Special-purposed pulverizer for coal mine fire extinguishing high hygrophanous resin, and application method thereof

A high water-absorbent resin and pulverizer technology, applied in grain processing, etc., can solve the problems of high device cost, easy wear of the blade, high maintenance cost, etc., and achieve the effects of simple structure, stable operation, and improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

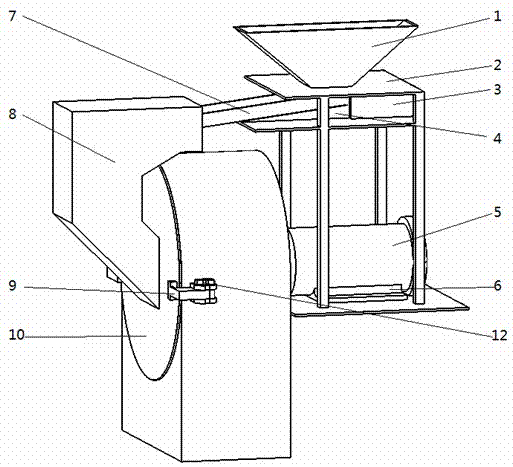

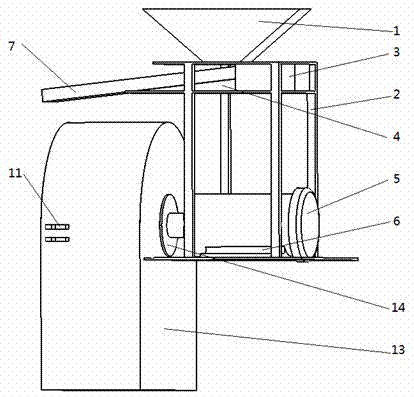

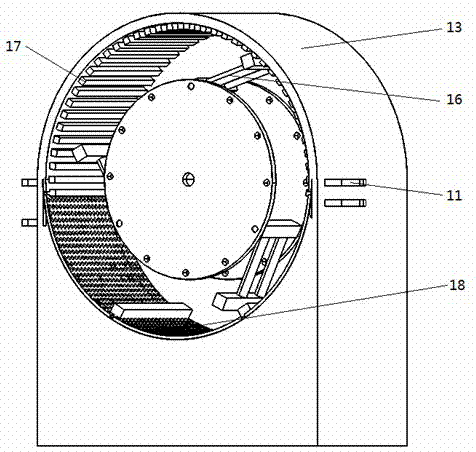

[0018] like Figures 1 to 4 As shown, a special crusher for coal mine fire extinguishing super absorbent resin includes a barrel 1, a main frame 2, an electromagnetic device 3, a guide rail 4, a motor 5, a motor fixing frame 6, a feeding trough 7, a feeding channel 8, a baffle 9, Pulverizing chamber 13, flange 14, disc 15, main blade 16, slave blade 17 and screen 18; the barrel 1 is fixed on the main frame 2, the outlet at the lower end of the barrel 1 is connected with the feeding chute 7, and the guide rail 4 is fixed on the Main frame 2, one end of the feeding chute 7 is fixed with the electromagnetic device 3, the feeding chute 7 is connected with the guide rail 4 through the dovetail groove, the other end of the feeding chute 7 is connected with the upper end of the feeding channel 8, and the lower end of the feeding channel 8 is connected with the connection on the baffle 9. The holes are connected, the baffle plate 9 is fixed on the crushing chamber 13, the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com