A multifunctional drilling and milling mechanism

A multi-functional, drilling and milling technology, applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problem that it is difficult to ensure the position accuracy and shape accuracy of parts, increase the labor intensity of producers, and disadvantage large batches Production and other issues, to achieve the effect of high rigidity, low manufacturing cost, and stable processing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

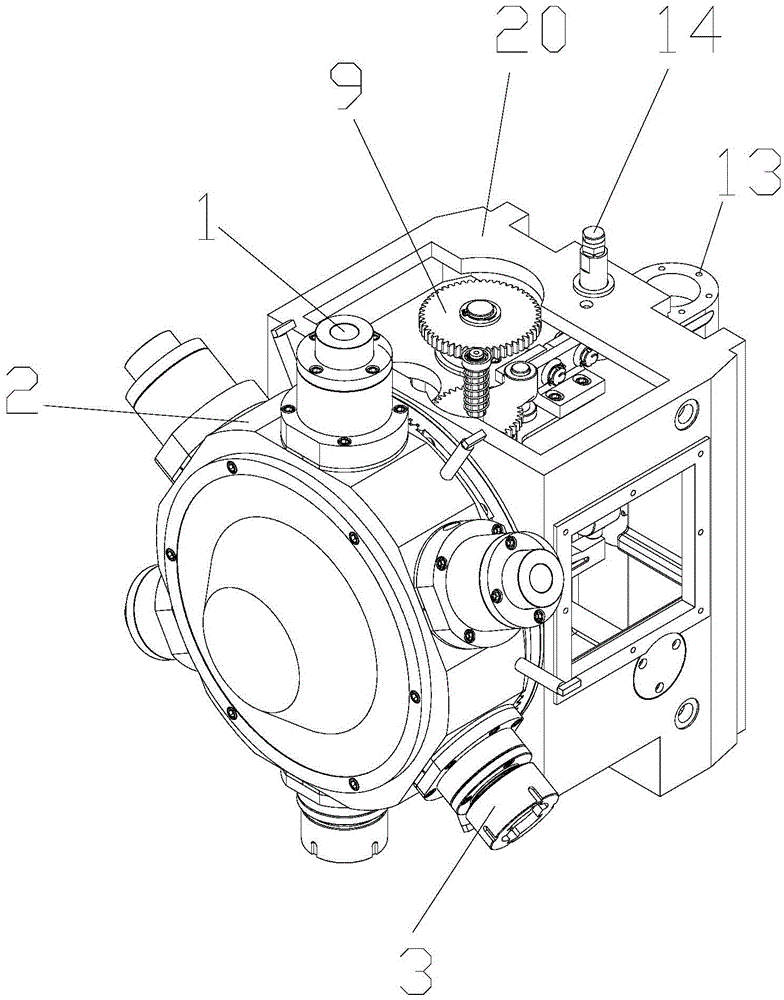

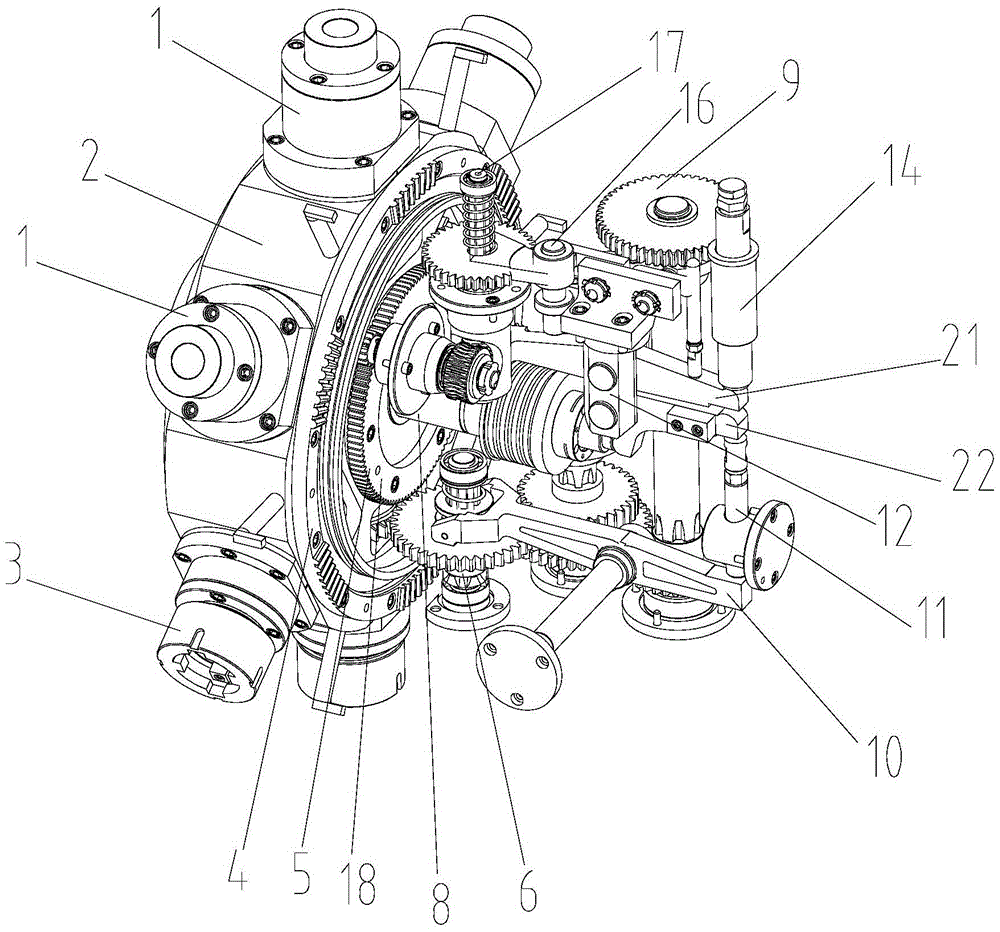

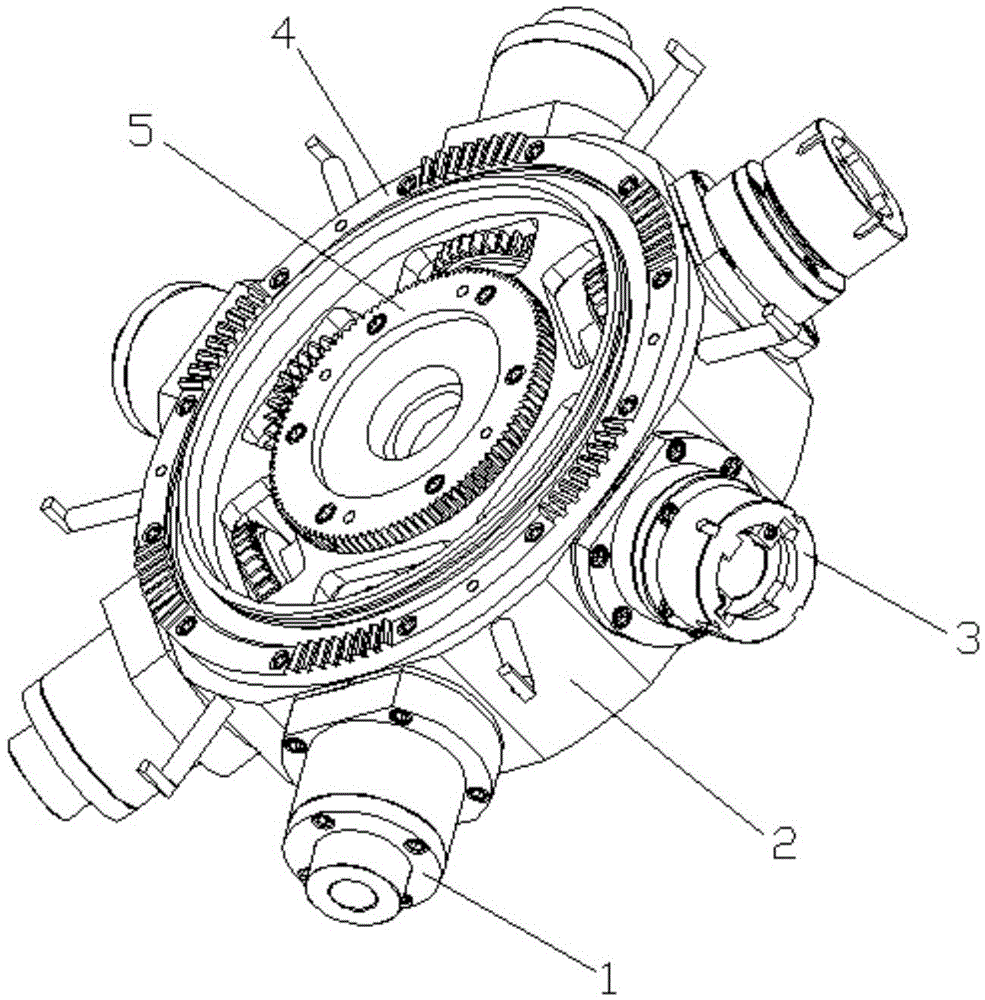

[0023] see Figure 1 to Figure 11 , a multifunctional drilling and milling mechanism of the present invention, comprising a spindle head and a headstock; the spindle head includes four drilling power heads 1, a headstock housing 2, two milling power heads 3, a Hirth 4 and a cutter head gear 5. Among them, four drilling power heads 1 and two milling power heads 3 are evenly arranged along the circumference of the cylindrical contour surface of the headstock shell 2, and are installed on the headstock shell 2 through bearing supports, and two The milling power head 3 is adjacently arranged along the cylindrical contour surface of the headstock housing 2; the hirth disc 4 is installed on the end face of the headstock housing 2 side, and the cutter head gear 5 is installed on the center of the headstock housing 2; The main shaft head is connected on one end of the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com