Self-lubricating cold welding preventing light self-locking nut and manufacturing and use methods thereof

A self-locking nut and self-lubricating technology, used in nuts, screws, bolts, etc., can solve the problems of high technical requirements, difficult process and high price of fasteners, and achieve stable mechanical properties, high safety and reliability, and prevent The effect of cold sweat bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

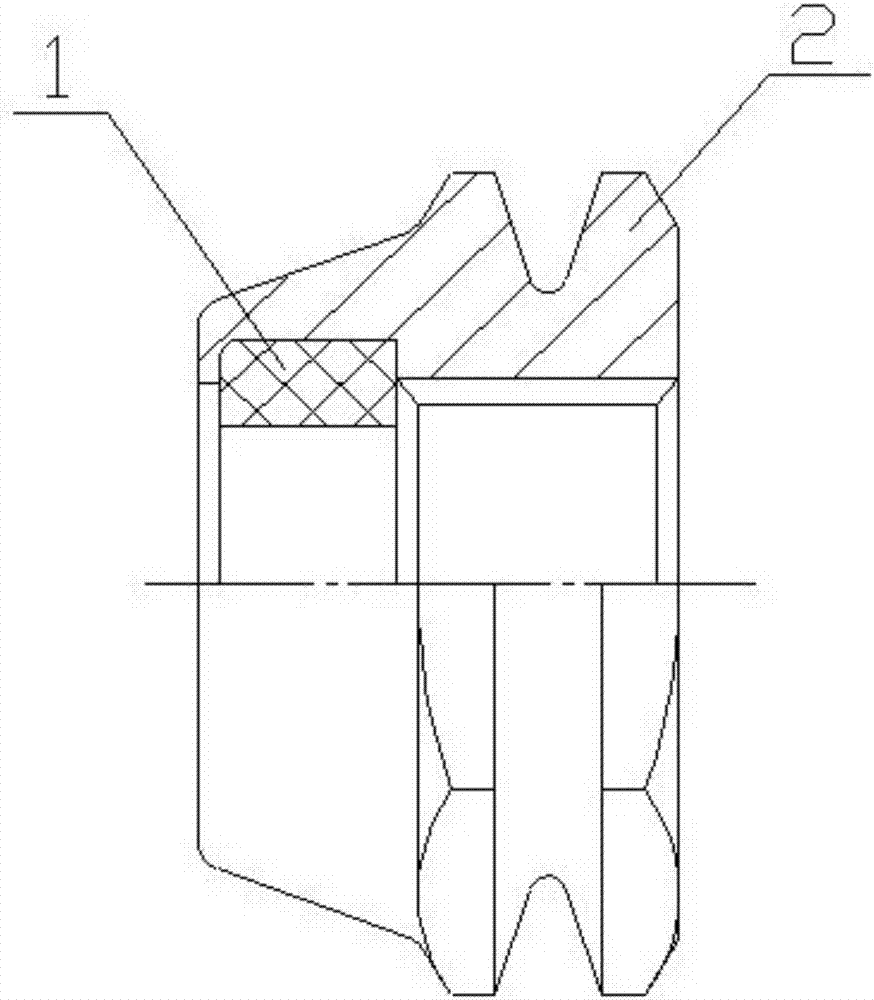

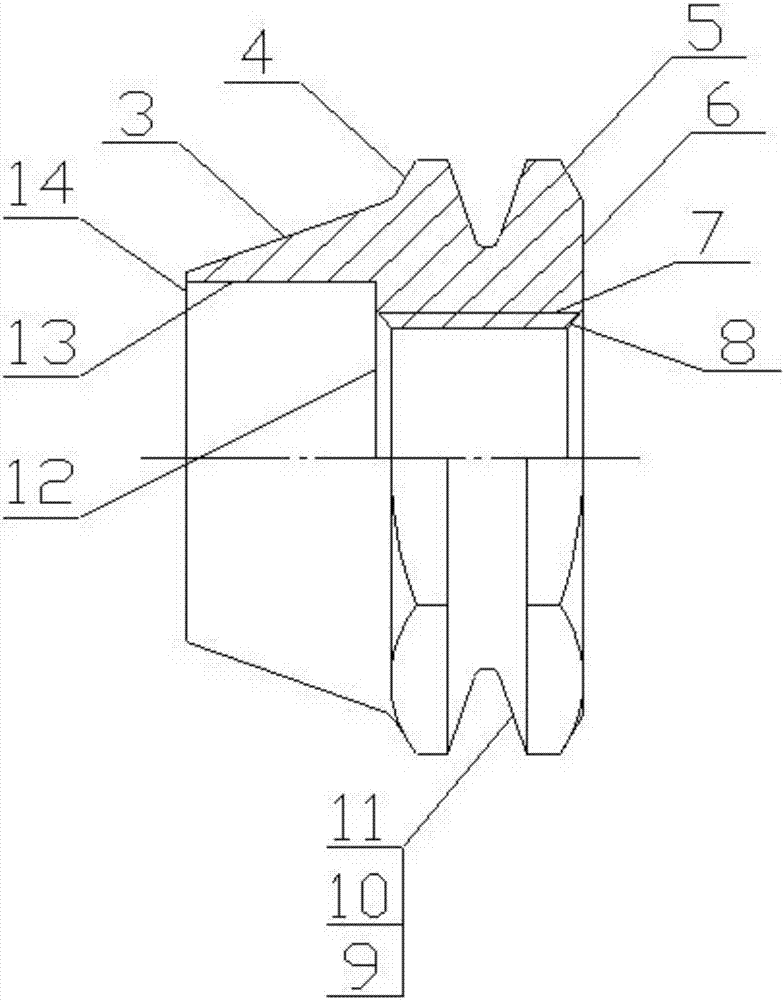

[0043] Self-lubricating anti-cold welding light-duty self-locking nut 22, including a sealing locking ring 1 and a self-locking nut body 2.

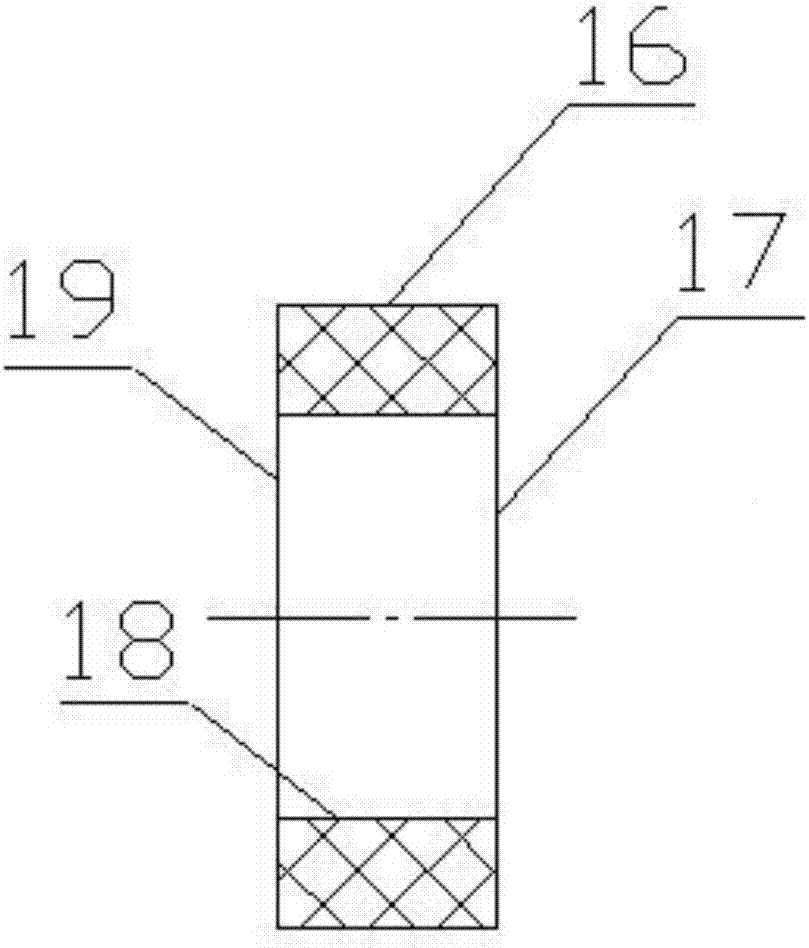

[0044] First, thread the connecting bolt 21 through the connected part 20 to the self-locking nut 22 and screw the hexagonal wrenching surface 15 of the self-locking nut 22 to achieve the required pre-tightening force. The installation process is now complete. like Figure 4 shown. The design of the lightening groove 9 effectively reduces the weight of the self-locking nut. The sealing and locking ring 1 is closed and fixed in the self-locking nut body 2 through the stamping and bending deformation of the nut body end face 6, and the sealing and locking ring 1 is plastically deformed to obtain a locking torque and a rational sealing effect at the same time. The organic combination of metal materials and non-metal materials can effectively prevent cold welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com