Rotary cutter sharpening seat for cutter

A tool sharpening seat and cutting tool technology, which is applied in lathe tools, planer/slotting machine tools, manufacturing tools, etc. It can solve the problem that the miniaturization and economy of tool grinding machines are difficult to achieve, and the overall structural rigidity of the tool grinding seat Insufficient, limited scope of application of tool grinding machines, etc., to achieve the effect of improving sharpening efficiency and convenience, improving rigidity, and good locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

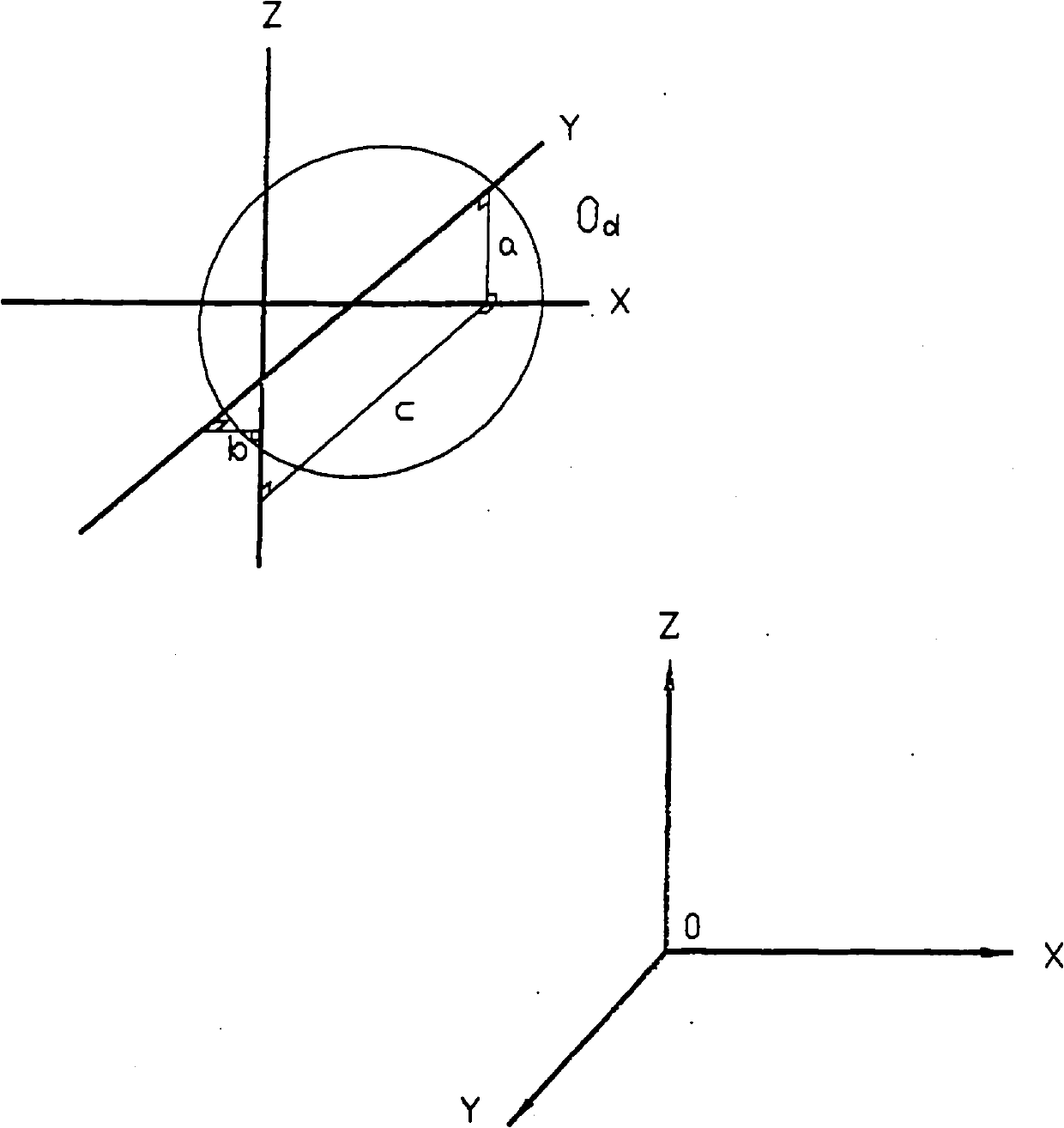

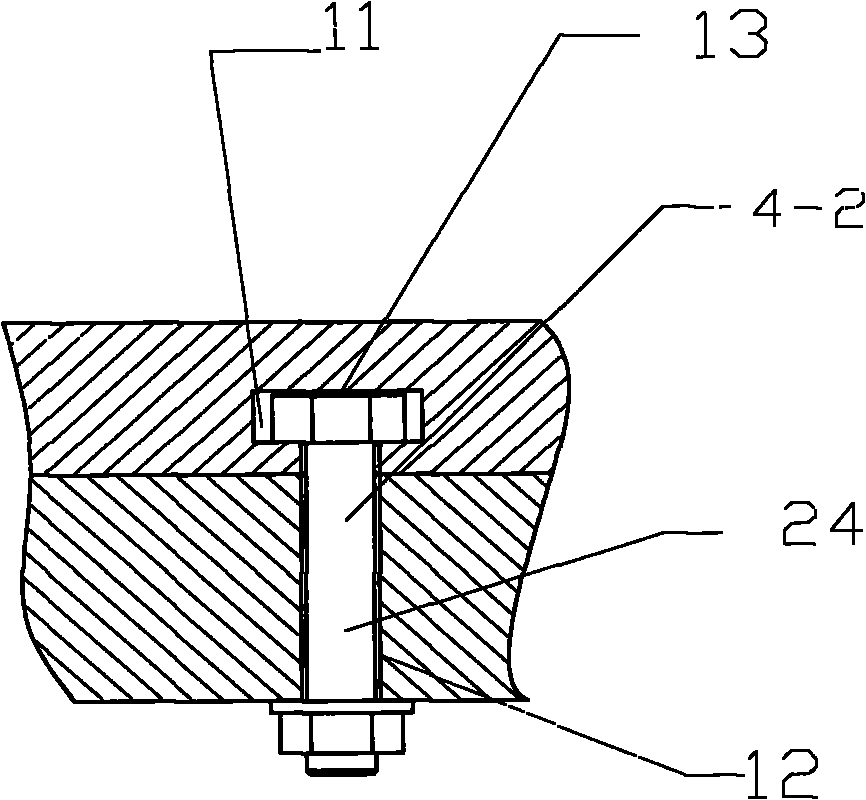

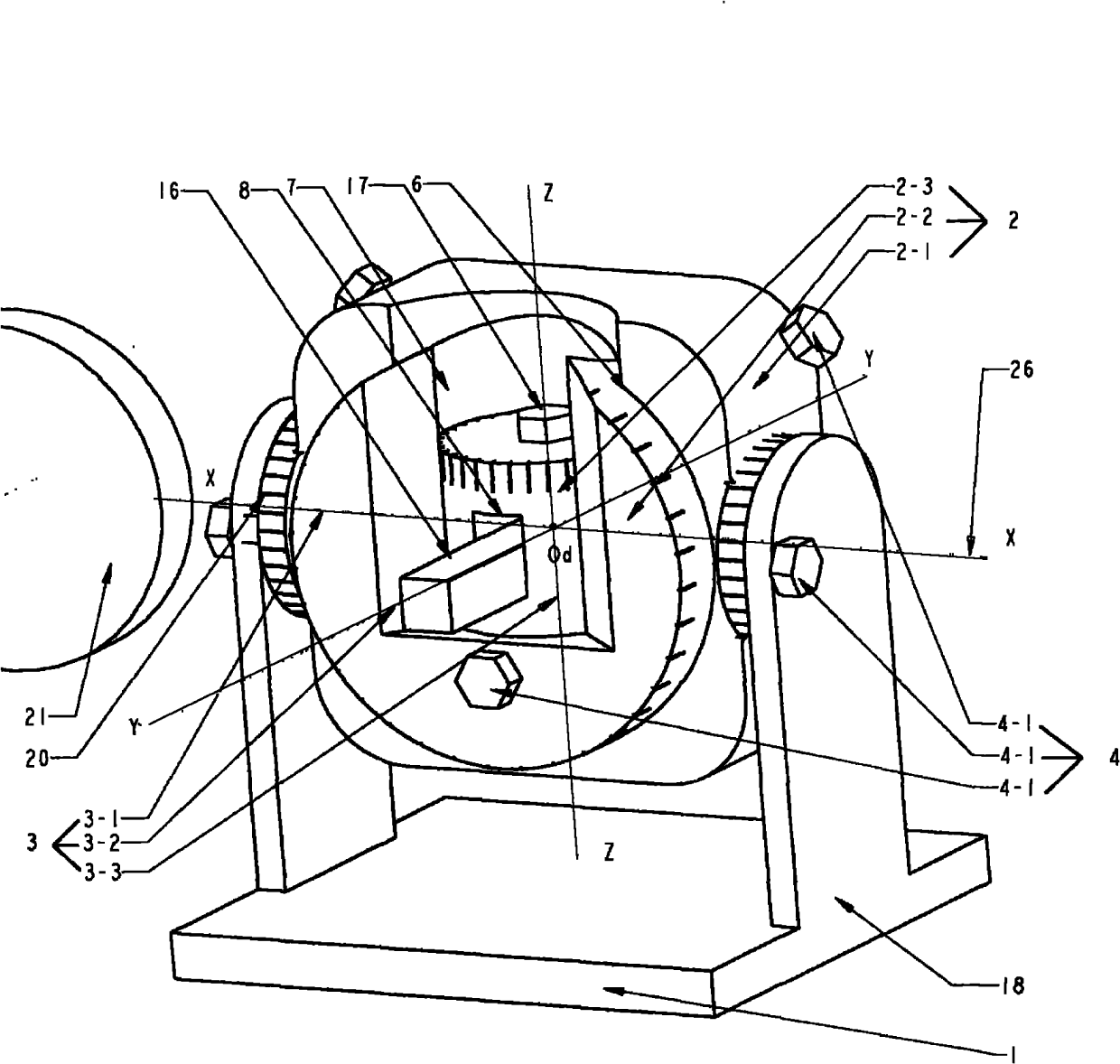

[0032] figure 2 It is the implementation structure diagram of the technical solution of the present invention, the Z rotating part 2-3 is in the middle of the mechanism, the turning tool 16 is installed in the turning tool installation hole 8 and is pressed by the screw 17, and the Z rotating part 2-3 is set on the Y rotating part 2-2Y Z In the middle hole 7, the Z rotating part 2-3 itself is the rotating shaft, and its Z rotating shaft 3-3 line is in line with the Y Z The center lines of the median hole 7 are collinear, and the turning tool 16 is perpendicular to the Z rotating shaft 3-3. due to Y Z Since the position hole 7 is arranged on the Y rotating member 2-2 and is perpendicular to the Y rotating shaft 3-2, the Z rotating shaft 3-3 of the Z rotating member 2-3 is also perpendicular to the Y rotating shaft 3-2. The Y rotating part 2-2 is set on the X of the X rotating part 2-1 Y In the center hole 6, the Y rotating part 2-2 itself is the rotating shaft, and its Y r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com