Floating motor type engine transient dynamic test two-purpose dynamometer and two-purpose method thereof

A dynamic test and engine technology, applied in the direction of power measurement, measuring devices, instruments, etc., can solve the problems of simulating the inertia of the whole vehicle, unable to test the transient performance of the engine, etc., and achieve small size, simple and reliable fixing method, and reduced system inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

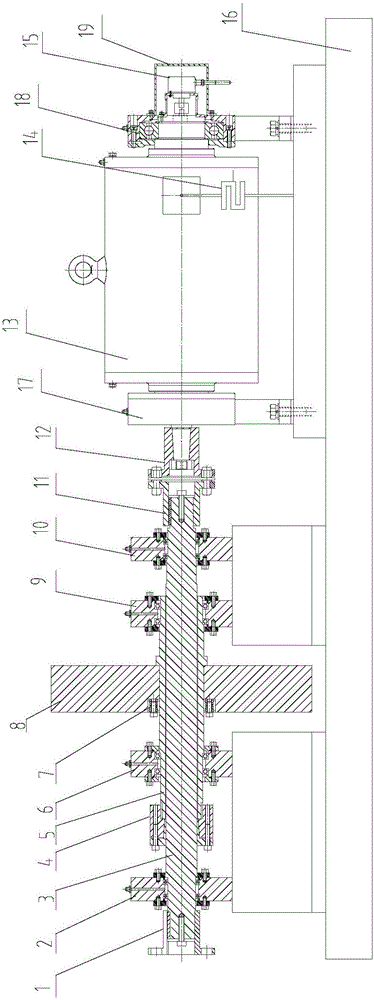

[0048] Such as figure 1 As shown, the floating motor type engine transient dynamic test dual-purpose dynamometer of the present invention includes a base 16 and a first transmission shaft bearing support 2 fixedly connected to the base 16, a second transmission shaft bearing support 10, a first motor Bearing support 17 and second motor bearing support 18, said first transmission shaft bearing support 2 and second transmission shaft bearing support 10 are equipped with transmission shaft 3, and one end of said transmission shaft 3 is connected with transmission shaft engine coupling 1. The other end of the transmission shaft 3 is connected to a transmission shaft motor coupling 11, and a section of the transmission shaft 3 between the first transmission shaft bearing support 2 and the second transmission shaft bearing support 10 is fitted with a flywheel shaft 5, The transmission shaft 3 is connected with the transmission shaft and the flywheel shaft 5 for disconnecting the fly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com