Multi-station tooth making clamp and clamping method for cutter used in sugar industry

A station system and tool technology, applied in the field of multi-station gear making fixtures, can solve problems such as affecting the speed of the machine tool, restricting the production efficiency of the blade, affecting the processing efficiency, etc. The effect of greatly reducing the procurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

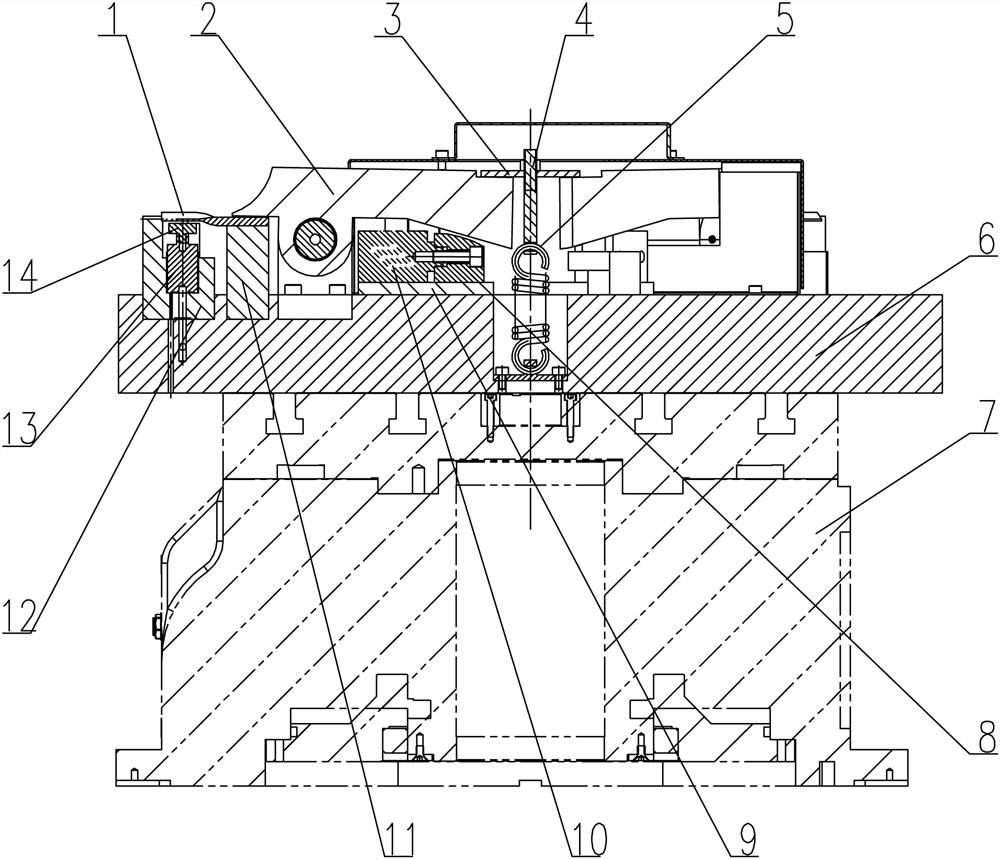

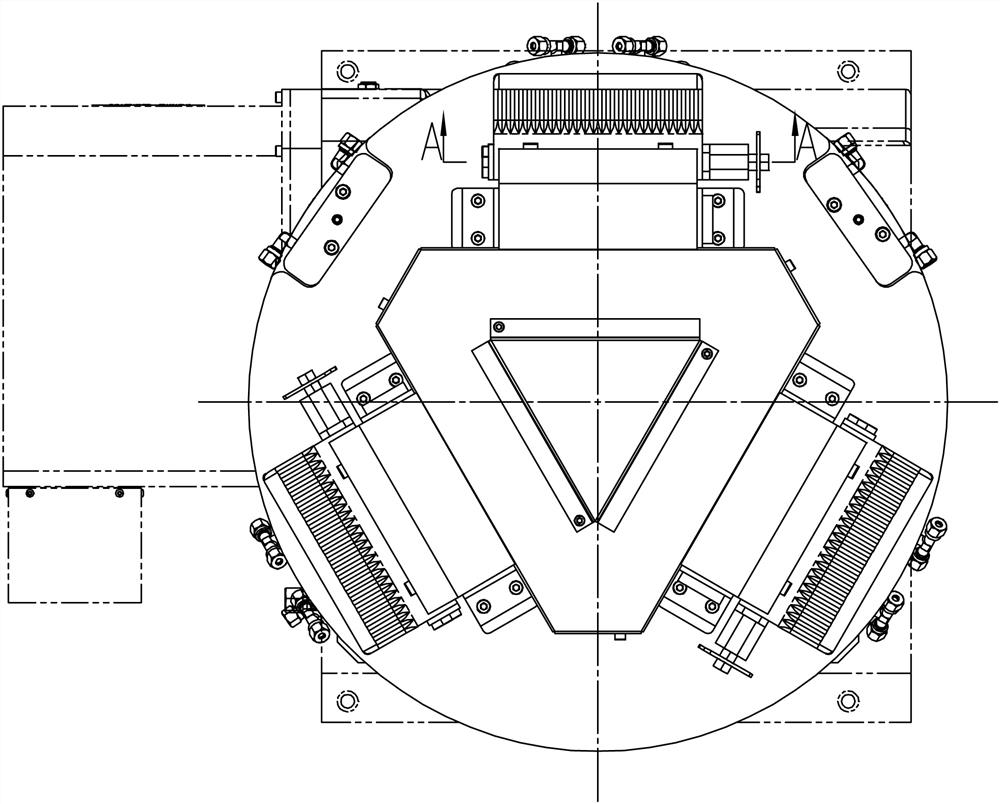

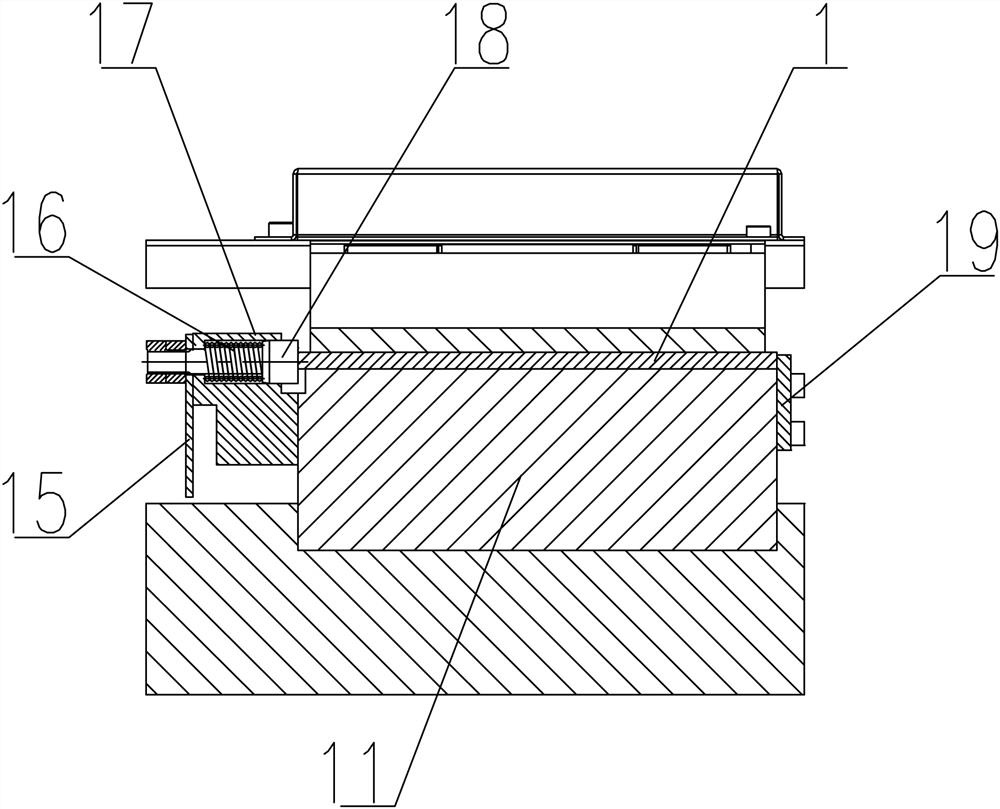

[0040] see Figure 1-5, a multi-station tooth-making fixture for tools used in the sugar industry, which includes an indexing plate 7, a transition plate 6 is fixedly installed on the top of the indexing plate 7, and the top of the transition plate 6 is uniform along the circumferential direction. The cloth is provided with a plurality of stations, and each station is correspondingly arranged with a set of fixtures; each set of fixtures includes a set of self-locking booster mechanism, and the booster mechanism includes a workpiece positioning plate 12, a workpiece pad plate 11, pressing plate 2, backing plate 9, oil cylinder 10 and slide block 8; two hydraulic support cylinders 13 are installed above the workpiece positioning plate 12; contact bolts are all installed on each of the hydraulic support cylinders 13 14; the left and right directions of the workpiece backing plate 11 are respectively equipped with a positioning plate 19 and a guide block 17; the guide block 17 is ...

Embodiment 2

[0055] The method for clamping workpieces by using any one of the multi-station tooth-making fixtures for tools used in the sugar industry includes the following steps:

[0056] Step 1: In the initial state, the oil cylinder 10 is in the retracted state, and the pressure plate 2 is in the loosened state; firstly, the index plate 7 is manually operated to rotate to the loading and unloading position, and then the operator manually pulls the spring rocker 15 with the right hand to make the push rod 18 go toward Retract, put the workpiece 1 under the pressure plate 2 with the left hand; then release the left and right hands at the same time and then hold the workpiece 1 to pull the workpiece 1 away from the rotation center, so that the workpiece 1 can be positioned in the width direction; after loosening the workpiece 1 due to the length The effect of direction compression spring clamping, the workpiece 1 has been fixed in a specific position and cannot be moved;

[0057] Step 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com