Automatic slicing machine for slitting ultrathin flexible magnetic sheets

A flexible magnetic sheet and slicing machine technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of low pass rate, low cutting efficiency, and low dimensional accuracy of ultra-thin flexible magnetic sheets. Pulling by external force, preventing and avoiding breaking, simple and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

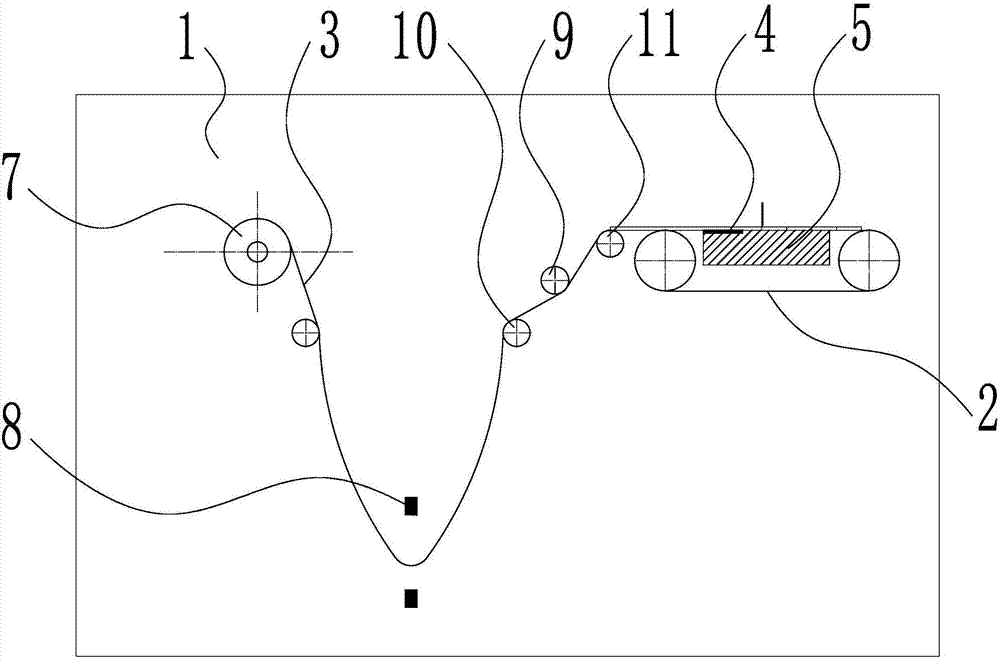

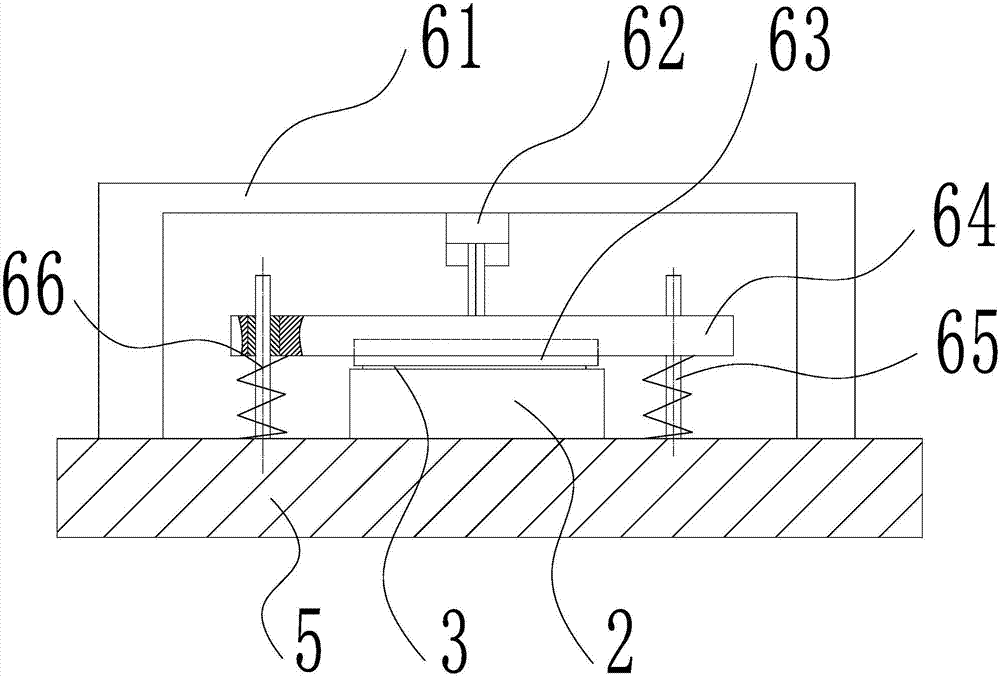

[0014] Such as figure 1 As shown, an automatic slicing machine for cutting ultra-thin flexible magnetic sheets of the present invention includes an airtight workshop 1 and a conveyor belt 2 placed horizontally in the airtight workshop 1. The conveyor belt 2 adopts a common release film conveyor belt. Driven by two left and right pulleys, one end of the ultra-thin flexible magnetic sheet raw material belt 3 is laid flat on the input end of the conveyor belt 2, and the airtight workshop 1 corresponding to the input end of the conveyor belt 2 is equipped with a discharge roller 7, which is ultra-thin and flexible. The magnetic sheet raw material tape 3 is wound on the discharge roller 7 and extends downwards and then passes upwards. After the introduction roller 11 is horizontally hung on the conveyor belt 2, it is near the lowest point where the ultra-thin flexible magnetic sheet raw material tape 3 sags. 1. An infrared sensor 8 is installed on both sides of the lower surface re...

Embodiment 2

[0016] The cutter 63 in the slicing device is driven downward by the screw mechanism to cut the ultra-thin flexible magnetic sheet raw material tape 3 in sections. All the other parts are identical to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com