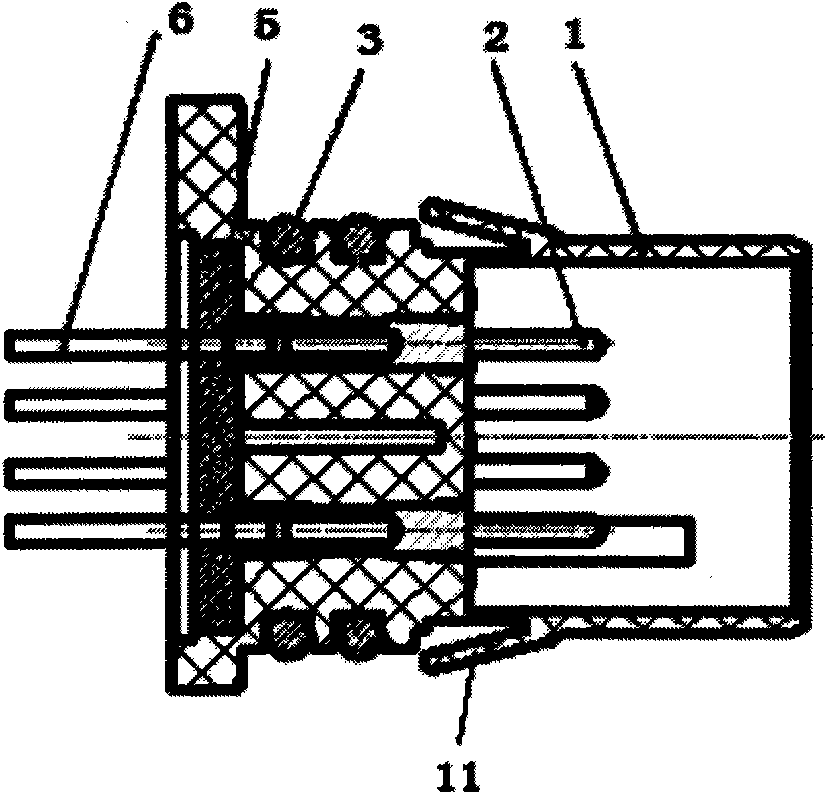

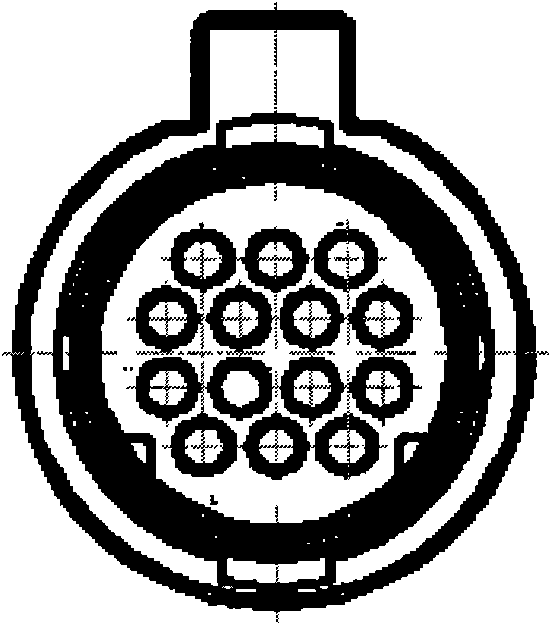

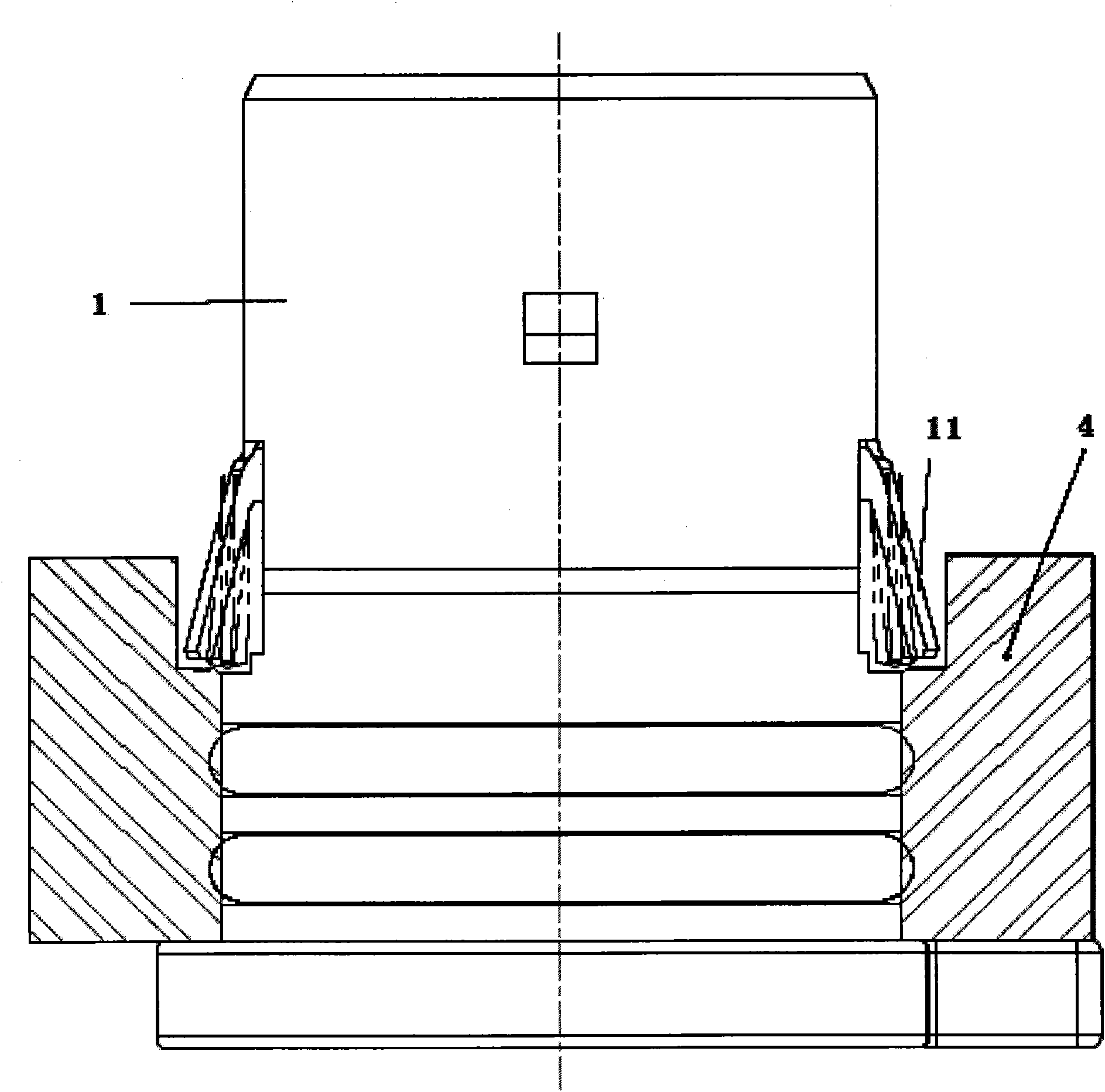

[0017] see Figure 1-2 , which is a barbed automatic transmission wire harness connector of the present invention. like figure 1 As shown: it includes a connector molded case 1 with a cylindrical body at the front end and a stopper at the rear end edge. The connector molded case 1 has a number of connectors distributed in the cylindrical body from the cylindrical body to the back of the connector molded case. The connection hole at the end; the front end of the connection hole is pierced with the terminal 2, and the rear end is pierced with the wire 6, and the front end of the wire 6 is connected to the rear end of the terminal 2, figure 2 Among them, the number of wires, connecting holes and terminals is 14. The feature of the present invention is that: the cylindrical outer body of the plastic connector housing 1 is symmetrically provided with oblique elastic barbs 11 . A sealing ring 3 is provided on the outer peripheral ring of the rear end of the connector plastic cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com